Master Sourcing Strategies for High-Quality Platform Scales

Introduction: Navigating the Global Market for platform scales

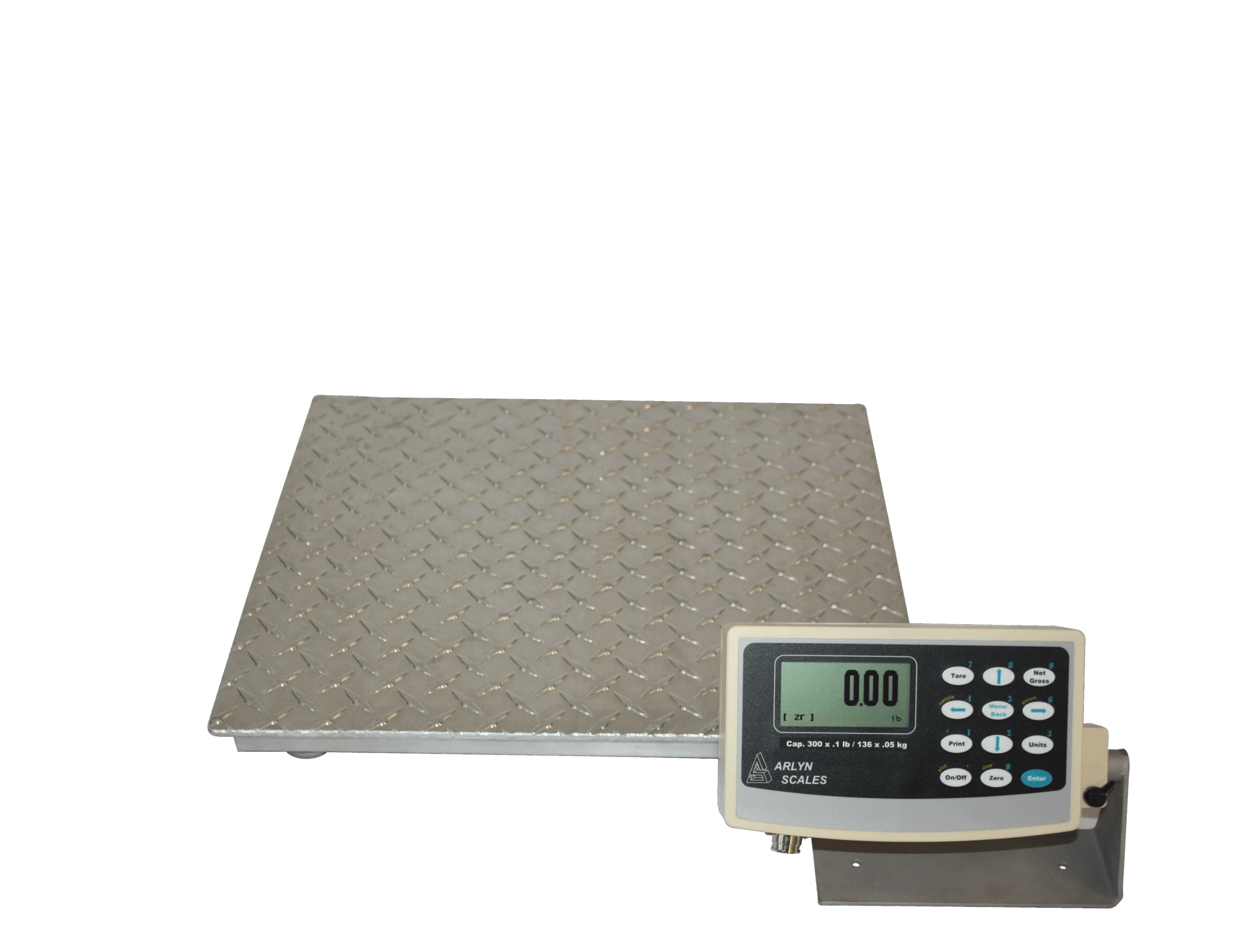

In today’s competitive global marketplace, the demand for accurate and reliable weighing solutions is paramount, particularly in industries ranging from logistics and manufacturing to agriculture and retail. Platform scales serve as a critical tool for businesses, enabling precise measurements that influence inventory management, quality control, and compliance with international standards. For B2B buyers from diverse regions—including Africa, South America, the Middle East, and Europe—understanding the nuances of platform scales can significantly enhance operational efficiency and cost-effectiveness.

