Master Sourcing Strategies for High-Quality Graphite Rods

Introduction: Navigating the Global Market for graphite rod

In the rapidly evolving landscape of global manufacturing, graphite rods have emerged as essential components across diverse industries, including aerospace, electronics, and renewable energy. Their unique properties—such as high thermal and electrical conductivity, resistance to extreme temperatures, and excellent dimensional stability—make them indispensable for applications ranging from high-performance molds to advanced semiconductor fabrication. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing graphite rods is crucial for maintaining competitive advantage.

This comprehensive guide delves into the various types of graphite rods, the materials used in their production, and the critical manufacturing and quality control processes that ensure their reliability and performance. Additionally, we will explore supplier selection criteria, cost factors, and market trends, equipping you with the knowledge necessary to make informed sourcing decisions.

By addressing frequently asked questions and providing actionable insights, this guide empowers B2B buyers to navigate the complexities of the graphite rod market confidently. Whether you are in Argentina seeking high-quality custom parts or in Germany looking for reliable suppliers, this resource will streamline your procurement process and enhance your operational efficiency. With the right information at your fingertips, you can forge strategic partnerships and leverage graphite rods to drive innovation in your business.

Understanding graphite rod Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Isostatic Graphite | Uniform density and structure | Aerospace, semiconductor manufacturing | Pros: Excellent thermal and electrical conductivity. Cons: Higher cost compared to other types. |

| Molded Graphite | High density with a variety of shapes | Foundries, electrical contacts | Pros: Cost-effective for mass production. Cons: Limited precision in complex geometries. |

| Extruded Graphite | Continuous shapes, often long and thin | Heat exchangers, electrodes | Pros: Versatile for various applications. Cons: May require additional machining for tight tolerances. |

| Graphite Rods for EDM | Specifically designed for electrical discharge machining | Tool and die making, precision machining | Pros: High purity and excellent conductivity. Cons: Requires careful handling to avoid breakage. |

| Reinforced Graphite | Composite materials for enhanced strength | High-stress environments, automotive parts | Pros: Increased durability and performance. Cons: More complex sourcing and higher costs. |

