Master Sourcing Strategies for Metal Burn Barrels in Global

Introduction: Navigating the Global Market for metal burn barrels

Navigating the global market for metal burn barrels presents a unique opportunity for international B2B buyers seeking efficient waste management solutions. Metal burn barrels are increasingly recognized as effective tools for the safe incineration of combustible waste, particularly in regions where traditional waste disposal services may be limited or impractical. Their design not only promotes environmental compliance but also aligns with growing global standards aimed at reducing landfill usage and minimizing ecological footprints.

This comprehensive guide delves into essential aspects of metal burn barrels, covering various types and materials, manufacturing processes, and quality control standards. It also highlights key suppliers and provides insights into cost structures and market dynamics across different regions, including Africa, South America, the Middle East, and Europe. By addressing frequently asked questions, this resource empowers buyers to make informed sourcing decisions tailored to their specific needs.

With the evolving regulatory landscape and increasing demand for eco-friendly waste disposal options, understanding the nuances of the burn barrel market is crucial. This guide will equip buyers with actionable insights, enabling them to navigate the complexities of selecting the right burn barrel solutions that meet both operational requirements and compliance standards. Whether you are in Saudi Arabia, Egypt, or elsewhere, this guide serves as a valuable tool for optimizing your waste management strategy and enhancing operational efficiency.

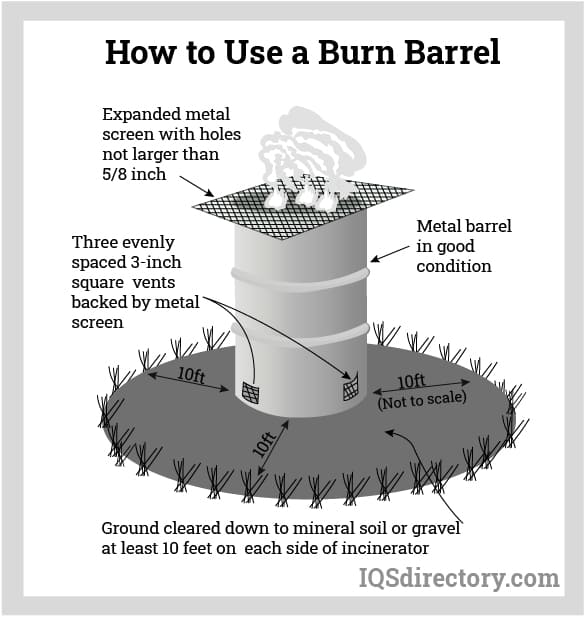

Illustrative Image (Source: Google Search)

Understanding metal burn barrels Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 55-Gallon Drum | Traditionally used, versatile, and readily available. | Waste disposal in rural areas | Pros: Cost-effective, widely accessible. Cons: May not meet all local regulations. |

| Yard Waste Burn Barrel | Designed for yard debris; often includes a lid for safety. | Landscaping, agricultural waste disposal | Pros: Reduces fire risk, controls emissions. Cons: Requires local permits and regulations adherence. |

| Industrial Burn Barrel | Heavier gauge metal, designed for more robust applications. | Manufacturing, construction waste | Pros: Durable, suitable for larger waste volumes. Cons: Higher initial cost, may need specialized handling. |

| Portable Burn Barrel | Smaller, lightweight design for easy transport and use. | Remote locations, outdoor events | Pros: Convenient, easy to set up. Cons: Limited capacity, may require frequent emptying. |

| Eco-Friendly Burn Barrel | Features emission control technology; designed for compliance. | Eco-conscious businesses, urban areas | Pros: Minimizes environmental impact, compliant with regulations. Cons: Higher upfront costs, specialized maintenance. |

Standard 55-Gallon Drum

The standard 55-gallon drum is the most common type of burn barrel, recognized for its versatility and availability. Typically repurposed from industrial applications, these drums are effective for incinerating various combustible waste types. However, B2B buyers must ensure compliance with local regulations, as some areas restrict open burning. This option is particularly suitable for rural businesses lacking formal waste disposal services but may not be ideal for urban settings due to stricter environmental laws.

