Master Sourcing Strategies for Mixing Equipment: A Complete

Introduction: Navigating the Global Market for mixing equipment

In today’s interconnected global marketplace, the role of mixing equipment is paramount for ensuring the quality and consistency of products across various industries, from pharmaceuticals to food processing. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to optimize their supply chains, understanding the intricacies of mixing technology becomes essential. The right mixing equipment not only enhances product performance but also drives operational efficiency, ultimately influencing profitability.

This comprehensive guide serves as a strategic resource for B2B procurement teams, delving into critical areas such as types of mixing equipment, material selection, manufacturing and quality control standards, and supplier evaluation. It also explores cost factors and market trends, providing insights into regional dynamics that can affect sourcing decisions. By addressing common challenges through a series of FAQs, this guide equips buyers with the knowledge needed to make informed and effective purchasing choices.

Navigating the complexities of mixing equipment is no small feat, especially in a landscape marked by evolving technologies and regulatory demands. However, by leveraging the insights provided here, international buyers can enhance their sourcing strategies, mitigate risks, and unlock new avenues for competitive advantage in their respective markets. Empower your procurement efforts and ensure the success of your product offerings with the right mixing solutions tailored to your specific operational needs.

Understanding mixing equipment Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Open Mill Mixing | Two horizontal counter-rotating rolls for manual mixing | Prototyping, specialty & smaller batch runs | Pros: Flexible for adjustments; Cons: Labor-intensive, limited automation. |

| Internal (Banbury) Mixing | Enclosed chamber with rotors for intense mixing | High-volume tire, hose, automotive products | Pros: Superior dispersion; Cons: Higher initial cost, complex cleanup. |

| Continuous Mixing | Automated, ongoing mixing using extruders or kneaders | Extruded rubber profiles, cables, conveyor belts | Pros: Consistent quality, high output; Cons: Less flexibility for formulation changes. |

| Dispersion Kneader Mixing | Tilted chamber for controlled shear and temperature | Footwear, adhesives, vibration dampening | Pros: Improved dispersion; Cons: Moderate batch sizes, requires skilled operators. |

| Twin-Screw Extruder Mixing | Co-rotating screws for high-shear, continuous mixing | Silicone compounds, specialty elastomers | Pros: Excellent for complex blends; Cons: Requires technical expertise. |

Open Mill Mixing

Open mill mixing is characterized by two horizontal, counter-rotating rolls that allow for manual blending of rubber with additives. This method is particularly suitable for prototyping and smaller batch runs, giving B2B buyers the flexibility to adjust formulas in real-time. However, the labor-intensive nature of this process can lead to inconsistencies between batches. Buyers should prioritize suppliers with skilled operators and robust quality control measures to mitigate these risks.

Internal (Banbury) Mixing

Internal (Banbury) mixing utilizes an enclosed chamber equipped with rotating rotors that generate intense shear and heat for effective mixing. This method is the industry standard for high-volume applications, such as tires and automotive goods, due to its ability to ensure consistent dispersion of materials. While the initial investment can be significant, the scalability and repeatability of the process offer substantial long-term benefits. Buyers must evaluate supplier capacity and maintenance practices to ensure reliability.

Continuous Mixing

Continuous mixing employs automated systems, such as extruders or kneaders, to deliver a steady output of mixed materials. This method is ideal for long production runs, such as those needed for conveyor belts and wire sheathing. B2B buyers benefit from reduced manual errors and enhanced operational efficiency. However, this approach is less adaptable to frequent formulation changes, which may necessitate extensive cleaning and downtime, making it crucial for buyers to assess their production needs carefully.