This comprehensive guide delves into various aspects of platform scales, including types, materials, manufacturing processes, and quality control measures. By examining the landscape of suppliers and pricing structures, buyers will gain valuable insights into the best sourcing strategies tailored to their specific market conditions. Furthermore, the guide addresses frequently asked questions, equipping international buyers with the knowledge necessary to make informed decisions.

Navigating the complexities of the platform scale market can be daunting, but this resource empowers you with the tools to evaluate options critically. Whether you are sourcing for a startup or an established enterprise, understanding these fundamental elements will enhance your procurement strategy and foster long-term success in your industry.

Understanding platform scales Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Digital Platform Scales | Cloud-based, real-time data analytics, remote access | E-commerce, logistics, inventory management | Pros: Scalability, ease of integration. Cons: Dependence on internet connectivity. |

| Mechanical Platform Scales | Heavy-duty construction, analog readouts, manual calibration | Warehousing, manufacturing, shipping | Pros: Robustness, low maintenance. Cons: Limited data capabilities, less precision. |

| Electronic Platform Scales | Digital readouts, high accuracy, programmable features | Retail, food service, pharmaceuticals | Pros: High precision, ease of use. Cons: Potential for electronic failure, battery dependency. |

| Portable Platform Scales | Lightweight, battery-operated, easy transport | Fieldwork, trade shows, temporary setups | Pros: Versatile, easy to store. Cons: Limited capacity, potential for wear and tear. |

| Weighbridges | Large scale for vehicles, integrated software systems | Logistics, freight, transportation | Pros: High capacity, comprehensive data management. Cons: High initial investment, installation space requirements. |

Digital Platform Scales

Digital platform scales leverage cloud technology to provide real-time data analytics and remote access capabilities. They are particularly suitable for businesses in e-commerce and logistics, where tracking inventory and managing shipments efficiently is crucial. When purchasing, buyers should consider the scalability of the solution and its integration capabilities with existing systems. However, reliance on internet connectivity can pose challenges in areas with unstable networks.

Mechanical Platform Scales

Mechanical platform scales are known for their heavy-duty construction and analog readouts, making them ideal for environments like warehouses and manufacturing facilities. These scales typically require manual calibration and are highly durable, ensuring long service life with minimal maintenance. Buyers should evaluate their specific weight requirements and consider that while these scales are robust, they lack the advanced data capabilities of digital counterparts.

Electronic Platform Scales

Electronic platform scales offer high accuracy and programmable features, making them suitable for retail, food service, and pharmaceutical applications. Their digital readouts provide easy visibility of weight measurements, and they often include features such as tare functions and unit conversions. Buyers should focus on precision and usability, but should also account for the potential risk of electronic failures and the need for battery replacements.

Portable Platform Scales

Designed for versatility, portable platform scales are lightweight and battery-operated, making them easy to transport for fieldwork, trade shows, or temporary setups. These scales can be an excellent investment for businesses that require mobility. However, buyers should be aware of their limited capacity and potential for wear and tear due to frequent movement.

Weighbridges

Weighbridges are large-scale solutions designed for weighing vehicles, commonly used in logistics and freight operations. They often come with integrated software systems that facilitate comprehensive data management and reporting. While weighbridges offer high capacity and precision, their installation requires significant space and investment, making them suitable for larger operations with high throughput demands. Buyers should carefully assess their operational needs and budget before committing to such a solution.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of platform scales

| Industry/Sector | Specific Application of platform scales | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Weighing raw materials and components | Ensures accurate material usage, reducing waste | Calibration standards, load capacity, and durability |

| Logistics and Warehousing | Inventory management and shipping | Improves operational efficiency and accuracy | Size and portability, integration with existing systems |

| Agriculture | Weighing produce and livestock | Enhances pricing accuracy and inventory management | Weather resistance, ease of cleaning, and portability |

| Retail | Point-of-sale transactions | Streamlines checkout process and enhances customer experience | Compatibility with POS systems, weight limits, and display features |

| Food Processing | Batch weighing for recipes | Ensures consistency in product quality | Hygiene standards, accuracy, and ease of use |

Manufacturing

In the manufacturing sector, platform scales are essential for weighing raw materials and components before production. This application ensures that the right quantities are used, minimizing waste and optimizing resource allocation. For international buyers, particularly in regions like Africa and South America, it’s crucial to consider calibration standards and the load capacity of the scales to meet local regulations and operational demands.