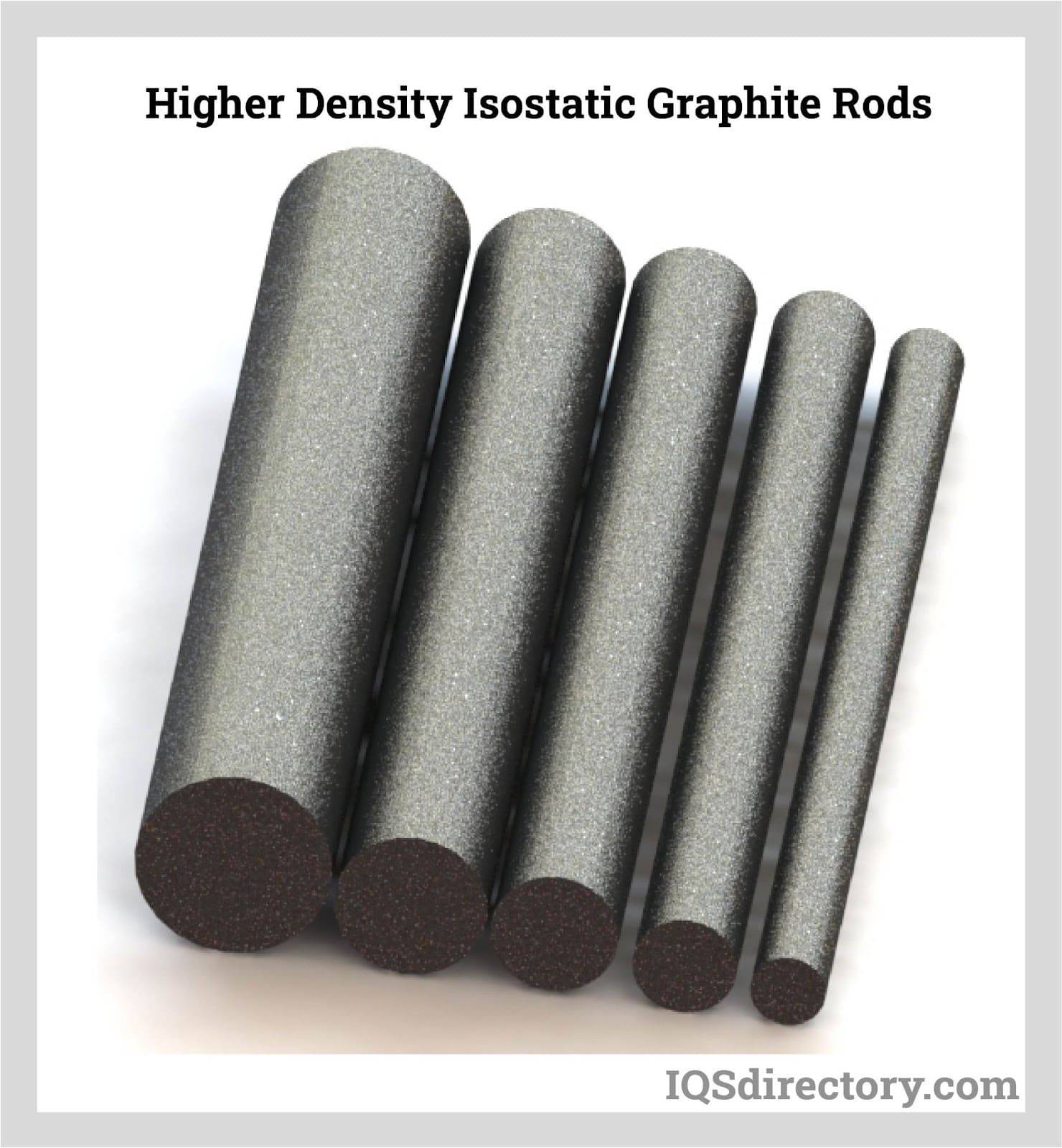

Isostatic Graphite

Isostatic graphite is known for its uniform density and structure, which is achieved through a unique manufacturing process that involves high-pressure compaction. This type is particularly suitable for industries requiring high thermal and electrical conductivity, such as aerospace and semiconductor manufacturing. When purchasing, buyers should consider the supplier’s ability to provide consistent quality and compliance with industry standards, as these factors directly impact performance in critical applications.

Molded Graphite

Molded graphite is produced by compressing graphite powder into molds, resulting in high-density components with a variety of shapes. This type is widely used in foundries and for electrical contacts due to its cost-effectiveness in mass production. Buyers should assess the supplier’s capabilities regarding custom shapes and sizes, as well as their quality control processes, to ensure that the products meet specific operational requirements.

Extruded Graphite

Extruded graphite is characterized by its continuous shapes, often long and thin, making it suitable for applications like heat exchangers and electrodes. This type offers versatility and can be customized to various lengths and diameters. Buyers should evaluate the machining capabilities of suppliers, as extruded graphite may require additional processing to achieve tight tolerances, which is crucial for applications demanding precision.

Graphite Rods for EDM

Graphite rods designed for electrical discharge machining (EDM) are specifically tailored for high-performance applications in tool and die making. They are known for their high purity and excellent conductivity, making them ideal for precision machining tasks. Buyers should prioritize suppliers who can guarantee consistent quality and provide detailed material specifications, as the performance of EDM processes heavily relies on the quality of the graphite used.

Reinforced Graphite

Reinforced graphite combines traditional graphite with composite materials to enhance strength and durability, making it suitable for high-stress environments such as automotive parts. This type provides improved performance in demanding applications. When sourcing reinforced graphite, buyers should consider the complexity of the material sourcing and the potential for higher costs, ensuring that the benefits align with their specific application needs.

