Master Sourcing Strategies for High-Quality Barrel Mixers

Introduction: Navigating the Global Market for barrel mixer

In the dynamic landscape of global manufacturing, the barrel mixer plays a pivotal role in ensuring the consistency and quality of products across various industries. This essential equipment is not just about mixing; it impacts production efficiency, product quality, and ultimately, the bottom line. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including key markets like Mexico and Egypt) seek to enhance their operations, understanding the nuances of barrel mixers becomes imperative.

This comprehensive guide offers a deep dive into the world of barrel mixers, covering essential topics such as types of mixers, materials used, manufacturing and quality control standards, supplier insights, and cost considerations. Each section is designed to equip buyers with the knowledge necessary to make informed sourcing decisions, facilitating a smoother procurement process.

With a focus on actionable insights, this guide empowers buyers to navigate the complexities of choosing the right barrel mixer for their specific needs. Whether you are looking to optimize your mixing processes or ensure compliance with international standards, the information provided herein will serve as a valuable resource. By leveraging the insights offered, international B2B buyers can enhance operational efficiency, reduce costs, and ultimately drive growth in their respective markets.

Understanding barrel mixer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Horizontal Barrel Mixer | Features a horizontal orientation; effective for bulk materials. | Food processing, chemical production | Pros: Efficient mixing of large volumes; easy to clean. Cons: Requires significant floor space. |

| Vertical Barrel Mixer | Operates in a vertical position; ideal for small batches. | Pharmaceutical, cosmetics | Pros: Space-saving design; suitable for small quantities. Cons: Limited capacity compared to horizontal models. |

| Tumble Mixer | Uses gravity to mix materials in a rotating barrel; gentle mixing action. | Powdered food products, pharmaceuticals | Pros: Minimal damage to delicate materials; uniform mixing. Cons: Slower mixing speed; not ideal for viscous materials. |

| Drum Mixer | Typically designed for mixing liquids; can handle various viscosities. | Paint, coatings, adhesives | Pros: Versatile for different material types; efficient for liquids. Cons: Less effective for solid materials; potential for settling. |

| High-Shear Barrel Mixer | Incorporates high-speed blades for intensive mixing; effective for emulsions. | Food production, cosmetics, pharmaceuticals | Pros: Achieves fine emulsions and consistent mixtures; fast mixing times. Cons: Higher energy consumption; potential for heat generation. |

Horizontal Barrel Mixer

Horizontal barrel mixers are designed with a horizontal orientation, making them suitable for mixing large volumes of bulk materials. They are widely used in food processing and chemical production due to their efficiency in handling substantial quantities. When considering this type, buyers should evaluate the available floor space, as these mixers require significant room. Additionally, ease of cleaning and maintenance is a notable advantage, making them a practical choice for high-volume operations.

