Master Sourcing Strategies for Head and Gasket Components

Introduction: Navigating the Global Market for head and gasket

Navigating the global market for head and gasket components is crucial for industries reliant on effective sealing solutions. These components play a pivotal role in ensuring mechanical integrity across a wide range of applications, from automotive engines to industrial machinery. As B2B buyers from diverse regions—Africa, South America, the Middle East, and Europe—seek reliable suppliers, understanding the intricacies of gasket manufacturing becomes essential.

This guide provides a comprehensive overview of the head and gasket landscape, addressing critical aspects such as types of gaskets, material selection, manufacturing processes, quality control standards, and cost considerations. By exploring these elements, buyers can make informed decisions that minimize downtime and enhance operational efficiency.

Additionally, the guide highlights key suppliers and market trends, empowering buyers to navigate supplier networks effectively. It also answers frequently asked questions, providing clarity on common concerns regarding gasket applications and sourcing.

Equipped with this knowledge, international B2B buyers will be better positioned to select the right gasket solutions tailored to their specific operational needs. This strategic approach not only fosters long-term partnerships with reliable suppliers but also ensures compliance with regional standards and regulations, ultimately driving business success in a competitive global market.

Understanding head and gasket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Metal Gaskets | High strength, durability, and resistance to extreme temperatures. | Oil & Gas, Aerospace, Automotive | Pros: Excellent sealing under high pressure; Cons: More expensive and may require precise fitting. |

| Spiral Wound Gaskets | Composed of alternating layers of metal and filler material, providing flexibility and resilience. | Chemical Processing, Power Generation | Pros: Suitable for fluctuating temperatures; Cons: May not be ideal for static applications. |

| Elastomeric Gaskets | Made from rubber or polymer materials, offering good compressibility and flexibility. | Food Processing, Pharmaceuticals | Pros: Cost-effective and easy to install; Cons: Limited temperature and chemical resistance. |

| Cork Gaskets | Natural material that provides good compressibility and is often used for low-pressure applications. | HVAC, General Industrial | Pros: Environmentally friendly; Cons: Not suitable for high-temperature applications. |

| Composite Gaskets | Made from a combination of materials to enhance performance characteristics. | Marine, Automotive, Industrial Equipment | Pros: Tailored for specific applications; Cons: Can be more complex to source and manufacture. |

Metal Gaskets

Metal gaskets are engineered for high-performance applications, offering exceptional strength and durability. Typically used in environments with extreme temperatures and pressures, they are ideal for sectors like oil and gas, aerospace, and automotive industries. When purchasing, consider the specific metal type, thickness, and surface finish to ensure compatibility with your equipment. While they provide robust sealing capabilities, they can be more costly and may necessitate precise fitting, which could increase installation time.

Spiral Wound Gaskets

Spiral wound gaskets consist of alternating layers of metal and filler material, making them particularly versatile. They excel in applications where temperature and pressure fluctuate, such as in chemical processing and power generation. When selecting spiral wound gaskets, pay attention to the material composition and the specific filler used, as these factors influence sealing effectiveness. Their flexibility is advantageous, but they may not perform optimally in static applications where rigid sealing is required.

Elastomeric Gaskets

Elastomeric gaskets are made from various rubber or polymer materials and are favored for their excellent compressibility and flexibility. Commonly used in food processing and pharmaceutical sectors, these gaskets are cost-effective and easy to install. Buyers should consider the specific elastomer type, as different materials offer varying levels of temperature and chemical resistance. While they are ideal for many applications, their limitations in extreme conditions can lead to potential failures if not matched correctly.

Cork Gaskets

Cork gaskets are a natural option that provides good compressibility, making them suitable for low-pressure applications in HVAC and general industrial settings. They are environmentally friendly and relatively inexpensive. However, when sourcing cork gaskets, it’s essential to evaluate their temperature limits and chemical resistance, as they are not suitable for high-temperature environments. Their simplicity and ease of use are advantages, but buyers must be aware of their limitations in demanding applications.

Composite Gaskets

Composite gaskets are crafted from a blend of materials to enhance their performance characteristics. They are particularly useful in marine, automotive, and industrial equipment applications, where specific sealing requirements must be met. When considering composite gaskets, focus on the intended application and the material combination, as these will dictate performance. Although they can be tailored to meet precise specifications, sourcing and manufacturing can be more complex, leading to longer lead times and potentially higher costs.

Related Video: Types of gaskets and gasket fundamental.