Related Video: Denoising Diffusion Probabilistic Models | DDPM Explained

Key Industrial Applications of graphite rod

| Industry/Sector | Specific Application of Graphite Rod | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Semiconductor Manufacturing | Electrodes in Etching Equipment | High precision and reliability in semiconductor fabrication | Need for high purity graphite and tight tolerances |

| Aerospace and Defense | Components in Missile Guidance Systems | Enhanced performance and durability under extreme conditions | Requirements for aerospace-grade certifications |

| Energy Sector | Anodes in Battery Production | Improved energy efficiency and longer battery life | Compliance with environmental standards and traceability |

| Metal Processing | Crucibles for Melting and Casting | Increased lifespan and reduced contamination risks | Material quality and machining capabilities |

| Renewable Energy | Components in Solar Panel Manufacturing | Higher efficiency in energy conversion | Customization and precision engineering support |

Semiconductor Manufacturing

In the semiconductor industry, graphite rods serve as electrodes in etching equipment, crucial for the precision fabrication of semiconductor devices. These rods must possess high purity and dimensional accuracy to prevent contamination and ensure reliable performance. International buyers should prioritize suppliers who can provide third-party testing certifications and traceability of raw materials, as these factors are critical for maintaining stringent quality control standards.

Aerospace and Defense

Graphite rods are utilized in missile guidance systems, where they function as critical components due to their exceptional thermal and electrical conductivity. The aerospace sector demands materials that can withstand extreme temperatures and pressures, making high-performance graphite essential. Buyers in this industry should look for suppliers with aerospace-grade certifications and a proven track record in producing components that meet military specifications.

Energy Sector

In battery production, graphite rods are employed as anodes, significantly enhancing energy efficiency and extending battery life. The growing demand for electric vehicles and renewable energy storage solutions has increased the need for high-quality graphite materials. Buyers should ensure that their suppliers comply with environmental regulations and can provide detailed documentation regarding the sourcing and processing of graphite to meet sustainability goals.

Metal Processing

Graphite rods are commonly used as crucibles in metal melting and casting processes. Their high thermal stability and resistance to chemical reactions make them ideal for handling molten metals. Businesses in this sector benefit from reduced contamination risks and prolonged crucible life. Buyers should evaluate suppliers based on their material quality and machining capabilities to ensure that the rods can withstand the rigors of high-temperature applications.

Renewable Energy

In solar panel manufacturing, graphite rods are integral to the production of photovoltaic cells. They help improve the efficiency of energy conversion and are vital in maintaining the structural integrity of solar panels. As the renewable energy market expands, international buyers must seek suppliers who offer customized solutions and precise engineering support to meet specific project requirements and enhance overall performance.

Related Video: Graphite-Structure, Properties and applications- By Dr. Anjali Ssaxena

Strategic Material Selection Guide for graphite rod

When selecting graphite rods for various applications, understanding the material properties and their implications is crucial for B2B buyers. Here, we analyze four common materials used in graphite rod manufacturing, focusing on their performance, advantages, disadvantages, and considerations for international buyers.

1. Isostatic Graphite

Key Properties: Isostatic graphite is known for its uniform density and fine grain structure, which contribute to excellent mechanical strength and thermal conductivity. It can withstand high temperatures (up to 3000°C) and has good resistance to thermal shock.

Pros & Cons: The primary advantage of isostatic graphite is its high purity and structural integrity, making it suitable for demanding applications such as semiconductor manufacturing. However, the production process is complex and can be costly, which may impact overall pricing for buyers.

Impact on Application: Its high thermal stability makes isostatic graphite ideal for high-temperature applications, such as in electric arc furnaces and aerospace components. It is compatible with various media, including molten metals and reactive gases.

Considerations for International Buyers: Buyers should ensure compliance with industry standards like ASTM and DIN. Additionally, understanding local regulations regarding sourcing and quality control is essential, especially in regions like Europe, where stringent environmental regulations may apply.

2. Extruded Graphite

Key Properties: Extruded graphite is characterized by its high strength and good thermal and electrical conductivity. It typically has a lower density compared to isostatic graphite, which can affect its performance under high-stress conditions.

