Master Sourcing Strategies for Metal Grate Sheet: Essential

Introduction: Navigating the Global Market for metal grate sheet

In the rapidly evolving landscape of global manufacturing, metal grate sheets stand out as a critical component for diverse applications ranging from industrial flooring to architectural designs. Their inherent strength, durability, and versatility make them indispensable in sectors such as construction, transportation, and energy. As B2B buyers from Africa, South America, the Middle East, and Europe seek to optimize their procurement strategies, understanding the nuances of metal grate sheets becomes essential for securing quality materials that enhance operational efficiency and safety.

This comprehensive guide is tailored specifically for international B2B buyers, offering invaluable insights into the various types of metal grate sheets available in the market. It will cover essential topics, including material selection—highlighting the benefits and drawbacks of different metals—manufacturing processes and quality control measures, supplier evaluation criteria, and cost considerations. Additionally, you will find market trends that shape the sourcing landscape, along with frequently asked questions that address common challenges faced by procurement leaders.

By equipping you with actionable knowledge and strategic recommendations, this guide empowers you to navigate the complexities of sourcing metal grate sheets. Whether you’re looking to enhance infrastructure projects in Lagos, streamline manufacturing in São Paulo, or upgrade facilities in the UK, informed decision-making in your procurement process will unlock new opportunities for growth and success.