Key Industrial Applications of head and gasket

| Industry/Sector | Specific Application of head and gasket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Sealing in pipelines and drilling equipment | Prevents leaks, enhances safety, and reduces downtime | Material compatibility with aggressive chemicals, high-pressure ratings |

| Automotive | Engine cylinder head gaskets | Ensures optimal engine performance and efficiency | Compliance with automotive standards, temperature resistance, and durability |

| Food & Beverage | Sealing in processing and packaging machinery | Maintains hygiene and prevents contamination | FDA compliance, chemical resistance, and temperature tolerance |

| Chemical Processing | Gaskets in reactors and storage tanks | Protects against leaks and chemical exposure | Chemical compatibility, high-temperature performance, and custom sizes |

| Renewable Energy | Sealing in wind turbines and solar panels | Enhances operational efficiency and reliability | Resistance to environmental factors, material certification, and custom designs |

Oil & Gas

In the oil and gas sector, head and gaskets play a crucial role in sealing pipelines and drilling equipment. These components are essential for preventing leaks, which can lead to hazardous spills and significant financial losses. Buyers in this industry must consider material compatibility with aggressive chemicals and high-pressure ratings to ensure safety and reliability. Selecting gaskets that meet ASTM and ISO standards is vital for operational integrity and compliance.

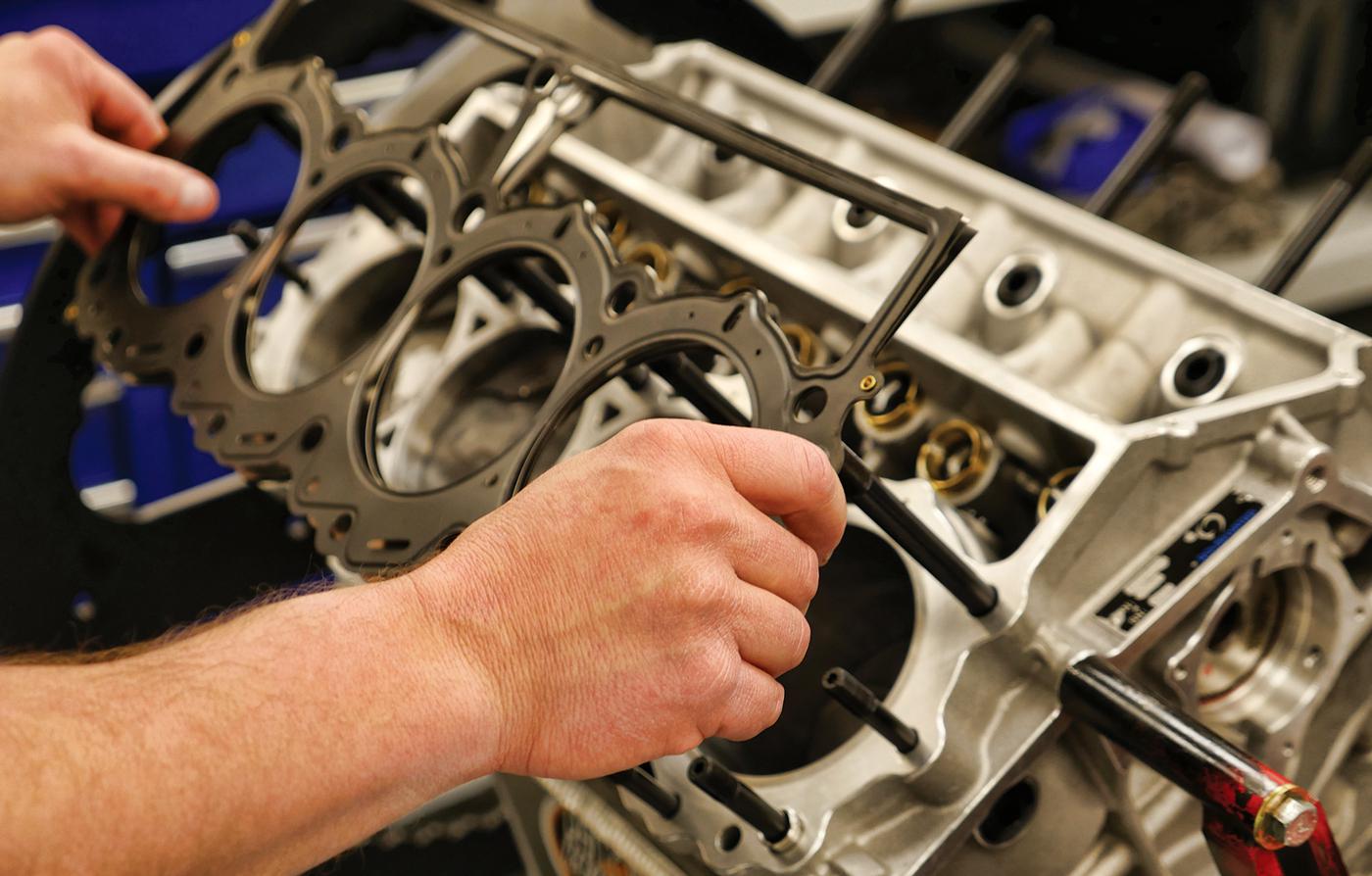

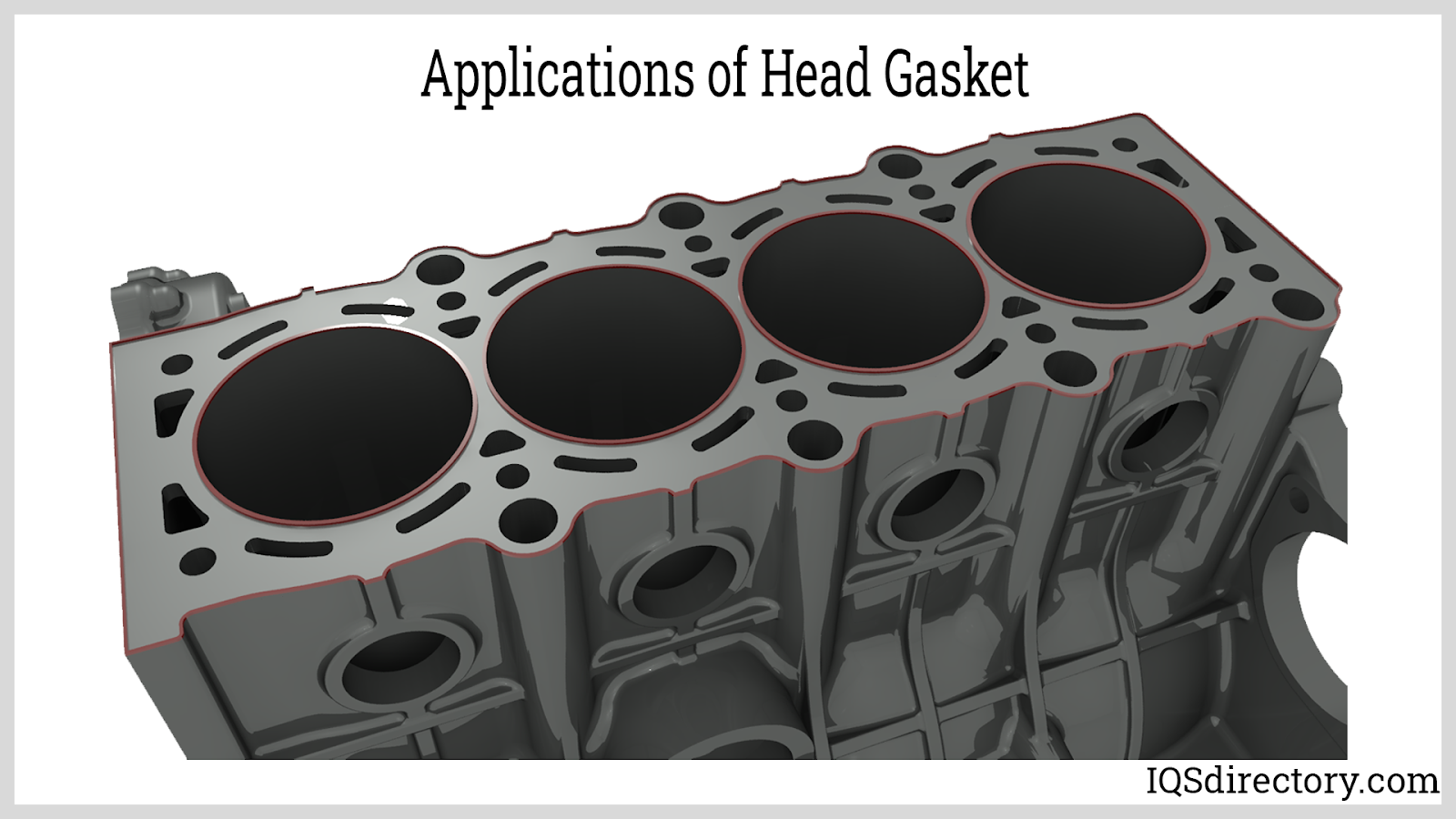

Automotive

In automotive applications, head gaskets are critical for ensuring a tight seal between the engine cylinder head and the engine block. This sealing prevents coolant and oil leaks, which can lead to engine overheating and failure. International buyers, particularly from regions with stringent automotive regulations, need to focus on compliance with industry standards, temperature resistance, and overall durability to ensure optimal engine performance and efficiency.