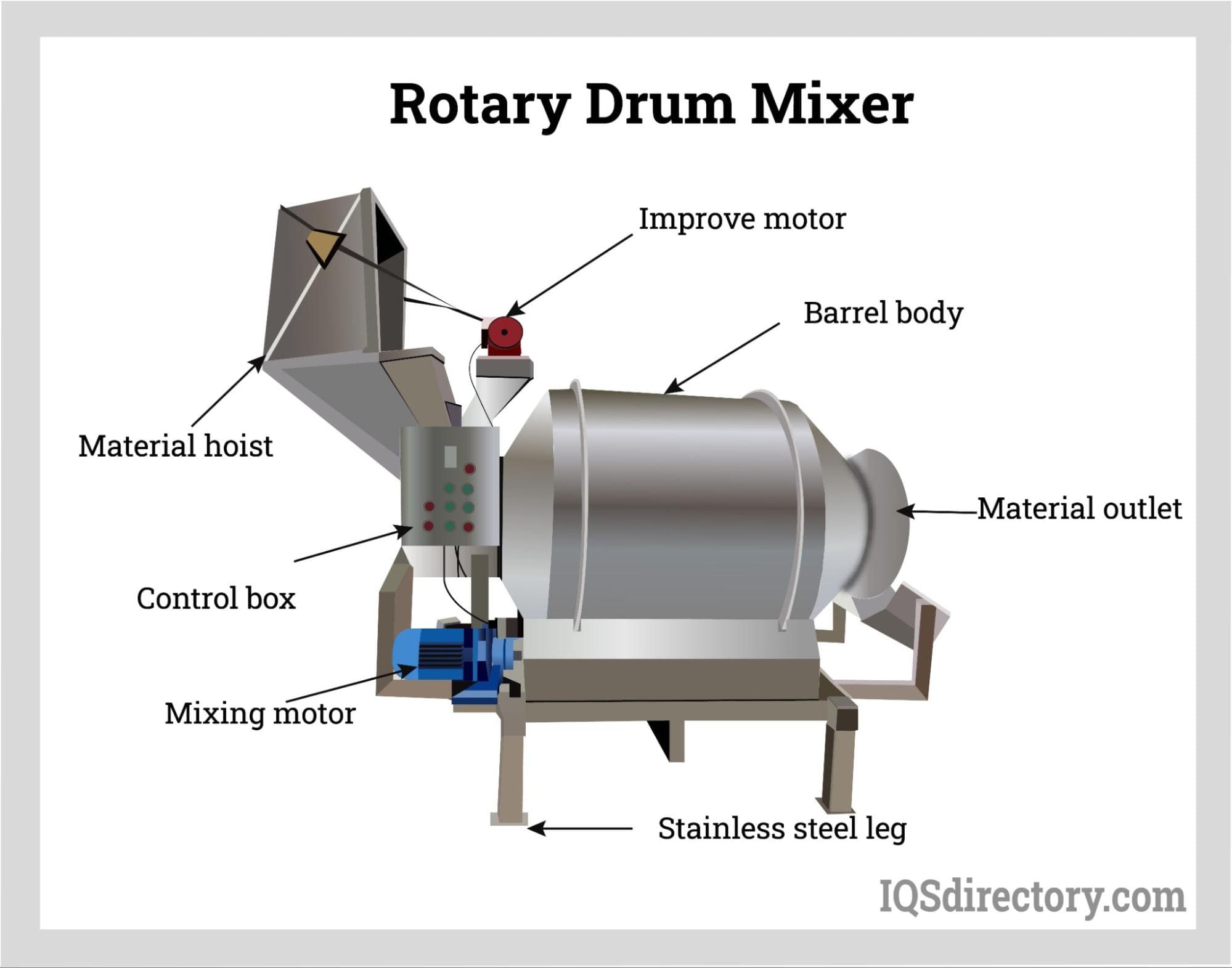

Illustrative Image (Source: Google Search)

Vertical Barrel Mixer

Vertical barrel mixers operate in an upright position and are ideal for smaller batch sizes, making them particularly useful in the pharmaceutical and cosmetics industries. Their space-saving design allows for efficient use of vertical space, which can be a critical factor in facilities with limited floor area. However, buyers should consider the limitations in capacity compared to horizontal models, as well as the potential need for additional mixing equipment for larger volumes.

Tumble Mixer

Tumble mixers utilize gravity to mix materials within a rotating barrel, providing a gentle mixing action that is particularly beneficial for powdered food products and pharmaceuticals. This method minimizes damage to delicate materials and ensures uniform mixing. However, potential buyers should be aware of the slower mixing speeds and that tumble mixers may not be suitable for viscous materials, which could limit their application range.

Drum Mixer

Drum mixers are specifically designed for mixing liquids and can accommodate a variety of viscosities, making them a versatile choice for industries such as paint, coatings, and adhesives. Their efficiency in handling liquids makes them popular, but buyers should be cautious about their limitations when dealing with solid materials, as settling can occur. Evaluating the specific requirements for liquid mixing will help buyers determine if this type aligns with their production needs.