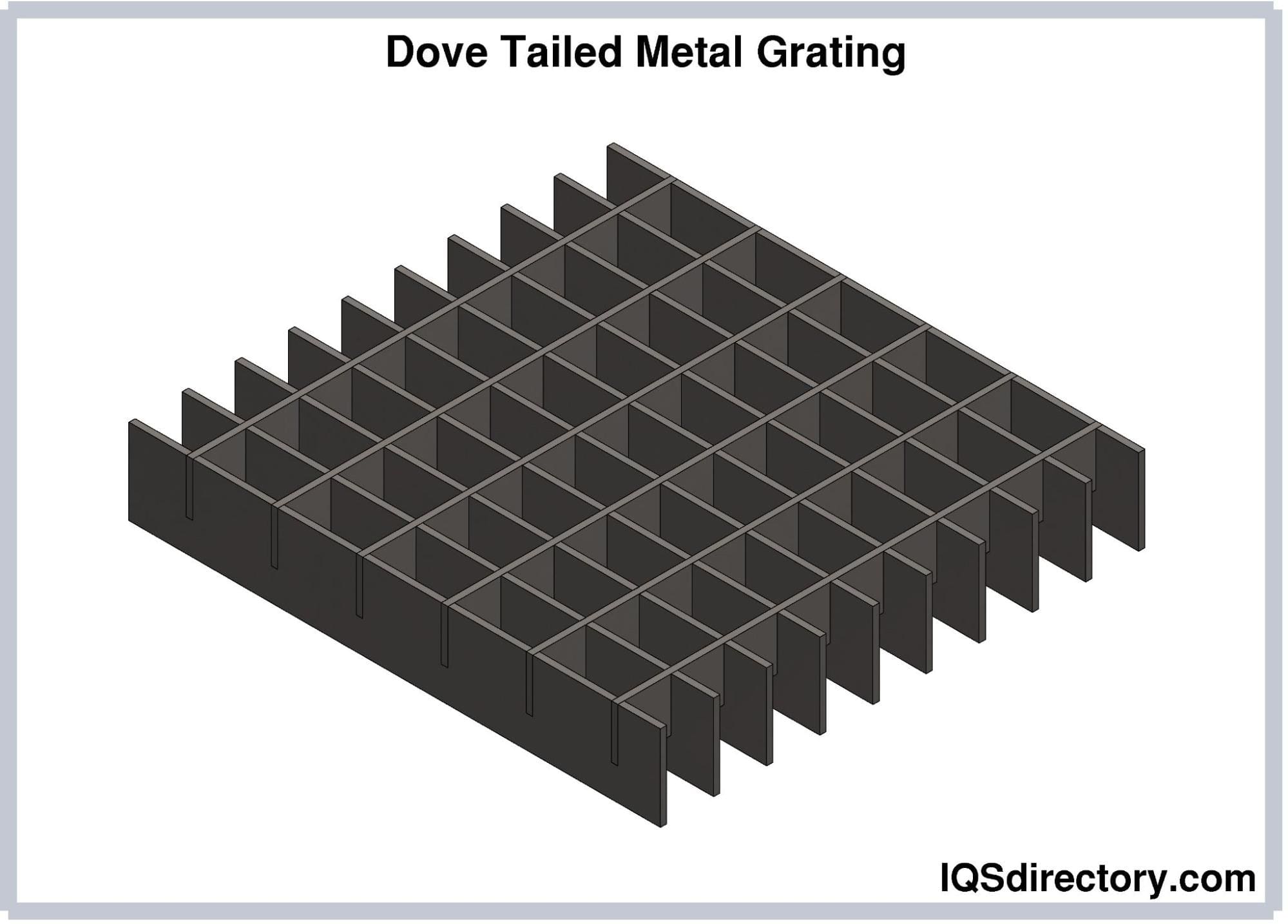

Understanding metal grate sheet Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Grate Sheet | High strength, durable, typically hot-dipped galvanized | Industrial flooring, walkways, drainage | Pros: Long-lasting, high load capacity; Cons: Heavier, may require maintenance against rust. |

| Aluminum Grate Sheet | Lightweight, corrosion-resistant, non-magnetic | Aerospace, automotive, marine applications | Pros: Lightweight, easy to handle; Cons: More expensive, lower load capacity than steel. |

| Fiberglass Grate Sheet | Non-conductive, chemical resistant, lightweight | Chemical processing, wastewater treatment | Pros: Resistant to corrosion, low maintenance; Cons: Limited load-bearing capacity, more costly. |

| Stainless Steel Grate Sheet | Corrosion-resistant, hygienic, aesthetically pleasing | Food processing, pharmaceutical industries | Pros: Durable, easy to clean; Cons: Higher cost, potential for scratching. |

| Expanded Metal Grate Sheet | Versatile, customizable openings, lightweight | Security fencing, ventilation, flooring | Pros: Good airflow, customizable; Cons: Limited structural strength, may not be suitable for heavy loads. |

Steel Grate Sheet

Steel grate sheets are renowned for their strength and durability. Typically hot-dipped galvanized, they offer excellent resistance to rust and corrosion, making them ideal for industrial flooring, walkways, and drainage applications. When purchasing, B2B buyers should consider the load capacity, maintenance requirements, and the environment in which the grates will be used, as heavy-duty options may be necessary for high-traffic areas.

Aluminum Grate Sheet

Aluminum grate sheets are lightweight and corrosion-resistant, making them suitable for applications in aerospace, automotive, and marine environments. Their non-magnetic properties are advantageous in specific technical settings. Buyers should evaluate the cost-effectiveness of aluminum compared to steel and consider the required load capacity, as aluminum may not support as much weight as its steel counterparts.

Fiberglass Grate Sheet

Fiberglass grate sheets excel in chemical resistance and are often used in corrosive environments such as chemical processing plants and wastewater treatment facilities. Their lightweight nature makes installation easier, while their non-conductive properties ensure safety in electrical applications. B2B buyers should assess the load-bearing capacity and potential costs, as fiberglass can be more expensive than metal options.

Stainless Steel Grate Sheet

Stainless steel grate sheets are prized for their hygiene and corrosion resistance, making them a staple in food processing and pharmaceutical industries. They are easy to clean and maintain, ensuring compliance with health standards. Buyers should consider the initial investment, as stainless steel is generally more expensive, but the long-term savings on maintenance and durability may justify the cost.

