Master Sourcing Strategies for Ceramic Element: A B2B

Introduction: Navigating the Global Market for ceramic element

In the dynamic landscape of global trade, the ceramic element has emerged as a pivotal component across numerous industries, from tableware to advanced engineering applications. For B2B buyers, particularly those hailing from diverse regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of sourcing ceramic products can significantly impact business success. The ceramic element not only offers aesthetic appeal and functionality but also serves as a testament to quality and craftsmanship in various applications.

This comprehensive guide serves as an essential resource for international B2B buyers, unraveling the complexities of the ceramic supply chain. It covers the variety of ceramic types available, the materials used in production, and the critical aspects of manufacturing and quality control. Additionally, buyers will find valuable insights into selecting reliable suppliers, evaluating cost structures, and understanding the broader market dynamics affecting ceramic products.

By providing answers to frequently asked questions and actionable tips, this guide empowers buyers to make informed sourcing decisions. Whether you are looking to enhance your product line or ensure compliance with international standards, mastering the nuances of the ceramic element will enable you to navigate the global market effectively and secure high-quality products that align with your business goals.

Understanding ceramic element Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Porcelain | Fine-grained, high strength, and translucency | Tableware, sanitary ware, electrical insulators | Pros: Durable, non-porous, aesthetic appeal. Cons: Higher cost, can be brittle. |

| Stoneware | Dense, durable, and resistant to chipping | Cookware, dinnerware, and bakeware | Pros: Versatile, affordable, retains heat well. Cons: Heavier, may absorb flavors. |

| Earthenware | Coarse texture, lower firing temperature | Decorative pottery, tiles, and garden pots | Pros: Cost-effective, easily moldable. Cons: Less durable, more porous. |

| Bone China | Made with bone ash, elegant appearance, and lightweight | High-end tableware, gift items | Pros: Luxurious, strong, and chip-resistant. Cons: Expensive, may require special care. |

| Ceramic Composites | Combination of ceramics with other materials for enhanced properties | Industrial applications, cutting tools | Pros: High strength-to-weight ratio, tailored properties. Cons: Complex manufacturing, higher cost. |

Porcelain

Porcelain is characterized by its fine-grained structure, high strength, and translucency, making it a popular choice for tableware, sanitary ware, and electrical insulators. Its non-porous nature ensures that it does not absorb moisture, which is essential for maintaining hygiene in food service applications. When considering porcelain, B2B buyers should focus on supplier certifications regarding material quality and durability, as the initial investment can be higher compared to other ceramic types.

