Master Sourcing Strategies for iso Transformers: Unlock

Introduction: Navigating the Global Market for iso transformer

In the ever-evolving global energy landscape, iso transformers play a pivotal role in ensuring efficient power distribution and stability across various sectors. For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of iso transformers is essential for navigating the complexities of procurement in an increasingly competitive market. These transformers are not only critical for enhancing grid reliability but also for supporting sustainable energy initiatives that are becoming paramount worldwide.

This guide offers a comprehensive exploration of iso transformers, covering crucial topics that matter to international buyers. It begins with an overview of different transformer types and their specific applications, helping buyers identify the most suitable solutions for their needs. The guide delves into material selection, emphasizing the implications of copper versus aluminum windings, and examines manufacturing practices and quality control measures to mitigate risks associated with sourcing.

Furthermore, it provides actionable insights into supplier assessment strategies, ensuring that buyers can identify credible partners in diverse logistical landscapes. Buyers will gain a clearer understanding of pricing structures and market trends, enabling them to negotiate favorable terms. Additionally, frequently asked questions are addressed, covering essential aspects like lead times, warranties, and compliance with environmental standards.

By equipping B2B buyers with this vital knowledge, this guide empowers informed sourcing decisions that not only meet immediate project requirements but also foster long-term resilience and success in the global market.

Understanding iso transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Isolation Transformer | Provides electrical isolation between primary and secondary windings; usually designed to reduce noise and voltage spikes | Medical equipment, sensitive electronics, industrial machinery | Excellent for protecting sensitive equipment; can be costly and larger footprint |

| Auto-Transformer | Uses a single winding with taps for voltage adjustment; compact design | Voltage regulation in industrial applications, power distribution | Economical and efficient; lacks full isolation, not suitable for all applications |

| Step-Up Transformer | Increases voltage from primary to secondary; essential for long-distance transmission | Renewable energy systems, power generation | Facilitates efficient power transmission; may require more complex maintenance |

| Step-Down Transformer | Decreases voltage from primary to secondary; critical for safe distribution | Commercial and residential power supply | Widely used and easy to install; potential for energy loss at low loads |

| Three-Phase Transformer | Consists of three sets of windings; designed for three-phase power systems | Industrial facilities, large commercial buildings | Supports high power loads; complex installation and higher costs |