High-Shear Barrel Mixer

High-shear barrel mixers incorporate high-speed blades to achieve intensive mixing, making them particularly effective for emulsions in food production, cosmetics, and pharmaceuticals. They provide fast mixing times and produce fine emulsions and consistent mixtures. However, buyers should consider the higher energy consumption associated with this type and the potential for heat generation, which may necessitate cooling mechanisms in certain applications. Understanding these factors is crucial for optimizing performance and efficiency.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of barrel mixer

| Industry/Sector | Specific Application of Barrel Mixer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Mixing of sauces and condiments | Ensures uniform consistency and flavor distribution | Food-grade materials, easy cleaning, compliance with safety standards |

| Pharmaceuticals | Preparation of ointments and creams | Achieves precise blending for effective formulations | High-quality components, customization options, regulatory compliance |

| Chemicals | Mixing of viscous and abrasive materials | Enhances efficiency in production and reduces waste | Durability against wear, suitable for hazardous materials, maintenance support |

| Construction Materials | Mixing of adhesives and sealants | Improves bonding strength and application efficiency | Resistance to chemical corrosion, mixing capacity, supplier reliability |

| Cosmetics and Personal Care | Blending of lotions and creams | Provides consistent texture and quality for products | Customization for different viscosities, adherence to cosmetic regulations, after-sales support |

In the Food and Beverage industry, barrel mixers are essential for the mixing of sauces and condiments, ensuring a uniform consistency and flavor distribution. This is particularly crucial for manufacturers aiming to meet consumer preferences for quality and taste. International buyers should consider sourcing mixers made from food-grade materials that facilitate easy cleaning and comply with safety standards to avoid contamination.

In the Pharmaceuticals sector, barrel mixers are used for preparing ointments and creams, where precise blending is critical for effective formulations. These mixers help in achieving the desired viscosity and homogeneity, which is vital for product efficacy. Buyers in this field should prioritize mixers with high-quality components and customization options to meet specific formulation requirements, along with ensuring compliance with regulatory standards.

The Chemicals industry utilizes barrel mixers for the mixing of viscous and abrasive materials, enhancing production efficiency and reducing waste. These mixers can handle tough materials and ensure a consistent output, which is essential for maintaining quality in chemical production. Buyers should consider the mixer’s durability against wear and its ability to handle hazardous materials, along with the availability of maintenance support.

In Construction Materials, barrel mixers are critical for mixing adhesives and sealants, improving bonding strength and application efficiency. A consistent mix is vital for ensuring the performance of construction materials. Buyers should look for mixers that offer resistance to chemical corrosion and adequate mixing capacity to meet their production demands, alongside evaluating supplier reliability.

Finally, in the Cosmetics and Personal Care industry, barrel mixers are employed for blending lotions and creams to achieve a consistent texture and quality. This is essential for maintaining brand reputation and customer satisfaction. Buyers should focus on sourcing mixers that can be customized for different viscosities and ensure adherence to cosmetic regulations, along with robust after-sales support to facilitate any necessary maintenance.

Related Video: Industrial Mixers and Mixing Equipment – PerMix PFB 3000 – Twin Shaft Paddle Mixer

Strategic Material Selection Guide for barrel mixer

When selecting materials for barrel mixers, international B2B buyers must consider various factors that affect performance, durability, and cost-effectiveness. Here, we analyze four common materials used in barrel mixers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high-temperature tolerance, and mechanical strength. It typically withstands temperatures up to 500°F (260°C) and pressures of around 150 psi, making it suitable for a wide range of mixing applications.

Pros & Cons:

The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it can be more expensive than other materials, which may impact budget constraints. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a variety of media, including food products, chemicals, and pharmaceuticals, making it a versatile choice for many industries. Its non-reactive nature ensures that the end product remains uncontaminated.

Considerations for International Buyers:

Buyers should ensure compliance with international food safety standards, such as those set by the FDA or EU regulations. Additionally, certifications like ASTM or DIN for material quality can be crucial for ensuring product integrity.

Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and good wear resistance. It can handle moderate temperatures (up to 400°F or 204°C) and is typically less resistant to corrosion compared to stainless steel.

Pros & Cons:

The primary advantage of carbon steel is its lower cost, making it an attractive option for budget-conscious buyers. However, its susceptibility to rust and corrosion limits its use in certain applications, particularly those involving moisture or corrosive substances.

Impact on Application:

Carbon steel is suitable for mixing dry materials or non-corrosive liquids. Its use in food applications may be limited unless properly coated or treated to prevent corrosion.

Considerations for International Buyers:

Buyers in humid or coastal regions, such as parts of Africa and South America, should consider the environmental impact on carbon steel. Compliance with local regulations regarding food-grade materials is essential to avoid contamination risks.

Polypropylene

Key Properties:

Polypropylene is a thermoplastic polymer known for its chemical resistance and lightweight characteristics. It can withstand temperatures up to 200°F (93°C) and is resistant to many acids and bases.

Pros & Cons:

The lightweight nature of polypropylene makes it easy to handle and install. It is also cost-effective and offers good resistance to chemical corrosion. However, its lower temperature tolerance may limit its use in high-heat applications.

Impact on Application:

Polypropylene is ideal for mixing applications involving aggressive chemicals or where weight reduction is a priority. However, it may not be suitable for food applications unless specifically designed for such use.

Considerations for International Buyers:

Buyers should verify that the polypropylene used complies with relevant food safety standards, particularly in regions with strict regulations, such as Europe. Understanding local disposal and recycling regulations for plastics is also crucial.

Aluminum

Key Properties:

Aluminum is lightweight and has excellent corrosion resistance, particularly when anodized. It can handle temperatures up to 300°F (149°C) and is known for its good thermal conductivity.

Pros & Cons:

The lightweight nature of aluminum allows for easier transport and installation. Its corrosion resistance makes it suitable for various applications. However, it may not be as durable as stainless steel, and its cost can be moderate to high depending on the alloy used.

Impact on Application:

Aluminum is suitable for mixing applications that require lightweight equipment, such as in mobile or temporary setups. However, it may not be ideal for high-pressure applications or where extreme durability is required.

Considerations for International Buyers:

Buyers should check for compliance with local standards, particularly in industries like food processing, where material safety is paramount. Understanding the specific alloy used can also impact performance and compliance.

| Material | Typical Use Case for barrel mixer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Dry materials, non-corrosive liquids | Cost-effective and strong | Susceptible to rust and corrosion | Low |

| Polypropylene | Chemical mixing, lightweight applications | Lightweight and chemically resistant | Limited temperature tolerance | Low |

| Aluminum | Mobile setups, lightweight mixing | Lightweight and good corrosion resistance | Less durable than stainless steel | Medium |

This strategic material selection guide provides international B2B buyers with essential insights into the various materials used in barrel mixers, helping them make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for barrel mixer

The manufacturing processes and quality assurance protocols for barrel mixers are critical for international B2B buyers to understand, especially when sourcing from diverse regions like Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of these processes, ensuring buyers can make informed decisions.

Manufacturing Process of Barrel Mixers

The production of barrel mixers involves several key stages, each essential for ensuring the final product meets industry standards and customer expectations.

1. Material Preparation

The first stage in manufacturing barrel mixers is material preparation, which involves selecting high-quality raw materials. Common materials include stainless steel for durability and corrosion resistance, as well as various alloys for components that require enhanced strength.

Key Techniques:

– Material Sourcing: Establish relationships with reliable suppliers to ensure consistent quality.

– Pre-Processing: Materials are often cut, treated, or alloyed based on specifications to enhance performance characteristics.

2. Forming

Once materials are prepared, the next step is forming. This involves shaping the raw materials into the necessary components of the barrel mixer, such as the barrel itself, mixing blades, and other mechanical parts.