Expanded Metal Grate Sheet

Expanded metal grate sheets are characterized by their versatility and customizable openings, making them ideal for applications requiring good airflow and visibility, such as security fencing and ventilation systems. While lightweight and easy to handle, their structural strength may not support heavy loads. Buyers should evaluate the specific application requirements to ensure the selected expanded metal meets necessary performance standards.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of metal grate sheet

| Industry/Sector | Specific Application of metal grate sheet | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Flooring and walkways | Provides slip resistance and durability, reducing maintenance costs. | Material specifications (steel or aluminum), load capacity, and anti-slip treatment. |

| Mining and Minerals | Grating for platforms and walkways | Enhances safety and accessibility in hazardous environments. | Corrosion resistance, load-bearing capacity, and compliance with safety standards. |

| Food Processing | Drainage covers and shelving | Ensures hygiene and easy cleaning, critical for food safety. | Non-corrosive materials, smooth finish, and compliance with health regulations. |

| Automotive | Ventilation grates and underbody shields | Improves airflow and protects components, enhancing vehicle performance. | Weight considerations, thermal resistance, and compatibility with existing systems. |

| Oil and Gas | Access platforms and protective barriers | Increases safety and operational efficiency in challenging environments. | Material durability, resistance to harsh chemicals, and custom fabrication needs. |

Detailed Overview of Key Industrial Applications

Construction

In the construction sector, metal grate sheets are widely used for flooring and walkways, providing essential slip resistance and durability. These sheets are engineered to withstand heavy loads, making them ideal for high-traffic areas such as industrial sites, warehouses, and commercial buildings. For international B2B buyers, it’s crucial to specify the material—whether steel for strength or aluminum for lightweight applications—and ensure compliance with local building codes and safety regulations.

Mining and Minerals

In mining operations, metal grate sheets serve as critical components for platforms and walkways, enhancing safety in often hazardous environments. The open design allows for drainage, reducing the risk of slips and falls. Buyers in this sector must prioritize corrosion resistance and load-bearing capacity when sourcing, as these factors are vital for ensuring longevity and safety in rugged conditions. Compliance with industry-specific safety standards is also essential.

Food Processing

In the food processing industry, metal grate sheets are utilized in drainage covers and shelving systems, where hygiene is paramount. Their smooth surfaces facilitate easy cleaning, preventing the buildup of contaminants. B2B buyers should focus on sourcing non-corrosive materials that meet health and safety regulations, as well as ensuring that the finish is suitable for food contact. This is particularly important for international buyers who must navigate varying compliance standards across regions.

Automotive

The automotive sector employs metal grate sheets for applications like ventilation grates and underbody shields. These components improve airflow and protect sensitive parts from debris and environmental damage, enhancing overall vehicle performance. Buyers should consider weight, thermal resistance, and compatibility with existing vehicle systems when sourcing metal grate sheets, especially in regions with stringent automotive standards.

Oil and Gas

In the oil and gas industry, metal grate sheets are essential for constructing access platforms and protective barriers. They provide safety and operational efficiency in challenging environments, often exposed to harsh chemicals and extreme conditions. Buyers must ensure the materials used are durable and resistant to corrosion while also considering custom fabrication to meet specific project requirements. Understanding local regulations and safety standards is vital for successful procurement in this sector.

Related Video: Forming Sheet Metal & Metal Forming Tools – Uses Explained By Gene Winfield at SEMA

Strategic Material Selection Guide for metal grate sheet

When selecting materials for metal grate sheets, international B2B buyers must consider various factors that influence performance, cost, and application suitability. Below is an analysis of four common materials used in metal grate sheet production, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is renowned for its excellent corrosion resistance, high tensile strength, and ability to withstand extreme temperatures and pressures. It typically features a temperature rating up to 800°C (1472°F) and is resistant to a wide range of chemicals.

Pros & Cons: The durability and low maintenance requirements of stainless steel make it an ideal choice for demanding environments, such as food processing and chemical plants. However, the higher cost compared to other materials can be a significant drawback for budget-conscious projects. Additionally, manufacturing complexity may increase due to the need for specialized tools and techniques.

