Master Sourcing Strategies for Lock Mechanisms: Enhance

Introduction: Navigating the Global Market for lock mechanisms

The global market for lock mechanisms is a dynamic and essential sector, underpinning security and access control across various industries. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the intricacies of lock mechanisms is crucial for making informed procurement decisions. These mechanisms are not just about physical security; they represent a blend of technology, innovation, and manufacturing excellence that can significantly impact operational efficiency and safety.

This guide offers a comprehensive exploration of lock mechanisms, covering a range of critical topics to empower buyers. You will find detailed insights into the types of lock mechanisms, including traditional and smart options, as well as a deep dive into the materials used in their production, which can affect durability and performance. The guide also addresses manufacturing processes and quality control standards, ensuring that you are aware of the best practices that reputable suppliers adhere to.

Additionally, we will discuss supplier selection criteria, helping you navigate the landscape of global suppliers while understanding cost considerations and market trends. Common questions and concerns will also be tackled in our FAQs section, providing clarity on various aspects of the procurement process. By leveraging this guide, B2B buyers will be better equipped to make strategic sourcing decisions that enhance security and operational effectiveness across their organizations.

Understanding lock mechanisms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pin Tumbler Lock | Utilizes a set of pins that must be aligned to a specific height to allow the lock to turn. | Office buildings, safes, and cabinets. | Pros: High security; easily rekeyed. Cons: Vulnerable to picking and bumping. |

| Deadbolt Lock | A locking mechanism that requires a key or thumb turn to engage a bolt into the door frame. | Residential and commercial doors. | Pros: Enhanced security; difficult to force open. Cons: Requires precise installation; may be cumbersome. |

| Electronic Lock | Operates with a keypad or biometric scanner, eliminating the need for physical keys. | Hotels, secure facilities, and data centers. | Pros: Keyless entry; audit trails available. Cons: Vulnerable to hacking; battery dependency. |