Food & Beverage

In the food and beverage industry, head and gaskets are utilized in processing and packaging machinery to maintain hygiene and prevent contamination. These gaskets must comply with FDA regulations, ensuring they are non-toxic and suitable for contact with food products. Buyers should prioritize materials with good chemical resistance and temperature tolerance, as they often encounter steam cleaning and hot water during operation. Ensuring proper certification is essential for maintaining product safety.

Chemical Processing

For chemical processing applications, gaskets are used in reactors and storage tanks to protect against leaks and chemical exposure. The choice of material is critical, as it must withstand aggressive chemicals and high temperatures. Buyers need to ensure that the selected gaskets are chemically compatible with the substances handled and can meet specific industry standards for safety and performance. Custom sizes may also be required to fit unique equipment configurations.

Renewable Energy

In the renewable energy sector, head and gaskets are essential for sealing components in wind turbines and solar panels. These gaskets help enhance operational efficiency and reliability by preventing leaks and ensuring proper functioning under varying environmental conditions. Buyers should consider materials that resist environmental factors such as UV exposure, moisture, and temperature fluctuations. Custom designs may be necessary to accommodate specific installation needs and enhance overall system performance.

Related Video: Engine RTV silicone gasket maker types application instructions comparison uses demonstration 2.0t

Strategic Material Selection Guide for head and gasket

When selecting materials for head and gasket applications, it is crucial to consider various factors that influence performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in head and gasket manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Graphite

Key Properties: Graphite gaskets exhibit excellent thermal stability, typically rated for temperatures up to 450°C. They also provide good pressure resistance and are chemically inert, making them suitable for aggressive environments.

Pros & Cons: Graphite gaskets are highly durable and can withstand extreme conditions, making them ideal for high-pressure applications like oil and gas. However, they can be more expensive than other materials and may require careful handling during installation to prevent flaking.

Impact on Application: Graphite is particularly effective in sealing applications involving steam, hydrocarbons, and other aggressive chemicals. Its ability to maintain integrity under fluctuating temperatures and pressures enhances system reliability.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations, as graphite gaskets may not meet certain environmental standards. Familiarity with ASTM and DIN standards can aid in selecting compliant products.

2. PTFE (Polytetrafluoroethylene)

Key Properties: PTFE gaskets can withstand temperatures ranging from -200°C to +260°C and possess excellent chemical resistance, making them suitable for a wide range of applications.

Pros & Cons: The primary advantage of PTFE is its versatility and non-stick properties, which prevent media from adhering to the gasket surface. However, PTFE gaskets can be more costly and may require specialized installation techniques due to their tendency to deform under high pressure.

Impact on Application: PTFE is ideal for applications in the pharmaceutical and food industries, where chemical compatibility and hygiene are paramount. Its inert nature ensures that it does not contaminate sensitive media.

Considerations for International Buyers: Compliance with FDA regulations is essential for buyers in the food and pharmaceutical sectors, particularly in Europe and North America. Buyers should verify that PTFE products meet relevant industry standards.

3. Nitrile (NBR)

Key Properties: Nitrile gaskets are effective in temperatures ranging from -30°C to +120°C and offer good resistance to oils and fuels, making them suitable for automotive and industrial applications.

Pros & Cons: Nitrile is cost-effective and provides good sealing performance in oil-based environments. However, it has limited resistance to high temperatures and certain chemicals, which may restrict its use in more demanding applications.

Impact on Application: Nitrile gaskets are commonly used in the automotive industry and machinery where oil and fuel exposure is prevalent. Their affordability makes them a popular choice for general-purpose sealing.

Considerations for International Buyers: Buyers should ensure that NBR gaskets comply with local automotive standards, especially in regions like Europe and South America, where regulations may differ. Understanding the specific requirements for automotive applications can enhance procurement decisions.

4. Silicone

Key Properties: Silicone gaskets can withstand temperatures from -60°C to +200°C and are known for their excellent flexibility and resilience against environmental factors.

Pros & Cons: Silicone is highly versatile and suitable for a variety of applications, including food processing and medical devices. However, it is less effective in high-pressure applications compared to other materials like graphite or PTFE.

