Master Sourcing Strategies for Closed-Cell Foam: A B2B

Introduction: Navigating the Global Market for closed-cell foam

Closed-cell foam is emerging as a critical component in various industries due to its remarkable properties, including insulation, shock absorption, and moisture resistance. As international B2B buyers from Africa, South America, the Middle East, and Europe seek innovative solutions, understanding the nuances of closed-cell foam becomes essential. This guide offers a comprehensive exploration of closed-cell foam, empowering businesses to make informed sourcing decisions.

The scope of this guide encompasses an array of closed-cell foam types such as polyethylene, cross-linked polyethylene, and polystyrene, each tailored for specific applications across sectors like automotive, construction, and medical. We delve into the manufacturing processes and quality control measures that define the reliability of foam products, ensuring that buyers can identify suppliers who adhere to rigorous standards.

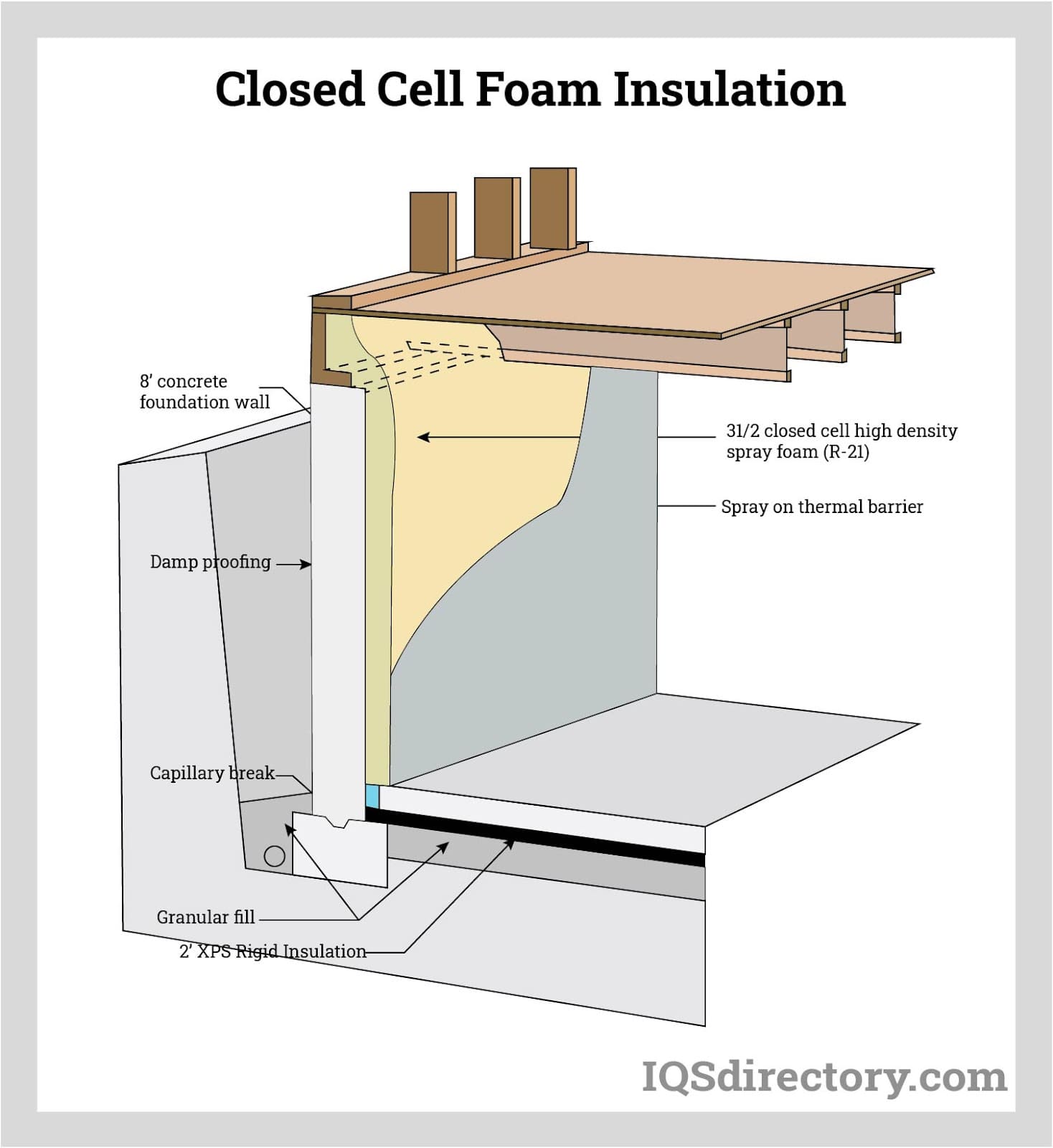

Illustrative Image (Source: Google Search)