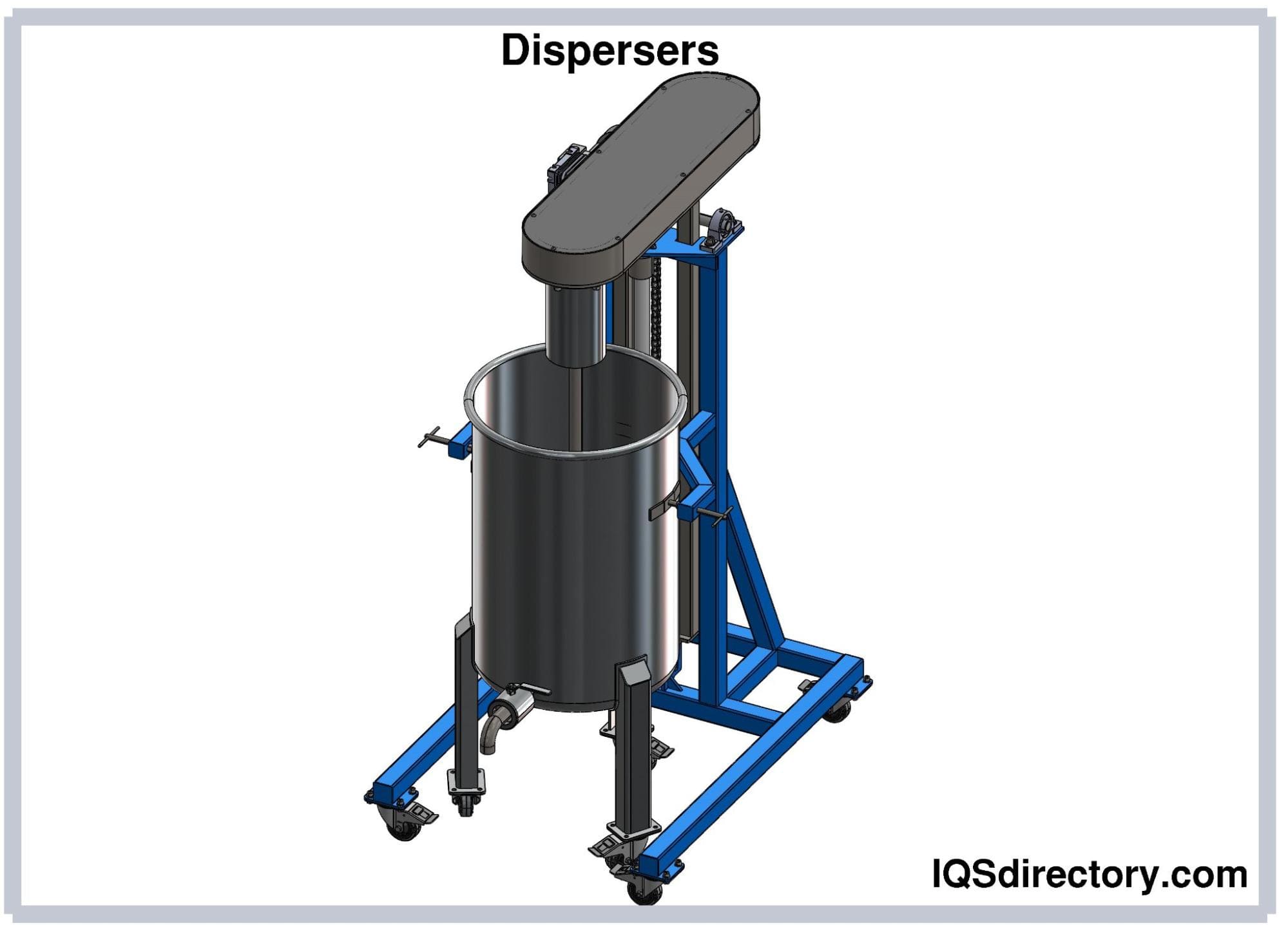

Dispersion Kneader Mixing

Dispersion kneader mixing features a tilted chamber that optimizes shear, temperature, and mixing time, resulting in improved dispersion of additives. This method is particularly effective for specialty compounds used in footwear and adhesives. B2B buyers should consider the moderate batch sizes and the necessity for skilled operators when selecting this type of equipment. Ensuring that the supplier can provide the required expertise will be vital for achieving optimal results.