Impact on Application: Silicone gaskets are particularly beneficial in applications requiring high flexibility and resistance to temperature fluctuations, such as in HVAC systems and food processing.

Considerations for International Buyers: Buyers in the food and beverage sectors must ensure that silicone gaskets meet FDA and EU food safety regulations. Understanding the specific compliance requirements in different regions can facilitate smoother procurement processes.

Summary Table

| Material | Typical Use Case for head and gasket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Graphite | Oil & gas, high-pressure environments | Excellent thermal and chemical resistance | Higher cost, requires careful handling | High |

| PTFE | Food and pharmaceuticals | Versatile and non-stick properties | Higher cost, deformation under pressure | High |

| Nitrile (NBR) | Automotive and industrial applications | Cost-effective, good oil resistance | Limited temperature and chemical resistance | Medium |

| Silicone | Food processing, HVAC systems | High flexibility and resilience | Less effective in high-pressure applications | Medium |

This strategic material selection guide provides B2B buyers with essential insights into choosing the right materials for head and gasket applications, helping to ensure optimal performance and compliance with industry standards.

In-depth Look: Manufacturing Processes and Quality Assurance for head and gasket

Manufacturing Processes for Head and Gasket

When it comes to manufacturing heads and gaskets, a series of systematic stages ensure that these critical components meet industry standards and operational demands. Understanding these processes is crucial for B2B buyers looking to source high-quality products.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step involves selecting appropriate materials based on the intended application. Common materials include aluminum, cast iron for heads, and various elastomers or composites for gaskets. Buyers should consider factors like thermal resistance, chemical compatibility, and mechanical strength.

– Material Inspection: Incoming materials undergo rigorous inspection (Incoming Quality Control – IQC) to ensure they meet predefined specifications. This step helps in identifying any defects early in the manufacturing process. -

Forming

– Casting and Machining: For heads, the forming process typically involves casting methods such as sand casting or die casting, followed by machining to achieve precise dimensions. This includes processes like milling, drilling, and turning.

– Gasket Fabrication: Gasket forming may involve cutting sheets using techniques such as die cutting, waterjet cutting, or laser cutting. The choice of method impacts the edge quality and dimensional accuracy of the gaskets produced. -

Assembly

– Joining Components: In the case of heads, assembly may involve integrating various machined components, such as valves and ports. For gaskets, this stage includes applying adhesives or bonding layers if multi-material gaskets are used.

– Alignment and Fit Testing: Proper alignment is critical to ensure that the assembled components will function correctly. This may involve checking tolerances and fit using precision instruments. -

Finishing

– Surface Treatment: The finishing process may include surface treatments like anodizing for heads or surface treatments for gaskets to enhance durability and resistance to environmental factors.

– Final Inspection: Before products leave the facility, they undergo Final Quality Control (FQC), where they are inspected for any defects or inconsistencies.

Quality Assurance in Manufacturing

Quality assurance is vital in ensuring that heads and gaskets meet international and industry-specific standards. A robust QC process not only protects the buyer’s investment but also enhances the reliability of the products.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization seeking to improve customer satisfaction and operational efficiency.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For the oil and gas sector, adherence to American Petroleum Institute (API) standards is critical for ensuring product reliability and safety.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verification of raw materials before production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process. Techniques include statistical process control (SPC) to identify variations and maintain quality.

- Final Quality Control (FQC): Comprehensive testing of the final products before shipment. This may include pressure testing for gaskets and dimensional checks for heads.

Illustrative Image (Source: Google Search)

Common Testing Methods

- Pressure Testing: To ensure that gaskets can withstand operational pressures without leaking.

- Dimensional Inspection: Utilizing tools like calipers and micrometers to ensure components meet specified tolerances.

- Material Testing: Techniques such as tensile testing and hardness testing to assess material properties.

Verifying Supplier Quality Control

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, ensuring that suppliers maintain high-quality standards is essential. Here are actionable steps to verify supplier QC:

- Supplier Audits: Conduct regular audits of suppliers’ manufacturing facilities to assess their adherence to quality standards and practices.

- Request Documentation: Obtain quality reports, certifications, and test results that validate compliance with international standards such as ISO 9001 and industry-specific regulations.

- Third-Party Inspections: Engage independent inspection agencies to assess the quality of products before shipment. This provides an unbiased evaluation of compliance with specifications.

QC and Certification Nuances for International Buyers

When sourcing heads and gaskets internationally, buyers should be aware of the following nuances:

- Cultural Differences: Different regions may have varying interpretations of quality standards. Buyers should ensure that suppliers understand and adhere to the specific requirements of the buyer’s country.