Impact on Application: Stainless steel is compatible with various media, including water, oils, and acids, making it suitable for applications in corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 and DIN 1.4301. In regions like Europe and the Middle East, preference often leans towards high-grade stainless steel for its longevity.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. Its temperature rating typically ranges from -50°C to 150°C (-58°F to 302°F), making it suitable for moderate temperature applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which simplifies handling and installation. However, it is less durable than stainless steel and can be more prone to deformation under high stress. The cost of aluminum can also fluctuate based on global market conditions.

Impact on Application: Aluminum is ideal for applications where weight is a critical factor, such as in aerospace and automotive industries. However, it may not be suitable for heavy-duty applications where high strength is required.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM B209 and JIS H4000. In South America, the availability of aluminum may vary, impacting sourcing strategies.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and toughness, with a temperature rating of up to 400°C (752°F). It is widely available and can be treated for enhanced corrosion resistance.

Pros & Cons: The affordability of carbon steel makes it a popular choice for construction and structural applications. However, it is prone to rusting if not properly coated or treated, which can limit its lifespan in corrosive environments. Manufacturing processes for carbon steel are generally straightforward, contributing to lower costs.

Impact on Application: Carbon steel is suitable for applications that require strength and structural integrity, such as in building frameworks and heavy machinery. However, its susceptibility to corrosion necessitates careful consideration of the environment in which it will be used.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM A36 and EN 10025. In Africa, where exposure to moisture is common, protective coatings are essential for enhancing longevity.

Galvanized Steel

Key Properties: Galvanized steel features a zinc coating that provides excellent corrosion resistance. It can withstand temperatures up to 300°C (572°F) and is particularly effective in outdoor applications.

Pros & Cons: The primary advantage of galvanized steel is its enhanced corrosion resistance at a relatively low cost. However, the zinc layer can wear off over time, reducing its protective capabilities. The welding of galvanized steel can also be more complex due to the presence of zinc.

Impact on Application: Galvanized steel is ideal for outdoor applications, such as in agricultural equipment and construction scaffolding, where exposure to moisture is a concern.

Considerations for International Buyers: Compliance with standards such as ASTM A123 and ISO 1461 is crucial. In regions like the Middle East, where humidity levels can be high, galvanized steel is often preferred for its durability.

Summary Table

| Material | Typical Use Case for metal grate sheet | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical plants | Excellent corrosion resistance | Higher cost, manufacturing complexity | High |

| Aluminum | Aerospace, automotive | Lightweight, easy to handle | Less durable, cost fluctuations | Medium |

| Carbon Steel | Construction, structural components | Affordable, high strength | Prone to rust, requires coating | Low |

| Galvanized Steel | Outdoor applications, scaffolding | Cost-effective corrosion resistance | Zinc layer wear, complex welding | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for metal grate sheet

Manufacturing Processes for Metal Grate Sheets

The production of metal grate sheets involves a series of systematic manufacturing stages designed to ensure precision, durability, and quality. Understanding these processes allows B2B buyers to make informed decisions when sourcing metal grate sheets.

Material Preparation

The first step in manufacturing metal grate sheets is material preparation. Typically, high-quality steel or aluminum is selected based on the desired properties, such as strength, weight, and corrosion resistance. This raw material is then cut into manageable sheets, often using processes like shearing or laser cutting, to achieve the required dimensions and specifications.

Buyers should ensure that the raw materials meet relevant industry standards, as this significantly impacts the final product’s performance. Verification of material certificates and compliance with international standards such as ASTM or EN standards is crucial during this phase.

Forming Techniques

The forming stage involves shaping the prepared sheets into the desired grate configuration. Key techniques include:

- Punching: This process creates holes or cutouts in the sheet metal, which is essential for the airflow and drainage capabilities of the grate.

- Bending: Metal sheets are bent to create structural supports or edges, enhancing the strength and functionality of the grate.

- Welding: In cases where multiple sections are assembled, welding is used to join components securely. Different welding techniques may be employed, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), depending on the material and application.

Buyers should consider the specific requirements of their projects when selecting suppliers, as not all manufacturers may have the capability to execute advanced forming techniques.

