Master Sourcing Strategies for Magnetic Latch: Boost

Introduction: Navigating the Global Market for magnetic latch

In an increasingly competitive global marketplace, the magnetic latch has emerged as a vital component across various industries. This innovative locking mechanism provides not only security but also convenience, making it ideal for applications ranging from cabinetry to industrial doors. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Brazil—understanding the nuances of magnetic latches is essential for making informed sourcing decisions.

This comprehensive guide delves into the diverse landscape of magnetic latches, covering their types, materials, and the critical aspects of manufacturing and quality control. Buyers will gain insights into the various suppliers available, alongside an analysis of cost factors that influence purchasing decisions. Furthermore, the guide addresses common FAQs and highlights market trends, empowering businesses to leverage the benefits of magnetic latches effectively.

By equipping buyers with detailed knowledge about magnetic latch solutions, this guide fosters strategic sourcing and enhances operational efficiency. It serves as a resource for navigating the complexities of product selection and supplier relationships, ultimately helping businesses enhance their product offerings while ensuring reliability and performance. Whether you are seeking to streamline your supply chain or innovate your product line, understanding magnetic latches is a critical step toward achieving your business objectives.

Understanding magnetic latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Magnetic Door Latch | Simple design; uses a magnet and a strike plate. | Cabinet doors, lightweight doors, furniture | Pros: Easy installation; cost-effective. Cons: Limited security for heavy doors. |

| Electromagnetic Lock | Operates on electrical power; high holding force. | Access control systems, secure entry points | Pros: High security; fail-safe operation. Cons: Requires power supply; higher initial cost. |

| Magnetic Catches | Compact; often used for soft-close mechanisms. | Kitchen cabinets, display cases | Pros: Enhances user experience; discreet. Cons: May not suit heavy-duty applications. |

| Concealed Magnetic Latch | Hidden installation; aesthetic appeal. | High-end furniture, modern cabinetry | Pros: Sleek design; space-saving. Cons: More complex installation; higher cost. |

| Compression Latch | Combines magnetic and mechanical features. | Industrial enclosures, outdoor equipment | Pros: Strong closure; versatile. Cons: Heavier; more expensive than standard latches. |