Key Techniques:

– CNC Machining: Precision equipment is used to cut and shape metal parts with high accuracy, crucial for ensuring effective mixing.

– Welding and Fabrication: Components are welded and assembled to create the mixer frame and barrel, ensuring structural integrity.

3. Assembly

The assembly stage combines all the formed components into a complete mixer. This is where functionality is integrated, including the installation of motors, control systems, and safety features.

Key Techniques:

– Modular Assembly: Components are often assembled in modules to streamline the process and facilitate repairs or upgrades.

– Testing During Assembly: Initial testing is conducted to ensure that moving parts function correctly before final assembly.

4. Finishing

The finishing stage involves applying surface treatments and coatings to enhance the mixer’s durability and aesthetic appeal. This may include polishing, painting, or applying anti-corrosive coatings.

Key Techniques:

– Surface Treatment: Processes such as anodizing or powder coating are used to protect against wear and corrosion.

– Final Inspection: Each unit undergoes a thorough inspection to ensure it meets specifications before leaving the factory.

Quality Assurance in Barrel Mixer Manufacturing

Quality assurance (QA) is paramount in the manufacturing of barrel mixers. It ensures that each unit produced meets both international standards and specific customer requirements.

International and Industry-Specific Standards

Adherence to recognized standards is crucial for B2B buyers. Some key standards include:

– ISO 9001: This international standard specifies requirements for a quality management system (QMS) and is applicable to any organization, including mixer manufacturers.

– CE Marking: This indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

– API Standards: Relevant for mixers used in the oil and gas industry, ensuring compatibility and safety.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, operators conduct regular checks to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly, each mixer undergoes a final inspection and testing to verify performance and safety.

Common Testing Methods

Testing methods are vital in ensuring that barrel mixers operate as intended. Common methods include:

– Performance Testing: Assessing the mixer’s efficiency and effectiveness in blending materials.

– Durability Testing: Subjecting the mixer to stress tests to evaluate its longevity under operational conditions.

– Safety Testing: Ensuring that all safety features function correctly to protect operators.

Verifying Supplier Quality Control

For international B2B buyers, particularly from diverse regions, verifying a supplier’s quality control processes is essential. Here are several strategies to ensure compliance:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Request QC Reports: Ask for detailed quality control reports, including results from testing phases and any corrective actions taken.

- Third-Party Inspections: Engage third-party inspection services to independently verify product quality and adherence to specifications.

Quality Control Nuances for International Buyers

When sourcing barrel mixers from different regions, buyers should be aware of certain nuances:

- Local Standards Variability: Different regions may have varying standards and regulations that affect product design and functionality.

- Language and Communication Barriers: Ensure that technical specifications and quality assurance processes are clearly communicated and understood by all parties involved.

- Cultural Differences: Recognize that cultural attitudes towards quality and compliance may vary, impacting supplier reliability.

Conclusion

Understanding the manufacturing processes and quality assurance measures for barrel mixers is crucial for B2B buyers. By focusing on the details of material preparation, forming, assembly, and finishing, along with robust quality control practices, buyers can ensure they select reliable suppliers. This knowledge not only aids in making informed purchasing decisions but also fosters long-term partnerships that enhance operational efficiency and product quality.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for barrel mixer Sourcing

Cost Structure of Barrel Mixer Sourcing

When sourcing barrel mixers, understanding the cost structure is essential for effective budgeting and negotiation. The primary components influencing the total cost include:

-

Materials: The type and quality of materials used in manufacturing the barrel mixer significantly impact costs. For instance, stainless steel is commonly used for its durability and resistance to corrosion, but it is more expensive than carbon steel.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs, such as those in parts of Africa and South America, may offer competitive pricing, while European manufacturers might have higher labor expenses due to stricter regulations and higher wage standards.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and indirect labor. Efficient production processes can lower these costs, impacting the final pricing of the mixer.

-

Tooling: Custom tooling for specialized mixers adds to the initial costs. This is particularly relevant for buyers requiring unique specifications or large-scale production runs.