Pros & Cons: One of the main advantages of extruded graphite is its cost-effectiveness due to simpler manufacturing processes. However, it may not perform as well under extreme conditions compared to isostatic graphite, limiting its use in high-performance applications.

Impact on Application: This material is often used in applications such as electrodes and heat exchangers. Its good thermal conductivity makes it suitable for environments where heat dissipation is critical.

Considerations for International Buyers: Buyers should check for relevant certifications and quality assurance processes. Understanding the local market dynamics, such as the availability of raw materials and manufacturing capabilities, is also vital, particularly in regions like Africa and South America.

3. Graphite Composite

Key Properties: Graphite composites combine graphite with polymers or other materials to enhance properties such as corrosion resistance and mechanical strength. These composites can be engineered for specific applications, providing tailored performance.

Pros & Cons: The key advantage of graphite composites is their versatility; they can be designed to meet specific requirements such as improved wear resistance or reduced weight. However, they may be more expensive to produce and require careful handling to maintain their properties.

Impact on Application: Graphite composites are often used in applications where lightweight and high strength are essential, such as in automotive and aerospace industries. Their enhanced corrosion resistance makes them suitable for chemical processing environments.

Considerations for International Buyers: Buyers should be aware of the specific standards applicable to composites in their region. For example, compliance with JIS standards in Japan or EN standards in Europe can be critical for market entry.

4. Natural Graphite

Key Properties: Natural graphite is sourced from mining operations and is known for its high thermal and electrical conductivity. It is generally less expensive than synthetic alternatives, but its properties can be more variable.

Pros & Cons: The primary advantage of natural graphite is its cost-effectiveness and availability. However, variability in quality can be a significant drawback, making it less suitable for precision applications.

Impact on Application: Natural graphite is often used in applications such as lubricants, batteries, and as a filler in various materials. Its compatibility with different media makes it a versatile choice.

Considerations for International Buyers: Buyers should conduct thorough due diligence on suppliers to ensure quality consistency. Understanding the geopolitical landscape in regions where natural graphite is sourced, such as Africa, is essential to mitigate risks related to supply chain disruptions.

Summary Table

| Material | Typical Use Case for graphite rod | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Isostatic Graphite | Semiconductor manufacturing | High purity and structural integrity | Complex and costly production | High |

| Extruded Graphite | Electrodes, heat exchangers | Cost-effective due to simpler manufacturing | Lower performance under extreme conditions | Medium |

| Graphite Composite | Automotive, aerospace components | Versatile with tailored performance | Higher production costs | High |

| Natural Graphite | Lubricants, batteries | Cost-effective and widely available | Variable quality | Low |

This analysis provides a comprehensive overview of the common materials used in graphite rod applications, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite rod

The manufacturing of graphite rods involves several critical processes and stringent quality assurance measures to ensure that the final products meet the high standards required by industries such as semiconductors, aerospace, and energy. For international B2B buyers, understanding these processes can facilitate better supplier selection and foster long-term partnerships. Below is an in-depth overview of the typical manufacturing processes and quality assurance protocols involved in the production of graphite rods.

Manufacturing Processes

1. Material Preparation

The foundation of any high-quality graphite rod begins with the selection and preparation of raw materials. Key steps in this phase include:

- Raw Material Selection: High-purity graphite is essential. Buyers should ensure that suppliers use graphite with a low impurity level, as this directly impacts the thermal and electrical conductivity of the final product.

- Grinding and Sizing: The graphite is ground into a fine powder, which is then sieved to achieve a uniform particle size. This is crucial for achieving consistent density and properties in the final product.

2. Forming

Forming is where the prepared material is shaped into the desired rod specifications. Techniques used include:

- Extrusion: This method involves forcing the graphite paste through a die to create rods of uniform cross-section. It’s suitable for producing long lengths with consistent dimensions.

- Molding: For specialized shapes, graphite can be pressed into molds under high pressure. This method allows for complex geometries and can be particularly useful for custom applications.