Yard Waste Burn Barrel

Yard waste burn barrels are specifically designed for incinerating organic materials such as leaves, branches, and grass clippings. Equipped with a lid, these barrels control smoke and embers, reducing fire hazards. Businesses in landscaping or agriculture can benefit significantly from these barrels, but they must secure necessary permits and adhere to local regulations. Proper use can enhance waste management practices while minimizing environmental impact, making them a preferred choice for eco-conscious operations.

Industrial Burn Barrel

Industrial burn barrels are constructed from heavier gauge metal, making them suitable for the disposal of larger volumes of waste generated in manufacturing or construction. These barrels are designed to withstand intense heat and frequent use, appealing to businesses with substantial waste management needs. However, their higher cost may deter smaller enterprises. Buyers should consider their specific waste disposal requirements and local regulations to determine if this robust option aligns with their operational needs.

Portable Burn Barrel

Portable burn barrels are smaller and lighter, designed for easy transport to remote locations or outdoor events. They offer convenience for businesses that require temporary waste disposal solutions, such as at construction sites or festivals. While their mobility is a significant advantage, they have a limited capacity and may require more frequent emptying, which can be a drawback for larger operations. B2B buyers should evaluate their waste generation rates to determine if this type meets their needs.

Eco-Friendly Burn Barrel

Eco-friendly burn barrels incorporate advanced emission control technologies to minimize environmental impact and ensure compliance with stringent regulations. These barrels are ideal for businesses prioritizing sustainability and social responsibility. Although the initial investment is higher, the long-term benefits include reduced environmental footprint and potential savings on regulatory fines. B2B buyers in urban areas or eco-conscious industries should consider these barrels as part of their waste management strategy to align with green initiatives.

Related Video: How to Make a Burn Barrel and a Lid + Easy Tips and Tricks

Key Industrial Applications of metal burn barrels

| Industry/Sector | Specific Application of metal burn barrels | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Incineration of agricultural waste (e.g., crop residues) | Reduces waste volume, promotes soil health | Ensure compliance with local environmental regulations and permits. |

| Construction | Disposal of construction debris (e.g., wood scraps, paper) | Streamlines waste management, reduces landfill use | Sourcing barrels with secure lids to minimize fire hazards on-site. |

| Manufacturing | Safe disposal of hazardous materials (e.g., treated wood) | Ensures compliance with safety standards | Verify material specifications to handle specific waste types. |

| Municipal Services | Controlled burning of municipal waste in rural areas | Efficient waste disposal, reduces transportation costs | Assess local regulations regarding waste incineration methods. |

| Forestry | Disposal of biomass and forest debris | Minimizes wildfire risks, promotes land management | Select barrels designed for high-temperature applications. |

Agriculture

In the agricultural sector, metal burn barrels are commonly utilized for incinerating crop residues and other organic waste. This method effectively reduces waste volume, thereby promoting healthier soil conditions through the recycling of nutrients. Buyers in this industry should ensure that their burn barrels comply with local environmental regulations, particularly concerning air quality standards. Additionally, they must secure the necessary permits for burning activities, which can vary significantly across regions in Africa, South America, the Middle East, and Europe.

Construction

The construction industry often generates significant amounts of debris, including untreated wood, paper, and other combustible materials. Metal burn barrels provide a practical solution for disposing of this waste on-site, streamlining waste management processes and reducing the need for transportation to landfills. When sourcing burn barrels for construction use, buyers should prioritize models with secure lids to minimize fire hazards and ensure compliance with local safety regulations. Understanding the specific requirements of each project can help in selecting the appropriate barrel size and type.

Manufacturing

In manufacturing, especially where hazardous materials are involved, metal burn barrels serve as a safe method for the disposal of waste like treated wood and other potentially harmful substances. This application is crucial for ensuring compliance with safety and environmental standards. Buyers must verify that the burn barrels are constructed from materials capable of withstanding the specific types of waste they will handle. Additionally, understanding local regulations regarding the incineration of hazardous materials is essential for international B2B buyers, particularly in regions with stringent environmental laws.

Municipal Services

In rural areas, municipal services can leverage metal burn barrels for the controlled burning of municipal waste. This approach allows for efficient waste disposal without the need for extensive transportation, which can be costly. It is essential for municipal buyers to assess local regulations regarding waste incineration methods to ensure compliance and safety. Sourcing barrels that are designed for durability and ease of use will also enhance operational efficiency in waste management practices.