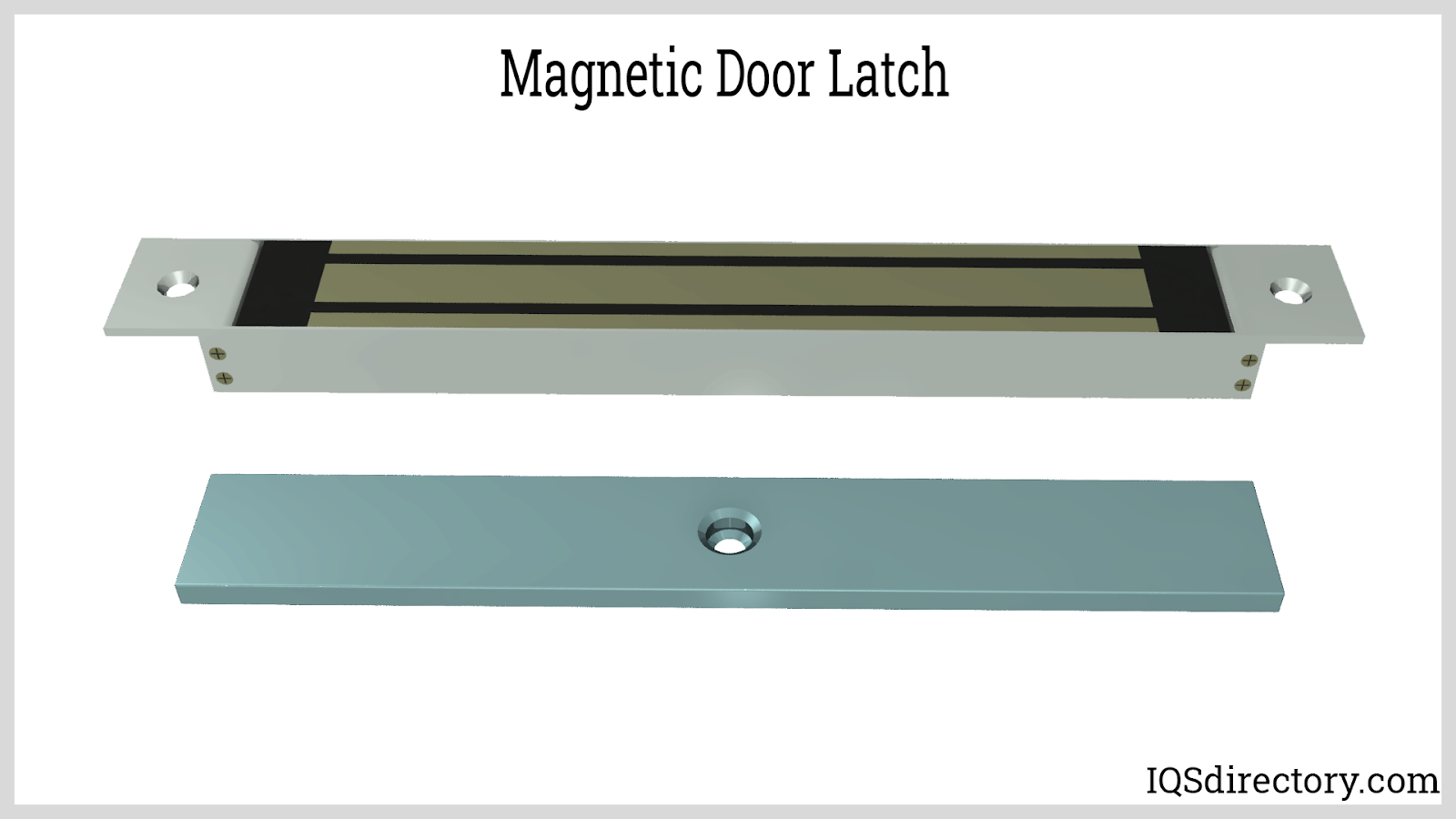

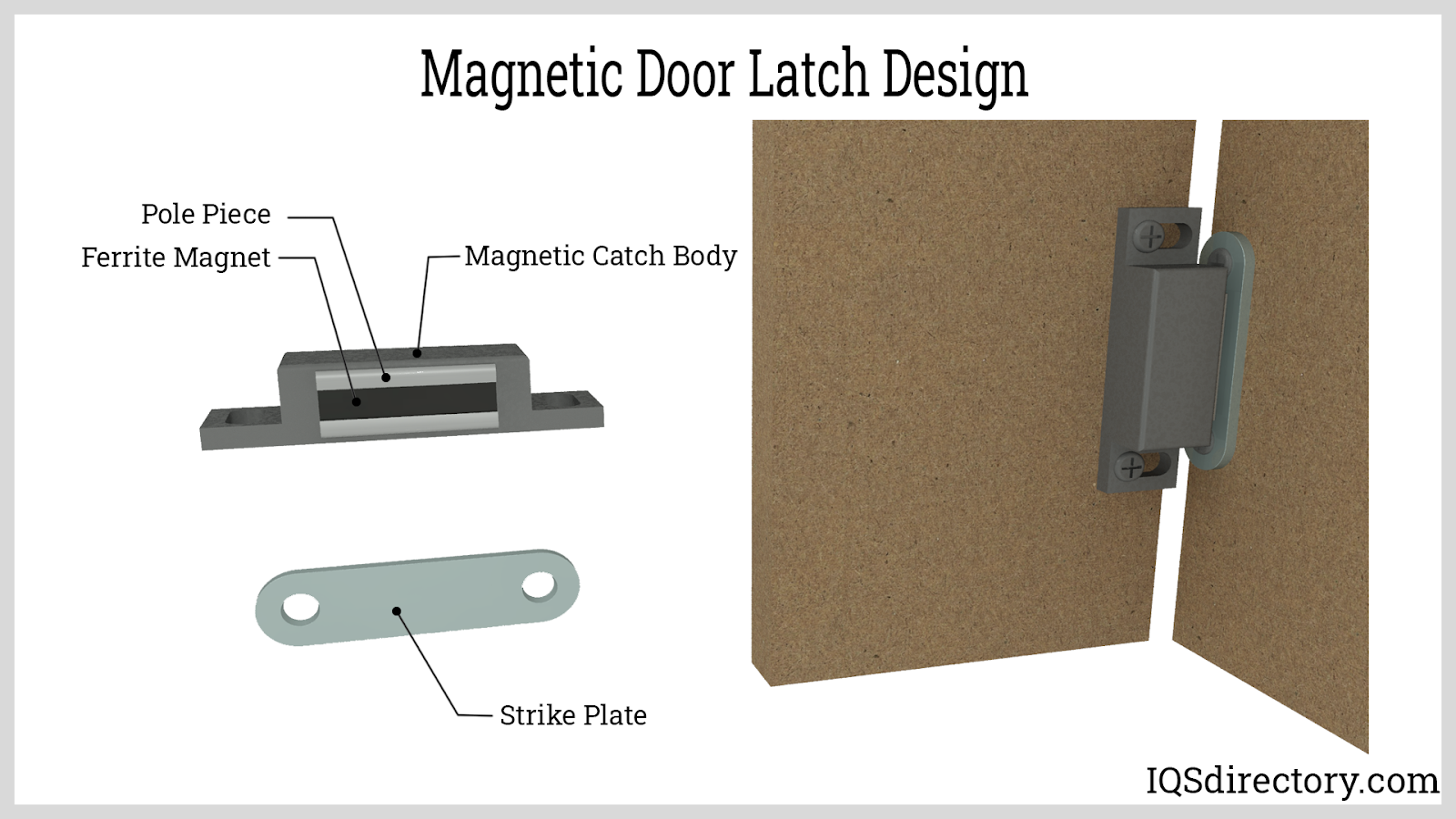

Magnetic Door Latch

Magnetic door latches are straightforward mechanisms that utilize a magnet paired with a strike plate to secure lightweight doors. They are particularly suitable for applications such as cabinet doors and furniture, where ease of use and installation are paramount. Buyers should consider the weight and frequency of use of the doors in question, as magnetic latches may not provide adequate security for heavier or high-traffic doors.

Electromagnetic Lock

Electromagnetic locks operate using electrical power to create a strong holding force, making them ideal for access control systems and secure entry points. They are favored in environments requiring high security, such as commercial buildings and facilities. While they offer fail-safe functionality and robust security, buyers must account for the need for a constant power supply and the higher initial investment compared to traditional locking mechanisms.

Illustrative Image (Source: Google Search)

Magnetic Catches

Magnetic catches are compact devices often used in soft-close applications, enhancing the user experience in kitchen cabinets and display cases. These latches are designed for light-duty use, providing a simple and effective way to keep doors closed. When purchasing, businesses should evaluate the weight of the doors and the potential for wear over time, as magnetic catches may not withstand frequent use in high-traffic areas.

Concealed Magnetic Latch

Concealed magnetic latches are installed within the door or frame, offering a sleek and modern appearance. They are particularly popular in high-end furniture and cabinetry where aesthetics are crucial. While they save space and provide a clean look, buyers should be aware that installation can be more complex, and the cost is generally higher than traditional latches. It’s essential to consider the design and materials of the furniture to ensure compatibility.

Compression Latch

Compression latches combine magnetic and mechanical elements, providing a strong closure suited for industrial applications and outdoor equipment. Their versatility allows them to accommodate a variety of door types and weights. However, buyers should note that while they offer robust performance, they tend to be heavier and more expensive than standard magnetic latches. Evaluating the specific application and environment will help determine if a compression latch is the right fit.