Additionally, the guide provides insights into cost considerations, helping businesses budget effectively while maximizing performance. A thorough market analysis highlights trends and opportunities, particularly for buyers operating in dynamic regions. Finally, an FAQ section addresses common queries, further supporting buyers in their decision-making process.

By leveraging this extensive resource, B2B buyers can navigate the global market for closed-cell foam with confidence, ensuring they select the right materials that align with their operational needs and market demands.

Understanding closed-cell foam Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyethylene Foam | Lightweight, moisture-resistant, excellent shock absorption | Packaging, insulation, medical devices | Pros: Cost-effective, versatile; Cons: Limited chemical resistance. |

| Cross-Linked Polyethylene | Enhanced durability, chemical resistance, high thermal stability | HVAC insulation, automotive, marine | Pros: Superior performance, aesthetic finish; Cons: Higher cost. |

| Polystyrene Foam | Rigid structure, excellent thermal insulation | Construction, packaging, electronics | Pros: Strong insulation properties; Cons: Less flexible, can be brittle. |

| Neoprene Foam | Flexible, resistant to oils and chemicals | Gasketing, seals, automotive applications | Pros: Durable, versatile; Cons: More expensive than other options. |

| EVA Foam | Lightweight, shock-absorbing, good elasticity | Sports equipment, protective packaging | Pros: Excellent cushioning; Cons: Limited thermal resistance. |

Polyethylene Foam

Polyethylene foam, often referred to as ethafoam, is characterized by its lightweight nature and robust moisture resistance. Its excellent shock absorption makes it a preferred choice in various B2B applications, including protective packaging and medical device components. Buyers should consider its cost-effectiveness and versatility, but be aware of its limitations regarding chemical resistance, which may affect its suitability in certain environments.

Cross-Linked Polyethylene

Cross-linked polyethylene (XLPE) foam offers enhanced durability and is particularly resistant to a broader range of chemicals and temperature extremes. This makes it ideal for applications in HVAC insulation and automotive interiors. B2B buyers should appreciate its superior performance and aesthetic finish, but they must also consider the higher costs associated with this advanced material, which could impact budget-sensitive projects.

Polystyrene Foam

Polystyrene foam is known for its rigid structure and exceptional thermal insulation properties. It is widely utilized in construction and electronics packaging. While its strong insulation capabilities are a significant advantage, buyers should be cautious of its brittleness and limited flexibility, which may pose challenges in applications requiring more adaptability.

Neoprene Foam

Neoprene foam is a flexible closed-cell material that offers excellent resistance to oils and chemicals, making it suitable for gasketing and sealing applications in automotive industries. Its durability and versatility are notable strengths; however, buyers should be prepared for a higher price point compared to other foam types, which may influence purchasing decisions, especially for large-scale projects.

EVA Foam

EVA (Ethylene Vinyl Acetate) foam is celebrated for its lightweight nature and excellent shock-absorbing qualities, making it ideal for sports equipment and protective packaging. While it provides superior cushioning, buyers should note its limitations in thermal resistance, which might restrict its use in environments exposed to extreme temperatures. Understanding these characteristics will help buyers make informed decisions based on their specific application needs.

Related Video: How does the bone-style cervical collar foam fit in flexible cell 3112721270 foam?