Forestry

Forestry operations often produce substantial biomass and debris that require efficient disposal methods to minimize wildfire risks. Metal burn barrels are an effective tool for this purpose, allowing for the safe incineration of excess materials. Buyers in the forestry sector should select burn barrels designed to withstand high temperatures and ensure that they comply with local environmental regulations regarding burning practices. Understanding the specific needs of their operations will help in choosing the right type of burn barrel for effective waste management.

Related Video: How to Cut Metal Using a CNC Plasma Table – Kevin Caron

Strategic Material Selection Guide for metal burn barrels

When selecting the appropriate materials for metal burn barrels, international B2B buyers must consider various factors that influence performance, durability, and compliance with local regulations. Below is an analysis of four common materials used in the manufacturing of metal burn barrels, highlighting their properties, pros and cons, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

1. Carbon Steel

Key Properties:

Carbon steel is known for its high strength and durability, with a temperature rating that can withstand high heat during combustion. It generally has good corrosion resistance when treated with protective coatings.

Pros & Cons:

The primary advantage of carbon steel is its robustness, making it suitable for heavy-duty applications. However, it can be susceptible to rust if not properly coated or maintained, which may lead to a shorter lifespan in humid environments. The manufacturing process is relatively straightforward, keeping costs moderate.

Impact on Application:

Carbon steel burn barrels are ideal for incinerating a variety of combustible materials, including yard waste and untreated wood. However, care must be taken to avoid burning corrosive materials that could damage the barrel.

Considerations for Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN for material quality. In regions with high humidity, additional protective coatings may be necessary to enhance corrosion resistance.

2. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance and high-temperature tolerance, making it suitable for burn barrels exposed to harsh environments.

Pros & Cons:

The main advantage is its longevity and resistance to rust, which can significantly reduce maintenance costs over time. However, stainless steel is more expensive than carbon steel, which could impact budget considerations for buyers. The manufacturing complexity is higher, often requiring specialized welding techniques.

Impact on Application:

Stainless steel burn barrels are particularly effective for burning waste that may produce corrosive byproducts, such as certain plastics. They are also less likely to leach harmful substances into the environment.

Considerations for Buyers:

Buyers in regions with stringent environmental regulations, such as Europe, may prefer stainless steel for its compliance with eco-friendly standards. Understanding local certifications for stainless steel quality is crucial.

3. Galvanized Steel

Key Properties:

Galvanized steel is carbon steel that has been coated with zinc to enhance its corrosion resistance. This material can withstand moderate temperatures and is less prone to rust.

Pros & Cons:

The key advantage of galvanized steel is its cost-effectiveness and decent durability. However, the zinc coating can wear off over time, especially in high-heat applications, leading to potential corrosion issues. The manufacturing process is relatively simple, keeping production costs low.

Impact on Application:

Galvanized steel burn barrels are suitable for general waste incineration but may not be ideal for high-temperature applications due to the risk of coating degradation.

Considerations for Buyers:

International buyers should verify that the galvanized steel meets local standards for safety and environmental compliance. In regions like Africa and South America, where cost is a significant factor, galvanized options may be attractive.

4. Aluminum

Key Properties:

Aluminum is lightweight and resistant to corrosion, with a good temperature tolerance, though it has a lower melting point compared to steel.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, making it easier to transport and handle. However, its lower strength and higher cost compared to steel may limit its use in heavy-duty applications.

Impact on Application:

Aluminum burn barrels can be effective for lighter waste materials but are not suitable for high-heat applications or heavy debris incineration.

Considerations for Buyers:

Buyers should consider the application requirements carefully, particularly in regions with strict waste management regulations. Compliance with local standards for aluminum quality is essential.