Related Video: What Makes Large Language Models Expensive?

Key Industrial Applications of magnetic latch

| Industry/Sector | Specific Application of Magnetic Latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Magnetic latches in vehicle doors and compartments | Enhanced security and ease of operation for vehicle access | Durability and resistance to environmental factors |

| Furniture | Magnetic latches for cabinets and drawers | Improved safety and functionality in home and office furniture | Aesthetic design and compatibility with various materials |

| Industrial Equipment | Magnetic latches in machinery enclosures | Secure access to machinery while preventing accidental openings | Load capacity and compliance with safety standards |

| Retail | Magnetic latches for display cases | Increased security for merchandise while allowing easy access | Customization options for branding and design |

| Healthcare | Magnetic latches in medical cabinets | Enhanced safety and hygiene in healthcare settings | Compliance with health regulations and ease of cleaning |

Automotive Applications

In the automotive industry, magnetic latches are increasingly utilized in vehicle doors and compartments. They provide a seamless and secure closure mechanism, significantly enhancing user experience by allowing for easy access while ensuring that doors remain firmly shut during transit. For international buyers, especially from regions with varying environmental conditions, sourcing magnetic latches that offer durability and resistance to factors like humidity and temperature fluctuations is crucial.

Furniture Applications

In the furniture sector, magnetic latches are commonly integrated into cabinets and drawers, providing a modern solution for secure closures. They prevent accidental openings and enhance the aesthetic appeal of furniture by eliminating visible hardware. Buyers should consider the design compatibility of magnetic latches with various materials and finishes, ensuring that the latches not only function effectively but also complement the overall design of the furniture.