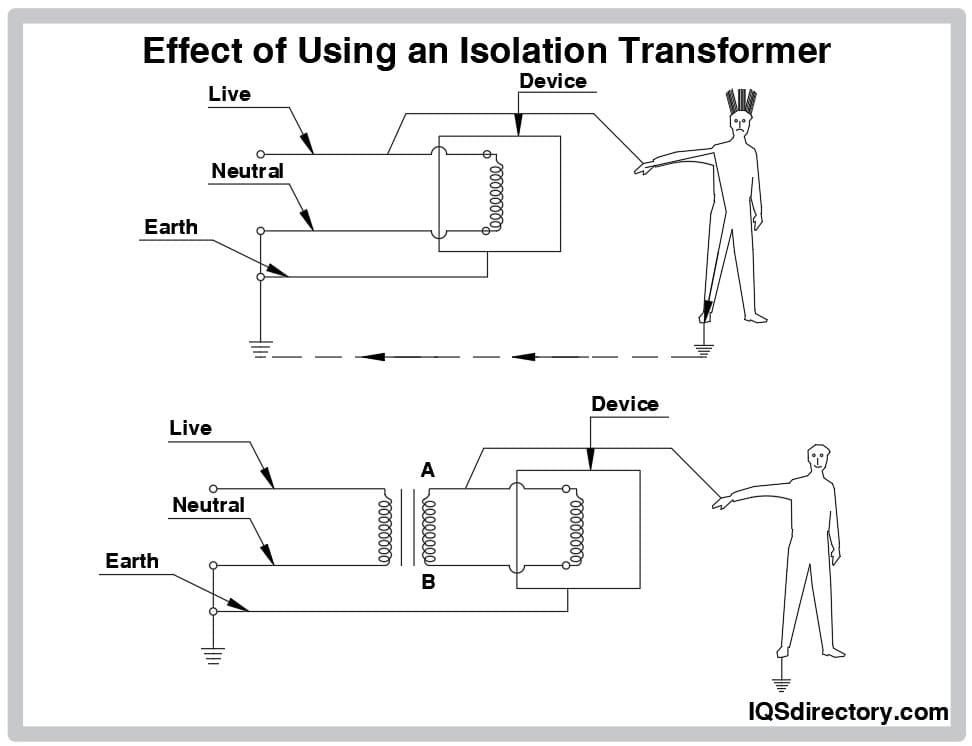

Isolation Transformer

Isolation transformers are designed to provide electrical separation between the primary and secondary circuits, which protects sensitive equipment from electrical noise and voltage spikes. Commonly used in medical devices and high-precision electronics, these transformers ensure the safety and reliability of critical systems. Buyers should consider the transformer’s voltage rating, efficiency, and size, as these can significantly impact installation and operational costs. Additionally, understanding the specific application requirements is essential to ensure optimal performance.

Auto-Transformer

Auto-transformers feature a single winding that acts as both the primary and secondary winding, allowing for voltage adjustment through taps. Their compact design makes them a popular choice for applications requiring space efficiency, such as voltage regulation in industrial settings. While they are cost-effective and offer high efficiency, buyers must be aware that they do not provide complete electrical isolation, which may pose risks in certain scenarios. Assessing the application’s safety requirements is crucial when considering this type.

Step-Up Transformer

Step-up transformers are utilized to increase voltage levels from the primary to secondary side, making them essential for efficient long-distance power transmission. They play a vital role in renewable energy systems, where electricity generated at lower voltages must be stepped up for transmission. B2B buyers should focus on the transformer’s capacity and efficiency ratings, as well as the maintenance requirements, which can be more complex due to their operational demands. Ensuring compatibility with existing infrastructure is also key to a successful purchase.

Step-Down Transformer

Step-down transformers serve to reduce voltage levels, making them critical for distributing power safely to commercial and residential users. Their straightforward installation and widespread availability make them a go-to choice for many applications. However, buyers should be mindful of potential energy losses when operating below optimal load conditions. Understanding local regulations and compliance standards is essential for ensuring that the chosen transformer meets all necessary requirements for safety and efficiency.

Three-Phase Transformer

Three-phase transformers are engineered to handle three-phase power systems, providing high capacity and efficiency for industrial and large commercial applications. They consist of three sets of windings that allow for balanced load distribution and reduced losses. While they support substantial power loads, the complexity of their installation and higher costs can be significant considerations for buyers. Conducting thorough evaluations of site requirements and potential return on investment will aid in making informed purchasing decisions.

Related Video: Attention is all you need (Transformer) – Model explanation (including math), Inference and Training

Key Industrial Applications of iso transformer

| Industry/Sector | Specific Application of iso transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Renewable Energy | Grid Integration for Solar and Wind Farms | Enhances energy efficiency and reliability in power distribution | Ensure compliance with local regulations and standards; assess supplier capability in renewable applications. |

| Industrial Manufacturing | Power Supply Isolation for Sensitive Equipment | Protects equipment from voltage spikes, ensuring operational continuity | Evaluate the transformer’s insulation class and cooling method; consider after-sales support for maintenance. |

| Data Centers | Voltage Regulation and Isolation | Maintains stable power supply, reducing downtime and equipment damage | Investigate the transformer’s footprint and cooling requirements; prioritize suppliers with proven reliability records. |

| Telecommunications | Signal Isolation and Power Distribution | Minimizes interference and ensures consistent signal quality | Assess the transformer’s compatibility with existing systems; consider lead times and supplier responsiveness. |

| Healthcare Facilities | Power Isolation for Critical Medical Equipment | Ensures uninterrupted power supply for essential services | Focus on suppliers with certifications for medical applications; verify warranty terms and after-sales support. |