- Regulatory Compliance: Compliance with local regulations is crucial. For example, EU buyers must ensure that products meet CE marking requirements, while buyers in the Middle East may need to consider GCC standards.

- Traceability: Ensure that suppliers provide traceability for materials used in production, including certifications of origin and compliance with safety standards.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for heads and gaskets is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can significantly reduce risks associated with sourcing these critical components. Engaging in thorough supplier audits and ensuring compliance with international standards will further safeguard investments and enhance operational reliability.

Related Video: How Gasket is Manufactured | Unseen Gasket Production Process | Silicon and Rubber Gasket Making

Comprehensive Cost and Pricing Analysis for head and gasket Sourcing

Analyzing the cost structure and pricing for head and gasket sourcing is essential for international B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. Understanding the various cost components and price influencers can lead to more informed purchasing decisions and ultimately better margins.

Cost Components

- Materials: The choice of materials significantly affects the overall cost of head and gasket products. Common materials include natural rubber, silicone, and compressed non-asbestos, each varying in price based on properties like durability and chemical resistance. Sourcing high-quality materials can reduce failure rates and maintenance costs in the long run.

Illustrative Image (Source: Google Search)

-

Labor: Labor costs can vary widely depending on the region and the complexity of the gasket manufacturing process. Automated production may reduce labor costs, but custom or intricate designs may require skilled labor, increasing expenses.

-

Manufacturing Overhead: This includes costs related to equipment maintenance, utilities, and facility costs. Manufacturers with advanced technologies may incur higher overhead but can achieve better precision and efficiency, which can be beneficial for buyers requiring high-quality products.

-

Tooling: Tooling costs are incurred for creating molds and dies necessary for gasket production. Custom specifications can lead to higher tooling costs but may be justified by the performance requirements of specific applications.

-

Quality Control (QC): Implementing stringent QC measures ensures that products meet industry standards and certifications, such as ISO or ASTM. While this may increase costs, it enhances reliability and reduces the risk of defects, which can lead to costly downtime.

-

Logistics: Shipping and handling costs can fluctuate based on distance, mode of transport, and Incoterms. Buyers should consider these costs when evaluating suppliers, especially when sourcing from overseas.

-

Margin: Supplier margins can vary based on market conditions and competition. Understanding the typical margins within your industry can help in negotiations and selecting a supplier that offers fair pricing.

Price Influencers

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can also impact pricing and should be discussed with suppliers.

-

Specifications/Customization: Custom gaskets tailored to specific applications generally come at a premium. Buyers should weigh the benefits of customization against the associated costs.

-

Material Choices: As previously mentioned, the selected material significantly influences price. Buyers should evaluate the trade-offs between cost and performance.

-

Quality and Certifications: Products that meet higher quality standards and certifications typically command higher prices. However, they may offer better performance and reliability, which could save costs over time.

-

Supplier Factors: The reliability and reputation of the supplier can impact pricing. Established suppliers with a track record of quality may charge more but offer reduced risk.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is crucial for international transactions. They define responsibilities for shipping, insurance, and tariffs, which can affect overall costs.

Buyer Tips

-

Negotiate: Leverage your purchasing power by negotiating prices, especially for larger orders. Establish long-term relationships with suppliers for better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes not just the initial purchase price but also maintenance, replacement, and operational costs. Investing in higher-quality materials may lead to lower TCO.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, tariffs and import duties can significantly impact costs when sourcing from outside your region.

-

Market Research: Conduct thorough market research to understand pricing benchmarks in your region. This knowledge will empower you during negotiations and supplier selection.

Disclaimer

Prices and costs mentioned in this analysis are indicative and can vary based on market conditions, supplier choices, and specific project requirements. Always consult directly with suppliers for the most accurate pricing.

Spotlight on Potential head and gasket Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘head and gasket’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for head and gasket

Understanding the critical technical properties and terminology associated with heads and gaskets is essential for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also fosters effective communication with suppliers and manufacturers.