- Isostatic Pressing: A more advanced technique where graphite powder is compressed uniformly from all directions. This results in superior density and mechanical properties.

3. Assembly

While graphite rods are often produced as standalone components, they may require assembly into larger systems. Key considerations include:

- Integration with Other Materials: In applications where rods are combined with metals or ceramics, attention must be given to thermal expansion compatibility and bonding techniques.

- Custom Fabrication: Some applications may require additional machining or fabrication to meet specific design requirements.

4. Finishing

Finishing processes enhance the surface quality and dimensional accuracy of graphite rods. Common techniques include:

- Machining: CNC machining is often used to achieve precise dimensions and tolerances. This is crucial for applications in sectors like aerospace and electronics.

- Surface Treatment: Treatments may include coating or polishing to improve wear resistance or electrical properties.

Quality Assurance

Quality assurance is vital in ensuring that graphite rods meet industry standards and customer specifications. Here’s an overview of the quality control measures typically in place:

International Standards

Buyers should look for suppliers that adhere to recognized international quality standards, including:

- ISO 9001: This standard outlines requirements for a quality management system and is essential for ensuring consistent product quality.

- Industry-Specific Certifications: Depending on the application, suppliers may also need to comply with standards such as CE for European markets or API for oil and gas applications.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials undergo inspection to verify their compliance with specified standards before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring and testing are conducted to ensure that each stage meets quality parameters. This includes checking dimensions, density, and consistency.

- Final Quality Control (FQC): Once production is complete, finished rods are subjected to rigorous testing to confirm that they meet all specifications and standards.

Common Testing Methods

Testing methods employed in the quality assurance of graphite rods include:

- Dimensional Inspection: Using tools like coordinate measuring machines (CMM) to verify that rods meet specified dimensions.

- Material Testing: Evaluating properties such as density, purity, and thermal conductivity through standardized tests.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing can be used to detect internal flaws without damaging the product.

Verifying Supplier Quality Control

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are actionable steps:

- Supplier Audits: Conduct on-site audits to review the supplier’s quality management systems and processes. This provides insight into their operational practices and compliance with standards.

- Request Documentation: Ask for detailed reports of quality tests, including inspection certificates and third-party testing results. This documentation should accompany each order.

- Third-Party Inspections: Engage independent inspectors to evaluate the quality of the graphite rods before shipment. This can help mitigate risks associated with quality discrepancies.

Quality Control Nuances for International Buyers

When sourcing graphite rods internationally, buyers should be aware of several nuances:

- Customs Compliance: Ensure that the supplier is knowledgeable about international shipping regulations and customs requirements to avoid delays.

- Cultural Considerations: Be prepared to navigate different business practices and communication styles in regions like Africa and South America. Establishing clear expectations from the outset can prevent misunderstandings.

- Currency and Payment Terms: Understand the implications of currency fluctuations on pricing and payment terms, which can affect the overall cost of procurement.

By comprehensively understanding the manufacturing processes and quality assurance measures for graphite rods, B2B buyers can make informed decisions that align with their operational needs and industry requirements. This knowledge not only aids in selecting the right supplier but also fosters long-term, reliable partnerships in an increasingly globalized market.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for graphite rod Sourcing

When sourcing graphite rods, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers, particularly those operating in diverse regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and provides actionable tips for effective negotiation and procurement.

Cost Components

-

Materials: The cost of graphite itself is a significant component. Prices can fluctuate based on purity, grade, and source. High-purity graphite rods used in specialized applications will command higher prices due to the stringent requirements for material quality.

-

Labor: Labor costs vary by region and can impact the overall cost structure. In regions with higher wage standards, such as parts of Europe, labor costs may contribute more significantly to the price than in regions with lower wage expectations.

-

Manufacturing Overhead: This includes costs associated with the production process, such as utilities, maintenance, and operational expenses. Efficient manufacturing processes can help mitigate these costs, which is crucial for keeping prices competitive.