Logistics and Warehousing

Within logistics and warehousing, platform scales play a vital role in inventory management and shipping processes. By accurately weighing goods, businesses can improve operational efficiency and ensure that shipments meet weight specifications, reducing shipping costs and errors. Buyers in Europe and the Middle East should prioritize the size and portability of scales, ensuring they can integrate seamlessly with existing warehouse management systems.

Agriculture

In agriculture, platform scales are used to weigh produce and livestock, which is critical for pricing and inventory management. Accurate weighing ensures that farmers can sell their products at fair market prices while maintaining inventory control. Buyers from regions like South Africa should look for scales that are weather-resistant and portable, allowing for use in various field conditions.

Retail

In the retail sector, platform scales are commonly used at points of sale to weigh products, enhancing the checkout process. This application not only speeds up transactions but also improves the accuracy of pricing, leading to better customer satisfaction. B2B buyers should ensure that the scales are compatible with existing POS systems and have the necessary weight limits and display features for their specific retail environment.

Food Processing

For food processing industries, platform scales are indispensable for batch weighing ingredients in recipes. This application is crucial for maintaining consistency and quality in food products. Buyers should focus on hygiene standards, as food processing requires equipment that is easy to clean and maintain. Additionally, accuracy in measurement is paramount, making it essential to choose high-quality scales that can withstand the demands of food production environments.

Related Video: Industrial Floor Scale, Bench Scales

Strategic Material Selection Guide for platform scales

When selecting materials for platform scales, international B2B buyers must consider several factors that influence performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the construction of platform scales, including their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Steel

Key Properties:

Steel is known for its high strength and durability, with a temperature rating up to 600°C (1112°F). It offers excellent resistance to mechanical stress and is often treated to enhance corrosion resistance.

Pros & Cons:

The primary advantage of steel is its strength, making it suitable for heavy-duty applications. However, it can be prone to rust if not adequately treated, which may increase maintenance costs. Additionally, while steel is relatively inexpensive, the manufacturing process can be complex due to the need for protective coatings.

Impact on Application:

Steel is compatible with a wide range of media, including liquids and solids, but its corrosion resistance must be considered when weighing materials for specific environments.

Considerations for International Buyers:

Steel scales must comply with standards such as ASTM A36 or DIN 17100. Buyers should verify that suppliers provide adequate corrosion protection, especially in humid climates prevalent in regions like South America and Africa.

2. Aluminum

Key Properties:

Aluminum is lightweight and has a high strength-to-weight ratio, with a temperature rating of approximately 400°C (752°F). It also exhibits good corrosion resistance due to a natural oxide layer.

Pros & Cons:

The main advantage of aluminum is its lightweight nature, making it easier to handle and transport. However, it is less durable than steel and may be more expensive due to the cost of raw materials and processing.

Impact on Application:

Aluminum scales are particularly suited for applications requiring portability. However, they may not be ideal for heavy-duty uses where high load capacities are essential.

Considerations for International Buyers:

Aluminum products should comply with standards like ASTM B221. Buyers in Europe and the Middle East should consider the availability of aluminum scales that meet local regulations regarding weight and safety.

3. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and can withstand temperatures up to 800°C (1472°F). It is also highly durable and maintains its structural integrity under various conditions.

Pros & Cons:

The key advantage of stainless steel is its resistance to rust and staining, making it ideal for food and pharmaceutical applications. However, it is more expensive than both standard steel and aluminum, which can impact budget considerations.

Impact on Application:

Stainless steel is compatible with a variety of media, including corrosive substances, which makes it suitable for diverse environments. Its durability ensures long-term performance.

Considerations for International Buyers:

Buyers should ensure compliance with standards like ASTM A304 or A316, especially in industries with stringent hygiene requirements, such as food processing in Europe and the Middle East.

4. Composite Materials

Key Properties:

Composite materials, often made from a blend of plastic and fiberglass, offer lightweight characteristics and can be engineered for specific applications. They generally have lower temperature ratings, around 120°C (248°F).