Renewable Energy

In the renewable energy sector, iso transformers are crucial for integrating solar and wind farms into the grid. They help step up or step down voltages, ensuring that energy generated at variable output levels can be reliably fed into the grid. This application is particularly relevant for international buyers in regions like Africa and South America, where renewable energy projects are rapidly expanding. Buyers should prioritize suppliers with a strong understanding of local grid standards and the ability to provide transformers that can withstand environmental challenges unique to these regions.

Industrial Manufacturing

In industrial settings, iso transformers are employed to isolate sensitive equipment from the main power supply, protecting against voltage spikes and ensuring operational continuity. This is especially important in sectors like automotive manufacturing or heavy machinery production, where equipment reliability is paramount. Buyers should consider the transformer’s insulation class and cooling method, as these factors directly influence performance and maintenance needs. Suppliers should also demonstrate experience in providing solutions tailored to specific manufacturing environments.

Data Centers

Iso transformers play a vital role in data centers by regulating voltage and providing isolation from the grid. This stability is essential for preventing downtime and protecting sensitive IT equipment from power fluctuations. For B2B buyers in Europe and the Middle East, where data center demand is surging, sourcing iso transformers that meet specific size and cooling requirements is critical. Buyers should engage suppliers with a proven track record in the data center industry and assess their ability to deliver timely support and maintenance.

Telecommunications

In the telecommunications sector, iso transformers are used for signal isolation and power distribution, ensuring consistent signal quality and minimizing interference. This is particularly important in regions with developing infrastructure, such as parts of Africa and South America, where reliable communication networks are essential. Buyers should evaluate potential suppliers based on their understanding of telecommunications applications and their ability to provide customized solutions that meet local operational standards.

Healthcare Facilities

Iso transformers are integral to healthcare facilities, providing power isolation for critical medical equipment. This application ensures that essential services, such as life support systems, remain operational during power disturbances. For international buyers, particularly in the Middle East and Europe, it is vital to source transformers from suppliers with certifications specific to medical applications. Additionally, understanding warranty terms and the availability of after-sales support is crucial for maintaining these critical systems.

Related Video: Uses of Radioisotope in Industry | Nuclear Energy | Science

Strategic Material Selection Guide for iso transformer

When selecting materials for iso transformers, international B2B buyers must consider various factors that influence performance, cost, and suitability for specific applications. Here, we analyze four common materials used in iso transformers: copper, aluminum, silicon steel, and resin. Each material has unique properties, advantages, and limitations that can significantly impact transformer performance and operational efficiency.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can operate effectively at high temperatures and has a melting point of approximately 1,984°F (1,085°C).

Pros & Cons: Copper windings provide superior efficiency and lower energy losses compared to alternatives. However, copper is more expensive than aluminum, which can increase the overall cost of the transformer. Additionally, the manufacturing process for copper components can be more complex, requiring skilled labor and specialized equipment.

Impact on Application: Copper is highly compatible with various insulating materials and is often used in high-performance applications where efficiency is critical. Its durability makes it suitable for environments with high thermal and electrical demands.

Considerations for International Buyers: Buyers in regions like Africa and South America should be aware of the fluctuating copper prices and their impact on project budgets. Compliance with international standards such as ASTM and IEC is crucial, particularly for projects funded by international bodies or governments.

Aluminum

Key Properties: Aluminum has a lower density than copper and is also a good conductor of electricity, although not as efficient as copper. It has a melting point of about 1,221°F (660.3°C) and is resistant to corrosion due to the formation of a protective oxide layer.

Pros & Cons: The primary advantage of aluminum is its lower cost and lightweight nature, making it easier to handle and install. However, aluminum windings may have higher resistive losses compared to copper, which can affect overall efficiency. Additionally, aluminum is more susceptible to mechanical damage and may require additional protective measures.