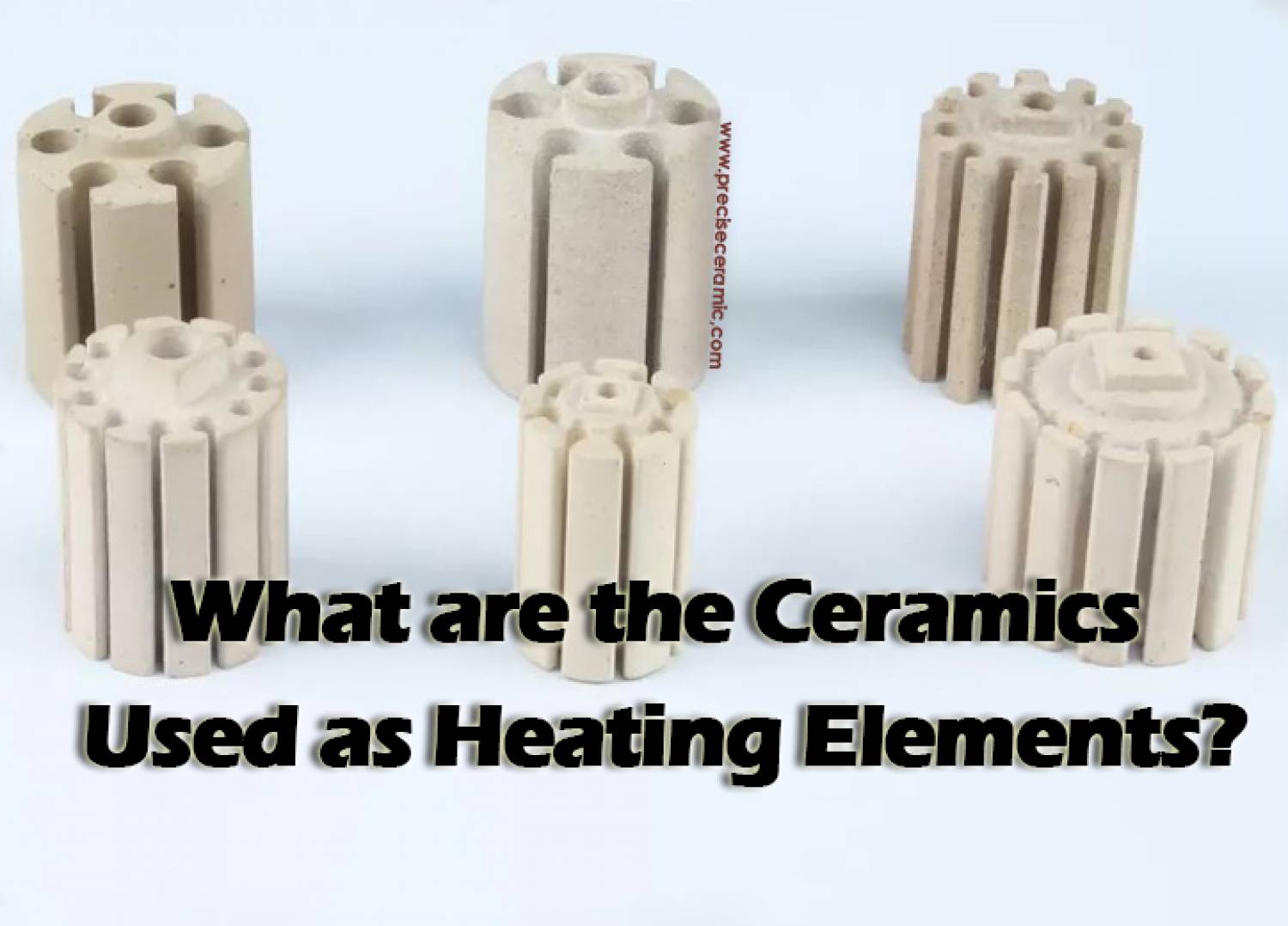

Illustrative Image (Source: Google Search)

Stoneware

Stoneware is known for its dense and durable composition, which makes it resistant to chipping and cracking. It is widely used in cookware, dinnerware, and bakeware. Buyers appreciate stoneware for its affordability and versatility, as it can withstand high temperatures and retain heat effectively. However, its heavier weight and potential to absorb flavors should be considered, especially for those in food service or retail sectors where presentation is key.

Earthenware

Earthenware features a coarse texture and is typically fired at lower temperatures, making it suitable for decorative pottery, tiles, and garden pots. Its cost-effectiveness and ease of molding make it an attractive option for smaller businesses or startups. However, buyers should be aware that earthenware is less durable and more porous than other types, which may limit its use in functional applications.

Bone China

Bone china is celebrated for its luxurious appearance and lightweight nature, primarily used for high-end tableware and gift items. The inclusion of bone ash in its composition provides strength and chip resistance, making it a preferred choice for premium markets. While bone china enhances brand prestige, the higher price point and care requirements may deter some buyers, necessitating a focus on target market alignment and branding strategies.

Ceramic Composites

Ceramic composites combine ceramics with other materials to achieve enhanced properties, such as increased strength or heat resistance. These materials are often utilized in industrial applications and cutting tools. Buyers should consider the complexity of manufacturing processes and the associated costs when opting for ceramic composites. However, their tailored properties can provide significant advantages in specialized applications, making them a valuable investment for businesses looking for innovative solutions.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of ceramic element

| Industry/Sector | Specific Application of ceramic element | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine components and exhaust systems | Enhanced durability and heat resistance, reducing maintenance costs | Supplier capability in producing high-temperature ceramics and compliance with automotive standards |