Key Industrial Applications of closed-cell foam

| Industry/Sector | Specific Application of closed-cell foam | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Seals and gaskets for vehicle components | Enhances durability and reduces noise and vibration | Ensure compliance with automotive industry standards |

| Medical | Protective packaging for medical devices | Safeguards sensitive equipment and ensures hygiene | Look for biocompatible materials and certifications |

| Construction | Insulation for buildings and HVAC systems | Improves energy efficiency and reduces operational costs | Assess thermal resistance and moisture resistance |

| Marine | Buoyancy aids and flotation devices | Provides safety and reliability in water applications | Evaluate material resistance to saltwater and UV exposure |

| Sports & Leisure | Padding for sports equipment | Enhances user comfort and safety during activities | Consider weight, flexibility, and shock absorption properties |

Automotive Applications

In the automotive sector, closed-cell foam is extensively used in seals and gaskets for various vehicle components. These foams provide exceptional durability and compressibility, which help to minimize noise and vibration, enhancing the overall driving experience. For international buyers, especially those in regions like Africa and the Middle East, sourcing closed-cell foam that meets stringent automotive standards is crucial. Buyers should ensure that materials are resistant to extreme temperatures and environmental factors to maintain performance over time.

Medical Applications

Closed-cell foam plays a vital role in the medical industry, particularly in the protective packaging of medical devices. Its moisture resistance and cushioning properties safeguard sensitive equipment during transportation and storage, ensuring that hygiene standards are met. For B2B buyers in Europe and South America, it’s essential to select foam that is biocompatible and complies with relevant health regulations. Understanding the specific certifications required in different markets can streamline the sourcing process and enhance product safety.

Construction Applications

In construction, closed-cell foam is widely utilized for insulation in buildings and HVAC systems. Its superior thermal resistance contributes to energy efficiency, significantly reducing heating and cooling costs. For buyers in Europe and South America, evaluating the foam’s moisture resistance is critical to prevent mold growth and structural damage. Additionally, understanding local building codes and insulation standards will help ensure compliance and optimize the selection process.

Marine Applications

The marine industry employs closed-cell foam for buoyancy aids and flotation devices, where reliability and safety are paramount. These foams are designed to withstand harsh marine environments, including exposure to saltwater and UV radiation. For international buyers, particularly in coastal regions of Africa and the Middle East, it’s important to assess the foam’s resistance to these elements to ensure longevity and performance. Suppliers should provide detailed specifications regarding material durability and safety certifications.

Sports & Leisure Applications

In the sports and leisure sector, closed-cell foam is commonly used as padding for various equipment, enhancing user comfort and safety. Its lightweight nature and shock-absorbing properties make it ideal for items such as helmets, mats, and protective gear. Buyers from Europe and South America should consider the foam’s flexibility and energy absorption capabilities to meet specific performance requirements. Additionally, sourcing foams that comply with safety standards can provide added assurance for end-users.

Strategic Material Selection Guide for closed-cell foam

Closed-cell foam materials are integral to various industrial applications due to their unique properties and versatility. Below is an analysis of four common materials used in closed-cell foam, focusing on their key properties, pros and cons, application impacts, and considerations for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

Polyethylene Foam

Key Properties:

Polyethylene foam is lightweight and has excellent moisture resistance, making it suitable for environments where water exposure is a concern. It can withstand temperatures ranging from -40°C to 80°C, providing good thermal insulation.

Pros & Cons:

The primary advantages of polyethylene foam include its affordability and durability. It is easy to manufacture and can be produced in various densities. However, it may not perform well in high-temperature applications exceeding its threshold, and its chemical resistance is limited compared to other materials.

Impact on Application:

Polyethylene foam is commonly used in protective packaging, sports equipment, and insulation. Its buoyancy makes it ideal for flotation devices. However, it may not be suitable for applications involving exposure to harsh chemicals.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations and standards, such as ASTM D-1056. In regions like Europe and the UAE, certifications for environmental sustainability can also influence purchasing decisions.

Cross-Linked Polyethylene Foam (XLPE)

Key Properties:

XLPE foam is characterized by its enhanced molecular structure, providing superior resistance to moisture, chemicals, and temperature extremes. It can operate effectively in temperatures ranging from -60°C to 100°C.

Pros & Cons:

XLPE foam offers exceptional durability and aesthetic appeal, making it suitable for high-end applications like automotive interiors and medical devices. However, its manufacturing process is more complex, leading to higher costs compared to standard polyethylene foam.