Twin-Screw Extruder Mixing

Twin-screw extruder mixing involves co-rotating screws that facilitate high-shear, continuous mixing of materials. This technique is particularly advantageous for producing silicone compounds and other specialty elastomers. While it excels in handling complex blends, it requires a higher level of technical expertise to operate effectively. B2B buyers should ensure that their teams are equipped with the necessary knowledge or consider partnering with suppliers who can provide comprehensive training and support.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of mixing equipment

| Industry/Sector | Specific Application of Mixing Equipment | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Formulation of drug compounds | Ensures precise dosage and consistent quality | Regulatory compliance, supplier certifications |

| Food and Beverage | Production of sauces and dressings | Enhances flavor consistency and product safety | Ingredient sourcing, food safety standards |

| Construction Materials | Mixing of concrete and adhesives | Increases strength and durability of products | Local material availability, mixing equipment capacity |

| Cosmetics | Creation of creams and lotions | Improves texture and stability of formulations | Ingredient quality, supplier reliability |

| Rubber and Plastics | Compounding rubber for tires and products | Achieves optimal performance and longevity | Material compatibility, technology capabilities |

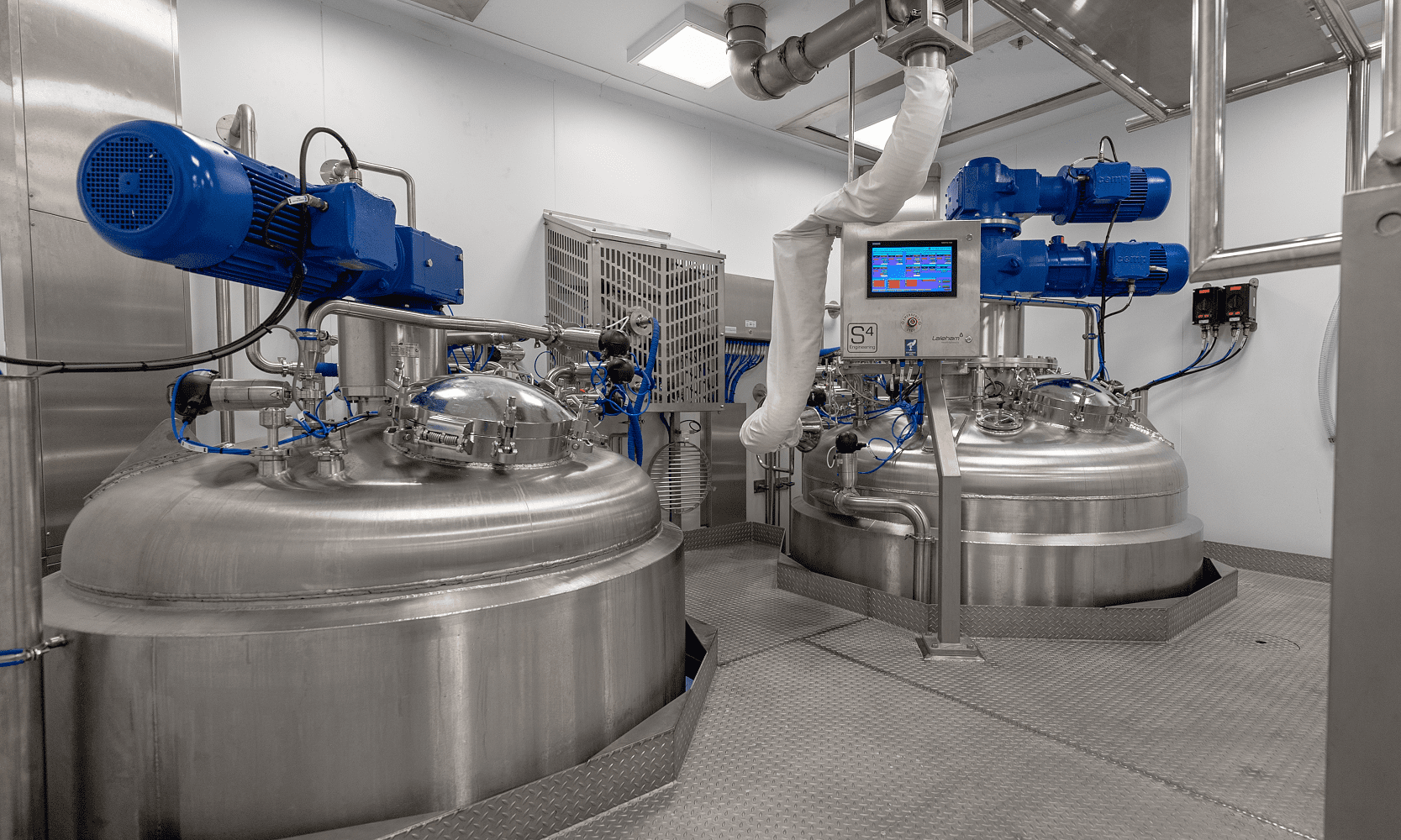

Pharmaceuticals

In the pharmaceutical industry, mixing equipment is essential for the formulation of drug compounds. This equipment ensures precise dosage and consistent quality, which are critical for regulatory compliance and patient safety. International B2B buyers must prioritize suppliers who adhere to stringent quality standards and possess necessary certifications. Additionally, understanding local regulations regarding pharmaceutical production is crucial, especially for buyers in regions like Africa and South America where compliance can be complex.

Food and Beverage

Mixing equipment plays a pivotal role in the production of sauces, dressings, and other food products. It enhances flavor consistency and ensures product safety by providing thorough blending of ingredients. For B2B buyers in this sector, sourcing high-quality raw materials is vital, as is compliance with food safety standards. Buyers should consider suppliers who demonstrate expertise in food-grade mixing technologies and can provide transparency in ingredient sourcing, particularly in the diverse markets of the Middle East and Europe.

Construction Materials