| Aerospace | Thermal barrier coatings | Improved fuel efficiency and reduced weight, leading to operational cost savings | Need for suppliers with certifications for aerospace-grade materials and quality assurance processes |

| Electronics | Insulators and capacitors | High dielectric strength and thermal stability, ensuring reliable performance | Sourcing from manufacturers with advanced quality control and testing facilities to meet electronic standards |

| Medical Devices | Dental ceramics and prosthetics | Biocompatibility and durability, enhancing patient outcomes | Ensure suppliers adhere to health regulations and provide traceability of materials used |

| Construction | Tiles and sanitary ware | Aesthetic appeal and longevity, reducing replacement costs | Focus on sustainable sourcing practices and availability of diverse designs and finishes |

Automotive Industry

Ceramic elements play a crucial role in automotive applications, particularly in engine components and exhaust systems. These materials provide enhanced durability and heat resistance, which are vital for high-performance vehicles. By using ceramic elements, manufacturers can significantly reduce maintenance costs associated with frequent replacements. International buyers must prioritize suppliers who demonstrate capability in producing high-temperature ceramics and adhere to stringent automotive standards.

Aerospace Sector

In the aerospace industry, ceramic elements are utilized for thermal barrier coatings on engines and other components. These coatings improve fuel efficiency and reduce weight, leading to substantial operational cost savings over time. For B2B buyers, it is essential to source from suppliers with the necessary certifications for aerospace-grade materials, ensuring that all products meet rigorous quality assurance processes.

Electronics Industry

Ceramic elements are fundamental in the electronics sector, particularly in the production of insulators and capacitors. Their high dielectric strength and thermal stability make them ideal for ensuring reliable performance in electronic devices. Buyers should focus on sourcing from manufacturers with advanced quality control measures and testing facilities to meet the specific standards required in the electronics industry.

Medical Devices

In the medical field, ceramic elements are used in dental ceramics and prosthetics due to their biocompatibility and durability. These properties enhance patient outcomes by providing long-lasting and safe solutions. Buyers in this sector must ensure that their suppliers comply with health regulations and can provide traceability for the materials used, which is critical for maintaining high standards in medical applications.

Construction Industry

Ceramic elements are widely used in the construction industry for tiles and sanitary ware. They offer both aesthetic appeal and longevity, which contribute to reduced replacement costs over time. B2B buyers should emphasize sustainable sourcing practices when selecting suppliers, as well as the availability of diverse designs and finishes to meet various market demands.

Related Video: How PTC Heating Element Technology Works

Strategic Material Selection Guide for ceramic element

When selecting materials for ceramic elements, international B2B buyers must consider various factors that impact product performance, cost, and application suitability. Below is an analysis of four common materials used in ceramic elements, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Alumina (Aluminum Oxide)

Key Properties: Alumina is known for its excellent thermal stability and high-temperature resistance, typically rated up to 1,600°C. It also offers good mechanical strength and is resistant to wear and corrosion.

Pros & Cons: The durability of alumina makes it suitable for high-stress applications. However, its brittleness can lead to chipping or cracking under impact, which may not be ideal for all environments. While alumina is relatively cost-effective, the manufacturing process can be complex, requiring precise control over sintering conditions.

Impact on Application: Alumina is compatible with a range of media, including acids and alkalis, making it suitable for chemical processing applications. However, its brittleness may limit its use in applications requiring high mechanical impact resistance.

Considerations for Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for quality assurance. Additionally, sourcing from suppliers with proven track records in alumina production can mitigate risks associated with material performance.

2. Zirconia (Zirconium Dioxide)

Key Properties: Zirconia exhibits exceptional toughness and thermal stability, withstanding temperatures up to 2,500°C. It has low thermal conductivity and excellent resistance to thermal shock.

Pros & Cons: The main advantage of zirconia is its superior mechanical properties, making it ideal for demanding applications like cutting tools and wear-resistant components. However, it is significantly more expensive than alumina, which may be a limiting factor for budget-conscious buyers. The manufacturing process is also more complex, requiring advanced technology.