Industrial Equipment Applications

Magnetic latches play a vital role in securing machinery enclosures in industrial settings. They ensure that access to machinery is controlled, preventing accidental openings that could lead to safety hazards. For B2B buyers, it is essential to assess the load capacity of magnetic latches and ensure compliance with industry safety standards. This is particularly important in regions with stringent regulations, as non-compliance can lead to significant liabilities.

Retail Applications

In the retail industry, magnetic latches are used in display cases to secure merchandise while allowing for easy access for staff. This dual functionality enhances security and improves customer interaction with products. Buyers should prioritize customization options for magnetic latches to align with branding efforts and store design, ensuring that the latches are not only functional but also visually appealing.

Healthcare Applications

Healthcare facilities utilize magnetic latches in medical cabinets to enhance safety and hygiene. These latches ensure that cabinets remain securely closed, reducing the risk of contamination while providing easy access for medical staff. Buyers in this sector must ensure that the magnetic latches comply with health regulations and are easy to clean, as maintaining hygiene is a critical concern in healthcare environments.

Related Video: Solenoid Fundamentals: Magnetic Latching Solenoids

Strategic Material Selection Guide for magnetic latch

When selecting materials for magnetic latches, international B2B buyers must consider various factors that influence performance, durability, and application suitability. Below is an analysis of four common materials used in magnetic latch manufacturing, along with their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 800°F (427°C) and offers good mechanical properties under pressure.

Pros & Cons:

Stainless steel is highly durable and resistant to wear and tear, making it ideal for high-traffic applications. However, its manufacturing complexity can lead to higher costs compared to other materials. Additionally, while it is resistant to corrosion, it may still require protective coatings in highly corrosive environments.

Impact on Application:

Stainless steel is suitable for environments exposed to moisture or chemicals, such as food processing and marine applications. Its compatibility with various media makes it a versatile choice for diverse industries.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. In regions like Europe, adherence to EN standards is crucial. Buyers in Africa and South America should consider local availability and import tariffs when sourcing.

2. Plastic (Polycarbonate or Nylon)

Key Properties:

Plastics like polycarbonate and nylon offer lightweight properties, good impact resistance, and moderate temperature ratings (typically around 180°F or 82°C). They are also resistant to many chemicals.

Pros & Cons:

The primary advantage of plastic is its low cost and ease of manufacturing, which allows for intricate designs. However, plastics may not offer the same strength or durability as metals, making them less suitable for heavy-duty applications.

Impact on Application:

Plastic magnetic latches are ideal for lightweight applications, such as in cabinetry or electronic devices. Their resistance to corrosion makes them suitable for environments where metal latches might corrode.

Considerations for International Buyers:

Buyers should consider local regulations regarding plastic materials, especially in Europe, where there are stringent environmental directives. Compliance with standards such as RoHS (Restriction of Hazardous Substances) is essential.

3. Zinc Alloy

Key Properties:

Zinc alloys provide good corrosion resistance and moderate strength, with temperature ratings typically around 300°F (149°C). They are often used for die-casting, allowing for complex shapes.

Pros & Cons:

Zinc alloys are cost-effective and can be easily molded into various shapes, making them suitable for high-volume production. However, they may not be as durable as stainless steel and can suffer from corrosion in harsh environments.

Impact on Application:

These alloys are commonly used in indoor applications where aesthetic appeal and moderate strength are required, such as in furniture and decorative hardware.

Considerations for International Buyers:

Buyers should ensure that zinc alloys meet local compliance standards, such as ASTM B86 in the U.S. or EN 12844 in Europe. Awareness of local corrosion resistance standards is also crucial, particularly in humid or coastal regions.

4. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has a temperature rating of up to 400°F (204°C). It offers a good strength-to-weight ratio and is easily machinable.

Pros & Cons:

Aluminum is highly versatile and cost-effective for various applications. However, it may not provide the same strength as stainless steel, making it less suitable for heavy-duty applications.

Impact on Application:

Aluminum magnetic latches are ideal for applications requiring lightweight solutions, such as in automotive or aerospace industries. Its corrosion resistance makes it suitable for outdoor applications.