In the construction materials sector, mixing equipment is used for creating concrete and adhesives. Effective mixing increases the strength and durability of these products, which directly impacts project success. Buyers must consider local material availability and the capacity of mixing equipment to handle varying batch sizes. For international buyers, understanding regional construction standards and performance requirements is essential to ensure that the materials meet local regulations and project specifications.

Cosmetics

The cosmetics industry relies on mixing equipment for the creation of creams and lotions. This equipment improves the texture and stability of formulations, critical for customer satisfaction and brand loyalty. B2B buyers should focus on the quality of ingredients and the reliability of suppliers, particularly in regions where ingredient sourcing may pose challenges. Additionally, buyers need to be aware of regional cosmetic regulations and standards to ensure compliance and product safety.

Rubber and Plastics

Mixing equipment is integral to compounding rubber for tires and other products, enabling manufacturers to achieve optimal performance and longevity. Buyers in this sector must assess material compatibility and the technological capabilities of suppliers. Given the rapid advancements in mixing technology, international buyers should seek suppliers who can offer innovative solutions and demonstrate a commitment to quality control, especially in markets experiencing industrial growth, such as Africa and South America.

Related Video: MIXING OPERATION IN FOOD PROCESS ENGINEERING AND TECHNOLOGY

Strategic Material Selection Guide for mixing equipment

When selecting materials for mixing equipment, international B2B buyers must consider various factors that affect performance, durability, and compliance. Below is an analysis of four common materials used in mixing equipment, highlighting their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures (up to 1,500°F or 815°C). It is non-reactive, making it suitable for a wide range of media, including food, pharmaceuticals, and chemicals.

Pros & Cons:

Stainless steel is durable and easy to clean, which is crucial for maintaining hygiene in food and pharmaceutical applications. However, it can be relatively expensive compared to other materials, and its manufacturing complexity can lead to longer lead times for custom equipment.

Impact on Application:

Its compatibility with various media makes stainless steel a versatile choice for mixing equipment. However, it may not be suitable for highly abrasive materials, which can cause wear over time.

Considerations for Buyers:

Buyers must ensure compliance with international standards such as ASTM and FDA regulations, especially in food and pharmaceutical sectors. Availability can vary by region, so sourcing from reputable suppliers is essential.

Carbon Steel

Key Properties:

Carbon steel is known for its high tensile strength and durability. It can withstand high pressures and is often used in applications where strength is critical.