Impact on Application: Zirconia is particularly effective in applications involving high thermal and mechanical stress, such as in the aerospace and automotive industries. Its compatibility with various media, including corrosive substances, enhances its versatility.

Considerations for Buyers: Buyers should be aware of the higher costs associated with zirconia and evaluate whether its performance justifies the investment. Compliance with relevant international standards and certifications is crucial for ensuring product reliability.

3. Silicon Carbide

Key Properties: Silicon carbide is known for its high thermal conductivity and exceptional hardness, withstanding temperatures up to 1,600°C. It also offers excellent chemical resistance and thermal shock resistance.

Pros & Cons: The durability and thermal properties of silicon carbide make it suitable for high-performance applications, such as in semiconductor manufacturing. However, it can be more challenging to machine compared to other materials, which may increase production costs. Its relative cost is moderate to high, depending on the grade.

Impact on Application: Silicon carbide is particularly effective in abrasive environments and is compatible with various corrosive media. Its thermal shock resistance makes it suitable for applications involving rapid temperature changes.

Considerations for Buyers: Buyers should consider the machining challenges associated with silicon carbide and ensure they have access to suppliers with the necessary expertise. Compliance with industry standards is also essential to guarantee product quality.

4. Cordierite

Key Properties: Cordierite is characterized by its excellent thermal shock resistance and low thermal expansion, withstanding temperatures up to 1,300°C. It is also lightweight and has good mechanical strength.

Pros & Cons: The main advantage of cordierite is its ability to withstand rapid temperature changes without cracking, making it ideal for applications like kiln furniture and catalytic converters. However, it has lower mechanical strength compared to other ceramics, which may limit its use in high-stress applications. Its cost is generally moderate.

Impact on Application: Cordierite is particularly suitable for applications involving thermal cycling and is compatible with various media. Its lightweight nature can also reduce overall system weight in applications like automotive components.

Considerations for Buyers: Buyers should evaluate the specific mechanical requirements of their applications when considering cordierite. Ensuring compliance with relevant standards and sourcing from reputable suppliers can help mitigate risks associated with material performance.

Summary Table

| Material | Typical Use Case for ceramic element | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alumina | High-stress applications | Excellent thermal stability | Brittle, prone to chipping | Medium |

| Zirconia | Aerospace, automotive applications | Superior toughness and thermal stability | High cost, complex manufacturing | High |

| Silicon Carbide | Semiconductor manufacturing | High thermal conductivity and hardness | Difficult to machine, moderate to high cost | Medium to High |

| Cordierite | Kiln furniture, catalytic converters | Excellent thermal shock resistance | Lower mechanical strength | Medium |

This guide serves as a foundational resource for international B2B buyers, helping them make informed decisions about material selection for ceramic elements based on specific application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for ceramic element

In the world of B2B procurement for ceramic elements, understanding the manufacturing processes and quality assurance protocols is crucial for ensuring product reliability and compliance with international standards. This section provides an in-depth look at the typical manufacturing stages, key techniques employed, and the quality control measures that should be considered by international buyers, particularly from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Ceramic elements undergo several key stages in their manufacturing process, each of which contributes to the final product’s quality and functionality.

1. Material Preparation

The foundation of any ceramic product begins with the selection and preparation of raw materials. The primary materials typically include:

- Clay: Various types, such as kaolin, ball clay, and fire clay, are chosen based on the desired properties of the final product.

- Additives: These may include fluxes, colorants, and other chemicals that enhance the performance and appearance of the ceramics.

- Water: Used to achieve the necessary consistency in the clay mixture.

The preparation process involves grinding and mixing the raw materials to ensure uniformity. Advanced manufacturers often employ automated systems for precise measurement and mixing, which enhances consistency.

2. Forming Techniques

The shaping of ceramic elements can be accomplished through various techniques, depending on the complexity and design of the product:

- Pressing: For simple shapes, this method involves pressing clay into molds under high pressure.

- Extrusion: This technique is used for producing long, continuous shapes, like tiles or tubes, by forcing clay through a die.

- Slip Casting: Used for intricate designs, liquid clay (slip) is poured into plaster molds, allowing for detailed shapes.