Impact on Application:

Due to its robust sealing capabilities, XLPE is ideal for gasketing and insulation in HVAC systems. Its resistance to mold and mildew makes it suitable for humid environments, but it may be over-engineered for simpler applications.

Considerations for International Buyers:

Buyers should verify compliance with industry standards such as DIN and JIS, especially in Europe and Asia. The higher cost of XLPE may necessitate a thorough cost-benefit analysis for projects in developing regions.

Polystyrene Foam

Key Properties:

Polystyrene foam is known for its rigidity and lightweight characteristics. It provides excellent thermal insulation and can withstand temperatures up to 70°C.

Pros & Cons:

The key advantage of polystyrene foam is its high compressive strength, making it suitable for structural applications. However, it is less flexible than other foam types, which can limit its use in applications requiring adaptability.

Impact on Application:

Polystyrene is widely used in construction for insulation panels and in packaging for fragile items. Its rigidity can be a disadvantage in applications that require cushioning.

Considerations for International Buyers:

Buyers should be aware of environmental regulations regarding polystyrene, particularly in Europe, where there are increasing restrictions on its use. Compliance with safety standards is crucial for applications in the food industry.

Neoprene Foam

Key Properties:

Neoprene foam offers excellent resistance to weather, ozone, and UV exposure, making it suitable for outdoor applications. It can operate effectively in a temperature range of -40°C to 120°C.

Pros & Cons:

The durability and flexibility of neoprene foam are significant advantages, especially in automotive and marine applications. However, it tends to be more expensive than other closed-cell foams, which may impact budget-sensitive projects.

Impact on Application:

Neoprene is ideal for applications requiring high resilience and resistance to environmental factors. It is commonly used in seals and gaskets but may not be necessary for less demanding applications.

Considerations for International Buyers:

International buyers should consider the availability of neoprene in their region and any import tariffs that may apply. Understanding local compliance standards, such as ASTM and ISO, is essential for ensuring product suitability.

Summary Table

| Material | Typical Use Case for closed-cell foam | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Foam | Protective packaging, insulation | Affordable and durable | Limited chemical resistance | Low |

| Cross-Linked Polyethylene Foam | Gasketing, HVAC insulation | Superior durability and moisture resistance | Higher manufacturing complexity | High |

| Polystyrene Foam | Construction insulation, packaging | High compressive strength | Less flexibility | Medium |

| Neoprene Foam | Automotive seals, marine applications | Excellent weather and UV resistance | Higher cost | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, enabling informed decisions when sourcing closed-cell foam materials for various applications.

In-depth Look: Manufacturing Processes and Quality Assurance for closed-cell foam

Closed-cell foam is an essential material for various industries, requiring a thorough understanding of its manufacturing processes and quality assurance protocols. This section will provide B2B buyers with actionable insights into the production stages, quality control measures, and international standards relevant to closed-cell foam.

Manufacturing Process of Closed-Cell Foam

The manufacturing of closed-cell foam involves several critical stages, each designed to ensure the final product meets the required specifications for performance and durability.

1. Material Preparation

The first stage in the manufacturing process is the preparation of raw materials. Typically, this includes polymers such as polyethylene or polystyrene, along with blowing agents (e.g., nitrogen or carbon dioxide). The choice of materials depends on the specific properties desired in the final product.

- Mixing: The raw materials are combined in a controlled environment to ensure uniformity. This can include the addition of additives that enhance properties such as flame resistance or UV stability.

- Heating: The mixture is then heated to a specific temperature to facilitate the chemical reactions necessary for foam formation.

2. Forming

The forming stage is crucial as it determines the cellular structure of the foam.

- Direct Gas Exposure: In this method, high-pressure gas is introduced to the heated mixture, causing it to expand and form closed cells. This technique offers precise control over the size and density of the foam.

- Blowing Agents: Alternatively, chemical blowing agents are blended into the material. During the curing phase, these agents release gas, creating the closed-cell structure.

The choice of technique affects the foam’s characteristics, including its density, resilience, and insulation properties.

3. Assembly

Following the forming stage, the foam is cut and shaped according to specifications.

- Cutting: The foam sheets are cut to size using precision cutting tools or CNC machines. This ensures consistency in dimensions for applications that require exact measurements.

- Lamination: In some cases, multiple layers of foam may be laminated together to enhance performance characteristics such as sound insulation or cushioning.