Pros & Cons:

The advantage of composites is their resistance to corrosion and chemical damage, which is beneficial in harsh environments. However, they may not offer the same load-bearing capacity as metals, limiting their use in heavy-duty applications.

Impact on Application:

Composite scales are suitable for environments where chemical exposure is a concern, such as laboratories or chemical plants. Their lightweight nature facilitates easy handling.

Considerations for International Buyers:

Buyers should verify compliance with relevant standards, such as ASTM D638 for plastics. In regions with diverse climates, the thermal stability of composites should also be assessed.

Summary Table

| Material | Typical Use Case for platform scales | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Prone to rust without treatment | Medium |

| Aluminum | Portable scales for light loads | Lightweight and easy to transport | Less durable than steel | Medium |

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | Higher cost compared to steel | High |

| Composite Materials | Chemical processing environments | Corrosion and chemical resistance | Limited load capacity | Medium |

This guide provides a foundational understanding of material selection for platform scales, enabling international B2B buyers to make informed decisions tailored to their specific operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for platform scales

Manufacturing platform scales involves several critical stages that ensure the final product meets both functionality and quality standards. Understanding these processes is essential for B2B buyers looking to source platform scales from international suppliers, particularly in regions like Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Material Preparation

The first stage in the manufacturing process is material preparation. High-quality materials, such as stainless steel or aluminum, are commonly used due to their durability and resistance to corrosion. The materials undergo initial inspections to verify their properties, including tensile strength and resistance to wear. Suppliers should provide material certifications to ensure compliance with international standards.

Key Techniques:

– Laser Cutting: Precision cutting of materials to shape the platform accurately.

– CNC Machining: Computer Numerical Control (CNC) machines allow for high precision in shaping components.

Forming

Once materials are prepared, the next step is forming. This involves shaping the components into their final form. Techniques such as stamping or bending are frequently employed. It’s critical to ensure that the dimensions are accurate to maintain the scale’s functionality.

Key Techniques:

– Hydraulic Pressing: Used for forming large metal sheets into the desired shapes.

– Roll Forming: Ideal for producing uniform shapes and profiles.

Assembly

The assembly process is where individual components come together to create the finished platform scale. This stage involves integrating electronic components, such as load cells, displays, and wiring systems. Proper assembly is crucial, as any errors can affect the scale’s accuracy.

Key Techniques:

– Soldering: Essential for connecting electronic components securely.

– Mechanical Fastening: Using screws and bolts to secure parts together.

Finishing

After assembly, the platform scales undergo finishing processes. This includes surface treatments such as powder coating or painting, which enhance durability and aesthetics. Proper finishing also protects against environmental factors, ensuring longevity.

Key Techniques:

– Powder Coating: Provides a durable, protective layer that is also visually appealing.

– Electroplating: Enhances corrosion resistance and improves surface finish.

Quality Assurance

Quality assurance (QA) is a vital aspect of the manufacturing process for platform scales. International buyers must ensure that their suppliers adhere to recognized quality standards and maintain stringent quality control measures.

Relevant International Standards

Buyers should look for compliance with international standards such as:

– ISO 9001: A widely recognized standard that ensures quality management systems are in place.

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

– API Standards: Relevant for scales used in the oil and gas industry, ensuring that products meet specific safety and quality criteria.

QC Checkpoints

Quality control checkpoints are integrated at various stages of the manufacturing process to ensure that any defects are identified and addressed promptly.

- Incoming Quality Control (IQC): Materials and components are inspected upon arrival at the manufacturing facility.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished products to ensure they meet specifications.

Common Testing Methods

Various testing methods are employed to verify the accuracy and reliability of platform scales:

– Load Testing: Assessing the scale’s performance under different weights to ensure accuracy.

– Calibration Checks: Regular calibration against certified weights to maintain precision.

– Durability Testing: Subjecting the scales to environmental conditions to evaluate their resilience.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure product reliability. Here are several strategies:

- Supplier Audits: Conduct regular audits of suppliers to assess their manufacturing processes and quality control systems. This can help identify potential issues before they affect product quality.