- Hand Forming: In some cases, artisans may hand-shape products for unique, custom designs.

Choosing the right forming technique is essential, as it affects the product’s density, strength, and surface finish.

3. Assembly and Drying

After forming, the components of ceramic elements may need to be assembled. This can involve joining different parts, such as handles to mugs or lids to jars. The assembly process is critical for ensuring structural integrity.

Following assembly, the items undergo a controlled drying phase to remove excess moisture. This is a delicate process, as uneven drying can lead to warping or cracking. Manufacturers often utilize climate-controlled environments to maintain consistent conditions.

4. Finishing

The finishing stage involves surface treatment and glazing, which are vital for both aesthetic and functional properties. Key activities include:

- Glazing: A liquid glass coating is applied to provide a waterproof surface and enhance visual appeal. Various application methods such as dipping, spraying, or brushing can be employed.

- Firing: The glazed ceramics are then subjected to high-temperature firing in kilns, which vitrifies the glaze and strengthens the body. This stage is critical, as it determines the final properties of the ceramic elements.

Quality Assurance Protocols

Quality control (QC) is an essential aspect of the ceramic manufacturing process. International B2B buyers should be familiar with the relevant standards and checkpoints to ensure product quality and compliance.

International Standards

Several international standards govern the manufacturing and quality assurance of ceramic products:

- ISO 9001: This standard outlines the requirements for a quality management system and is applicable across various industries, including ceramics.

- CE Marking: For products sold in the European Economic Area, this marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For ceramics used in the oil and gas industries, adherence to American Petroleum Institute (API) standards is critical.

Quality Control Checkpoints

Quality control should be integrated at multiple stages of the production process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during production help identify any deviations from quality standards in real-time.

- Final Quality Control (FQC): A comprehensive inspection of finished products is conducted to verify compliance with specifications before shipping.

Common testing methods include dimensional checks, visual inspections, and performance tests such as thermal shock resistance and mechanical strength assessments.

Verification of Supplier QC

B2B buyers should implement thorough verification processes to ensure their suppliers adhere to high-quality standards:

- Audits: Conducting regular audits of the supplier’s facilities and processes can provide insight into their quality management practices.

- Quality Reports: Requesting detailed QC reports, including testing results and compliance certifications, can help verify a supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing process and final products can provide an unbiased assessment of quality.

Considerations for International Buyers

International buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances in QC and certification processes:

- Cultural and Regional Differences: Understand that manufacturing practices and quality expectations may vary significantly across regions. Buyers should communicate their quality requirements clearly and be prepared to adapt to local practices.

- Import Regulations: Familiarize yourself with import regulations and compliance requirements specific to your region, including any necessary certifications for health and safety.

- Sustainability Practices: Increasingly, buyers are prioritizing suppliers who demonstrate sustainable practices, such as using eco-friendly materials and processes. Ensure that your supplier aligns with these values.

By understanding the manufacturing processes and implementing rigorous quality assurance protocols, B2B buyers can ensure they source high-quality ceramic elements that meet their needs and compliance standards.

Related Video: Ceramic tiles manufacturing process by Ceratec – How it’s made?

Comprehensive Cost and Pricing Analysis for ceramic element Sourcing

Understanding the cost structure and pricing dynamics of ceramic element sourcing is crucial for B2B buyers aiming to optimize their procurement strategies. This analysis dissects the various cost components involved and identifies the key influencers that affect pricing.

Cost Components

-

Materials

– The primary raw materials for ceramic elements include kaolin, feldspar, quartz, and various additives. The quality and sourcing of these materials can significantly impact costs. Buyers should prioritize suppliers that use high-grade, sustainable materials, as this can enhance product durability and compliance with international standards. -

Labor

– Labor costs can vary greatly depending on the region of production. Countries with lower labor costs may offer competitive pricing, but it’s essential to ensure that quality standards are maintained. Skilled artisans are often necessary for high-quality ceramic production, and their wages should be factored into the overall cost. -