Summary Table

| Material | Typical Use Case for metal burn barrels | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General waste incineration | High strength and durability | Susceptible to rust | Medium |

| Stainless Steel | Corrosive waste incineration | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Galvanized Steel | General waste incineration | Cost-effective and decent durability | Zinc coating can degrade | Low |

| Aluminum | Light waste incineration | Lightweight and corrosion-resistant | Lower strength and higher cost | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for metal burn barrels

Metal burn barrels are essential tools for waste management, particularly in regions where conventional disposal methods are lacking. Understanding the manufacturing processes and quality assurance measures for these products can significantly aid international B2B buyers in making informed purchasing decisions. This section provides a comprehensive overview of the typical manufacturing processes, quality control standards, and actionable insights for buyers from Africa, South America, the Middle East, and Europe.

Manufacturing Processes

The manufacturing of metal burn barrels involves several key stages:

1. Material Preparation

The primary material for burn barrels is steel, often in the form of recycled 55-gallon drums. The initial stage involves sourcing high-quality steel, which is then cleaned and inspected for defects. This stage is crucial, as the quality of the raw material directly impacts the durability and safety of the final product.

- Sourcing: Ensure that suppliers use steel from reputable sources to minimize the risk of defects.

- Cleaning: Remove any contaminants such as oil or rust that could affect the final finish.

2. Forming

In this stage, the prepared steel is shaped into the desired form using various techniques:

- Roll Forming: Steel sheets are rolled into cylindrical shapes.

- Stamping: For certain designs, stamping techniques create precise shapes and openings.

- Welding: The cylindrical body is welded together, often using MIG or TIG welding methods, ensuring strong seams that can withstand high temperatures.

3. Assembly

Once formed, the components of the burn barrel are assembled. This may include:

- Adding Features: Such as air holes for ventilation, lids, and handles.

- Quality Checks: Assembly lines typically integrate quality checkpoints to ensure that each barrel meets specific standards.

4. Finishing

The finishing process involves several steps to enhance the barrel’s durability and safety:

- Coating: A protective coating is applied to prevent rust and corrosion. Options include powder coating or galvanization.

- Labeling: Compliance labels indicating safety standards and usage instructions are affixed.

- Final Inspection: A thorough inspection to check for any defects in the finish or assembly.

Quality Assurance

Quality assurance (QA) is critical in the manufacturing of burn barrels, ensuring that products meet international standards and customer expectations.

International Standards

B2B buyers should be aware of the following quality standards relevant to burn barrels:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

- CE Marking: Essential for products sold in Europe, indicating compliance with health, safety, and environmental protection standards.

- API Standards: While primarily used in the oil and gas industry, adherence to API standards can indicate a high level of quality and safety in manufacturing processes.

Quality Control Checkpoints

Quality control (QC) is embedded throughout the manufacturing process, with specific checkpoints:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Conducting inspections at various stages of production to catch defects early.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before it is packaged and shipped.

Common Testing Methods

To ensure the safety and effectiveness of burn barrels, manufacturers employ various testing methods:

- Pressure Testing: To ensure that the barrel can withstand high temperatures without deforming.

- Corrosion Resistance Testing: To evaluate the effectiveness of coatings and materials in preventing rust.

- Functional Testing: Ensuring that the burn barrel operates as intended under various conditions.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential:

- Supplier Audits: Conduct regular audits of potential suppliers to review their manufacturing processes, quality control systems, and compliance with international standards.

- Quality Reports: Request detailed quality reports and certifications from suppliers to ensure they meet relevant industry standards.

- Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of manufacturing facilities and products.

Quality Control and Certification Nuances

Buyers should be aware of specific nuances related to quality control and certification that may vary by region:

- Regional Regulations: Different regions may have unique regulatory requirements for burn barrels. Understanding these can prevent compliance issues.

- Cultural Considerations: In some regions, the emphasis on environmental sustainability may influence the choice of materials and manufacturing methods. Buyers should consider suppliers who prioritize eco-friendly practices.

Conclusion

Understanding the manufacturing processes and quality assurance measures for metal burn barrels is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control standards, buyers can ensure they source safe, durable, and compliant products. Verifying supplier practices through audits, reports, and third-party inspections will further enhance procurement decisions, ultimately leading to better operational outcomes in waste management.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for metal burn barrels Sourcing

Understanding the cost structure and pricing dynamics of metal burn barrels is essential for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This analysis will help you navigate sourcing effectively, ensuring that you make informed purchasing decisions.