Pros & Cons:

While carbon steel is more cost-effective than stainless steel, it is prone to corrosion and requires protective coatings or finishes. This can increase maintenance costs over time.

Impact on Application:

Carbon steel is suitable for mixing applications involving non-corrosive materials. However, its susceptibility to rust makes it less ideal for applications involving moisture or corrosive substances.

Considerations for Buyers:

Buyers in humid regions or those dealing with corrosive materials should consider the long-term costs of maintenance and protective coatings. Compliance with local industry standards is also essential.

Polypropylene

Key Properties:

Polypropylene is a lightweight, chemical-resistant thermoplastic that can withstand temperatures up to 200°F (93°C). It is non-toxic and has excellent impact resistance.

Pros & Cons:

This material is cost-effective and easy to mold into complex shapes, making it ideal for custom mixing equipment. However, it has lower temperature and pressure ratings compared to metals, limiting its applications.

Impact on Application:

Polypropylene is suitable for mixing applications involving acids, bases, and other corrosive materials. However, it may not be suitable for high-temperature processes.

Considerations for Buyers:

International buyers should verify that the polypropylene used complies with relevant chemical safety standards. Additionally, understanding the thermal and chemical limitations is crucial for ensuring long-term performance.

Glass-Filled Nylon

Key Properties:

Glass-filled nylon offers enhanced strength and rigidity due to the addition of glass fibers. It can withstand temperatures up to 300°F (149°C) and has good chemical resistance.

Pros & Cons:

This material combines the lightweight nature of nylon with increased durability, making it suitable for various applications. However, it can be more expensive than standard nylon and may require specialized processing techniques.

Impact on Application:

Glass-filled nylon is ideal for mixing applications that require both strength and chemical resistance, such as in the automotive and electronics industries. Its brittleness under certain conditions can be a limitation.

Considerations for Buyers:

B2B buyers should consider the specific application requirements, including temperature and chemical exposure. Compliance with industry standards such as ISO and ASTM is essential for ensuring product quality.

Summary Table

| Material | Typical Use Case for mixing equipment | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and pharmaceutical mixing equipment | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Carbon Steel | Heavy-duty industrial mixing applications | Cost-effective and durable | Prone to corrosion without coatings | Medium |

| Polypropylene | Chemical mixing applications | Lightweight and chemical-resistant | Lower temperature and pressure ratings | Low |

| Glass-Filled Nylon | Automotive and electronics mixing | Enhanced strength and rigidity | More expensive and requires special processing | Medium |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for mixing equipment

Manufacturing Processes for Mixing Equipment

The production of mixing equipment involves several critical stages that ensure the final product meets the required specifications for performance, durability, and compliance. B2B buyers must understand these processes to evaluate potential suppliers effectively. The main stages of manufacturing mixing equipment include:

1. Material Preparation

The first step in the manufacturing process is material preparation, where raw materials such as metals, polymers, and other components are sourced and inspected. This stage is crucial as the quality of materials directly affects the performance of the mixing equipment.

- Sourcing Quality Materials: Buyers should prioritize suppliers who source high-grade raw materials and provide certification of material properties.

- Pre-Processing: Materials may undergo processes like cutting, welding, or coating to enhance their properties before being used in the assembly.

2. Forming

In this stage, raw materials are shaped into components using various forming techniques.

- Casting: Commonly used for producing complex shapes, casting involves pouring molten material into a mold.

- Machining: Precision machining processes, such as milling and turning, are employed to achieve exact dimensions and surface finishes.

- Fabrication: Techniques like bending and assembling parts are utilized to create the structure of the mixing equipment.

Each forming technique has its pros and cons, influencing factors such as cost, lead time, and the ability to meet specific design requirements.

3. Assembly

After forming, the components are assembled to create the mixing equipment.

- Sub-Assembly: Components are often grouped into sub-assemblies, making the final assembly process more efficient.

- Integration of Systems: This stage involves integrating mechanical, electrical, and control systems, ensuring that all parts work seamlessly together.