Considerations for International Buyers:

International buyers should be aware of the aluminum grades and standards applicable in their regions. Compliance with standards such as ASTM B221 for extruded aluminum products is vital, especially in Europe and the Middle East.

| Material | Typical Use Case for Magnetic Latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty applications | Excellent durability and corrosion resistance | Higher cost and manufacturing complexity | High |

| Plastic | Lightweight applications | Low cost and easy to manufacture | Lower strength and durability | Low |

| Zinc Alloy | Indoor decorative hardware | Cost-effective and easily molded | Susceptible to corrosion in harsh environments | Medium |

| Aluminum | Automotive and aerospace | Lightweight and versatile | Lower strength compared to steel | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for magnetic latch

Manufacturing magnetic latches involves a series of well-defined processes that ensure high-quality output suitable for various applications, from light-duty domestic uses to heavy industrial requirements. Understanding these processes and the quality assurance measures in place is crucial for international B2B buyers looking to procure reliable latch solutions.

Manufacturing Processes

1. Material Preparation

The manufacturing of magnetic latches begins with the selection of appropriate materials. Common materials include:

- Plastics: Used for lightweight applications, offering corrosion resistance and ease of molding.

- Metals: Typically stainless steel or aluminum, chosen for their durability and strength.

- Magnets: Neodymium or ferrite magnets are often used due to their excellent magnetic properties.

Material preparation involves sourcing high-quality raw materials that meet industry specifications. Suppliers should provide documentation regarding the material properties, ensuring they meet relevant international standards.

2. Forming

Once materials are prepared, the next stage is forming. This can involve various techniques, such as:

- Injection Molding: Used primarily for plastic components, allowing for complex shapes and high-volume production.

- Stamping: Metal parts are created by stamping sheets, ensuring precise dimensions and reducing waste.

- Machining: This technique is used for both metal and plastic parts, where precise cuts are made to achieve the desired shape.

Each forming method has its advantages, and manufacturers often choose based on the specific requirements of the latch design.

3. Assembly

The assembly process is crucial for ensuring the magnetic latch functions correctly. This stage typically involves:

- Combining Components: Magnets are attached to their respective plates or casings, ensuring a secure fit.

- Alignment Checks: Proper alignment is essential for the latch to operate effectively. This may involve using jigs and fixtures during assembly.

- Adhesive Application: Some designs may require adhesives to bond components, necessitating precise application to avoid excess that could impair functionality.

Effective assembly practices can significantly influence the durability and performance of the final product.

4. Finishing

The finishing process enhances the appearance and longevity of magnetic latches. This includes:

- Surface Treatment: Processes such as anodizing for aluminum or plating for steel improve corrosion resistance and aesthetic appeal.

- Painting or Coating: Protective coatings may be applied to prevent wear and enhance the product’s durability.

- Quality Inspection: Before packaging, latches undergo visual and functional inspections to ensure they meet quality standards.

Quality Assurance (QA)

Quality assurance is critical in the manufacturing of magnetic latches, ensuring that products meet both customer expectations and regulatory standards.

International Standards

Internationally recognized quality standards such as ISO 9001 are crucial for manufacturers. Compliance with ISO 9001 signifies a commitment to quality management principles, including:

- Customer focus

- Leadership

- Engagement of people

- Process approach

- Improvement

- Evidence-based decision making

- Relationship management

In addition to ISO certifications, industry-specific standards may apply, such as CE marking in Europe or API standards for industrial applications.

Quality Control Checkpoints

Quality control is integrated throughout the manufacturing process, with checkpoints established at various stages:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during manufacturing help catch defects early. This may include dimensional checks and functional tests.

- Final Quality Control (FQC): A thorough inspection is conducted before products are packaged. This includes testing the magnetic strength and operational functionality of latches.

Common Testing Methods

Testing methods employed during quality assurance include:

- Magnetic Force Testing: Measuring the holding strength of the latch to ensure it meets specified performance criteria.

- Durability Testing: Subjecting latches to repeated use scenarios to assess wear and tear over time.

- Environmental Testing: Evaluating how latches perform under various environmental conditions, such as humidity and temperature extremes.

Verification of Supplier Quality Control

For B2B buyers, verifying the quality control measures of potential suppliers is essential. Here are actionable steps to consider:

- Supplier Audits: Conducting audits of suppliers can provide insights into their manufacturing processes and quality control measures. Look for compliance with ISO standards and other relevant certifications.

- Quality Reports: Requesting detailed reports on quality control processes and outcomes can help assess a supplier’s reliability. This may include data on defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality assurance practices. This is particularly useful for buyers in regions where direct oversight is challenging.