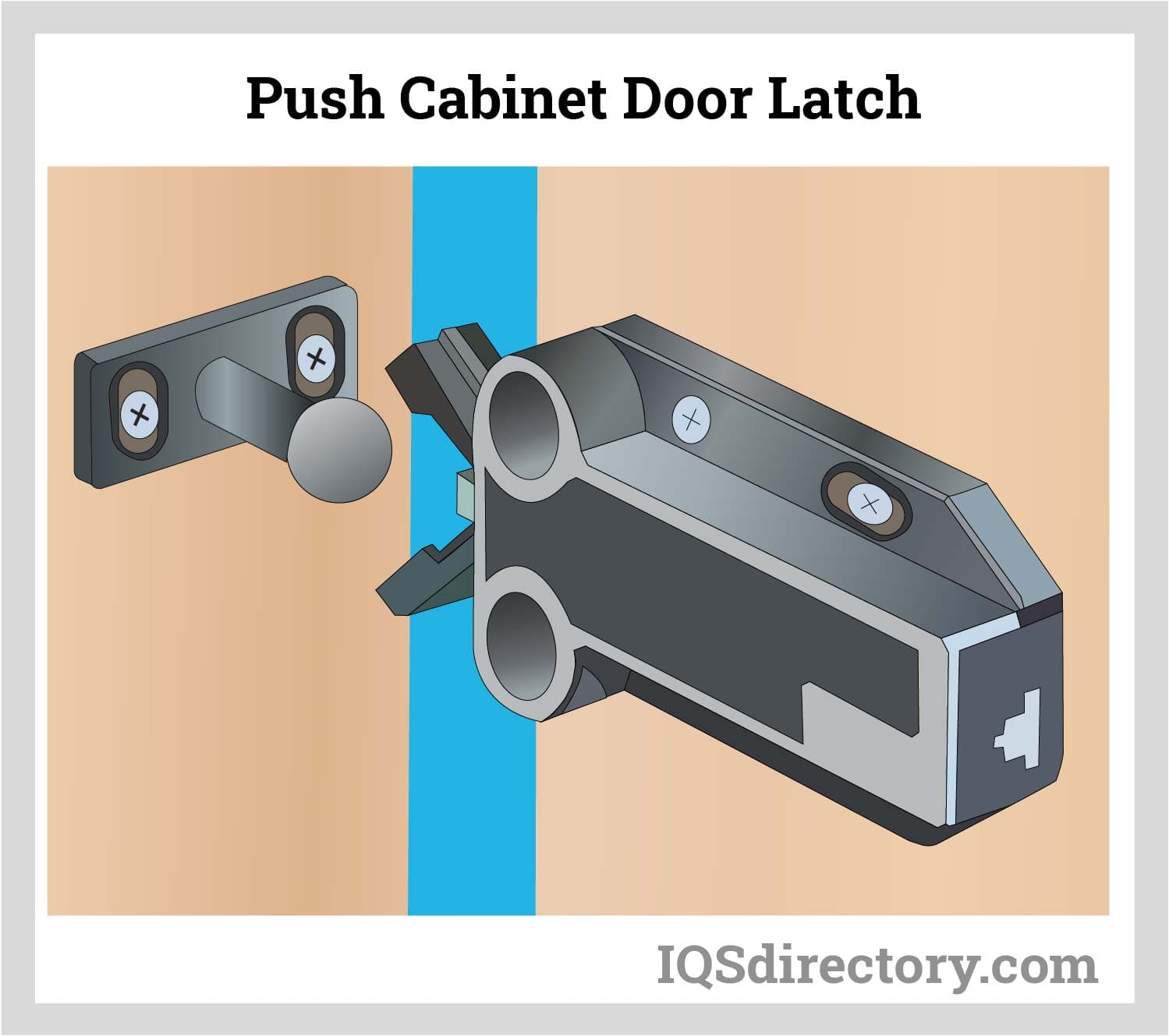

| Cam Lock | A simple rotating mechanism often used in cabinets and lockers. | Storage units, lockers, and cabinets. | Pros: Cost-effective; easy to install. Cons: Limited security; easily bypassed. |

| Mortise Lock | A complex lock installed within a pocket in the door, providing high security. | High-end residential and commercial properties. | Pros: Robust security; durable. Cons: More expensive; requires skilled installation. |

Pin Tumbler Lock

Pin tumbler locks are one of the most common types utilized in various applications, from office buildings to safes. They consist of a cylinder containing pins that must be aligned by a key for the lock to turn. When considering this lock type, B2B buyers should evaluate the security needs of their environment. While pin tumbler locks offer high security and can be easily rekeyed, they are not immune to picking or bumping, which may pose risks in high-security areas.

Deadbolt Lock

Deadbolt locks are known for their strength and resistance to forced entry, making them a popular choice for both residential and commercial doors. This lock type requires a key or a thumb turn to extend a solid bolt into the door frame, providing an additional layer of security. B2B buyers should consider the installation requirements, as deadbolts need to be precisely installed to function effectively. Although they offer superior security, they may be cumbersome to operate, especially in high-traffic areas.

Electronic Lock

Electronic locks utilize keypads or biometric scanners for access, eliminating the need for physical keys. This modern lock mechanism is commonly found in hotels, secure facilities, and data centers, providing convenience and enhanced security features like audit trails. B2B buyers should weigh the advantages of keyless entry against potential vulnerabilities, such as hacking risks and battery dependency. Regular maintenance and updates are essential to ensure security.

Cam Lock

Cam locks are simple mechanisms often used in cabinets and lockers. They feature a rotating arm that secures the door when turned. Their cost-effectiveness and ease of installation make them attractive for businesses requiring basic security solutions, such as storage units and lockers. However, buyers should be aware that cam locks provide limited security and can be easily bypassed, making them less suitable for high-security applications.