Impact on Application: Aluminum is suitable for applications where weight and cost are significant factors, such as in transportation or portable transformers. However, its lower conductivity may limit its use in high-demand scenarios.

Considerations for International Buyers: Buyers should consider local availability and the potential need for additional protective coatings to enhance durability, especially in humid or corrosive environments typical in the Middle East and parts of Africa.

Silicon Steel

Key Properties: Silicon steel is used for transformer cores due to its high magnetic permeability and low hysteresis loss. It typically contains 3-5% silicon, which enhances its electrical properties and reduces energy losses.

Pros & Cons: The use of silicon steel in transformer cores leads to improved efficiency and reduced operational costs. However, the manufacturing process can be complex and requires precision engineering, which may increase costs. Additionally, silicon steel is more brittle than other materials, which can pose challenges during fabrication.

Impact on Application: Silicon steel is critical for applications requiring high efficiency and low noise, such as in urban environments where noise pollution is a concern. Its magnetic properties make it ideal for high-frequency applications.

Considerations for International Buyers: Compliance with standards like DIN and JIS is essential when sourcing silicon steel, particularly for projects in Europe and Asia. Buyers should also evaluate the supplier’s ability to meet specific material grades and thicknesses.

Resin

Key Properties: Resin is used for insulation in dry-type transformers. It is non-conductive and provides excellent thermal stability and moisture resistance.

Pros & Cons: Resin insulation offers superior safety, as it eliminates fire risks associated with oil-filled transformers. However, the initial cost of resin-insulated transformers can be higher, and the manufacturing process may require specialized techniques.

Impact on Application: Resin is particularly suitable for indoor applications and environments where safety is paramount, such as hospitals and data centers. Its resistance to environmental factors makes it ideal for diverse applications.

Considerations for International Buyers: Buyers should ensure that resin materials comply with local safety and environmental regulations, which can vary significantly across regions. Understanding the specific requirements for resin insulation in different markets is vital for successful procurement.

| Material | Typical Use Case for iso transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | High-performance transformers | Superior conductivity and efficiency | Higher cost and complex manufacturing | High |

| Aluminum | Cost-sensitive applications | Lightweight and lower cost | Higher resistive losses and mechanical fragility | Medium |

| Silicon Steel | Transformer cores | Improved efficiency and low losses | Brittle and complex manufacturing | Medium |

| Resin | Dry-type transformers | Enhanced safety and moisture resistance | Higher initial cost and specialized manufacturing | High |

In-depth Look: Manufacturing Processes and Quality Assurance for iso transformer

The manufacturing processes and quality assurance measures for ISO transformers are crucial for ensuring performance, reliability, and longevity. Understanding these processes is essential for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. This guide delves into the typical manufacturing stages, key techniques involved, and the quality control (QC) measures that buyers should consider when sourcing ISO transformers.

Manufacturing Processes for ISO Transformers

The manufacturing of ISO transformers involves several critical stages, each designed to ensure the highest quality and performance standards.

1. Material Preparation

The first step in the manufacturing process is the preparation of materials. This includes sourcing high-grade raw materials such as copper or aluminum for windings, grain-oriented electrical steel for cores, and insulation materials. The choice of materials significantly impacts the efficiency and operational lifespan of the transformer.

- Key Considerations:

- Material Specifications: Ensure that suppliers provide materials that meet international standards, such as ASTM or IEC certifications.

- Sustainability: Opt for suppliers who utilize environmentally friendly practices in sourcing and processing materials.

2. Forming

The next stage involves forming the core and windings. The core is typically constructed from laminated sheets of electrical steel to minimize energy losses.

- Key Techniques:

- Lamination: This process reduces eddy current losses, enhancing transformer efficiency.

- Winding Techniques: Advanced winding techniques like precision coil winding ensure uniformity and reduce the risk of short circuits.

3. Assembly

Once the core and windings are prepared, the assembly process begins. This involves placing the windings onto the core and securing them in place.