4. Finishing

The finishing stage involves applying any necessary treatments to enhance the foam’s properties.

- Surface Treatment: This can include coatings for improved durability, resistance to moisture, or UV protection.

- Quality Inspection: Before the final product is packaged, it undergoes a thorough inspection to ensure it meets all specified requirements.

Quality Assurance in Closed-Cell Foam Production

Quality assurance is vital in the manufacturing of closed-cell foam, ensuring that the product performs reliably in its intended applications.

International Standards

B2B buyers should be aware of the international standards that govern the production of closed-cell foam:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For industries such as oil and gas, adherence to API standards is crucial for materials used in harsh environments.

Quality Control Checkpoints

Quality control is typically structured around several key checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor processes and ensure they remain within defined parameters.

- Final Quality Control (FQC): Once the production is complete, the final product undergoes thorough testing to confirm it meets all specifications before shipping.

Common Testing Methods

Manufacturers use various testing methods to ensure the quality of closed-cell foam:

- Compression Testing: Determines the foam’s resilience and ability to return to its original shape after compression.

- Water Absorption Testing: Evaluates the foam’s resistance to moisture, which is critical for applications in humid environments.

- Thermal Conductivity Testing: Assesses the insulation properties of the foam, ensuring it meets energy efficiency standards.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of their suppliers, particularly when sourcing internationally.

Audits and Reports

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their quality control processes and adherence to international standards.

- Quality Reports: Requesting detailed quality reports can help buyers understand the testing methods used and the results obtained, ensuring transparency.

Third-Party Inspection

Engaging third-party inspection services can further assure buyers of product quality. These independent entities can perform comprehensive evaluations of the manufacturing processes and final products, providing an unbiased assessment.

Quality Control Nuances for International Buyers

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is crucial:

- Regulatory Compliance: Different regions may have varying requirements for materials, especially for products used in construction or automotive applications. Familiarity with local regulations can prevent compliance issues.

- Cultural Considerations: Communication styles and business practices vary across regions, which can affect negotiations and expectations around quality assurance. Understanding these cultural nuances can enhance supplier relationships.

By being informed about the manufacturing processes and quality assurance protocols for closed-cell foam, international B2B buyers can make more informed decisions, ensuring that the materials they procure meet their specific needs and standards.

Related Video: Water Quality Testing Methods

Comprehensive Cost and Pricing Analysis for closed-cell foam Sourcing

The cost structure and pricing of closed-cell foam sourcing are influenced by several critical components that international B2B buyers should consider. Understanding these elements can help buyers make informed decisions and negotiate better deals.

Cost Components

-

Materials: The choice of foam material significantly impacts the overall cost. Common types include polyethylene, cross-linked polyethylene, and polystyrene, each with varying price points based on properties such as density, thermal resistance, and chemical stability.

-

Labor: Labor costs depend on the complexity of the manufacturing process and the geographic location of the supplier. Regions with higher labor costs may lead to increased pricing but could also offer superior quality and craftsmanship.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Effective management of overhead costs can influence the final pricing of closed-cell foam.

-

Tooling: Custom tooling for specific applications can add to the initial cost. Buyers should assess whether the tooling investment is justified based on the expected volume and use of the foam.

-

Quality Control (QC): Implementing stringent QC measures ensures product consistency and reliability. Suppliers with robust QC processes may charge a premium, but this can prevent costly defects and returns in the long run.

-

Logistics: Shipping and handling costs vary based on distance, weight, and chosen Incoterms. International buyers should factor in these costs when calculating total expenses.

-

Margin: Supplier profit margins can vary widely based on market conditions, competition, and perceived value. Understanding these margins can provide insights into potential negotiation leeway.

Price Influencers

Several factors can influence the pricing of closed-cell foam:

-

Volume/MOQ: Larger orders typically reduce per-unit costs due to economies of scale. Establishing a Minimum Order Quantity (MOQ) with suppliers can lead to better pricing.

-

Specifications/Customization: Custom formulations or specific thicknesses can raise costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: Premium materials or specialized properties (e.g., fire resistance, UV stability) will incur higher costs. Buyers should evaluate the necessity of these features against their project needs.