- Requesting Reports: Buyers should request detailed quality control reports, including inspection results, testing methods used, and compliance with relevant standards.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

QC/Certifications Nuances for International Buyers

Buyers from regions like Africa, South America, the Middle East, and Europe must be aware of specific nuances regarding quality control and certifications:

- Regional Regulations: Understand the local regulations and standards that may affect product certifications. For instance, CE marking is crucial for European buyers, while South American countries may have their own standards.

- Documentation: Ensure that suppliers provide all necessary documentation, including certificates of compliance and testing results. This can facilitate smoother customs clearance and regulatory compliance.

- Cultural Considerations: Different cultures may have varying approaches to quality management. Establishing clear communication with suppliers about quality expectations is crucial for successful partnerships.

By understanding the manufacturing processes and quality assurance measures associated with platform scales, international B2B buyers can make informed decisions when sourcing products. Ensuring that suppliers adhere to rigorous quality standards will ultimately lead to better operational efficiency and customer satisfaction.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for platform scales Sourcing

When considering the sourcing of platform scales, B2B buyers must navigate a complex cost structure that influences overall pricing. Understanding these cost components is crucial for effective negotiation and ensuring long-term value.

Key Cost Components

-

Materials: The type and quality of materials used significantly impact the cost. High-grade steel or specialized alloys for durability and precision can increase costs, while more economical materials may reduce initial expenses but could affect longevity and performance.

-

Labor: Labor costs vary significantly based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can come at the expense of quality. Skilled labor, particularly for precision instruments like platform scales, often demands higher wages, which can elevate overall costs.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce these costs, which is a vital consideration for buyers.

-

Tooling: Custom tooling for specific scale configurations can be a substantial upfront cost. Buyers should assess whether the need for specialized tooling is justifiable based on expected volume and product lifecycle.

-

Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with international standards. While this adds to the cost, it is essential for maintaining product integrity, especially in regulated industries.

-

Logistics: Shipping costs can vary widely based on the origin, destination, and chosen logistics provider. Buyers must consider both transportation costs and potential delays that could impact supply chain efficiency.

-

Margin: Supplier profit margins can fluctuate based on market conditions and competition. Understanding industry standards for margins can help buyers gauge the fairness of pricing.

Influencers of Pricing

Several factors can influence the pricing of platform scales:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically yield lower unit prices. Buyers should negotiate terms that allow for bulk purchasing to take advantage of discounts.

-

Specifications/Customization: Custom features or specifications can significantly increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (such as ISO or CE marking) often come with increased costs. Buyers must weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect pricing. Engaging with multiple suppliers can provide leverage during negotiations.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining who bears the cost of shipping, insurance, and tariffs. This knowledge can prevent unexpected expenses.

Buyer Tips for Cost-Efficiency

-

Negotiate Effectively: Prepare for negotiations by understanding the cost components and pricing influencers. Leverage volume commitments to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the purchase price. Consider maintenance, operating costs, and potential downtime when evaluating offers.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce logistics costs and lead times.

-

Stay Informed About Market Trends: Being aware of fluctuations in material costs and labor markets can provide leverage during negotiations.

-

Request Transparent Pricing: Encourage suppliers to provide a breakdown of costs. This transparency allows for better comparison and understanding of what you are paying for.

Disclaimer

Prices for platform scales can vary widely based on specifications, supplier capabilities, and market conditions. This analysis serves as a guideline, and buyers should conduct thorough due diligence to obtain accurate pricing relevant to their specific requirements and context.

Spotlight on Potential platform scales Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘platform scales’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for platform scales

When selecting platform scales for industrial and commercial use, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This section outlines the critical specifications and common jargon that international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should consider.

Key Technical Properties of Platform Scales

-

Material Grade

– Definition: The quality and composition of the materials used in the construction of the scale, typically stainless steel or mild steel.

– Importance: Higher-grade materials enhance durability and corrosion resistance, crucial for operations in harsh environments. Selecting the right material can significantly extend the lifespan of the scale, reducing replacement costs. -

Load Capacity

– Definition: The maximum weight that the platform scale can accurately measure, typically ranging from a few hundred kilograms to several tons.

– Importance: Understanding load capacity is vital for ensuring that the scale meets operational needs. Choosing a scale with inadequate load capacity can lead to inaccurate readings and potential damage to the equipment. -

Accuracy/Tolerance

– Definition: The degree to which the scale’s measurements conform to the actual weight, expressed as a percentage of the full scale or in specific units (e.g., ±0.1%).