QC and Certification Nuances for International Buyers

When sourcing magnetic latches from different regions, it’s vital to understand the specific quality certification requirements that may vary by country. For instance:

- Europe: CE marking is often required, indicating compliance with European health, safety, and environmental protection standards.

- Africa and South America: Local certifications may be less standardized, but buyers should ensure suppliers meet basic quality expectations and safety standards relevant to their markets.

- Middle East: Compliance with GCC standards may be necessary, depending on the product application.

By understanding these nuances, B2B buyers can navigate the complexities of international procurement more effectively, ensuring they choose suppliers capable of delivering high-quality magnetic latches that meet their specific needs.

Related Video: The Production Planning Process

Comprehensive Cost and Pricing Analysis for magnetic latch Sourcing

Understanding Cost Structure in Magnetic Latch Sourcing

When sourcing magnetic latches, international B2B buyers should be aware of the various cost components that contribute to the final pricing. The primary cost elements include:

-

Materials: The choice of materials significantly impacts cost. High-quality magnets, metal casings, and durable plastics are common in magnetic latches. For instance, stainless steel latches may command a premium due to their corrosion resistance and durability.

-

Labor: Labor costs vary depending on the manufacturing location. Regions with higher labor costs, such as parts of Europe, may lead to higher overall product prices compared to countries in Africa or South America, where labor may be more affordable.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs, impacting the final price.

-

Tooling: Custom tooling for specialized latch designs can be a significant upfront cost. Buyers should consider whether the investment in custom tooling justifies the potential savings in unit costs over larger production runs.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability but adds to the cost. Buyers should evaluate the balance between cost and quality assurance to avoid future expenses related to product failures.

-

Logistics: Shipping and handling costs are essential in the total cost calculation. Factors such as distance, shipping methods, and customs duties can significantly influence logistics expenses.

-

Margin: Supplier profit margins can vary widely. Understanding the supplier’s pricing strategy can help buyers negotiate better deals.

Influencers of Magnetic Latch Pricing

Several factors influence the pricing of magnetic latches, which buyers should consider when negotiating:

-

Volume/MOQ: Purchasing in bulk often leads to lower prices per unit. Understanding the supplier’s minimum order quantity (MOQ) can help in planning orders to optimize costs.

-

Specifications and Customization: Customized designs or specifications typically incur additional costs. Buyers should assess the necessity of these customizations against their budget and requirements.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but often enhance product reliability and safety, which can be crucial in certain applications.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can affect pricing. Established suppliers may offer better warranties and support but may also have higher prices.

-

Incoterms: Understanding the agreed Incoterms can clarify who bears the risk and costs during transportation. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost.

Buyer Tips for Cost-Efficiency

To maximize cost-efficiency when sourcing magnetic latches, buyers should consider the following tips:

-

Negotiate: Always engage in negotiations with suppliers. Presenting competitive quotes from other manufacturers can leverage better pricing.

-

Total Cost of Ownership (TCO): Look beyond the purchase price. Assess long-term costs, including maintenance, replacement, and potential downtime due to failures.

-

Understand Pricing Nuances: International buyers should be aware of regional pricing differences. For instance, European suppliers may have higher prices due to labor and regulatory standards, whereas suppliers in Africa or South America may offer more competitive rates.

-

Evaluate Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing, priority service, and more favorable payment terms.

Disclaimer

Prices for magnetic latches can vary widely based on the factors outlined above. The information provided here serves as a guideline, and actual costs may differ based on market conditions, supplier negotiations, and specific buyer requirements. Always seek multiple quotes and conduct thorough due diligence when sourcing products.

Spotlight on Potential magnetic latch Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘magnetic latch’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for magnetic latch

Key Technical Properties of Magnetic Latches

Understanding the critical specifications of magnetic latches is essential for B2B buyers, particularly when selecting the right product for specific applications. Here are some key technical properties:

-

Material Grade

– Magnetic latches are typically made from various materials, including stainless steel, plastic, and aluminum. The material affects durability, corrosion resistance, and weight. For instance, stainless steel is often preferred for outdoor applications due to its strength and resistance to rust, while plastic may be suitable for lightweight, indoor use. Selecting the right material ensures longevity and reliability. -

Holding Force

– This specification indicates the maximum weight that the latch can securely hold when closed. Holding forces can vary significantly, ranging from 5 lbs for lightweight applications to over 3,000 lbs for heavy-duty industrial uses. Understanding the necessary holding force is crucial for ensuring that the latch meets safety and operational requirements. -