Assembly

For grates that require multiple components, the assembly stage is critical. This may involve the integration of additional features such as frames or supports, which enhance the durability and functionality of the metal grate sheet.

B2B buyers should inquire about the manufacturer’s assembly process and the types of fasteners or joints used, as these can significantly affect the structural integrity of the final product.

Finishing

The finishing stage is essential for enhancing the appearance and longevity of metal grate sheets. Common finishing processes include:

- Surface Treatment: Techniques such as galvanizing, powder coating, or painting are used to protect the metal from corrosion and wear.

- Deburring and Polishing: These processes remove sharp edges and improve the aesthetic quality of the product.

For buyers, understanding the finishing options available is important, as it can impact the maintenance requirements and overall lifespan of the grates in their specific applications.

Quality Assurance Processes

Quality assurance is a critical aspect of the manufacturing process, ensuring that the final product meets both the buyer’s expectations and international standards.

Relevant International Standards

B2B buyers should be aware of various quality standards that govern metal grate sheet manufacturing, including:

- ISO 9001: This standard outlines the criteria for a quality management system and is crucial for ensuring consistent product quality.

- CE Marking: Required in the European Union, this certification indicates conformity with health, safety, and environmental protection standards.

- API Standards: For grates used in oil and gas applications, adherence to American Petroleum Institute standards ensures safety and reliability.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial check verifies the quality of raw materials upon delivery.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify any deviations from quality standards early in the process.

- Final Quality Control (FQC): This final inspection checks the completed products against specifications before shipping.

Implementing these QC checkpoints ensures that defects are minimized and helps maintain high-quality standards throughout production.

Common Testing Methods

Testing methods play a vital role in verifying the quality and performance of metal grate sheets. Common tests include:

- Tensile Testing: Measures the strength and ductility of the material.

- Impact Testing: Assesses the material’s toughness and resistance to sudden forces.

- Corrosion Resistance Testing: Evaluates how well the metal withstands corrosive environments, which is crucial for long-term durability.

B2B buyers should request documentation of these tests to ensure that the products meet their specific requirements.

Verifying Supplier Quality Control

To ensure that suppliers maintain high-quality standards, B2B buyers should adopt the following strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to evaluate their quality control processes, equipment, and workforce capabilities.

- Request Quality Reports: Ask for detailed QC reports that outline testing methods, results, and compliance with international standards.

- Third-Party Inspections: Engage independent inspection services to verify the quality of the products before shipment, providing an additional layer of assurance.

Regional Considerations for International Buyers

For buyers in Africa, South America, the Middle East, and Europe, it is essential to understand the nuances of QC and certification requirements in their respective regions.

- Regional Standards: Different regions may have specific standards that must be adhered to, such as SANS in South Africa or ABNT in Brazil. Buyers should ensure that their suppliers comply with these standards.

- Logistics and Supply Chain: International shipping can introduce risks; therefore, verifying the supplier’s ability to manage quality during transit is crucial.

In conclusion, understanding the manufacturing processes and quality assurance measures for metal grate sheets is vital for B2B buyers looking to secure reliable, high-quality products. By focusing on material preparation, forming techniques, assembly, and finishing, along with stringent quality control practices, buyers can ensure they are making informed sourcing decisions that will support their operational needs.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for metal grate sheet Sourcing

Understanding the cost structure and pricing dynamics of sourcing metal grate sheets is essential for international B2B buyers. This section delves into the various components influencing costs, key price influencers, and actionable tips to enhance procurement strategies.

Cost Components

-

Materials: The primary cost driver for metal grate sheets is the raw material used. Common materials include stainless steel, aluminum, and carbon steel. Prices fluctuate based on market demand, geopolitical factors, and availability. Stainless steel, for example, tends to be more expensive due to its corrosion-resistant properties.

-

Labor: Labor costs encompass wages for skilled workers involved in cutting, welding, and assembling the metal sheets. Geographic location significantly impacts labor rates, with developed regions typically incurring higher costs.