- Testing During Assembly: Immediate testing of certain functionalities during assembly can help catch defects early in the process.

4. Finishing

The finishing stage involves surface treatments and final inspections.

- Surface Treatments: Processes like painting, anodizing, or powder coating improve corrosion resistance and aesthetic appeal.

- Final Assembly and Quality Checks: Before shipping, equipment undergoes final assembly and thorough quality checks to ensure compliance with specifications.

Quality Assurance for Mixing Equipment

Quality assurance (QA) is paramount in the manufacturing of mixing equipment, ensuring that the final product meets international and industry-specific standards. Here are the key aspects of QA relevant to B2B buyers:

International Standards and Certifications

B2B buyers should look for suppliers that adhere to recognized international standards, such as:

- ISO 9001: This standard outlines requirements for a quality management system (QMS), ensuring consistent product quality and service.

- CE Marking: In Europe, CE marking indicates that the equipment meets health, safety, and environmental protection standards.

- API Standards: For equipment used in the oil and gas industry, API standards are crucial for ensuring safety and reliability.

Quality Control Checkpoints

Quality control involves various checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspections of raw materials and components as they arrive at the manufacturing facility.

- In-Process Quality Control (IPQC): Continuous monitoring during production to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to verify that it meets all specifications before shipping.

Common Testing Methods

Several testing methods are utilized to ensure the equipment’s performance and reliability:

- Functional Testing: Simulates real-world operation to ensure the equipment performs as expected.

- Performance Testing: Assesses efficiency, throughput, and other performance metrics.

- Durability Testing: Evaluates the equipment’s lifespan under extreme conditions.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control measures of potential suppliers:

- Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing processes and quality assurance practices.

- Reports and Certifications: Requesting quality control reports and certifications can help assess compliance with international standards.

- Third-Party Inspections: Engaging independent inspectors can provide an unbiased assessment of the supplier’s quality control processes.

QC and Certification Nuances for International Buyers

For international B2B buyers, understanding the nuances of quality control and certification is crucial:

- Regional Standards: Be aware of the specific standards and certifications required in your region. For instance, African and South American markets may have different compliance requirements compared to European markets.

- Cultural Factors: Cultural differences can impact supplier communication and adherence to quality standards. Establishing clear expectations and regular communication can mitigate potential misunderstandings.

- Logistical Considerations: International shipping can affect product quality; hence, buyers should ensure that suppliers have robust packaging and handling protocols to protect equipment during transport.

By understanding the manufacturing processes and quality assurance protocols for mixing equipment, international B2B buyers can make informed decisions, ensuring they partner with suppliers that uphold high standards of quality, reliability, and compliance. This knowledge not only aids in mitigating risks but also fosters long-term relationships with dependable manufacturers.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for mixing equipment Sourcing

Understanding the cost structure and pricing dynamics for mixing equipment is crucial for international B2B buyers looking to optimize their procurement strategies. The sourcing of mixing equipment involves various cost components and price influencers that can significantly impact overall expenditure.

Cost Components

-

Materials: The primary cost driver in mixing equipment is the materials used in manufacturing. High-quality steel, specialized alloys, and advanced composites can increase the base cost. Additionally, the choice of materials directly influences durability and performance, which can lead to higher long-term savings.

-

Labor: Labor costs vary widely depending on the region and the expertise required for equipment assembly. In regions like Africa and South America, labor costs may be lower, but the availability of skilled technicians can impact the total cost if additional training or remote support is needed.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, making it essential for buyers to evaluate the operational efficiency of their suppliers.

-

Tooling: Custom tooling for specific mixing applications can be a significant upfront investment. Buyers should consider whether they require standard equipment or if customization is necessary, as this will affect both initial costs and lead times.

-

Quality Control (QC): Investing in robust QC processes ensures the reliability and performance of mixing equipment. While this adds to the cost, it is crucial for minimizing defects and ensuring compliance with international standards, which is particularly important for buyers in regulated industries.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping costs can vary based on the Incoterms agreed upon, distance, and shipping method. Buyers should factor in not only the cost of delivery but also potential customs duties and tariffs, especially when sourcing from international suppliers.