– Importance: High accuracy is essential for industries where precise measurements are critical, such as pharmaceuticals and food production. Inaccurate measurements can lead to compliance issues and financial losses. -

Platform Size

– Definition: The dimensions of the weighing surface, which can vary significantly depending on the scale’s design and intended use.

– Importance: The right platform size ensures that items can be weighed comfortably and accurately. Insufficient platform size may lead to measurement errors or operational inefficiencies. -

Calibration

– Definition: The process of adjusting the scale to ensure its accuracy and reliability, often requiring periodic checks and adjustments.

– Importance: Regular calibration is necessary to maintain compliance with industry standards and regulations. Buyers should consider whether the scale is easy to calibrate and if calibration services are available. -

Connectivity Options

– Definition: The methods available for connecting the scale to other systems, such as USB, Bluetooth, or Wi-Fi.

– Importance: Scales with advanced connectivity options enable better integration into automated systems and data management solutions, enhancing operational efficiency and data accuracy.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers and assess the quality of components used in platform scales. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units that a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory management. Buyers should ensure that the MOQ aligns with their operational needs to avoid excess inventory. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price bids from suppliers for specific products or services.

– Relevance: An RFQ helps buyers compare prices and terms from different suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is crucial for international transactions, as they define the shipping, insurance, and import/export obligations, impacting overall costs and logistics. -

Lead Time

– Definition: The amount of time from placing an order to receiving the product.

– Relevance: Understanding lead times is essential for planning and inventory management. Longer lead times may affect production schedules and operational efficiency. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the product and the terms under which it can be repaired or replaced.

– Relevance: A robust warranty can provide peace of mind and financial protection against defects or failures, making it a critical consideration for buyers.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing platform scales, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the platform scales Sector

Market Overview & Key Trends

The platform scales sector is witnessing transformative changes driven by globalization, technological advancements, and evolving customer expectations. Key market drivers include the increasing need for precise weighing solutions in diverse industries, such as manufacturing, logistics, and agriculture, particularly in emerging markets across Africa, South America, the Middle East, and Europe. As businesses seek to enhance operational efficiency and reduce costs, automation and digitalization are becoming pivotal.

Current B2B technology trends emphasize the integration of IoT (Internet of Things) in platform scales, enabling real-time data collection and monitoring. This shift allows companies to make informed decisions based on accurate weight measurements and analytics. Furthermore, the rise of cloud-based solutions is facilitating remote access and management, making it easier for international buyers to monitor their equipment regardless of location.

Emerging sourcing trends reflect a growing preference for local suppliers to mitigate risks associated with global supply chains, particularly in light of recent disruptions. B2B buyers are encouraged to evaluate suppliers not just based on price, but also on their ability to deliver quality and reliability. Additionally, the trend towards customized solutions is gaining traction, allowing businesses to tailor platform scales to specific operational needs, thus enhancing their competitive edge.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of sourcing decisions in the platform scales sector. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, prompting buyers to prioritize suppliers with sustainable practices. This includes utilizing eco-friendly materials and adopting energy-efficient manufacturing processes.

Illustrative Image (Source: Google Search)

The importance of ethical supply chains cannot be overstated. Buyers are increasingly looking for partners that adhere to ethical labor practices and demonstrate a commitment to social responsibility. This not only helps in compliance with regulatory standards but also enhances brand reputation in the global market.

Buyers should also consider suppliers with green certifications such as ISO 14001, which signifies a commitment to effective environmental management systems. Additionally, using recyclable or biodegradable materials in the production of platform scales contributes to minimizing environmental footprints, making it a critical factor for modern B2B buyers.

Brief Evolution/History

The evolution of platform scales dates back to ancient civilizations where balance scales were utilized for trade. Over the centuries, technological advancements have led to the development of electronic and digital scales, increasing accuracy and efficiency. The introduction of automated weighing systems in the late 20th century marked a significant turning point, allowing for integration with other industrial processes. Today, platform scales are not only essential for accurate measurements but are also integral to the smart manufacturing landscape, reflecting the ongoing trend of digital transformation in various industries.

In conclusion, international B2B buyers in the platform scales sector must navigate these dynamic market trends and sustainability challenges to maintain competitiveness and meet evolving customer demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of platform scales

-

How can I effectively vet suppliers of platform scales?