Mortise Lock

Mortise locks are installed within a pocket cut into the door, offering robust security for high-end residential and commercial properties. This complex locking mechanism is known for its durability and resistance to tampering. B2B buyers should consider the higher cost and the need for skilled installation when opting for mortise locks. While they provide excellent security, the initial investment and installation complexity may be a barrier for some businesses.

Related Video: 10 Mental Models Explained

Key Industrial Applications of lock mechanisms

| Industry/Sector | Specific Application of lock mechanisms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Secure access control to production areas | Enhances safety, prevents unauthorized access | Durability, compliance with industry standards, ease of integration |

| Logistics & Warehousing | Locking systems for shipping containers | Protects goods in transit, reduces theft risk | Weather resistance, compatibility with shipping protocols, ease of use |

| Healthcare | Lock mechanisms for medical storage cabinets | Ensures patient safety, secures sensitive materials | Compliance with health regulations, reliability, and ease of access for authorized personnel |

| Retail | Anti-theft locking systems for display cases | Reduces shrinkage, enhances customer trust | Aesthetic design, ease of operation, and integration with existing systems |

| Telecommunications | Locking solutions for server rooms | Protects sensitive equipment, prevents downtime | Robustness, fire resistance, and compatibility with existing infrastructure |

In the manufacturing sector, lock mechanisms are essential for securing access to production areas. These systems not only enhance safety by preventing unauthorized access but also ensure that sensitive equipment and proprietary processes are protected. International B2B buyers should prioritize durability and compliance with industry standards, as well as the ease of integration into existing security protocols.

For logistics and warehousing, locking systems for shipping containers are critical. They protect goods during transit, significantly reducing the risk of theft and loss. Buyers should consider weather resistance and compatibility with shipping protocols to ensure that the locks can withstand various environmental conditions while remaining user-friendly for logistics personnel.

In the healthcare industry, lock mechanisms are vital for securing medical storage cabinets. This application ensures patient safety and secures sensitive materials like medications and medical records. Compliance with health regulations is paramount, and buyers must look for reliable systems that allow for easy access by authorized personnel, ensuring that care is not compromised.

In the retail sector, anti-theft locking systems for display cases play a crucial role in reducing shrinkage and enhancing customer trust. Such mechanisms deter theft while providing an aesthetically pleasing solution that fits within the retail environment. Buyers should seek locks that are easy to operate and integrate seamlessly with existing security systems, maintaining both functionality and visual appeal.

Lastly, in telecommunications, locking solutions for server rooms are necessary to protect sensitive equipment and prevent downtime. These mechanisms must be robust and fire-resistant to ensure the safety of critical infrastructure. Buyers should focus on compatibility with existing infrastructure and the ability to withstand various environmental challenges, ensuring that their investments are secure and reliable.

Related Video: Locking Mechanisms Applicable to Connectors

Strategic Material Selection Guide for lock mechanisms

When selecting materials for lock mechanisms, it is essential to consider their performance, durability, and suitability for specific applications. Below is an analysis of four common materials used in lock mechanisms, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Steel

Key Properties: Steel is known for its high tensile strength and durability. It can withstand significant mechanical stress and is resistant to deformation. Additionally, it offers good resistance to wear and tear, making it suitable for high-traffic applications.

Pros & Cons: The main advantage of steel is its durability and strength, which make it ideal for heavy-duty locks. However, it is susceptible to corrosion if not properly treated or coated, which can limit its lifespan in humid or corrosive environments. The manufacturing complexity is moderate, and costs can vary based on the type of steel used.

Impact on Application: Steel locks are particularly effective in environments where physical security is paramount, such as in industrial settings. However, they may not be suitable for applications exposed to saltwater or extreme moisture without additional protective coatings.

Considerations for International Buyers: Buyers in regions like the Middle East and Africa should be aware of local corrosion resistance standards. Compliance with ASTM standards for steel grades can help ensure product reliability.