- Key Considerations:

- Alignment: Proper alignment of the windings is critical to prevent overheating and ensure optimal performance.

- Insulation: Adequate insulation must be applied to prevent electrical faults and enhance safety.

4. Finishing

The final stage of manufacturing includes finishing processes such as encapsulation and painting.

- Key Techniques:

- Encapsulation: Encapsulating the transformer in resin or oil, depending on the type (dry-type or oil-filled), protects against environmental factors.

- Surface Treatment: Painting and surface treatments enhance corrosion resistance, particularly for transformers used in harsh environments.

Quality Assurance Measures

Quality assurance is integral to the manufacturing process, ensuring that ISO transformers meet both international standards and customer expectations.

International Standards

For B2B buyers, understanding the relevant international standards is crucial. Key standards include:

- ISO 9001: Focuses on quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

- API Standards: Applicable for transformers used in the oil and gas sector, focusing on safety and performance.

QC Checkpoints

Quality control is typically performed at several checkpoints during the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify issues early.

- Final Quality Control (FQC): Comprehensive testing of the finished product ensures it meets all design specifications.

Common Testing Methods

Various testing methods are employed to assess transformer performance and safety:

- Dielectric Testing: Measures insulation strength and ensures it can withstand operational voltages.

- Thermal Imaging: Identifies hot spots in the transformer that could indicate potential failures.

- Power Factor Testing: Assesses the efficiency of insulation materials.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of potential suppliers. Here are effective strategies:

- Conduct Supplier Audits: On-site audits allow buyers to assess manufacturing capabilities and quality control processes firsthand.

- Request Quality Reports: Suppliers should provide documentation of their quality control measures, including test results and certifications.

- Engage Third-Party Inspectors: Independent inspections can provide an unbiased assessment of manufacturing quality and compliance with international standards.

QC and Certification Nuances for International Buyers

International buyers must navigate various certification and quality assurance challenges. Here are some nuances to consider:

- Regional Compliance: Different regions may have specific compliance requirements. For instance, transformers sold in Europe must meet CE standards, while those in the Middle East may require adherence to local regulations.

- Documentation: Ensure that all certifications and quality assurance documents are in a format acceptable in your region. Language and formatting can vary significantly.

- Cultural Considerations: Engage with suppliers who understand the local business culture and can facilitate smoother transactions, particularly in regions with different regulatory landscapes.

Conclusion

Understanding the manufacturing processes and quality assurance measures for ISO transformers is essential for B2B buyers aiming to source reliable and efficient products. By focusing on material preparation, forming, assembly, and finishing, while also emphasizing rigorous quality control practices, buyers can make informed decisions. Engaging in thorough supplier assessments and understanding regional compliance nuances will further enhance procurement strategies, ensuring that investments yield long-term operational benefits.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for iso transformer Sourcing

Understanding the cost structure and pricing dynamics of iso transformers is crucial for B2B buyers aiming to make informed procurement decisions. The costs associated with sourcing iso transformers can be categorized into several components, while various factors influence pricing.

Cost Components

-

Materials: The primary materials used in iso transformers include copper or aluminum for windings, steel for the core, and insulating materials. Fluctuations in commodity prices, particularly for copper and grain-oriented electrical steel, can significantly impact overall costs. As of late 2023, copper prices have surged by over 40% since the pandemic, highlighting the importance of material sourcing strategies.

-

Labor: Labor costs vary widely depending on the region and the complexity of the transformer design. Skilled labor is essential for high-quality manufacturing and assembly, especially for custom specifications. Buyers should consider the labor market conditions in the supplier’s location when assessing total costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, impacting the final pricing of transformers.

-

Tooling: Custom transformers often require specialized tooling, which can lead to higher upfront costs. Buyers should evaluate whether the tooling costs can be amortized over multiple units to optimize pricing.