Cost Components

-

Materials: The primary materials for metal burn barrels typically include steel or galvanized metal. The choice of material influences both durability and cost. High-quality materials that meet safety standards may come at a premium but will often result in lower long-term maintenance costs.

-

Labor: Labor costs vary significantly based on the region of production. Skilled labor in developed countries typically commands higher wages, which can elevate the overall price of burn barrels. Conversely, sourcing from countries with lower labor costs can reduce expenses but may impact quality.

-

Manufacturing Overhead: This encompasses the costs of utilities, equipment maintenance, and factory operations. Efficient manufacturing processes can lead to lower overhead costs, which may be reflected in the pricing offered to buyers.

-

Tooling: Initial tooling costs for manufacturing custom designs can be significant. If you require unique specifications or modifications, be prepared for higher upfront costs that can affect your overall budget.

-

Quality Control (QC): Robust QC processes ensure that burn barrels meet safety and environmental standards. Investing in thorough QC can increase costs but ultimately provides assurance of product reliability and compliance, which is critical for regulatory adherence in many regions.

-

Logistics: Transportation costs can be a significant factor, especially when sourcing internationally. This includes shipping fees, customs duties, and potential delays. Selecting suppliers with established logistics networks can help mitigate these costs.

-

Margin: Supplier margins can vary based on market competition and the perceived value of the product. Understanding the typical margins in your target market can provide leverage during negotiations.

Price Influencers

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts. Understand the minimum order quantities (MOQ) set by suppliers to maximize your purchasing power.

-

Specifications/Customization: Custom designs or specific features may increase costs. Clearly define your requirements to avoid unnecessary expenditures.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can significantly influence prices. Assess the necessity of these certifications based on your market’s regulatory environment.

-

Supplier Factors: Established suppliers with a strong reputation may charge more due to their reliability. However, they can also offer better warranty terms and customer support.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects cost allocation between buyer and seller. Understanding these terms can help you negotiate better shipping terms and manage risks associated with transportation.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of your budget, specifications, and the competitive landscape. Build relationships with suppliers to foster better terms and service.

-

Cost-Efficiency: Evaluate the total cost of ownership (TCO), not just the purchase price. Consider maintenance, operational efficiency, and potential resale value when assessing costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import tariffs, and local regulations that may affect pricing. Engage local experts or consultants to navigate these complexities.

Disclaimer

Prices for metal burn barrels can vary widely based on the factors mentioned above. This analysis serves as a guideline, and actual costs may differ based on specific supplier offerings and market conditions. Always request detailed quotations from multiple suppliers to ensure competitive pricing and alignment with your requirements.

Spotlight on Potential metal burn barrels Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘metal burn barrels’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for metal burn barrels

Key Technical Properties of Metal Burn Barrels

Understanding the essential technical specifications of metal burn barrels is crucial for international B2B buyers. Here are some critical properties that should be considered:

-

Material Grade

Metal burn barrels are typically constructed from steel or galvanized steel. The grade of the material affects the barrel’s durability, resistance to corrosion, and ability to withstand high temperatures. For B2B buyers, selecting a barrel made from high-grade materials ensures longevity and minimizes maintenance costs. -

Capacity

Burn barrels generally come in various capacities, most commonly 30 to 55 gallons. The capacity dictates the volume of waste that can be incinerated at one time, impacting operational efficiency. Buyers must assess their waste disposal needs to choose the appropriate size, ensuring compliance with local regulations regarding waste management. -

Wall Thickness

The wall thickness of a burn barrel impacts its structural integrity and heat retention capabilities. Thicker walls provide better heat insulation and are less likely to warp under high temperatures. For B2B operations, investing in barrels with adequate wall thickness reduces the risk of failure and enhances safety during use. -

Ventilation Design

Effective ventilation is essential for controlling combustion within the barrel. A well-designed burn barrel features strategically placed vents to allow airflow, facilitating more efficient burning and reducing smoke emissions. Buyers should prioritize barrels with adjustable ventilation options to accommodate different types of waste materials. -

Compliance Standards

Many countries have specific regulations governing the use of burn barrels, including emissions standards and safety requirements. Understanding these compliance standards is vital for buyers to avoid legal penalties and ensure safe operation. Purchasing from manufacturers who provide documentation of compliance can simplify the regulatory process.