Brass

Key Properties: Brass is an alloy of copper and zinc, known for its excellent corrosion resistance and aesthetic appeal. It has a lower tensile strength compared to steel but offers good machinability.

Pros & Cons: Brass is favored for its resistance to tarnishing and corrosion, making it suitable for outdoor applications. Its aesthetic qualities make it popular in decorative locks. However, it is less durable under heavy mechanical stress compared to steel and can be more expensive due to its alloying elements.

Impact on Application: Brass is commonly used in residential locks and decorative hardware. Its compatibility with various environments, including coastal areas, makes it a popular choice for outdoor applications.

Considerations for International Buyers: Buyers should ensure compliance with local standards for brass alloys and consider the implications of using brass in specific climates, particularly in humid regions.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It is less dense than steel and brass, making it an attractive option for applications where weight is a concern.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs and ease installation. However, it has lower tensile strength compared to steel and may not be suitable for high-security applications. The manufacturing process can be complex, particularly for intricate designs.

Impact on Application: Aluminum is often used in applications where weight savings are critical, such as in portable locks or locks for vehicles. It is also suitable for environments that require corrosion resistance.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet international standards. Compliance with DIN standards for aluminum alloys can ensure quality and performance.

Polycarbonate

Key Properties: Polycarbonate is a high-performance plastic known for its impact resistance and lightweight properties. It can withstand a wide range of temperatures and is inherently resistant to UV radiation.

Pros & Cons: The key advantage of polycarbonate is its high impact resistance, making it suitable for applications where breakage is a concern. However, it is less durable than metal options and can be more susceptible to scratching. The cost is generally lower than metals, making it an economical choice.

Impact on Application: Polycarbonate is often used in applications where security is important but extreme durability is not as critical, such as in electronic locks or access control systems.

Considerations for International Buyers: Buyers should check for compliance with relevant safety standards for plastics in their region, especially in Europe, where strict regulations may apply.

| Material | Typical Use Case for lock mechanisms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty locks in industrial settings | High durability and strength | Susceptible to corrosion | Medium |

| Brass | Residential and decorative locks | Excellent corrosion resistance | Lower durability under stress | High |

| Aluminum | Portable locks and vehicle locks | Lightweight and corrosion-resistant | Lower tensile strength | Medium |

| Polycarbonate | Electronic locks and access control | High impact resistance | Less durable than metal options | Low |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing lock mechanisms. Understanding the properties and implications of each material can lead to better product performance and customer satisfaction.

In-depth Look: Manufacturing Processes and Quality Assurance for lock mechanisms

Manufacturing Processes for Lock Mechanisms

The manufacturing of lock mechanisms involves a series of critical stages, each integral to producing high-quality, reliable products. Understanding these stages will empower B2B buyers to make informed decisions when sourcing from international suppliers.

1. Material Preparation

The initial stage involves selecting and preparing materials suitable for lock mechanisms. Common materials include:

- Steel: Known for its strength and durability, often used for high-security locks.

- Brass: Offers corrosion resistance and is commonly used in traditional locks.

- Aluminum: Lightweight and resistant to corrosion, ideal for specific applications.

Material preparation includes processes like cutting, machining, and heat treatment to enhance properties such as hardness and toughness. Buyers should inquire about the source of materials and verify compliance with international standards to ensure quality.

2. Forming

Forming processes shape the prepared materials into components of the lock. Key techniques include:

- Casting: Suitable for complex shapes, where molten metal is poured into molds.

- Stamping: Involves cutting and shaping metal sheets using dies; efficient for mass production.

- Machining: Utilizes tools to remove material and create precise shapes; essential for high-tolerance components.

Each technique offers distinct advantages based on the design and performance requirements of the lock mechanism. Buyers should evaluate the supplier’s capabilities in these processes, particularly if custom solutions are needed.

3. Assembly

The assembly stage combines individual components into a functioning lock mechanism. This process can be manual or automated, depending on the complexity of the lock. Key considerations include:

- Precision: Ensuring components fit together correctly to prevent malfunction.