-

Quality Control (QC): Stringent QC processes ensure product reliability but can increase costs. Buyers should verify the QC measures in place to ensure the mixer meets their operational standards.

-

Logistics: Transportation costs depend on the supplier’s location and the delivery terms. Buyers should consider potential tariffs, freight charges, and the impact of Incoterms on overall costs.

-

Margin: Supplier margins vary widely. Factors such as brand reputation, market demand, and competition influence how much a supplier marks up the price.

Price Influencers

Several factors can influence the pricing of barrel mixers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs. Suppliers may offer discounts for minimum order quantities (MOQs), making it beneficial for buyers with substantial needs.

-

Specifications/Customization: Custom features, such as specific mixing capabilities or sizes, can increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials: As mentioned, material choice directly affects pricing. High-quality, durable materials will increase upfront costs but may reduce maintenance and replacement expenses.

-

Quality/Certifications: Mixers that meet specific industry standards (e.g., ISO certifications) may come at a premium but ensure reliability and compliance with regulatory requirements.

-

Supplier Factors: The reputation and experience of the supplier can influence pricing. Established suppliers may charge more due to their proven reliability and support services.

-

Incoterms: Understanding the terms of delivery is crucial. Incoterms define responsibilities for shipping costs, insurance, and risk, which can significantly affect total expenses.

Buyer Tips

To optimize costs when sourcing barrel mixers, international buyers should consider the following strategies:

-

Negotiate: Leverage bulk purchasing and long-term contracts to negotiate better prices. Suppliers are often willing to offer discounts for repeat business.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, operational costs, maintenance, and expected lifespan. A cheaper initial price might lead to higher long-term costs if the equipment is less durable.

-

Understand Pricing Nuances: International buyers must be aware of fluctuating exchange rates, tariffs, and local taxes that can affect the final cost. Engage with local experts to navigate these complexities.

-

Assess Supplier Support: Prioritize suppliers that offer robust after-sales support, including maintenance services and readily available spare parts, to minimize downtime and additional costs.

-

Research Market Trends: Staying informed about market conditions and trends can provide leverage during negotiations and help buyers make informed decisions regarding timing and supplier selection.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on specific requirements, market conditions, and supplier negotiations. Always conduct thorough research and obtain multiple quotes to ensure competitive pricing for barrel mixers.

Spotlight on Potential barrel mixer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘barrel mixer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for barrel mixer

When considering a barrel mixer for your industrial processes, understanding the essential technical properties and trade terminology can significantly enhance your purchasing decisions. This knowledge not only aids in selecting the right equipment but also facilitates smoother negotiations and interactions with suppliers.

Critical Technical Properties of Barrel Mixers

-

Material Grade

– Definition: The material grade refers to the type of materials used in the construction of the barrel mixer, commonly stainless steel or carbon steel.

– Importance: High-grade materials ensure durability, resistance to corrosion, and compliance with hygiene standards, especially in food and pharmaceutical industries. -

Capacity

– Definition: This refers to the volume of material that the mixer can handle, typically measured in liters or gallons.

– Importance: Understanding capacity helps in selecting a mixer that aligns with production needs, ensuring efficiency and preventing bottlenecks in the manufacturing process. -

Viscosity Rating

– Definition: This rating indicates the thickness or flow characteristics of the materials being mixed.

– Importance: Knowing the viscosity of your materials allows you to choose a mixer that can effectively handle the required mixing action, whether it be for high-viscosity pastes or low-viscosity liquids. -

Power Rating

– Definition: Measured in horsepower (HP) or kilowatts (kW), this indicates the mixer’s motor power.

– Importance: A sufficient power rating is crucial for achieving the desired mixing intensity and speed, influencing overall mixing efficiency and product quality. -

Speed Control

– Definition: This feature allows for adjustment of the mixing speed during operation.