-

Quality/Certifications: Suppliers who provide certifications (e.g., ASTM compliance) may charge more due to the added assurance of quality. However, these certifications can enhance product reliability and marketability.

-

Supplier Factors: Supplier reputation, experience, and geographical location can influence pricing. Established suppliers may charge more but offer better support and reliability.

-

Incoterms: The choice of Incoterms affects who is responsible for shipping costs and risks, impacting the overall price. Buyers should choose terms that align with their logistical capabilities.

Buyer Tips

To optimize costs and ensure a favorable sourcing experience, consider the following strategies:

-

Negotiation: Leverage volume and long-term contracts to negotiate better terms. Establish a relationship with suppliers to foster goodwill that can lead to future discounts.

-

Cost-Efficiency: Assess total cost of ownership (TCO) rather than just initial purchase price. This includes logistics, handling, and potential quality-related expenses.

-

Pricing Nuances for International Buyers: Understand local market conditions and currency fluctuations that can impact pricing. Building relationships with local suppliers in regions like Africa or South America may yield more competitive pricing.

-

Research and Compare: Conduct thorough research on multiple suppliers to understand market rates and capabilities. Use this information to make informed decisions.

-

Stay Informed: Keep abreast of market trends and material innovations that could affect pricing. Being proactive can help in negotiating better deals.

Disclaimer

Prices for closed-cell foam can vary widely based on the factors mentioned above. The information provided here is indicative and should be validated with suppliers for current market pricing. Always conduct comprehensive due diligence before making purchasing decisions.

Spotlight on Potential closed-cell foam Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘closed-cell foam’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for closed-cell foam

Key Technical Properties of Closed-Cell Foam

Understanding the essential technical properties of closed-cell foam is crucial for B2B buyers looking to make informed purchasing decisions. Here are several critical specifications:

-

Material Grade

The material grade refers to the specific formulation of the foam, which affects its performance characteristics. Different grades of closed-cell foam are engineered for distinct applications, such as insulation, cushioning, or sealing. Choosing the right material grade ensures that the foam will meet the demands of your specific industry, whether it be automotive, medical, or construction. -

Density

Density, measured in kilograms per cubic meter (kg/m³), indicates the mass of the foam relative to its volume. Higher density foams typically offer better durability, insulation, and shock absorption. For B2B buyers, understanding density is essential for evaluating the foam’s suitability for applications requiring specific levels of protection or thermal efficiency. -

Compression Deflection

This property measures the foam’s resistance to deformation under load. It is expressed in pounds per square inch (psi) and indicates how much the foam compresses when a force is applied. High compression deflection values are critical for applications like gaskets and seals, where maintaining a reliable seal under pressure is necessary. -

Thermal Conductivity

Thermal conductivity measures the foam’s ability to conduct heat. Lower values indicate better insulation properties, making the foam suitable for applications requiring temperature control, such as HVAC systems or refrigeration. B2B buyers must assess thermal conductivity to ensure energy efficiency in their products. -

Water Absorption

This specification indicates how much water the foam can absorb over a specified period. Closed-cell foams are designed to minimize water absorption, making them ideal for applications exposed to moisture. Understanding water absorption is vital for buyers in industries like marine and construction, where moisture resistance is critical.

Common Trade Terminology in Closed-Cell Foam

Familiarizing yourself with industry jargon can enhance communication and negotiation with suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of closed-cell foam, OEMs often require specific foam formulations tailored to their product specifications. Understanding OEM requirements can help buyers ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. B2B buyers must be aware of MOQs when sourcing closed-cell foam, as they can significantly impact purchasing decisions, especially for smaller projects or companies. -

RFQ (Request for Quotation)

An RFQ is a formal process through which buyers request price quotes from suppliers for specific quantities of closed-cell foam. Submitting an RFQ helps buyers obtain competitive pricing and terms, enabling better budget management and cost analysis. -

Incoterms (International Commercial Terms)

These are globally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping, delivery, and risk responsibilities when sourcing closed-cell foam from international suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For closed-cell foam, lead times can vary based on customization and supplier capabilities. Knowing lead times helps buyers plan their production schedules and manage inventory effectively. -

Custom Fabrication

This term describes the process of tailoring closed-cell foam products to meet specific requirements, such as size, shape, or performance characteristics. B2B buyers often seek custom fabrication to ensure that the foam meets the precise needs of their applications, which can enhance product performance and customer satisfaction.