- Quality Control: Implementing checks during assembly to catch defects early.

B2B buyers should assess the assembly processes of potential suppliers, looking for facilities that employ skilled labor and advanced technology to enhance precision and efficiency.

4. Finishing

Finishing processes enhance the appearance and durability of lock mechanisms. Common techniques include:

- Plating: Applying a thin layer of metal to improve corrosion resistance and aesthetics.

- Coating: Using paints or powders for additional protection and design.

- Polishing: Ensuring surfaces are smooth to prevent wear and enhance visual appeal.

Buyers should request information on finishing options and processes to ensure they meet specific requirements for aesthetics and functionality.

Quality Assurance in Lock Mechanism Manufacturing

Quality assurance (QA) is paramount in lock mechanism manufacturing, ensuring that products meet rigorous standards and perform reliably over time.

International Standards

B2B buyers should be familiar with relevant international standards such as:

- ISO 9001: A widely recognized standard for quality management systems, ensuring consistent quality in manufacturing.

- CE Marking: Indicates compliance with European health, safety, and environmental protection standards, crucial for buyers in Europe.

- API (American Petroleum Institute) Standards: Important for locks used in oil and gas applications, ensuring safety and reliability.

Understanding these standards helps buyers evaluate suppliers’ commitment to quality.

Quality Control Checkpoints

Quality control encompasses various checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Monitoring production processes to detect and rectify issues in real-time.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before shipment.

Buyers should inquire about the specific QC protocols used by suppliers to ensure they maintain high standards throughout production.

Common Testing Methods

Testing methods are critical for verifying the quality and functionality of lock mechanisms. Common techniques include:

- Functional Testing: Ensuring locks operate as intended under various conditions.

- Durability Testing: Assessing resistance to wear and tear, including tests for corrosion and impact.

- Safety Testing: Evaluating locks against forced entry attempts to ensure security.

B2B buyers can request detailed testing reports and certifications to confirm the reliability of the locks they are sourcing.

Verifying Supplier Quality Control

To ensure that potential suppliers maintain rigorous quality control, B2B buyers should consider the following actions:

- Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing practices and adherence to quality standards.

- Request Documentation: Suppliers should provide quality assurance documentation, including certifications and test reports, to verify compliance with international standards.

- Engage Third-party Inspectors: Utilizing independent inspection services can offer an objective assessment of the supplier’s quality control processes and product integrity.

Navigating QC Nuances for International Buyers

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific nuances that can impact quality assurance:

- Cultural Differences: Understanding different manufacturing practices and quality expectations across regions can aid in effective communication with suppliers.

- Regulatory Compliance: Buyers must ensure that products meet local regulations and standards in their respective markets, which may differ from the supplier’s country.

- Supply Chain Risks: International logistics can introduce risks that affect quality, such as damage during transport. Buyers should discuss packaging and shipping methods with suppliers to mitigate these risks.

By comprehensively evaluating manufacturing processes and quality assurance practices, B2B buyers can establish strong partnerships with suppliers that prioritize quality and reliability in lock mechanisms. This proactive approach will not only ensure the integrity of the products sourced but also enhance the buyer’s reputation in their respective markets.

Related Video: Inspection and Quality control in Manufacturing

Comprehensive Cost and Pricing Analysis for lock mechanisms Sourcing

When sourcing lock mechanisms, understanding the cost structure and pricing dynamics is essential for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will delve into the various cost components, price influencers, and actionable insights that can help optimize purchasing decisions.

Cost Components

-

Materials: The primary cost driver in lock mechanisms is the raw materials used, which may include metals (such as steel or brass), plastics, and specialized components. Prices fluctuate based on global market conditions, availability, and quality specifications.

-

Labor: Labor costs vary significantly across regions. Countries with lower labor costs can offer competitive pricing, but the trade-off might be in quality or reliability. Understanding the labor landscape in the supplier’s location is crucial.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and other operational expenses. Efficient manufacturing processes can reduce overhead costs, affecting the final pricing.