-

Tooling: Custom tooling for specific graphite rod specifications can add to initial costs. Investing in high-quality tooling can enhance precision and reduce defects, ultimately leading to cost savings in the long run.

-

Quality Control (QC): Rigorous quality control processes are vital, particularly for industries requiring high-performance graphite rods. Costs associated with testing and certification can affect pricing but ensure that the products meet necessary industry standards.

-

Logistics: Transportation and delivery costs can vary significantly, especially for international shipments. Factors such as shipping distance, Incoterms, and customs duties must be considered to avoid unexpected expenses.

-

Margin: Suppliers will include a profit margin in their pricing. Understanding the market rates and typical margins in the graphite industry can help buyers gauge whether they are receiving a fair price.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger volumes often result in lower per-unit costs, making it essential for buyers to assess their needs against supplier capabilities.

-

Specifications/Customization: Custom designs or specifications may incur additional costs due to the need for specialized manufacturing processes. Clear communication of requirements can help suppliers provide accurate pricing.

-

Quality and Certifications: Higher quality and certifications (e.g., ISO, RoHS) can lead to increased prices but are essential for ensuring product reliability in critical applications.

-

Supplier Factors: The supplier’s reputation, experience, and technical support capabilities can also influence pricing. Established suppliers may charge a premium for their reliability and service quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers, as they define responsibilities for transportation costs and risks. Choosing the right Incoterm can lead to significant cost savings.

Buyer Tips

-

Negotiation: Engage in proactive discussions with suppliers about pricing. Highlighting potential long-term relationships can motivate suppliers to offer better terms.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just upfront costs. High-quality graphite rods may have higher initial costs but can lead to savings through reduced failure rates and maintenance.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to varying labor and material costs.

-

Research and Benchmarking: Conduct thorough market research and benchmark prices against competitors. This will provide insight into fair pricing and help in negotiations.

-

Supplier Relationships: Cultivating strong relationships with suppliers can lead to better pricing and terms. Regular communication and feedback can enhance collaboration and trust.

Disclaimer

Prices for graphite rods can vary widely based on the factors mentioned above. Buyers should conduct due diligence and request multiple quotes to ensure they receive competitive pricing that aligns with their specific needs.

Spotlight on Potential graphite rod Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘graphite rod’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for graphite rod

When sourcing graphite rods for various industrial applications, understanding their essential technical properties and industry terminology is crucial for making informed purchasing decisions. Below are critical specifications to consider, along with common trade terms that will enhance your procurement strategy.

Key Technical Properties of Graphite Rods

-

Material Grade

– Definition: Material grade refers to the specific classification of graphite based on its composition and purity levels. Common grades include high-purity graphite and semi-graphite.

– B2B Importance: Selecting the right material grade ensures the graphite rod meets the performance requirements of your application, whether in high-temperature environments or in electrical conductivity applications. -

Density

– Definition: Density is the mass per unit volume of the graphite rod, typically measured in g/cm³. It influences the mechanical strength and thermal stability of the material.

– B2B Importance: A higher density often indicates better performance in thermal and electrical applications, making it essential for sectors like aerospace or semiconductor manufacturing. -

Tolerance

– Definition: Tolerance refers to the allowable deviation from specified dimensions in manufacturing. It is critical for ensuring the proper fit and function of components.

– B2B Importance: Tight tolerances are crucial in precision applications, where even minor deviations can lead to operational failures or safety hazards, particularly in high-stakes environments.

Illustrative Image (Source: Google Search)

-

Thermal Conductivity

– Definition: This property measures how well the graphite rod can conduct heat, typically expressed in W/mK (watts per meter Kelvin).

– B2B Importance: High thermal conductivity is essential for applications like heat exchangers and furnace components, where efficient heat transfer is critical for performance. -

Purity Level

– Definition: Purity level indicates the percentage of carbon content in the graphite rod, with higher purity levels typically yielding better performance.

– B2B Importance: In sensitive applications like electronics, lower impurity levels can significantly reduce contamination risks, leading to more reliable products.