Tolerance

– Tolerance refers to the permissible limit of variation in a physical dimension of the latch components. High tolerance levels are vital for ensuring that parts fit correctly and function seamlessly in their intended applications. For B2B buyers, knowing the tolerance can prevent issues related to installation and performance, especially in precision applications. -

Operational Temperature Range

– Magnetic latches can be affected by temperature extremes. The operational temperature range defines the limits within which the latch will function effectively without degradation. Buyers should consider this property, especially in regions with extreme climates or in applications that involve temperature fluctuations. -

Mounting Style

– Magnetic latches can be surface-mounted or concealed. The choice between these styles depends on aesthetic preferences and functional requirements. Surface-mounted latches are easier to install and replace, while concealed latches provide a cleaner look. Understanding the mounting style is important for integration into existing designs. -

Electromagnetic Specifications

– For electromagnetic latches, specifications such as voltage and current ratings are crucial. These latches operate using electrical power, and their performance can be affected by the electrical supply. Buyers must ensure compatibility with existing systems to avoid operational issues.

Illustrative Image (Source: Google Search)

Common Trade Terminology

Navigating the trade terminology associated with magnetic latches can enhance communication and procurement efficiency. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– OEMs are companies that produce parts or equipment that may be marketed by another manufacturer. In the context of magnetic latches, working with OEMs can ensure high-quality components that meet specific industry standards. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to plan their purchasing strategy, especially when trying to manage inventory costs effectively. -

RFQ (Request for Quote)

– An RFQ is a document sent to suppliers to solicit pricing and terms for specific products. For buyers, submitting an RFQ for magnetic latches enables them to compare costs, specifications, and delivery times, facilitating better purchasing decisions. -

Incoterms

– International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms can help buyers understand shipping, insurance, and delivery obligations, ensuring smoother transactions. -

Lead Time

– Lead time is the amount of time from placing an order to the delivery of the product. Buyers should consider lead times when planning projects, as delays can impact schedules and operational efficiency. -

Certification Standards

– Many industries require products to meet specific certification standards, such as ISO or ANSI. Understanding these standards is vital for ensuring that the magnetic latches meet safety and quality regulations relevant to the buyer’s industry.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the magnetic latch Sector

Market Overview & Key Trends

The global magnetic latch market is currently witnessing robust growth, driven by increasing demand across various sectors such as automotive, construction, and consumer goods. Key trends influencing this market include the rising emphasis on automation and security in commercial settings, particularly in regions like Europe and the Middle East. In Africa and South America, infrastructure development projects are propelling the need for efficient and reliable closure mechanisms, thereby boosting the demand for magnetic latches.

Additionally, the integration of smart technologies is reshaping sourcing trends. Innovations such as electromagnetic locks with advanced access control systems are becoming increasingly popular. This trend is particularly relevant for B2B buyers looking to enhance security solutions in commercial environments. Moreover, sustainability is emerging as a significant factor in purchasing decisions, with buyers favoring suppliers that demonstrate commitment to eco-friendly practices and products.

International buyers are also increasingly looking for suppliers who can provide customized solutions tailored to specific industry needs. This is especially pertinent in regions like Germany, where precision engineering is highly valued. As the market matures, partnerships between manufacturers and buyers will be crucial in navigating these dynamics, ensuring that products meet both performance and sustainability criteria.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of procurement strategies in the magnetic latch sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. B2B buyers are increasingly prioritizing suppliers who employ sustainable practices, such as using recycled materials and minimizing carbon footprints.

Ethical sourcing also plays a critical role. Companies are expected to maintain transparency in their supply chains, ensuring that materials are sourced responsibly without compromising environmental integrity. Certifications like ISO 14001 for environmental management and the use of eco-labels can help buyers identify suppliers committed to sustainability.

In the magnetic latch market, the use of “green” materials—such as biodegradable plastics or sustainably sourced metals—can enhance a company’s reputation and appeal to environmentally conscious consumers. Buyers are encouraged to engage with suppliers who are willing to provide detailed information about their sourcing practices and environmental certifications, as this can influence purchasing decisions and foster long-term partnerships.

Brief Evolution/History

The evolution of magnetic latches dates back to the early 20th century when their application was primarily limited to simple household items. Over the decades, advancements in magnetic technology and materials science have led to the development of more sophisticated latching mechanisms suitable for diverse industrial applications.