– Importance: Variable speed control can enhance mixing precision and adaptability to different product formulations, ensuring consistent results across batches. -

Tolerance

– Definition: Tolerance refers to the allowable variation in dimensions or performance specifications.

– Importance: Tight tolerances are essential for ensuring that the mixer operates within designated parameters, affecting the quality and consistency of the final product.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding whether you are dealing with an OEM can inform you about the quality and reliability of the mixer, as OEMs typically adhere to higher manufacturing standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps in budgeting and inventory planning, particularly for smaller businesses or startups that may not need large quantities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Relevance: Submitting an RFQ is a crucial step in the procurement process, allowing buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is vital for understanding shipping responsibilities, costs, and risk management in international transactions. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Relevance: Knowing the lead time is essential for planning production schedules and ensuring timely delivery of materials. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the quality and performance of the product over a specified period.

– Relevance: Understanding warranty terms can protect buyers from potential defects and ensure long-term satisfaction with the equipment.

By familiarizing yourself with these technical properties and terms, you can make informed decisions that align with your operational needs and enhance your purchasing strategy.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the barrel mixer Sector

Global drivers in the barrel mixer market are influenced by several factors, including the growing demand for efficient production processes across various industries such as food and beverage, pharmaceuticals, and chemicals. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their manufacturing capabilities, the focus on automation and technology integration has intensified. Current trends indicate a shift towards smart mixers equipped with IoT capabilities, allowing for real-time monitoring and adjustments, which can significantly improve operational efficiency and reduce waste.

Emerging technologies such as machine learning and advanced analytics are also reshaping the sourcing landscape, enabling buyers to make data-driven decisions regarding their mixing processes. Furthermore, the increasing emphasis on sustainability is driving manufacturers to innovate in both product design and operational practices. This includes the use of energy-efficient motors and materials that minimize environmental impact, aligning with global sustainability goals.

Illustrative Image (Source: Google Search)

For international buyers, understanding these dynamics is crucial. They must assess suppliers not only on product quality and pricing but also on their ability to adapt to these market trends. Engaging with manufacturers who demonstrate a commitment to innovation and sustainability can provide a competitive edge in an increasingly complex market.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the barrel mixer sector, driven by both regulatory pressures and consumer preferences. The environmental impact of manufacturing processes cannot be understated; thus, buyers are increasingly prioritizing suppliers who adopt eco-friendly practices. This includes the use of sustainable materials in the construction of mixers and energy-efficient designs that reduce power consumption during operation.

Moreover, ethical sourcing is vital for establishing a robust supply chain. B2B buyers should seek out manufacturers who are transparent about their sourcing practices and demonstrate compliance with international sustainability standards. Certifications such as ISO 14001 for environmental management systems and other ‘green’ certifications not only validate a company’s commitment to sustainability but also provide assurance to buyers that they are engaging with responsible partners.

Investing in barrel mixers that are designed with sustainability in mind can also lead to long-term cost savings through reduced energy consumption and lower maintenance requirements. As the global market evolves, prioritizing suppliers with a strong sustainability ethos will not only contribute to environmental goals but can also enhance brand reputation and customer loyalty.

Brief Evolution/History

The barrel mixer has evolved significantly since its inception, initially designed for simple blending tasks. Over the decades, advancements in technology have transformed these mixers into sophisticated machines capable of handling a wide range of materials and complexities. Early models primarily focused on mechanical mixing, while modern iterations incorporate advanced features such as programmable logic controllers (PLCs) and automation capabilities.

This evolution has enabled manufacturers to produce more consistent and high-quality products, catering to diverse industries such as food processing, pharmaceuticals, and cosmetics. As international B2B buyers seek mixers that offer both efficiency and versatility, understanding the historical context of barrel mixers can inform better purchasing decisions and align with current technological trends.

Related Video: Specialization and Trade: Crash Course Economics #2

Frequently Asked Questions (FAQs) for B2B Buyers of barrel mixer

-

What key factors should I consider when vetting a barrel mixer supplier?