-

Quality Control (QC): Ensuring quality through rigorous QC processes is vital for reliability. Costs associated with inspections, testing, and certifications can add to the overall price but are essential to prevent future failures and operational issues.

-

Logistics: Transportation costs can vary significantly based on the distance from the manufacturer to the buyer, the mode of transport, and any tariffs or duties. Incoterms also play a critical role, influencing who bears the cost and risk during shipping.

-

Margin: Suppliers typically include a margin that reflects their operational risks and profit objectives. Understanding the competitive landscape can help buyers negotiate better terms.

Price Influencers

Several factors can affect the pricing of iso transformers:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to maximize savings.

-

Specifications/Customization: Custom specifications can increase costs due to additional design, engineering, and tooling requirements. Buyers should clearly define their needs to avoid unexpected costs.

-

Quality/Certifications: Higher quality standards and certifications may come at a premium. However, investing in quality can lead to reduced long-term maintenance costs and increased reliability.

-

Supplier Factors: The supplier’s reputation, experience, and production capacity can influence pricing. Conducting thorough due diligence on suppliers can lead to better partnerships and pricing agreements.

-

Incoterms: The choice of Incoterms affects the total landed cost. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to ensure transparency in pricing.

Buyer Tips

To navigate the complexities of iso transformer pricing effectively, consider the following strategies:

-

Negotiate: Leverage your purchasing power by negotiating terms, especially for bulk purchases. Discussing long-term partnerships can lead to favorable pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational efficiency, and longevity. A higher initial investment in quality may yield lower TCO over the lifespan of the transformer.

-

Understand Pricing Nuances: Be aware of regional factors affecting pricing. For example, buyers in Africa may face different logistical challenges compared to those in Europe. Understanding these nuances can help in negotiating better deals.

-

Stay Informed on Market Trends: Keep abreast of fluctuations in material prices and supply chain developments. This knowledge can empower buyers to make timely purchasing decisions.

Disclaimer

Prices for iso transformers can vary widely based on specifications, supplier, and market conditions. The insights provided here are indicative and should be validated through direct engagement with suppliers and market research.

Spotlight on Potential iso transformer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘iso transformer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for iso transformer

To ensure effective procurement and utilization of iso transformers, understanding their essential technical properties and trade terminology is crucial for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also facilitates smoother communication with suppliers.

Key Technical Properties of Iso Transformers

-

Material Grade

The quality of materials used in iso transformers significantly affects their performance and longevity. Common materials include copper and aluminum for windings, with copper offering better conductivity and efficiency. Buyers should prioritize high-grade materials to ensure reliability, particularly in regions with unstable power conditions. -

Voltage Rating

This specification indicates the maximum voltage the transformer can handle safely. For international buyers, ensuring the voltage rating aligns with local grid requirements is vital. Mismatched voltage ratings can lead to equipment failure and safety hazards, making it critical to verify this specification during procurement.

Illustrative Image (Source: Google Search)

-

Insulation Class

The insulation class determines the transformer’s ability to withstand temperature variations. Classes such as A, B, F, and H denote different temperature limits. Choosing the right insulation class is essential for ensuring operational efficiency and longevity, particularly in extreme climates found in Africa and the Middle East. -

Efficiency Rating

Efficiency ratings reflect how effectively a transformer converts electrical energy. A higher efficiency rating leads to lower energy losses and operational costs. B2B buyers should look for transformers with high efficiency ratings, as this can significantly impact long-term operational expenses and sustainability goals. -

Tolerance Levels

Tolerance levels indicate the permissible deviation from the specified parameters during manufacturing. They are critical for ensuring the transformer meets operational requirements. Buyers should understand the tolerance levels to avoid future operational issues, especially when working with tight specifications in sensitive applications. -

Cooling Method

Iso transformers can employ various cooling methods, including oil cooling and air cooling. The choice of cooling method affects operational efficiency, maintenance needs, and safety. Buyers must consider the local environment and application requirements when selecting a transformer with the appropriate cooling method.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is essential for buyers seeking quality assurance and reliability in their transformer sourcing. -