-

Tooling: Custom tooling may be required for specific lock designs, impacting initial costs. The investment in tooling can be substantial, especially for unique or bespoke lock mechanisms.

-

Quality Control (QC): Implementing stringent QC processes is vital, particularly in security applications. QC costs can vary based on the level of certification required (e.g., ISO, ANSI).

-

Logistics: Shipping and handling costs significantly impact total expenses, especially for international buyers. Factors such as distance, shipping method, and Incoterms will influence logistics costs.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the typical markup in your industry can aid in negotiation.

Price Influencers

Several factors can influence the pricing of lock mechanisms:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in lower per-unit costs. Negotiating favorable terms for larger purchases can be advantageous.

-

Specifications/Customization: Custom designs or specific features can increase costs. Clearly defining specifications upfront can help manage expectations and costs.

-

Materials: The choice of materials directly impacts pricing. Premium materials or those requiring special treatments will elevate costs.

-

Quality/Certifications: Higher quality locks with certifications will generally command a premium price. Assessing the necessity of certifications based on the application can be a cost-saving strategy.

-

Supplier Factors: The supplier’s reputation, stability, and reliability play a role in pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can shift responsibilities and costs between the buyer and seller, impacting the total price.

Buyer Tips

-

Negotiate Wisely: Leverage your understanding of cost components and price influencers during negotiations. Be prepared to discuss volume discounts and payment terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as maintenance, replacement, and potential downtime costs associated with lower-quality products.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and taxes that can affect pricing. Engaging in forward contracts for currency exchange can mitigate risks.

-

Establish Strong Relationships: Building long-term relationships with suppliers can lead to better pricing and more favorable terms. Regular communication and feedback can enhance supplier performance and responsiveness.

-

Research Market Trends: Stay informed about market conditions, material costs, and emerging technologies that can impact pricing. This knowledge can provide leverage in negotiations.

Disclaimer

Prices can vary widely based on the specific requirements and market conditions. It is recommended to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential lock mechanisms Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘lock mechanisms’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for lock mechanisms

Key Technical Properties of Lock Mechanisms

Understanding the technical properties of lock mechanisms is crucial for international B2B buyers to ensure they select products that meet their specific needs. Here are some essential specifications:

-

Material Grade

The material used in lock mechanisms significantly impacts their durability and security. Common materials include stainless steel, brass, and zinc alloys. Stainless steel is preferred for its corrosion resistance, while brass offers a classic aesthetic and good machinability. When sourcing locks, consider the material grade to ensure it aligns with the environmental conditions and security requirements. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In lock mechanisms, tight tolerances are essential for ensuring proper fit and function. For instance, a lock with a tolerance of ±0.01 mm will fit more securely than one with a tolerance of ±0.1 mm. Accurate tolerances are critical for performance and longevity, particularly in high-security applications. -

Security Rating

Lock mechanisms often come with a security rating, which is a classification that indicates their resistance to unauthorized access or forced entry. Different regions have varying standards (e.g., ANSI/BHMA in the U.S. or EN 1303 in Europe). Buyers should assess security ratings to ensure compliance with local regulations and to meet their clients’ security expectations. -

Operational Cycle

This specification indicates how many times a lock can be used before failure occurs. A higher operational cycle rating (e.g., 100,000 cycles) indicates better durability, making it ideal for high-traffic areas. For businesses, understanding the operational cycle helps in selecting locks that will withstand daily use without frequent replacements. -

Fire and Weather Resistance

Some lock mechanisms are designed to withstand extreme conditions, such as high temperatures or moisture. Fire-rated locks are essential in buildings for safety compliance, while weather-resistant locks are vital for outdoor applications. B2B buyers should evaluate these properties based on the intended use environment to ensure longevity and reliability.