When vetting a barrel mixer supplier, prioritize their expertise in your industry and the specific mixing applications. Look for a solid track record and client testimonials, ensuring they understand the unique challenges you face. Assess their product range for customization options, and verify compliance with international quality standards such as ISO. Additionally, consider their customer service capabilities, including after-sales support and technical assistance, as these can significantly impact your overall experience and satisfaction. -

Can barrel mixers be customized to meet specific production needs?

Yes, many manufacturers offer customization options for barrel mixers to cater to specific production requirements. You can request features such as varying capacities, materials of construction, and additional functionalities like heating or cooling. Before finalizing your order, discuss your precise needs with potential suppliers to ensure they can provide a tailored solution that integrates seamlessly into your existing processes. -

What are the typical minimum order quantities (MOQ) and lead times for barrel mixers?

Minimum order quantities and lead times can vary significantly between manufacturers and depending on the customization required. Generally, MOQs for barrel mixers may range from one unit for standard models to larger quantities for customized solutions. Lead times can vary from a few weeks to several months, influenced by production schedules and shipping logistics. Always clarify these details upfront to avoid unexpected delays in your supply chain. -

What certifications and quality assurance measures should I look for?

When sourcing barrel mixers, ensure that the manufacturer holds relevant quality certifications such as ISO 9001 or CE marking. These certifications indicate adherence to international quality standards and safety regulations. Additionally, inquire about their quality control processes, including material inspections and testing protocols, to ensure that the mixers meet your performance and durability expectations. A reputable supplier will provide documentation to support their claims. -

How can I navigate logistics when importing barrel mixers?

Navigating logistics for importing barrel mixers involves several steps, including understanding shipping regulations, customs duties, and import taxes relevant to your country. Collaborate with a freight forwarder experienced in handling industrial equipment to ensure compliance and minimize delays. Additionally, confirm shipping timelines with your supplier and consider insurance options for added protection during transit. Clear communication with all parties involved is crucial for a smooth logistics process. -

What should I do if a dispute arises with my barrel mixer supplier?

In the event of a dispute with your barrel mixer supplier, begin by addressing the issue directly with them through formal communication. Document all correspondences and agreements to establish a clear record. If the matter remains unresolved, consult your contract for dispute resolution mechanisms, such as mediation or arbitration. It may also be beneficial to seek legal advice, especially when dealing with international contracts, to understand your rights and options. -

Are there specific payment terms I should negotiate with suppliers?

Yes, negotiating favorable payment terms is essential when sourcing barrel mixers. Common arrangements include upfront deposits with the balance due upon delivery or after installation. Consider options like letters of credit, which can provide security for both parties. Always ensure that payment terms are clearly outlined in the contract to prevent misunderstandings and protect your financial interests during the transaction. -

What are the common maintenance requirements for barrel mixers?

Regular maintenance is crucial for ensuring the longevity and performance of barrel mixers. Common maintenance tasks include routine cleaning, inspection of wear parts, lubrication of moving components, and periodic calibration. Consult the manufacturer’s guidelines for specific maintenance schedules and procedures. Additionally, consider training your staff on maintenance best practices to minimize downtime and extend the life of the equipment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for barrel mixer

In conclusion, the strategic sourcing of barrel mixers is essential for enhancing operational efficiency and product quality across various industries. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should focus on understanding their specific mixing requirements, including material types, viscosity levels, and production capacities. This knowledge will facilitate better decision-making when selecting a manufacturer that aligns with their operational needs.

Key takeaways include prioritizing manufacturers with proven expertise, a diverse product range, and a commitment to quality and customer support. Engaging with suppliers that offer customization options can also lead to solutions that optimize mixing processes and improve overall productivity.

As the global market continues to evolve, staying abreast of technological advancements and industry trends will be crucial. Buyers are encouraged to leverage strategic sourcing not just as a procurement process but as a pathway to innovation and competitive advantage. By making informed decisions today, businesses can position themselves for success in tomorrow’s dynamic landscape.