By understanding these technical properties and trade terms, international B2B buyers can make better-informed decisions when sourcing closed-cell foam for their diverse applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the closed-cell foam Sector

Market Overview & Key Trends

The closed-cell foam market is witnessing significant growth globally, driven by increased demand in diverse industries such as automotive, construction, and healthcare. Key factors propelling this growth include the need for lightweight materials that offer excellent insulation, sound dampening, and moisture resistance. Notably, emerging markets in Africa and South America are seeing a surge in infrastructure development, which in turn boosts the demand for closed-cell foam in insulation and protective applications.

Current sourcing trends indicate a shift toward digital platforms and e-commerce, allowing international B2B buyers to access a broader range of suppliers and products. Buyers are increasingly utilizing online marketplaces to compare products, read reviews, and negotiate prices, which enhances their purchasing power. Moreover, the adoption of advanced manufacturing technologies, such as automation and 3D printing, is transforming the closed-cell foam sector, enabling suppliers to offer customized solutions that meet specific client needs.

From a market dynamics perspective, fluctuating raw material prices and supply chain disruptions pose challenges for international buyers. It is essential for companies to maintain robust relationships with suppliers to ensure a steady supply of materials. Additionally, the growing focus on product performance and certification standards, such as ASTM D-1056, is influencing buyer decisions, emphasizing the need for compliance and quality assurance in sourcing.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming increasingly crucial in the closed-cell foam sector, with environmental impacts and ethical sourcing practices taking center stage. Closed-cell foams are often derived from petroleum-based products, leading to significant carbon footprints. As a result, buyers are urged to consider suppliers who prioritize sustainable practices, such as using recycled materials or bio-based alternatives.

The importance of ethical supply chains cannot be overstated, particularly for international buyers from regions like the Middle East and Europe, where regulatory frameworks are becoming more stringent. Companies that adopt sustainable sourcing can enhance their brand reputation and appeal to environmentally conscious consumers. Certifications such as ISO 14001 for environmental management and Green Seal for eco-friendly products are indicators of a supplier’s commitment to sustainability.

Furthermore, the trend toward circular economy practices is gaining traction, encouraging manufacturers to develop closed-cell foams that can be recycled or repurposed at the end of their lifecycle. Buyers should seek out materials that align with these sustainable practices, ensuring that their sourcing decisions contribute positively to environmental conservation.

Brief Evolution/History

The closed-cell foam industry has evolved significantly since its inception in the mid-20th century. Originally utilized in niche applications, such as marine and military uses, the versatility of closed-cell foam has led to its widespread adoption across multiple sectors. Innovations in manufacturing processes, such as the introduction of cross-linking technology, have enhanced the material’s performance characteristics, making it suitable for a variety of applications, from automotive interiors to medical cushioning.

Over the years, the focus has shifted from merely functional performance to include sustainability and ethical sourcing, reflecting the growing awareness of environmental issues among manufacturers and buyers alike. As the industry continues to advance, the integration of smart technologies and sustainable practices will likely shape the future of closed-cell foam sourcing and usage.

Frequently Asked Questions (FAQs) for B2B Buyers of closed-cell foam

-

What factors should I consider when vetting suppliers of closed-cell foam?

When vetting suppliers, prioritize their experience in the closed-cell foam industry and their ability to meet specific application requirements. Assess their manufacturing capabilities, certifications (like ISO or ASTM), and whether they provide customization options. Request samples to evaluate the quality and performance of their products. Additionally, consider their reputation in international markets, delivery reliability, and customer service responsiveness, especially if you are sourcing from regions like Africa, South America, the Middle East, or Europe. -

Can I customize closed-cell foam products to suit my specific needs?

Yes, many manufacturers offer customization options for closed-cell foam products. This includes variations in density, thickness, and formulation tailored to your application requirements. When discussing customization, provide detailed specifications about your project’s needs, such as temperature resistance, chemical exposure, or mechanical properties. Ensure that the supplier can meet these requirements and is willing to collaborate on prototypes to validate the product’s performance before full-scale production. -

What are the typical minimum order quantities (MOQs) and lead times for closed-cell foam?