Common Trade Terms in Graphite Rod Procurement

-

OEM (Original Equipment Manufacturer)

– Definition: OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify trusted suppliers who adhere to industry standards and specifications. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Being aware of the MOQ can help buyers manage inventory costs and ensure they do not overcommit financially when sourcing graphite rods.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Definition: An RFQ is a document that solicits price bids from suppliers for specific quantities of goods or services.

– Importance: Using RFQs effectively allows buyers to compare pricing and terms across different suppliers, ensuring competitive procurement. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother transactions across borders. -

Lead Time

– Definition: Lead time is the total time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is essential for effective supply chain management, particularly in industries where time-sensitive projects are common.

By grasping these technical properties and trade terms, international B2B buyers can navigate the procurement process of graphite rods more effectively, ensuring that they select the right products and suppliers for their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the graphite rod Sector

Market Overview & Key Trends

The graphite rod sector is witnessing significant transformation driven by various global factors, including technological advancements and the growing demand for high-performance materials in industries such as energy storage, electronics, and metallurgy. Key trends shaping this market include the increasing adoption of custom graphite components, which cater to specific industry needs, particularly in high-tech applications like semiconductors and aerospace. Buyers from regions such as Africa, South America, the Middle East, and Europe (notably Argentina and Germany) should be aware of the rising demand for graphite rods that meet stringent quality and performance standards.

Emerging B2B technologies are enhancing the sourcing process. Innovations in CNC machining and additive manufacturing are allowing suppliers to produce more complex and precise graphite components, thereby reducing lead times and improving customization capabilities. Moreover, digital platforms are streamlining supplier selection and procurement processes, enabling buyers to evaluate potential partners based on real-time data regarding material quality, production capabilities, and compliance with industry standards.

Another dynamic influencing the market is the increasing emphasis on reliability and responsiveness in supply chains. International buyers are seeking suppliers who not only provide high-quality products but also demonstrate flexibility in lead times and a commitment to customer service. As competition intensifies, buyers must prioritize establishing partnerships with suppliers that can offer technical support and innovative solutions to meet their specific operational requirements.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical focus for B2B buyers in the graphite rod sector. The environmental impact of graphite mining and processing has raised concerns about resource depletion and ecological damage. Thus, buyers are increasingly prioritizing suppliers that adopt sustainable practices and adhere to ethical sourcing standards.

Adopting “green” certifications, such as ISO 14001 for environmental management, can be a key differentiator for suppliers in this space. Buyers should look for suppliers who can provide transparency in their sourcing practices, including traceability of raw materials and evidence of responsible mining operations. Additionally, the use of recycled graphite and low-impact production methods can help mitigate the environmental footprint, which is becoming increasingly important in procurement decisions.

Furthermore, as the global market shifts toward sustainability, buyers may find that suppliers with strong environmental credentials not only enhance their brand reputation but also align with the corporate social responsibility (CSR) goals of their organizations. Engaging with suppliers who prioritize sustainability can foster long-term partnerships and contribute to a more resilient supply chain.

Brief Evolution/History

The use of graphite in industrial applications dates back centuries, but the modern graphite rod sector has evolved significantly over the last few decades. Initially, graphite rods were primarily used in electrical applications, such as electrodes in arc furnaces. However, advancements in material science and manufacturing techniques have expanded their applications across various high-tech sectors.

In recent years, the demand for graphite rods has surged due to the rise of electric vehicles (EVs), renewable energy technologies, and advanced manufacturing processes. This evolution has compelled suppliers to innovate continually, focusing on producing high-purity, custom graphite components that meet the specific needs of industries like aerospace, electronics, and renewable energy. As a result, international B2B buyers must stay informed about these developments to leverage the best opportunities in the graphite rod market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of graphite rod

-

What should I consider when vetting suppliers for graphite rods?