Common Trade Terminology in the Burn Barrel Industry

Familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of burn barrels, understanding who the OEM is can provide insights into product quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers to plan inventory and manage cash flow effectively. It can also affect negotiations regarding pricing and shipping costs. -

RFQ (Request for Quote)

An RFQ is a document used by buyers to solicit price quotations from suppliers. For international buyers, an RFQ can help gather competitive pricing and ensure that all potential suppliers meet specific requirements, such as compliance and delivery timelines. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for clarifying shipping costs, insurance, and liability, which can significantly impact the total cost of procurement. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. For B2B buyers, knowing the lead time is vital for planning and ensuring that waste disposal needs are met promptly, especially in regions with specific waste management regulations. -

Certification

Certification refers to the validation of a product’s compliance with industry standards and regulations. Buyers should seek burn barrels that come with certifications, as this indicates adherence to safety and environmental guidelines, ensuring a reliable product.

By understanding these technical properties and terminology, B2B buyers can make informed decisions when procuring metal burn barrels, ensuring compliance, safety, and efficiency in waste management practices.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal burn barrels Sector

Market Overview & Key Trends

The global metal burn barrels market is witnessing significant growth driven by several factors, including the increasing need for effective waste management solutions, regulatory changes, and heightened environmental awareness. As urbanization expands, particularly in regions like Africa, South America, and the Middle East, the demand for safe and efficient waste disposal methods has surged. Burn barrels, traditionally utilized in rural areas, are now being adopted in urban settings due to their ability to comply with stringent regulations aimed at minimizing landfill usage and reducing environmental pollution.

Emerging trends in sourcing include a shift towards localized manufacturing to reduce lead times and transportation costs. B2B buyers are increasingly leveraging technology to streamline procurement processes, with digital platforms facilitating supplier discovery and engagement. The adoption of smart technologies in burn barrel production—such as IoT-enabled monitoring systems—enhances operational efficiency and safety, appealing to environmentally conscious companies. Furthermore, companies are diversifying their product offerings to include burn barrels with features that cater to specific regional regulations and waste types, thus broadening their market reach.

Market dynamics are also shaped by competitive pressures, with established manufacturers investing in innovative designs and sustainable materials. In regions like Europe, buyers are particularly focused on sourcing from suppliers who can demonstrate compliance with environmental standards and certifications. This shift highlights the necessity for international B2B buyers to stay informed about market changes and emerging technologies to make strategic sourcing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the sourcing of metal burn barrels, driven by both regulatory requirements and consumer demand for environmentally responsible practices. The environmental impact of burn barrels is significantly lower than that of traditional waste disposal methods, as they facilitate controlled incineration, reducing the likelihood of uncontrolled fires and harmful emissions.

Ethical sourcing is also paramount, as buyers increasingly prioritize suppliers who adhere to fair labor practices and sustainable materials. The use of recycled steel in burn barrel production not only reduces waste but also lessens the carbon footprint associated with manufacturing. Additionally, buyers should seek suppliers who possess recognized green certifications, such as ISO 14001, which demonstrate a commitment to environmental management standards.

Incorporating sustainability into procurement strategies is not merely a compliance issue; it is also a competitive advantage. Companies that prioritize ethical sourcing practices are likely to enhance their brand reputation and customer loyalty, particularly in regions where consumers are increasingly aware of environmental issues.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The history of burn barrels dates back several decades, initially serving as a rudimentary method for waste disposal in rural settings. Traditionally made from repurposed 55-gallon drums, these barrels have evolved into more sophisticated products designed to meet modern safety and environmental standards.

As regulations around waste disposal tightened, particularly in developed markets, burn barrels were re-engineered to minimize emissions and enhance safety. Innovations in design, such as improved airflow systems and fire-retardant materials, have enabled burn barrels to align with contemporary environmental policies. This evolution reflects a broader trend in the waste management industry towards more sustainable practices, which is particularly relevant for B2B buyers looking to invest in compliant and responsible waste disposal solutions.