-

Manufacturing Overhead: This includes costs related to utilities, rent, and administrative expenses necessary for operating a manufacturing facility. Efficient production processes can mitigate overhead costs, making it crucial for buyers to assess suppliers’ operational efficiency.

-

Tooling: Tooling costs are associated with the equipment and tools needed for production. Custom designs may require specialized tools, leading to higher initial costs but potentially lower unit prices for large orders.

-

Quality Control (QC): Ensuring that metal grate sheets meet specified standards incurs additional costs. Suppliers with rigorous QC processes may charge a premium, but this investment can lead to reduced risk of defects and returns.

-

Logistics: Transportation costs depend on the shipping method, distance, and any customs duties involved. Buyers should consider local suppliers to minimize logistics costs and ensure faster delivery.

-

Margin: The profit margin set by suppliers can vary significantly. Understanding typical margins within the industry can help buyers negotiate better prices.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) and bulk purchasing can significantly affect pricing. Suppliers often provide discounts for larger orders, incentivizing buyers to consolidate their purchases.

-

Specifications/Customization: Customized metal grate sheets, tailored to specific applications, will generally incur higher costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: The choice of materials affects both price and performance. Buyers should consider the long-term benefits of investing in higher-quality materials, especially in demanding environments.

-

Quality/Certifications: Suppliers offering certified products (e.g., ISO standards) may charge higher prices. However, these certifications often assure quality and compliance, which can justify the cost.

-

Supplier Factors: Supplier reliability, reputation, and location play crucial roles in pricing. Established suppliers with a track record of quality and timely delivery may command higher prices, reflecting their value.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms can impact the total landed cost, which includes shipping, insurance, and duties. Buyers should clarify responsibilities to avoid unexpected charges.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers regarding pricing structures and potential discounts for bulk purchases or long-term contracts. Building strong relationships can lead to better terms over time.

-

Cost-Efficiency: Evaluate total cost of ownership (TCO) rather than just the purchase price. Consider factors such as durability, maintenance, and longevity of the metal grate sheets in your calculations.

-

Pricing Nuances: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations and geopolitical factors that may affect pricing.

-

Local Sourcing: Whenever possible, sourcing from local manufacturers can reduce logistics costs and lead times, enhancing overall cost-efficiency.

Disclaimer

Prices for metal grate sheets can vary widely based on the factors outlined above. The information provided here serves as a general guideline and should be verified with specific suppliers to obtain accurate and up-to-date pricing.

Spotlight on Potential metal grate sheet Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘metal grate sheet’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for metal grate sheet

Understanding the technical properties and trade terminology associated with metal grate sheets is vital for international B2B buyers. This knowledge not only aids in making informed purchasing decisions but also ensures compliance with industry standards and project specifications.

Key Technical Properties of Metal Grate Sheets

-

Material Grade

The material grade of metal grate sheets typically refers to the type of metal used, such as stainless steel, carbon steel, or aluminum. Each material grade offers different properties, such as corrosion resistance, strength, and weight. For instance, stainless steel is ideal for outdoor applications due to its rust resistance, while aluminum is favored for its lightweight nature. Understanding these grades helps buyers select the right material for their specific applications, enhancing durability and performance. -

Load Capacity

Load capacity indicates the maximum weight a metal grate sheet can support without failure. This specification is crucial for applications like flooring, walkways, or industrial platforms, where safety is paramount. Buyers must assess the expected load conditions of their projects to ensure the selected grate sheet can handle the required weight, preventing costly failures and ensuring user safety.