MOQ (Minimum Order Quantity)

The smallest amount of product a supplier is willing to sell. This term is crucial for B2B buyers to understand pricing structures and negotiate better terms, especially in regions where large-scale procurement may not be feasible.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

A formal request sent to suppliers to obtain price quotes for specific products. Utilizing RFQs effectively can help buyers compare offers and ensure they are getting competitive pricing and terms. -

Incoterms (International Commercial Terms)

A set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping obligations, risk transfer, and cost responsibilities, particularly in complex logistics scenarios. -

Lead Time

The amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for project planning and can significantly affect operational schedules, especially in regions experiencing supply chain disruptions. -

Certification Standards

These are industry-specific standards that products must meet to ensure safety and performance. Familiarity with certification standards relevant to iso transformers is crucial for buyers to ensure compliance and mitigate risks associated with product failures.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, enhance supplier negotiations, and ultimately secure high-quality iso transformers that meet their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the iso transformer Sector

In the current landscape of the iso transformer sector, international B2B buyers are navigating a complex web of market dynamics that include escalating demand, supply chain challenges, and evolving technological trends. The surge in renewable energy projects, coupled with the urgent need for infrastructure upgrades, is driving a significant increase in transformer orders globally. This boom is particularly pronounced in regions like Africa and South America, where electrification efforts are vital for economic growth. However, buyers face daunting lead times, which have ballooned to 120 weeks or more due to supply chain disruptions and increased raw material costs. Consequently, understanding these dynamics is crucial for effective sourcing strategies.

Emerging trends include a shift towards smart transformers that integrate digital monitoring and automation capabilities. These innovations not only enhance operational efficiency but also enable predictive maintenance, reducing downtime and extending the lifespan of equipment. B2B buyers should prioritize suppliers who are investing in advanced technologies and can provide robust after-sales support. Additionally, there is a growing emphasis on local sourcing to mitigate risks associated with long lead times and transportation logistics. Establishing relationships with regional manufacturers can provide a competitive edge in terms of responsiveness and cost-effectiveness.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a key consideration in procurement decisions, B2B buyers must assess the environmental impact of iso transformers throughout their lifecycle. The production and operation of transformers contribute significantly to energy consumption and greenhouse gas emissions. Therefore, selecting suppliers who adhere to sustainable manufacturing practices is essential. Buyers should look for certifications such as ISO 14001, which indicates a commitment to environmental management systems.

Moreover, the adoption of green materials in transformer construction, such as recyclable insulation and lower-impact cooling fluids, is gaining traction. These materials not only reduce the carbon footprint but also appeal to increasingly eco-conscious stakeholders. Ethical supply chains, characterized by transparency and fair labor practices, are becoming non-negotiable for many buyers. Investing in suppliers who prioritize these values can enhance corporate reputation and meet regulatory compliance in various markets, particularly in Europe and the Middle East.

Brief Evolution/History

The iso transformer has evolved significantly since its inception, driven by advancements in technology and changing market demands. Initially designed for basic voltage regulation, transformers have transformed into sophisticated devices capable of meeting the complexities of modern power systems. Over the last few decades, innovations in materials and design have led to enhanced efficiency, reduced losses, and improved safety. The shift towards renewable energy sources has further accelerated the need for high-performance transformers that can adapt to variable loads and integrate seamlessly with smart grid technologies. Understanding this evolution is crucial for B2B buyers seeking reliable and future-proof solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of iso transformer

-

What key factors should I consider when vetting suppliers for iso transformers?

When vetting suppliers, prioritize their experience in manufacturing iso transformers, particularly with specifications relevant to your market. Check for certifications such as ISO 9001, which indicates adherence to quality management standards. Assess their production capacity and lead times, as well as customer reviews and case studies that demonstrate reliability. It’s also essential to inquire about their after-sales support and warranty policies, which can be critical for long-term partnerships. -

Can iso transformers be customized to meet specific requirements?