When vetting suppliers, start by checking their industry reputation through reviews and testimonials. Request references from current or past clients, particularly those in your region, to understand their service quality. Verify certifications relevant to your industry standards, such as ISO 9001 for quality management. Conduct a site visit if feasible to assess their manufacturing processes and facilities. Utilizing platforms like Alibaba or global trade directories can also provide insights into supplier reliability. -

Can platform scales be customized to meet specific needs?

Yes, many manufacturers offer customization options for platform scales. This can include adjustments in size, weight capacity, and additional features like integrated software for data management. When discussing customization, clearly outline your requirements and ask for examples of previous custom projects. Ensure that the supplier has the capability and experience to deliver customized solutions, as this can affect both functionality and compliance with local regulations. -

What are the typical minimum order quantities (MOQ) and lead times for platform scales?

Minimum order quantities can vary significantly among suppliers, typically ranging from 1 to 100 units. Smaller manufacturers may offer lower MOQs, while larger suppliers may require bulk orders. Lead times generally depend on the complexity of the order and the supplier’s production schedule, usually ranging from 2 to 12 weeks. Always confirm these details upfront to align your purchasing strategy with your operational needs and timelines. -

What payment options are commonly accepted by suppliers?

Payment options can include wire transfers, letters of credit, PayPal, or escrow services, depending on the supplier’s location and business model. For international transactions, letters of credit can provide security for both parties. Discuss payment terms early in negotiations to ensure mutual understanding. Additionally, be wary of upfront payments exceeding 30% of the total cost, as this can expose you to risks if the supplier fails to deliver. -

What quality assurance measures should I look for?

Inquire about the supplier’s quality assurance processes, including testing protocols for their platform scales. Look for certifications that indicate adherence to international quality standards, such as CE marking in Europe or NTEP certification in the U.S. It’s beneficial to request detailed documentation of quality control checks and test results for the specific models you are interested in. A robust QA process can significantly reduce the risk of receiving defective products. -

How can I ensure compliance with local regulations?

Compliance with local regulations is crucial when sourcing platform scales. Research the relevant standards in your country, such as weight and measurement regulations, and verify that the supplier’s products meet these requirements. Ask for compliance certifications and documentation to support their claims. Engaging with local regulatory bodies or consultants can provide additional insights into necessary compliance measures, ensuring you avoid potential legal issues. -

What should I consider regarding logistics and shipping?

Logistics can significantly impact your sourcing experience. Discuss shipping options with your supplier, including freight costs, delivery timelines, and insurance coverage. Understand the incoterms (e.g., FOB, CIF) to clarify responsibilities for shipping costs and risks. Additionally, consider customs clearance processes in your country, as this can affect delivery times and additional costs. Choosing a supplier with experience in international shipping can streamline this process.

Illustrative Image (Source: Google Search)

- How should I handle disputes with suppliers?

To manage disputes effectively, establish clear contracts that outline terms of sale, quality expectations, and dispute resolution procedures. If issues arise, maintain open communication with the supplier to resolve them amicably. Many suppliers may prefer negotiation or mediation before escalating to legal action. Familiarize yourself with international trade laws that apply to your transaction, as this knowledge can guide your approach and protect your interests in the event of a dispute.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for platform scales

In conclusion, effective strategic sourcing of platform scales is essential for businesses looking to optimize their operations and ensure quality control across various sectors. By focusing on key factors such as supplier reliability, technological integration, and cost efficiency, international B2B buyers can significantly enhance their procurement processes. Understanding local market dynamics in regions like Africa, South America, the Middle East, and Europe is crucial for making informed decisions that align with specific business needs.

Moreover, leveraging technology and data analytics can facilitate better supplier selection and performance monitoring, ultimately leading to improved operational efficiency. As industries continue to evolve, the ability to adapt sourcing strategies will become increasingly important.

Looking ahead, businesses are encouraged to embrace innovation in their sourcing practices and remain agile in response to market changes. Engaging with local suppliers and fostering strategic partnerships can provide a competitive edge, ensuring that your organization not only meets current demands but is also well-positioned for future growth. Prioritize strategic sourcing today to secure a sustainable and prosperous tomorrow.