-

Margin: Supplier profit margins can vary significantly based on market demand and competition. Understanding the typical margins in the industry can help buyers negotiate better pricing.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically lead to lower per-unit costs. Buyers should assess their production needs to negotiate favorable pricing based on volume.

-

Specifications/Customization: Customization often leads to higher costs due to additional design and engineering work. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: The choice of raw materials can greatly affect pricing. Premium materials may offer better performance but at a higher cost. Buyers should weigh the benefits against their budget constraints.

-

Quality/Certifications: Equipment that meets international quality standards or possesses specific certifications may come at a premium. However, this investment can ensure compliance and reduce long-term operational risks.

-

Supplier Factors: The supplier’s reputation, reliability, and service offerings (like technical support and maintenance) can influence pricing. Established suppliers may charge more but offer better support and product quality.

-

Incoterms: The agreed Incoterms can affect the total landed cost. Buyers should understand their responsibilities for freight, insurance, and customs clearance to avoid surprises.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers to explore pricing flexibility. Leverage competitive quotes to negotiate better terms and conditions.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, operational costs, and potential downtime. A higher initial investment may lead to lower long-term costs.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on pricing. Establishing contracts in stable currencies can help mitigate risks.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service levels. Regular communication and collaboration can result in mutually beneficial arrangements.

Disclaimer

The pricing insights provided are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations to ensure the best procurement decisions.

Spotlight on Potential mixing equipment Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘mixing equipment’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for mixing equipment

Key Technical Properties of Mixing Equipment

Understanding the technical specifications of mixing equipment is crucial for B2B buyers to ensure optimal performance and compatibility with production needs. Here are some essential properties:

-

Material Grade

– Definition: Refers to the quality and type of materials used in the construction of the mixing equipment, such as stainless steel, carbon steel, or specialized alloys.

– Importance: Material grade impacts durability, resistance to corrosion, and suitability for specific applications (e.g., food, pharmaceuticals). Buyers must choose equipment made from materials that comply with industry standards to prevent contamination and ensure longevity. -

Tolerance

– Definition: The allowable deviation from a standard dimension in the equipment’s components, such as the mixing blades or vessel size.

– Importance: Precise tolerances are essential for maintaining consistency in mixing processes. For buyers, understanding tolerance levels helps ensure that equipment can deliver the desired product specifications and minimize waste. -

Agitation Speed

– Definition: The rotational speed of mixing components, typically measured in revolutions per minute (RPM).

– Importance: Different materials require varying agitation speeds for optimal mixing. Buyers must assess the speed capabilities of mixers to ensure they can achieve the desired homogeneity and prevent issues like sedimentation or aeration. -

Volume Capacity

– Definition: The maximum amount of material the mixer can handle, usually expressed in liters or gallons.

– Importance: Knowing the volume capacity helps buyers select equipment that meets their production scale. Underestimating capacity can lead to bottlenecks, while overestimating can result in unnecessary costs. -

Power Consumption

– Definition: The energy required for the equipment to operate, often measured in kilowatts (kW).

– Importance: Understanding power consumption is critical for evaluating operational costs. Buyers should consider energy-efficient models to reduce long-term expenses and environmental impact. -

Control System

– Definition: The technology that regulates the mixing process, which may include manual, semi-automated, or fully automated controls.

– Importance: An advanced control system can enhance precision and consistency in mixing. Buyers should prioritize equipment with user-friendly interfaces and robust monitoring capabilities to improve operational efficiency.

Common Trade Terminology in Mixing Equipment

Familiarity with industry terminology is essential for effective communication and negotiation in the procurement process. Here are several key terms:

- OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Buyers often work directly with OEMs for custom solutions and reliable support, ensuring that equipment meets specific needs and standards.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding MOQ is crucial for buyers to manage inventory costs and production schedules. It helps in negotiating better terms with suppliers, especially for bulk purchases. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a quote on specific products or services.

– Significance: An RFQ allows buyers to compare prices, terms, and capabilities from different suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international commercial law.