Illustrative Image (Source: Google Search)

Trade Terminology in Lock Mechanisms

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the lock industry, an OEM might create locks that are then sold under a different brand. Understanding OEM relationships can help buyers navigate supply chains and evaluate product quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It’s crucial for buyers to understand the MOQ to manage inventory costs effectively. Suppliers may set MOQs based on production costs, and negotiating these terms can lead to better pricing and flexibility. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It typically includes details like quantity, specifications, and delivery requirements. For international buyers, issuing RFQs can streamline the procurement process and ensure competitive pricing. -

Incoterms (International Commercial Terms)

These are pre-defined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps mitigate risks in international transactions. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the lock mechanism industry, lead times can vary significantly based on manufacturing processes and shipping logistics. Understanding lead times is essential for planning and inventory management, particularly in regions with longer shipping durations.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ensuring they select the right lock mechanisms for their needs while also negotiating effectively with suppliers.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the lock mechanisms Sector

Market Overview & Key Trends

The lock mechanisms sector is currently experiencing significant transformation driven by globalization, technological advancements, and evolving consumer preferences. Key market drivers include increasing security concerns, regulatory compliance in various industries, and the rise of smart locks that integrate with IoT (Internet of Things) technologies. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial.

Emerging B2B sourcing trends reflect a shift towards dual and multi-sourcing strategies to mitigate risks associated with single sourcing. This is particularly relevant post-pandemic, as companies reassess supply chain vulnerabilities. Buyers are encouraged to diversify their supplier base to enhance resilience and maintain flexibility. Additionally, the adoption of advanced manufacturing techniques, such as 3D printing and automation, is reshaping production processes, enabling customization, and reducing lead times.

Moreover, digital transformation is becoming a significant trend within the lock mechanisms industry. Buyers should be aware of tools such as e-procurement platforms that streamline sourcing and procurement processes. These innovations not only enhance efficiency but also provide access to a wider range of products and suppliers, fostering competitive pricing.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly critical in the lock mechanisms sector, influenced by global environmental concerns and consumer demand for responsible sourcing practices. B2B buyers must prioritize suppliers who demonstrate a commitment to environmentally friendly practices, such as using recycled materials and minimizing waste in production. The adoption of green certifications (e.g., ISO 14001, LEED) can serve as a benchmark for assessing suppliers’ sustainability efforts.

Ethical sourcing is equally important, encompassing fair labor practices and transparency in supply chains. Buyers should engage with suppliers that adhere to ethical standards, as this not only mitigates risk but also enhances brand reputation. Implementing supplier audits and engaging in collaborative initiatives can strengthen relationships and ensure compliance with ethical sourcing practices.

Furthermore, the demand for eco-friendly lock mechanisms is on the rise, with innovations in biodegradable materials and energy-efficient manufacturing processes. Buyers should seek out products that align with sustainability goals, as this can differentiate their offerings in competitive markets.

Brief Evolution/History

The lock mechanisms sector has evolved significantly from its origins in simple mechanical devices to sophisticated electronic systems. Early locks were primarily mechanical, utilizing intricate designs to ensure security. The introduction of electronic locks in the late 20th century marked a pivotal shift, enabling enhanced security features, such as keyless entry and remote access.

In recent years, the integration of IoT technology has revolutionized the industry, leading to the development of smart locks that offer convenience and advanced security features. This evolution reflects a broader trend towards digital solutions in the B2B landscape, emphasizing the importance of staying abreast of technological advancements to meet the demands of contemporary buyers.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of lock mechanisms

-

What should I consider when vetting suppliers for lock mechanisms?

When vetting suppliers, assess their industry reputation, experience, and compliance with international quality standards. Request references from previous clients and evaluate their financial stability. Additionally, consider their manufacturing capabilities, product range, and responsiveness to inquiries. It’s also beneficial to visit their facilities if possible, or request a virtual tour to ensure they meet your expectations in terms of technology and quality control processes. -

Can I customize lock mechanisms to meet specific requirements?