Yes, many manufacturers offer customization options for iso transformers. This can include variations in voltage, capacity, cooling methods, and insulation types. When discussing customization, ensure you provide detailed specifications and operational conditions to the supplier. Additionally, clarify how these customizations may impact lead times and costs. Engaging in early discussions can help align expectations and facilitate a smoother procurement process. -

What are the typical minimum order quantities (MOQ) and lead times for iso transformers?

MOQs for iso transformers can vary significantly based on the manufacturer and the specific product configuration. Generally, MOQs can range from a single unit to several units, particularly for custom designs. Lead times have been extended in recent years due to supply chain challenges, often ranging from 12 to 24 weeks for standard models and up to 210 weeks for larger or custom units. It’s crucial to discuss these factors upfront to plan your project timelines effectively.

-

What quality assurance measures should I look for in iso transformer suppliers?

Ensure your chosen supplier implements rigorous quality assurance (QA) protocols, including in-process inspections and final testing. Request documentation of their QA processes and any relevant certifications, such as IEC or UL compliance. Additionally, consider third-party inspections to verify manufacturing quality before shipment. This is especially important for international buyers to mitigate risks associated with cross-border procurement. -

What certifications should iso transformers have to ensure compliance with international standards?

Look for iso transformers that comply with international standards such as IEC 60076 for power transformers and IEC 61558 for safety. Other important certifications include ISO 9001 for quality management systems and any regional certifications that may apply, such as CE marking in Europe. These certifications not only ensure product safety and reliability but also facilitate smoother customs processes and regulatory compliance in your target market. -

How should I approach logistics and transportation for iso transformers?

Logistics for iso transformers can be complex due to their size and weight. Collaborate with your supplier to determine the best shipping methods, considering factors like cost, transit time, and insurance coverage. It’s advisable to engage with freight forwarders experienced in handling heavy industrial equipment to ensure safe and timely delivery. Also, confirm the supplier’s responsibilities regarding shipping terms (e.g., FOB, CIF) to avoid any unexpected costs. -

What steps can I take to resolve disputes with suppliers?

To resolve disputes effectively, maintain clear communication throughout the procurement process. Document all agreements and correspondence to serve as a reference in case of misunderstandings. If a dispute arises, approach the supplier with the aim of collaborative problem-solving. Consider including a mediation clause in your contract, which can provide a structured approach to conflict resolution without resorting to legal action. -

What payment terms are typical when sourcing iso transformers internationally?

Payment terms for international purchases of iso transformers typically include options like letters of credit, advance payments, or staggered payments based on production milestones. It’s essential to negotiate terms that protect your interests while also being acceptable to the supplier. Understand the implications of currency fluctuations and transaction fees, and consider using escrow services for larger orders to ensure security for both parties involved.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for iso transformer

In navigating the complexities of sourcing iso transformers, international B2B buyers are presented with both challenges and opportunities. The ongoing supply chain crisis, marked by extended lead times and rising costs, underscores the importance of strategic sourcing as a means to secure reliable partnerships. Buyers must prioritize due diligence in supplier assessments, focusing on manufacturers with proven capabilities and robust quality control measures. Additionally, understanding the nuances of transformer types—such as power, distribution, and dry-type—is critical for aligning products with specific application needs.

As the demand for sustainable energy solutions grows, so does the necessity for transformers that can support new technologies and evolving infrastructure. This creates an imperative for buyers in Africa, South America, the Middle East, and Europe to act decisively. By leveraging insights into market trends and pricing dynamics, businesses can enhance their procurement strategies and foster resilience against future supply disruptions.

Looking ahead, the focus should be on building long-term relationships with credible suppliers and investing in innovative solutions that ensure operational efficiency. Engaging proactively in the transformer market now will position businesses advantageously for the energy demands of tomorrow. Take the next step in your sourcing journey—secure your supply chain today.