-

Tolerance

Tolerance refers to the permissible limits of variation in dimensions of the grate sheet. This specification is essential for ensuring that the sheets fit correctly within the intended application, especially in custom installations. Tight tolerances may be necessary for precision engineering projects, while broader tolerances may suffice for general construction. Buyers should clearly communicate their tolerance requirements to suppliers to avoid issues during installation. -

Thickness

The thickness of metal grate sheets affects both their strength and weight. Thicker sheets typically offer increased durability and load-bearing capacity, making them suitable for heavy-duty applications. Conversely, thinner sheets may be more appropriate for lighter applications where weight savings are essential. Buyers need to evaluate the specific requirements of their projects to select the appropriate thickness. -

Finish

The finish of a metal grate sheet (such as galvanized, painted, or untreated) impacts its appearance, corrosion resistance, and maintenance requirements. A galvanized finish, for instance, provides a protective layer against rust, which is crucial for outdoor applications. Buyers should consider the environmental conditions where the grate sheets will be used to determine the most suitable finish.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of metal grate sheets, buyers often engage OEMs for custom designs tailored to their specific needs. Understanding this term helps buyers navigate supplier relationships and ensure they receive high-quality products. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of product that a supplier is willing to sell. This term is significant for buyers as it impacts inventory management and cost efficiency. Understanding the MOQ can help buyers plan their purchases effectively, ensuring they meet production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ for metal grate sheets allows them to compare prices, terms, and delivery schedules from multiple suppliers, facilitating better decision-making and cost management. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is essential for B2B buyers to understand shipping responsibilities, risk, and cost allocation. -

Lead Time

Lead time is the time between the initiation of a process and its completion. In the context of ordering metal grate sheets, lead time affects project timelines. Buyers should inquire about lead times when placing orders to ensure that materials arrive when needed, preventing delays in project execution.

By grasping these essential properties and terminologies, international B2B buyers can navigate the complexities of sourcing metal grate sheets more effectively, ensuring they make well-informed procurement decisions that align with their operational needs and project requirements.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the metal grate sheet Sector

Market Overview & Key Trends

The metal grate sheet sector is witnessing significant growth driven by a confluence of global economic activities, urbanization, and increasing infrastructure investments, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The demand for metal grate sheets is primarily fueled by their applications in construction, transportation, and industrial sectors, where they serve critical roles in flooring, walkways, and ventilation systems.

One key trend shaping the market is the adoption of advanced manufacturing technologies. Techniques such as laser cutting and automated CNC machining are enhancing precision and efficiency, allowing for customized solutions that cater to specific client needs. Additionally, the integration of Industry 4.0 technologies—including IoT and data analytics—enables manufacturers to optimize production processes and reduce waste, offering significant cost savings for B2B buyers.

International B2B buyers should also be aware of fluctuating raw material prices and geopolitical factors that can disrupt supply chains. For instance, the ongoing shifts in trade policies and tariffs can impact sourcing strategies, prompting buyers to diversify their supplier base and consider local sourcing options. Moreover, buyers are increasingly seeking sustainable and ethically sourced materials, reflecting a growing emphasis on corporate social responsibility within procurement strategies.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer an optional consideration; it is a fundamental aspect of sourcing strategies in the metal grate sheet sector. The production and disposal of metal products can have significant environmental impacts, including carbon emissions and resource depletion. Consequently, B2B buyers must prioritize sourcing from suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and implementing energy-efficient production methods.

Ethical sourcing is equally critical. Buyers should ensure their suppliers adhere to fair labor practices and environmental regulations. Certifications like ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability. Furthermore, materials that are certified as green or low-impact, such as recycled aluminum or sustainably sourced steel, are increasingly favored. By aligning procurement strategies with sustainability goals, buyers not only mitigate risks but also enhance their brand reputation in a market that increasingly values environmental stewardship.

Brief Evolution/History

The history of metal grate sheets is closely tied to advancements in metallurgy and manufacturing. Initially crafted for basic industrial applications, these sheets have evolved significantly over the decades. The introduction of high-strength alloys and innovative fabrication methods has expanded their use across various sectors, including construction and transportation. Today, metal grate sheets are engineered to meet stringent quality standards and are available in a multitude of designs and finishes, catering to both functional and aesthetic requirements. This evolution reflects a broader trend in manufacturing towards increased customization and performance, which is crucial for B2B buyers aiming to meet specific project needs.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of metal grate sheet

-

How can I effectively vet suppliers for metal grate sheets?