Yes, many manufacturers offer customization options for lock mechanisms. When discussing customization, clearly outline your specifications, including size, materials, and functionality. Ensure that the supplier has the capability to meet your design requirements and inquire about any associated costs or lead times for customized products. Collaborating closely during the design phase can help avoid miscommunications and ensure the final product meets your needs. -

What are the typical minimum order quantities (MOQs) and lead times for lock mechanisms?

Minimum order quantities can vary widely based on the manufacturer and the complexity of the lock mechanisms. Generally, MOQs may range from a few hundred to several thousand units. Lead times also depend on factors such as customization and production capacity, typically ranging from 4 to 12 weeks. It’s essential to communicate your needs upfront to negotiate favorable terms and ensure timely delivery aligned with your project schedules. -

What payment terms should I expect when sourcing lock mechanisms?

Payment terms will often vary by supplier, but common practices include a deposit upon order confirmation and the balance upon shipment. Some suppliers may offer letters of credit or payment upon delivery for larger orders. Be sure to clarify payment methods accepted, such as wire transfers or credit terms, and understand any potential fees. Establishing clear terms in a formal agreement helps mitigate risks related to payment disputes.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certification for lock mechanisms?

Request documentation of quality certifications, such as ISO 9001, from potential suppliers. Inquire about their quality control processes, including testing methods and inspection protocols. Consider conducting an independent quality audit or requesting samples for evaluation before placing a large order. Building a strong relationship with your supplier can also facilitate better communication regarding quality expectations and compliance with international standards. -

What logistics considerations should I keep in mind when sourcing lock mechanisms internationally?

Logistics is crucial when importing lock mechanisms. Assess the supplier’s shipping capabilities and experience with international logistics, including customs clearance. Discuss shipping methods, insurance options, and delivery timelines. Additionally, factor in potential tariffs and duties that may apply based on your country’s trade agreements. Partnering with a reliable freight forwarder can help streamline the process and mitigate potential delays. -

How can I resolve disputes with suppliers in international transactions?

To resolve disputes effectively, establish clear terms in your contract regarding dispute resolution, including preferred methods such as mediation or arbitration. Maintain open communication with the supplier to address issues promptly. If a dispute arises, document all communications and agreements to support your position. Involving a legal professional with expertise in international trade can also provide guidance on your rights and obligations. -

What are the trends affecting the lock mechanisms industry that I should be aware of?

Key trends include the increasing demand for smart locks and integrated security solutions, driven by advancements in technology. Sustainability is also gaining traction, with buyers increasingly favoring eco-friendly materials and manufacturing practices. Additionally, the rise of e-commerce is influencing supply chain dynamics, leading to shorter lead times and more flexible sourcing strategies. Staying informed about these trends can help you make strategic purchasing decisions that align with market demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for lock mechanisms

As international B2B buyers navigate the complex landscape of lock mechanisms, the importance of strategic sourcing cannot be overstated. Key takeaways from this guide emphasize the need for diversified sourcing strategies—balancing single, dual, and multi-sourcing approaches to mitigate risks and ensure supply chain resilience. Buyers should prioritize supplier relationships that foster collaboration, innovation, and long-term value, recognizing that post-pandemic dynamics have shifted the landscape towards increased supplier stickiness and reliability.

Actionable insights include leveraging technology for enhanced supplier visibility and adopting a proactive stance on compliance and quality assurance. Buyers from regions such as Africa, South America, the Middle East, and Europe should also consider regional trends and preferences, aligning their sourcing strategies accordingly to maximize local market opportunities.

Looking ahead, the demand for sophisticated lock mechanisms will continue to grow, driven by advancements in technology and evolving security needs. By embracing strategic sourcing and fostering strong supplier partnerships, international buyers can position themselves for success in an increasingly competitive marketplace. Take the next step—evaluate your sourcing strategies today to secure your supply chain for tomorrow.