Manufacturing Overhead

– This includes expenses related to utilities, factory maintenance, and equipment depreciation. Efficient manufacturing processes can minimize overhead costs, which is why it’s beneficial to partner with suppliers who utilize modern, automated technologies. -

Tooling

– Tooling costs involve the initial investment in molds and other production tools specific to ceramic elements. Custom tooling for unique designs can lead to higher upfront costs but can be amortized over larger production runs, making it cost-effective in the long run. -

Quality Control (QC)

– Implementing a robust QC process is vital to ensure product consistency and compliance with safety standards. This may involve additional costs, but investing in QC can reduce returns and enhance customer satisfaction. -

Logistics

– Shipping and handling costs can greatly affect the total cost of ownership. International buyers should account for freight, insurance, and customs duties, which can vary based on the shipping method and destination. -

Margin

– Suppliers typically mark up their prices to cover operational costs and profit. Understanding the typical margins within the ceramic industry can aid buyers in negotiating better terms.

Price Influencers

-

Volume/MOQ: Larger orders often qualify for volume discounts. Establishing a long-term relationship with suppliers can also lead to better pricing structures.

-

Specifications/Customization: Custom designs or specific material requirements can increase costs. Clearly defining specifications upfront can minimize unexpected charges.

-

Materials: The choice of raw materials directly impacts pricing. High-quality, non-toxic materials may come at a premium but can enhance product value.

-

Quality/Certifications: Products with certifications (e.g., FDA, CE) may incur higher costs due to the additional testing and compliance measures required.

-

Supplier Factors: Supplier reputation, production capabilities, and geographical location all play a role in pricing. Reliable suppliers with a proven track record may charge higher prices but offer better quality assurance.

-

Incoterms: Understanding Incoterms (e.g., FOB, CIF) is crucial as they determine who bears the shipping costs and risks, impacting the overall pricing strategy.

Buyer Tips

-

Negotiate Wisely: Always negotiate pricing and payment terms upfront. Leverage your purchasing power, especially if you’re placing large orders.

-

Focus on Total Cost of Ownership (TCO): Consider all cost components, including logistics and potential QC issues, rather than just the unit price.

-

Evaluate Pricing Nuances: Be aware of regional pricing trends and currency fluctuations, especially when sourcing from different continents. For instance, suppliers in Africa or South America may have different cost structures compared to those in Europe or the Middle East.

-

Build Long-Term Relationships: Establishing a reliable supplier relationship can lead to better pricing, improved service, and priority in production during peak times.

Disclaimer

Prices for ceramic elements can vary widely based on the factors outlined above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitiveness and quality.

Spotlight on Potential ceramic element Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ceramic element’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ceramic element

Understanding the essential technical properties and trade terminology related to ceramic elements is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also facilitates clearer communication with suppliers.

Key Technical Properties of Ceramic Elements

-

Material Grade

Material grade refers to the classification of the ceramic based on its composition and intended use. Common grades include porcelain, stoneware, and earthenware. For B2B buyers, selecting the right material grade is vital as it impacts the product’s durability, heat resistance, and overall quality. -

Tolerance

Tolerance defines the allowable variation in dimensions during production. In ceramics, this can refer to the diameter of a plate or the thickness of a mug. Understanding tolerances is crucial for ensuring that products fit specific applications, especially in industries like hospitality and manufacturing where consistency is key.

Illustrative Image (Source: Google Search)

-

Vitrification

Vitrification is the process that transforms clay into a glass-like substance through firing. This property affects the ceramic’s strength, porosity, and glaze adherence. B2B buyers should consider vitrification levels when sourcing ceramics for high-temperature applications, as higher vitrification usually results in greater durability and lower moisture absorption. -

Glaze Type

The type of glaze applied can significantly influence both aesthetic and functional properties. Common types include glossy, matte, and reactive glazes. Different glazes not only enhance appearance but also impact food safety and scratch resistance. Buyers must specify glaze requirements to meet their brand standards and customer expectations. -

Thermal Shock Resistance

This property indicates how well a ceramic can withstand sudden temperature changes without cracking. For applications in kitchens or foodservice, ceramics with high thermal shock resistance are essential to ensure longevity and usability. B2B buyers should inquire about this property, particularly for products intended for cooking or serving hot foods. -

Food Safety Compliance

Compliance with food safety standards, such as FDA or LFGB certifications, ensures that the ceramics are safe for food contact. This is particularly important for buyers in the foodservice and retail sectors. Sourcing from suppliers who provide certification documentation helps mitigate risks associated with non-compliant products.