Key Technical Properties

-

Material Grade

– The material grade of a gasket or head component significantly impacts its performance under various environmental conditions. Common materials include rubber, silicone, PTFE, and metal composites. Each material has distinct properties, such as temperature resistance and chemical compatibility, which determine suitability for specific applications. For instance, PTFE is ideal for chemical processing due to its excellent inertness. -

Tolerance

– Tolerance refers to the allowable deviation from a specified dimension. It is critical in ensuring that gaskets fit precisely within their designated spaces, preventing leaks and maintaining system integrity. Tight tolerances are especially important in high-pressure applications, where even minor deviations can lead to catastrophic failures. -

Pressure Rating

– The pressure rating indicates the maximum pressure a gasket or head can withstand without failure. This property is vital for applications in industries such as oil and gas, where high pressures are common. Knowing the pressure rating helps buyers select appropriate components that meet their operational requirements. -

Temperature Resistance

– Temperature resistance denotes the range of temperatures a gasket or head can endure while maintaining its sealing capabilities. Materials such as silicone or graphite are chosen for their ability to perform under extreme temperatures. Understanding this property helps buyers avoid premature failures caused by thermal degradation. -

Chemical Compatibility

– This property assesses how well a gasket or head material can withstand exposure to various chemicals. In industries like pharmaceuticals or food processing, where cross-contamination is a concern, selecting materials with high chemical resistance is crucial. Buyers should evaluate compatibility charts to ensure long-term reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for buyers looking to replace or source components that meet original design standards. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest number of units a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and budgeting. Buyers should negotiate MOQs to align with their operational needs and cash flow. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent to suppliers to request pricing and terms for specific products or services. This process is crucial for buyers to compare costs, ensuring they receive competitive pricing while meeting their quality standards. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers. Familiarity with these terms helps buyers understand shipping, risk, and cost responsibilities, facilitating smoother international transactions. -

Lead Time

– Lead time refers to the duration from when an order is placed until it is fulfilled. Understanding lead times is essential for inventory planning and production schedules, allowing buyers to minimize downtime and maintain operational efficiency. -

Custom Fabrication

– This term refers to the process of creating components tailored to specific requirements. For B2B buyers, understanding custom fabrication options can lead to better product fit and performance, especially in specialized applications.

By grasping these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right components while fostering effective supplier relationships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the head and gasket Sector

Market Overview & Key Trends

The head and gasket sector is experiencing dynamic growth driven by various global factors. As industries increasingly prioritize efficiency and reliability, the demand for high-quality gaskets—critical for sealing applications in engines, pipelines, and heavy machinery—continues to rise. Notably, increased industrialization in regions such as Africa and South America is creating new opportunities for suppliers and manufacturers.

Emerging technologies, particularly in digitalization and automation, are reshaping sourcing and production processes. Companies are leveraging advanced manufacturing techniques, such as 3D printing and laser cutting, to enhance precision and reduce lead times. These technologies facilitate the customization of gaskets, meeting specific requirements for diverse applications across sectors such as automotive, oil and gas, and food processing.

International B2B buyers must also navigate fluctuating raw material prices and supply chain disruptions. The ongoing geopolitical tensions and the effects of the COVID-19 pandemic have underscored the need for robust sourcing strategies. Establishing local partnerships and diversifying supplier networks are becoming essential to mitigate risks associated with long lead times and material shortages.

Furthermore, the sustainability trend is gaining momentum, with buyers increasingly seeking eco-friendly materials and practices in their sourcing decisions. This shift is not only driven by regulatory compliance but also by growing consumer demand for sustainable products, making it imperative for businesses to adapt their procurement strategies accordingly.

Sustainability & Ethical Sourcing in B2B

The head and gasket industry faces significant environmental challenges, particularly concerning waste generation and the carbon footprint associated with traditional manufacturing processes. As global awareness of sustainability increases, buyers are urged to prioritize ethical sourcing and sustainable practices within their supply chains.

Adopting green materials—such as non-asbestos gaskets and those made from recycled or biodegradable substances—can significantly reduce environmental impact. Buyers should actively seek suppliers who provide certifications, such as ISO 14001 (Environmental Management) or those that comply with the European Union’s REACH regulations. These certifications not only demonstrate a commitment to sustainability but also ensure compliance with industry standards.

Additionally, fostering ethical supply chains is crucial for enhancing brand reputation and consumer trust. Buyers should conduct thorough assessments of potential suppliers, evaluating their labor practices, waste management systems, and resource utilization. By aligning procurement strategies with sustainability goals, businesses can contribute to a more resilient and responsible industry while also gaining a competitive edge in the marketplace.

Brief Evolution/History

The head and gasket sector has evolved significantly over the past century. Initially, gaskets were made from basic materials like cork and rubber, primarily serving to prevent leaks in mechanical systems. The advent of synthetic materials in the mid-20th century revolutionized gasket manufacturing, introducing enhanced durability and chemical resistance.