Related Video: The Shadow World: Inside the Global Arms Trade

Frequently Asked Questions (FAQs) for B2B Buyers of metal burn barrels

-

What factors should I consider when vetting suppliers for metal burn barrels?

When vetting suppliers, prioritize their industry experience, reputation, and compliance with international standards. Request references from previous clients and verify their certifications, such as ISO or environmental compliance. Assess their production capabilities, including whether they can meet your customization requirements. Additionally, consider their financial stability to ensure they can fulfill large orders consistently, as well as their ability to provide after-sales support. -

Can I customize the metal burn barrels to meet specific requirements?

Yes, many manufacturers offer customization options for metal burn barrels. You can specify dimensions, coating materials, and additional features like air vents or spark guards. When discussing customization, provide clear specifications to the supplier and inquire about any associated costs or minimum order quantities (MOQs). Be sure to confirm the supplier’s experience with custom projects to ensure they can meet your expectations. -

What are the typical minimum order quantities (MOQ) and lead times for metal burn barrels?

MOQs for metal burn barrels can vary widely based on the supplier and customization options. Generally, they range from 50 to 500 units. Lead times can also differ, typically ranging from 4 to 12 weeks, depending on the order size and complexity. Always clarify these details with the supplier during the negotiation phase to avoid unexpected delays in your supply chain. -

What payment methods are commonly accepted for international orders of metal burn barrels?

Common payment methods for international transactions include wire transfers, letters of credit, and secure online payment platforms. It’s advisable to negotiate favorable payment terms, such as a deposit upfront and the balance upon shipment. Additionally, discuss the possibility of using escrow services for added security, especially for large orders, ensuring that both parties are protected throughout the transaction. -

How can I ensure quality assurance and compliance with safety standards for burn barrels?

To ensure quality, request samples before placing a large order. Verify that the supplier adheres to international safety and environmental standards, such as ISO 9001 or local regulations applicable in your region. Ask for documentation proving compliance and consider third-party inspections for large shipments. Establishing a clear quality control process with the supplier can help mitigate risks associated with defective products. -

What logistics considerations should I keep in mind when importing metal burn barrels?

When importing, consider shipping methods (air freight vs. sea freight) based on cost and urgency. Understand the customs regulations and import duties applicable in your country, as these can significantly affect the total landed cost. Work with a reputable freight forwarder familiar with shipping metal products to navigate logistics efficiently. Ensure that the supplier provides all necessary shipping documentation to avoid delays at customs. -

What steps should I take if a dispute arises with a supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements for reference. If resolution is not reached, refer to the terms outlined in your contract regarding dispute resolution, which may include mediation or arbitration. Having a clear contractual framework can help protect your interests and provide a pathway for resolution. -

What are the best practices for managing the disposal of ashes and residual waste from burn barrels?

Proper disposal of ashes is essential to comply with environmental regulations. After the burn, allow ashes to cool completely before disposal. Check local regulations regarding ash disposal; some regions may require specific methods, such as depositing them in designated landfills. Additionally, consider recycling or reusing ashes in gardening or landscaping, as they can provide nutrients to soil. Educating users on these practices can enhance your company’s sustainability efforts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal burn barrels

In the evolving landscape of waste management, strategic sourcing for metal burn barrels is not merely a purchasing decision; it is a pivotal aspect of operational efficiency and environmental responsibility. B2B buyers across Africa, South America, the Middle East, and Europe should prioritize suppliers who adhere to stringent safety standards and environmental regulations, ensuring compliance with local laws while minimizing ecological impact.

Key takeaways include understanding the diverse types of burn barrels available, recognizing the importance of sourcing from reputable manufacturers, and ensuring that the selected products meet the specific needs of your operations—whether for yard waste disposal or industrial applications. Additionally, leveraging local suppliers can enhance supply chain efficiency and reduce costs.

As the global market for burn barrels continues to expand, driven by increased awareness and regulatory demands, international buyers are encouraged to engage in strategic partnerships with suppliers who demonstrate innovation and sustainability in their offerings. By proactively addressing these factors, businesses can position themselves for success in a competitive market.

Take action today by evaluating your current waste management practices and exploring the potential of metal burn barrels. Embrace the opportunity to not only streamline operations but also contribute to a cleaner, more sustainable future.