Minimum order quantities can vary significantly based on the supplier and the specific type of closed-cell foam. Generally, MOQs range from a few hundred to several thousand units. Lead times also depend on the complexity of the order, customization, and the supplier’s production capacity. For international buyers, consider potential delays in shipping and customs clearance. Always clarify these details upfront to align expectations and avoid disruptions in your supply chain. -

What payment terms should I expect when sourcing closed-cell foam internationally?

Payment terms can vary by supplier and region. Common practices include upfront deposits (typically 30-50%), with the balance due upon delivery or after inspection. For international transactions, consider using secure payment methods like letters of credit, which protect both parties. Discuss and negotiate payment terms early in the negotiation process to ensure transparency and to accommodate any specific financial practices common in your region, such as in Africa or South America. -

How can I ensure quality assurance and certifications for closed-cell foam?

Request documentation of quality assurance processes and certifications from potential suppliers. Look for compliance with international standards such as ISO 9001 for quality management and relevant ASTM standards for material properties. Some suppliers may also provide third-party testing results to verify performance claims. Establish clear quality control expectations, including inspection protocols upon delivery, to mitigate risks associated with product quality. -

What logistics considerations should I be aware of when importing closed-cell foam?

Logistics are crucial for timely delivery and cost management. Ensure that your supplier has experience in international shipping and can handle customs documentation. Discuss the shipping method (air or sea) based on urgency and cost-effectiveness. Additionally, account for potential tariffs or duties that may apply when importing closed-cell foam into your country. Collaborate with a reliable logistics partner who understands the regulations and can facilitate smooth customs clearance. -

What should I do in case of disputes with my closed-cell foam supplier?

In the event of a dispute, first attempt to resolve the issue directly with your supplier through open communication. Refer to the terms outlined in your purchase agreement, including any dispute resolution mechanisms. If necessary, consider mediation or arbitration to address the issue professionally. For international transactions, familiarize yourself with the legal frameworks and dispute resolution practices in both your country and the supplier’s country to ensure an effective resolution process. -

How can I evaluate the performance of closed-cell foam in my applications?

Evaluating performance requires testing foam samples under conditions similar to your application. Assess key properties such as thermal insulation, moisture resistance, shock absorption, and durability. Consider conducting performance tests for specific applications, like sealing or gasketing, to verify that the foam meets your requirements. Collaborate with your supplier to obtain guidance on appropriate testing methods and standards to ensure that the selected foam performs effectively in its intended use.

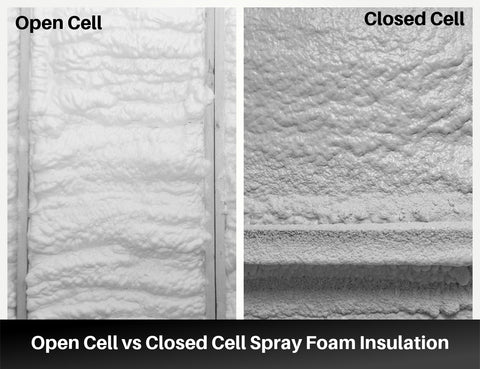

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for closed-cell foam

In summary, the strategic sourcing of closed-cell foam presents a unique opportunity for international B2B buyers to leverage its diverse applications across various industries. Key takeaways include understanding the different types of closed-cell foams available, such as polyethylene and cross-linked polyethylene, each offering distinct advantages like moisture resistance, thermal insulation, and mechanical resilience.

By focusing on strategic sourcing, businesses can not only optimize their supply chains but also ensure they select materials that meet specific performance and regulatory requirements, such as ASTM standards. This approach enables companies to mitigate risks and enhance product reliability.

As the demand for closed-cell foam continues to grow, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential for buyers to stay informed about market trends and supplier capabilities. Engaging with reputable suppliers and exploring custom fabrication options can unlock innovative solutions tailored to unique project specifications.

Take action today by evaluating your sourcing strategy for closed-cell foam and connecting with suppliers who can meet your needs efficiently and effectively. The future of your projects depends on the quality of materials you choose, so make informed decisions that will drive success and sustainability.