As industries advanced, so did the complexity of sealing applications, leading to the development of specialized gaskets tailored for specific environments, such as high-pressure and high-temperature applications in the oil and gas sector. Today, with the integration of smart technologies and a focus on sustainability, the industry continues to innovate, ensuring that gaskets not only meet stringent performance standards but also contribute to environmental goals. This evolution highlights the importance of adapting to market demands and leveraging technological advancements for B2B buyers in the sector.

Related Video: What are Global Value Chains and why they matter for economic & regional development | LSE Research

Frequently Asked Questions (FAQs) for B2B Buyers of head and gasket

-

How do I vet suppliers for head and gasket products?

When vetting suppliers, consider their industry experience, reputation, and certifications. Verify their compliance with international quality standards like ISO, ASTM, or FDA/NSF. Request references and case studies from previous clients to assess reliability and product performance. Additionally, evaluate their manufacturing capabilities and technology used in production, as modern processes can enhance product precision and durability. Finally, consider their geographical location and the implications for lead times and shipping costs. -

Can I customize the head and gasket products to my specifications?

Yes, most manufacturers offer customization options, including material selection, thickness, size, shape, and surface treatments. When discussing customization, provide detailed specifications and requirements, such as operating conditions and application types. It’s crucial to communicate any industry-specific regulations your application might require, ensuring the manufacturer can meet those standards. Customization can enhance product performance, but ensure that the supplier can accommodate your needs within the desired timelines. -

What are the typical minimum order quantities (MOQs) and lead times for head and gasket products?

Minimum order quantities vary by supplier and product type; they can range from as low as 50 pieces to several hundred. Lead times typically depend on the complexity of the order and the supplier’s production capacity, often ranging from 2 to 8 weeks. For customized products, longer lead times may be necessary. Always clarify these aspects before placing an order to align your procurement strategy with your project timelines. -

What payment terms should I expect when sourcing head and gasket products?

Payment terms can vary significantly among suppliers, but common practices include 30% upfront payment with the balance due upon shipment or delivery. Some suppliers may offer credit terms for established customers. Always discuss payment options early in the negotiation process to avoid misunderstandings. Additionally, consider using secure payment methods and ensure that all terms are documented in the purchase agreement to protect both parties. -

What quality assurance processes should suppliers have in place?

Reputable suppliers should implement rigorous quality assurance processes, including regular inspections and testing of materials and finished products. Request information on their quality management systems and any relevant certifications. Ensure they conduct compliance checks with industry standards, such as ISO 9001, and offer traceability for materials used in their gaskets. Quality control is essential for preventing issues that could lead to equipment failure or operational downtime. -

How can I manage logistics and shipping when sourcing internationally?

Collaborate with your supplier to establish an efficient logistics plan. Understand the shipping methods available (air, sea, or land) and their associated costs and delivery times. Familiarize yourself with customs regulations in both the exporting and importing countries to ensure compliance and avoid delays. Consider using freight forwarders or logistics companies with expertise in international shipping to streamline the process and handle documentation. -

What should I do in case of disputes with my supplier?

In the event of a dispute, first, review your contract to understand the agreed terms and conditions. Maintain open communication with your supplier to resolve issues amicably. If necessary, escalate the matter internally within the supplier’s organization. If a resolution cannot be reached, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Always document communications and agreements to support your position during dispute resolution. -

How can I ensure compliance with international regulations when sourcing head and gasket products?

To ensure compliance, familiarize yourself with the regulations applicable to your industry and region, such as environmental standards, safety regulations, and material certifications. Engage with suppliers who demonstrate a clear understanding of these regulations and can provide the necessary documentation, such as certificates of compliance. Conduct periodic audits or assessments of your suppliers to verify adherence to these standards, fostering a reliable supply chain that meets international expectations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for head and gasket

In summary, effective strategic sourcing for head and gasket components is essential for ensuring operational efficiency and reliability across diverse industrial applications. By focusing on material selection, manufacturing processes, and cutting-edge technologies, buyers can significantly reduce costs while enhancing product performance. Understanding the specific requirements of your industry—whether it’s chemical processing, food and beverage, or automotive—can guide you in selecting the most suitable gasket materials, thereby minimizing risks associated with leaks and system failures.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should leverage global networks and local suppliers to optimize their procurement strategies. Emphasizing quality certifications and compliance with international standards will further ensure that the chosen components meet safety and performance benchmarks.

Looking ahead, the demand for innovative gasket solutions is set to rise, driven by advancements in material science and manufacturing technologies. Now is the time to evaluate your sourcing strategies and align them with the evolving market needs. Engage with suppliers who offer customization and rapid prototyping to stay ahead of the competition, ensuring that your operations remain seamless and reliable in an increasingly dynamic global marketplace.