Common Trade Terms in the Ceramic Industry

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are then sold by another company under its brand name. For B2B buyers, understanding OEM capabilities is essential when seeking customized ceramic solutions, as it can influence pricing, quality, and production timelines. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budget management and inventory planning, especially for small businesses or startups looking to enter the market without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. B2B buyers should use RFQs to compare costs and conditions across multiple suppliers, ensuring they secure the best deal while meeting quality and delivery expectations. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free On Board) and CIF (Cost, Insurance, and Freight), helps buyers understand shipping costs, risk management, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time from placing an order to receiving it. Understanding lead times is vital for effective inventory management and ensuring that products are available when needed, particularly in industries with seasonal demands or promotional timelines. -

Batch Testing

This process involves sampling products from a production batch to assess quality and compliance with specifications. B2B buyers should prioritize suppliers who implement batch testing, as it assures product consistency and helps identify defects early in the supply chain.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make more informed purchasing decisions, negotiate better terms, and ultimately enhance their product offerings in the competitive ceramic market.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ceramic element Sector

In the global ceramic element market, several key dynamics are shaping the landscape for international B2B buyers. The increasing demand for high-quality ceramic products is primarily driven by the construction, automotive, and consumer goods sectors, where ceramics are valued for their durability and aesthetic appeal. Emerging trends include the adoption of advanced technologies such as automation and digitalization in production processes, enabling manufacturers to improve efficiency and reduce lead times. Moreover, the rise of e-commerce platforms is transforming how buyers source products, providing greater access to diverse suppliers and facilitating streamlined procurement processes.

International buyers from regions like Africa, South America, the Middle East, and Europe must stay informed about these market shifts to remain competitive. A notable trend is the increasing focus on customization, as brands seek unique designs to differentiate themselves in crowded markets. Additionally, geopolitical factors, including trade policies and tariffs, influence sourcing decisions, necessitating thorough market analysis and risk assessment. B2B buyers should leverage data analytics tools to forecast demand and optimize inventory management, ensuring they can respond swiftly to changing market conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial consideration in the ceramic element sector, impacting both sourcing strategies and consumer preferences. The environmental impact of ceramic production, including resource extraction and waste generation, has prompted a shift towards more sustainable practices. Buyers should prioritize suppliers who utilize eco-friendly materials, such as recycled ceramics and non-toxic glazes, to minimize their carbon footprint.

Ethical supply chains are equally important, with increasing scrutiny on labor practices in the ceramic industry. B2B buyers should seek suppliers who adhere to ethical standards, ensuring fair wages and safe working conditions. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability. By aligning with suppliers who prioritize ethical practices, international buyers can enhance their brand reputation and meet the growing consumer demand for responsible sourcing.

Brief Evolution/History

The ceramic industry has evolved significantly over the centuries, transitioning from artisanal craftsmanship to industrial-scale production. Initially, ceramics were handmade, with each piece reflecting the individual artisan’s skill. The introduction of mass production techniques in the 19th century revolutionized the sector, allowing for greater consistency and lower costs. Today, advanced technologies such as 3D printing and computer-aided design (CAD) are further transforming the industry, enabling complex designs and rapid prototyping. This evolution has opened new opportunities for B2B buyers, providing access to innovative products and efficient sourcing options that meet modern market demands.

In summary, understanding market dynamics, embracing sustainability, and recognizing the historical context of the ceramic element sector are vital for international B2B buyers. By leveraging these insights, businesses can make informed decisions that enhance their sourcing strategies and contribute to a more sustainable future.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of ceramic element

-

How do I vet potential ceramic suppliers?