Vetting suppliers involves assessing their industry experience, quality control processes, and production capabilities. Request references and case studies from previous clients to gauge reliability. It’s also essential to evaluate their compliance with international quality standards, such as ISO certifications. For international buyers, consider visiting the supplier’s facility if possible, or use virtual tours to ensure they have the necessary equipment and skilled workforce to meet your specifications. -

Can metal grate sheets be customized to specific dimensions or designs?

Yes, most suppliers offer customization options for metal grate sheets. When discussing your needs, provide detailed specifications, including dimensions, material type, and load-bearing requirements. Ensure the supplier has the capability for custom fabrication processes, such as cutting and welding. Confirm any additional costs and lead times associated with customization, as these can vary significantly depending on the complexity of the design. -

What are the typical minimum order quantities (MOQs) and lead times for metal grate sheets?

Minimum order quantities can vary widely based on the supplier and the specific product. Generally, MOQs range from a few hundred to several thousand units. Lead times also depend on factors like customization, production capacity, and shipping logistics. As a best practice, clarify these details during the initial discussions with suppliers to manage expectations and avoid delays in your project timeline. -

What payment terms are common when sourcing metal grate sheets internationally?

Payment terms can vary, but many suppliers require a deposit (often 30-50%) upfront, with the balance due upon delivery or before shipment. Consider using secure payment methods, such as letters of credit or escrow services, to protect your investment. It’s also wise to discuss potential discounts for early payments or bulk orders, which can enhance your cash flow management. -

How do I ensure quality assurance and compliance with certifications?

To ensure quality, request copies of relevant certifications from your supplier, such as ISO 9001 for quality management and any material-specific certifications. Establish a clear quality assurance process, including inspections at various production stages. Consider conducting third-party inspections or audits to verify compliance with international standards and your specific requirements. -

What logistics considerations should I keep in mind when sourcing metal grate sheets?

Logistics play a crucial role in international sourcing. Consider shipping methods, costs, and delivery times when evaluating suppliers. Discuss packaging standards to prevent damage during transit. Additionally, familiarize yourself with customs regulations and import duties in your country, as these can significantly impact overall project costs and timelines. -

How should I handle disputes with suppliers during the sourcing process?

To mitigate disputes, establish clear communication channels and document all agreements in writing. In case of disagreements, initiate dialogue to resolve issues amicably, referring to the terms outlined in your contract. If a resolution cannot be reached, consider mediation or arbitration, especially for international transactions, to avoid lengthy and costly legal battles.

Illustrative Image (Source: Google Search)

- What should I do if I encounter quality issues with delivered metal grate sheets?

If quality issues arise, first document the problems with photos and detailed descriptions. Contact the supplier immediately to discuss the concerns and refer to the quality assurance agreements made prior to delivery. Most reputable suppliers will have procedures for handling defects, which may include refunds, replacements, or repairs. Ensure you have a clear process in place to address such situations to maintain a good supplier relationship while protecting your interests.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for metal grate sheet

In conclusion, strategic sourcing of metal grate sheets is paramount for international B2B buyers aiming to enhance operational efficiency and maintain a competitive edge. By understanding the diverse types of metal grate sheets, including their materials, applications, and specifications, buyers can make informed decisions that align with their specific project needs.

Key takeaways include the importance of evaluating suppliers based on their experience, quality control processes, and technological capabilities. Additionally, staying abreast of market trends and fluctuating commodity prices is essential for optimizing costs and ensuring timely delivery.

As the global market continues to evolve, embracing a proactive sourcing strategy will empower businesses across Africa, South America, the Middle East, and Europe to unlock new opportunities. Buyers are encouraged to leverage the insights provided in this guide to forge robust supplier relationships and streamline procurement processes.

Looking ahead, the future of metal grate sheet sourcing is bright, with advancements in fabrication technology and materials science paving the way for innovative solutions. Now is the time to take action—refine your sourcing strategy, explore new partnerships, and elevate your procurement practices to drive success in your next project.