The introduction of electromagnetic locks in the latter half of the century marked a significant milestone, allowing for enhanced security features in commercial settings. Today, magnetic latches are integral to various sectors, reflecting a shift toward innovative and efficient closure solutions that meet modern demands for security and sustainability. As manufacturers continue to innovate, the future of magnetic latches promises further enhancements in functionality and eco-friendliness, aligning with the evolving needs of B2B buyers globally.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of magnetic latch

-

What key factors should I consider when vetting suppliers for magnetic latches?

When vetting suppliers for magnetic latches, prioritize their industry experience, product range, and customer reviews. Evaluate their manufacturing capabilities to ensure they can meet your specific needs, such as customization options. Verify certifications that demonstrate compliance with international standards, particularly if you are sourcing from different regions. Finally, assess their communication responsiveness and customer service, as these factors are vital for ongoing partnerships and support. -

Can I customize magnetic latches to suit my specific application?

Yes, many manufacturers offer customization options for magnetic latches. This can include modifications in size, strength, materials, and design features to meet particular application requirements. When discussing customization, provide detailed specifications and discuss your application environment to ensure the manufacturer can deliver a solution that aligns with your needs. Always request samples to evaluate the custom product before making large orders. -

What are typical minimum order quantities (MOQ) and lead times for magnetic latches?

Minimum order quantities for magnetic latches can vary significantly between suppliers, often ranging from 100 to 1,000 units depending on the manufacturer and product specifications. Lead times typically range from 2 to 12 weeks, influenced by factors such as customization complexity and current production schedules. When planning your purchase, factor in these timelines to avoid disruptions in your supply chain, especially in regions with longer shipping routes. -

What payment terms are common for international purchases of magnetic latches?

Payment terms for international purchases can vary widely; however, options such as letter of credit, advance payment, or staggered payments upon shipment are common. It’s essential to clarify payment terms upfront to avoid misunderstandings. Additionally, consider using escrow services for high-value transactions to mitigate risks. Ensure that the payment method aligns with your financial policies and offers sufficient protection against potential disputes. -

What quality assurance measures should I look for in magnetic latch suppliers?

Look for suppliers that implement robust quality assurance (QA) processes, including ISO certifications, regular product testing, and adherence to international standards. Inquire about their QA protocols, such as material inspections, production monitoring, and final product testing. Request documentation of certifications and quality control processes to ensure that the latches meet your performance and safety requirements. -

How can I handle logistics and shipping when sourcing magnetic latches internationally?

Effective logistics management is crucial when sourcing magnetic latches internationally. Collaborate with your supplier to understand their shipping options and costs. Utilize a reliable freight forwarder experienced in handling international shipments to navigate customs regulations and ensure timely delivery. Additionally, consider the total landed cost, including tariffs, taxes, and shipping fees, to make informed purchasing decisions. -

What should I do if there is a dispute with my magnetic latch supplier?

In case of a dispute, maintain open communication with the supplier to resolve issues amicably. Document all correspondence and agreements to support your position. If the issue cannot be resolved directly, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration. Engaging a legal advisor familiar with international trade laws may also be necessary to protect your interests. -

Are there specific certifications I should request for magnetic latches?

Yes, depending on your application, you may require certain certifications for magnetic latches. Common certifications include ISO 9001 for quality management, CE marking for compliance with European safety standards, and RoHS for restriction of hazardous substances. If the latches will be used in specific industries, such as food processing or pharmaceuticals, additional certifications like FDA approval may be necessary. Always clarify these requirements during supplier negotiations to ensure compliance with local regulations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for magnetic latch

In conclusion, the strategic sourcing of magnetic latches presents a myriad of opportunities for international B2B buyers across Africa, South America, the Middle East, and Europe. Key takeaways include the importance of understanding the specific applications and benefits of various magnetic latch designs, as well as the value of selecting suppliers who offer customization options tailored to industry needs.

By leveraging strategic sourcing practices, businesses can enhance operational efficiency, reduce costs, and ensure the reliability of their closure systems. Investing in high-quality magnetic latches not only ensures durability but also promotes safety and user satisfaction in diverse environments, from industrial applications to residential settings.

As the global market continues to evolve, buyers should remain vigilant about emerging trends and technological advancements in magnetic latch solutions. Engaging with reputable manufacturers who provide comprehensive technical support and innovative designs will be essential for maintaining a competitive edge.

Now is the time for international buyers to explore partnerships with leading manufacturers and capitalize on the advantages of magnetic latch technology. Act now to secure the best solutions for your business needs and stay ahead in this dynamic market landscape.