Vetting suppliers involves checking their credentials, production capabilities, and past performance. Start by requesting samples to evaluate the quality of their products. Look for certifications such as ISO, FDA, or CE that indicate compliance with international standards. It’s also beneficial to check reviews or testimonials from other clients, especially those in your industry. Finally, consider visiting their manufacturing facility if possible, as this provides firsthand insight into their operations and quality control processes. -

What customization options are available for ceramic products?

Many suppliers offer various customization options, including design, color, size, and packaging. When discussing your needs, be specific about your design requirements and any unique features you want. Some suppliers may also provide assistance with artwork and prototyping to help bring your ideas to life. Keep in mind that extensive customization may affect lead times and minimum order quantities (MOQs), so clarify these details during negotiations. -

What are the typical lead times and minimum order quantities (MOQs) for ceramic products?

Lead times can vary significantly based on the supplier and the complexity of your order. Generally, production lead times range from 35 to 45 days for mass orders, with additional time for shipping. MOQs can also vary, with some suppliers requiring a minimum of 500 pieces, while others may accommodate smaller orders. Always discuss these details upfront to ensure the supplier can meet your needs without delays. -

How can I ensure quality assurance and certifications for ceramic products?

To ensure quality, request detailed documentation regarding the supplier’s quality control processes. Certifications such as ISO 9001 or relevant health and safety standards (e.g., FDA compliance for food-safe ceramics) should be provided. It’s also prudent to inquire about their inspection processes, including how they handle defects and returns. Establishing a pre-shipment inspection protocol can further safeguard your order against quality issues. -

What logistics considerations should I be aware of when sourcing ceramics?

Logistics for ceramic products can be complex due to their fragility. Ensure your supplier has experience in handling and shipping ceramics. Discuss packaging options that minimize damage during transit, such as reinforced cartons or foam inserts. Additionally, clarify shipping methods—sea freight is typical for larger orders, while air freight may be used for urgent shipments. Be aware of customs regulations and documentation required for your specific destination to prevent delays. -

How should I handle disputes or issues with a ceramic supplier?

Clear communication is key when addressing disputes with suppliers. Establish a formal complaint process and document all interactions. If an issue arises, raise it promptly and provide evidence, such as photos or reports. Many suppliers are willing to resolve issues amicably, whether through refunds, replacements, or credits. If necessary, refer to the terms outlined in your contract regarding dispute resolution, including mediation or arbitration clauses, to guide the process. -

What payment terms are common when sourcing ceramic products?

Payment terms can vary widely among suppliers, but common practices include deposits (often 30-50%) before production and the balance upon delivery. Some suppliers may offer net payment terms, allowing payment within a specified period post-delivery. Always negotiate terms that align with your cash flow and financial strategies. Additionally, consider using secure payment methods or escrow services for larger orders to mitigate financial risk. -

How important are sustainability and ethical practices in selecting a ceramic supplier?

Sustainability and ethical practices are increasingly important for B2B buyers. Look for suppliers that use sustainable materials and environmentally friendly processes, such as recycling and waste reduction. Certifications like Fair Trade or BSCI indicate adherence to ethical labor practices. Aligning with a supplier that prioritizes these values can enhance your brand’s reputation and appeal to a growing segment of eco-conscious consumers, particularly in markets across Africa, South America, the Middle East, and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ceramic element

In conclusion, strategic sourcing of ceramic elements is pivotal for B2B buyers aiming to enhance their product offerings and operational efficiency. By understanding the intricate supply chain—from raw material sourcing to final delivery—buyers can optimize their procurement processes. Key takeaways include prioritizing quality and consistency, leveraging production capabilities, and ensuring ethical practices to align with growing consumer demands for sustainability.

As you navigate the global ceramic market, consider establishing strong relationships with reputable suppliers who demonstrate transparency and reliability. This not only mitigates risks associated with sourcing but also fosters innovation and adaptability in your product lines.

Looking ahead, the ceramic industry is poised for growth, driven by increasing demand across various sectors, including hospitality, retail, and consumer goods. Engage proactively with suppliers to explore opportunities for customization and product development. By doing so, you can position your brand for success in a competitive landscape. Embrace strategic sourcing today and unlock the potential of ceramics to elevate your business.