When vetting suppliers, prioritize their experience in your specific industry and their ability to provide high-quality materials. Request documentation that showcases their compliance with industry standards, such as ISO certifications. Additionally, inquire about their track record with international shipping and customs, as this can affect delivery timelines and reliability. Look for testimonials or case studies from other clients in your region to gauge their reputation and customer service responsiveness. -

Can I customize graphite rods to meet specific requirements?

Yes, many suppliers offer customization options for graphite rods. You can specify dimensions, grades, and even machining tolerances to meet your application needs. It’s crucial to communicate your specifications clearly and ask for design support if necessary. Ensure that the supplier has the capability to produce the custom rods consistently and can provide prototypes for testing before placing a larger order. -

What are the minimum order quantities (MOQs) and lead times for graphite rods?

MOQs can vary significantly between suppliers, often depending on the complexity of the customization and the type of graphite used. Generally, suppliers may require a minimum order of several kilograms or units. Lead times can range from a few weeks to several months, influenced by production schedules and shipping logistics. Always discuss these factors upfront to avoid disruptions in your supply chain. -

What quality assurance measures should I expect from suppliers?

Quality assurance is critical in sourcing graphite rods. Reputable suppliers should provide detailed material specifications, including purity levels and test results from third-party laboratories. Look for suppliers that conduct regular quality checks throughout the manufacturing process and offer documentation such as inspection reports and certificates of compliance. This transparency helps ensure that the products meet your operational standards and reduce the risk of defects. -

What certifications should I look for in a graphite rod supplier?

Essential certifications include ISO 9001 for quality management systems and any relevant industry-specific certifications, such as RoHS or REACH compliance for environmental standards. Depending on your application, you may also require certification for high-temperature or semiconductor-grade materials. Ensure that the supplier can provide documentation verifying these certifications, which will aid in regulatory compliance for your operations. -

How do logistics and shipping affect the sourcing of graphite rods?

Logistics plays a vital role in the timely delivery of graphite rods, especially in international trade. Consider suppliers with established logistics networks that can navigate customs and import regulations in your region. Discuss shipping options, including air freight for urgent needs or sea freight for cost-effective solutions. Additionally, inquire about their inventory management practices to ensure they can handle fluctuations in demand without delays. -

What should I do if I encounter disputes with a supplier?

If a dispute arises, the first step is to communicate your concerns directly with the supplier. Document all interactions and agreements to establish a clear record. If the issue remains unresolved, consider mediation or arbitration as a formal approach to settle disputes amicably. It’s also beneficial to review the supplier’s terms and conditions, particularly regarding warranties and liabilities, before finalizing contracts to mitigate potential conflicts. -

How can I ensure long-term relationships with graphite rod suppliers?

Building strong relationships with suppliers requires consistent communication and feedback. Regularly assess their performance in terms of quality, delivery, and service to identify areas for improvement. Engaging in collaborative projects or sharing future needs can foster a sense of partnership. Additionally, honoring payment terms and being transparent about your business needs will encourage suppliers to prioritize your orders and invest in your partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for graphite rod

In conclusion, the strategic sourcing of graphite rods is vital for international B2B buyers aiming to enhance operational efficiency and product quality. As industries increasingly require high-performance graphite components, it is essential to prioritize suppliers who offer exceptional material quality, robust machining capabilities, and comprehensive technical support.

Key Takeaways:

– Material Quality: Ensure suppliers provide high-purity graphite that meets specific industry standards.

– Machining Expertise: Assess the supplier’s capabilities in precision machining to meet your unique requirements.

– Quality Assurance: Look for rigorous quality control measures and certifications that confirm the reliability of the products.

As the demand for graphite rods continues to grow, particularly in sectors like semiconductors and renewable energy, establishing strong partnerships with reliable suppliers will be crucial. Buyers from Africa, South America, the Middle East, and Europe should leverage these insights to make informed sourcing decisions.

Call to Action: Engage with suppliers who can not only deliver high-quality products but also offer strategic support tailored to your operational needs. Embrace the opportunities that come with effective sourcing to drive innovation and competitive advantage in your markets.