– Significance: Incoterms clarify the responsibilities of buyers and sellers in shipping arrangements, including delivery points and risk transfer, which is vital for international transactions. -

Lead Time

– Definition: The total time from placing an order to the delivery of the equipment.

– Significance: Understanding lead time helps buyers plan their production schedules effectively, minimizing downtime and ensuring timely availability of necessary equipment. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the equipment and the commitment to repair or replace defective parts.

– Significance: A robust warranty can mitigate risks for buyers, ensuring support for maintenance and repairs, which is essential for long-term operational reliability.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their procurement strategies and operational efficiencies in the mixing equipment sector.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the mixing equipment Sector

Market Overview & Key Trends

The mixing equipment sector is experiencing significant transformation driven by several global factors. Industrialization in emerging markets, particularly in regions like Africa and South America, is prompting a surge in demand for efficient mixing technologies. Companies are increasingly prioritizing automation and digitalization to enhance productivity and reduce operational costs. Technologies such as smart mixers equipped with IoT capabilities are gaining traction, enabling real-time monitoring and predictive maintenance, which are crucial for maintaining high standards of quality in production.

Furthermore, there is a notable trend towards sustainability. As environmental regulations tighten, buyers are seeking suppliers who can provide eco-friendly mixing solutions. This includes equipment designed for energy efficiency and waste reduction, which not only helps in compliance with regulations but also appeals to a growing base of environmentally-conscious consumers.

In addition, the supply chain dynamics are shifting. Buyers are advised to establish resilient sourcing strategies that mitigate risks associated with geopolitical tensions and material shortages. Diversification of suppliers, especially from regions like the Middle East and Europe, can help buffer against disruptions. This approach also allows buyers to take advantage of competitive pricing and innovative technologies that different markets offer.

Lastly, customization and flexibility in mixing solutions are becoming essential. Buyers are increasingly looking for equipment that can handle various materials and formulations, enabling them to respond swiftly to market changes and consumer demands. This adaptability will be vital for maintaining a competitive edge in a rapidly evolving landscape.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend; it has become a critical component of business strategy in the mixing equipment sector. The environmental impact of production processes can be substantial, making it essential for B2B buyers to consider ethical sourcing practices. This involves evaluating the entire supply chain to ensure that materials are obtained responsibly, minimizing ecological footprints.

Buyers should prioritize suppliers who adhere to green certifications and demonstrate a commitment to sustainable practices. Certifications such as ISO 14001 for environmental management systems or the Forest Stewardship Council (FSC) for wood-based materials can serve as reliable indicators of a supplier’s dedication to sustainability. Additionally, sourcing materials that are recyclable or made from renewable resources contributes significantly to reducing waste and promoting circular economy principles.

Investing in energy-efficient mixing technologies not only aligns with sustainability goals but also leads to long-term cost savings. For instance, equipment that reduces energy consumption during operations can significantly lower utility costs and improve overall operational efficiency. By integrating sustainable practices into procurement strategies, international buyers can enhance their brand reputation and appeal to a more environmentally-conscious clientele.

Brief Evolution/History

The evolution of mixing equipment has been marked by significant technological advancements and shifts in industrial practices. Initially, mixing processes were manual and labor-intensive, relying on basic machinery that offered limited control over quality. As industries evolved, the introduction of mechanical mixers in the mid-20th century allowed for more consistent blending and greater efficiency.

The late 20th century saw the rise of automation in mixing technologies, with the integration of programmable logic controllers (PLCs) and computerized systems that enabled precise control of mixing parameters. Today, the focus has shifted towards smart technologies that incorporate IoT and machine learning, allowing for real-time data collection and analysis. This evolution not only enhances productivity but also supports the growing demand for customization and sustainability in mixing processes.

In summary, understanding these historical trends is vital for B2B buyers as they navigate the complexities of sourcing mixing equipment in an increasingly competitive and environmentally-conscious global marketplace.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of mixing equipment

-

What should I consider when vetting suppliers for mixing equipment?

When vetting suppliers, prioritize their industry experience, reputation, and compliance with international standards. Request references and case studies from similar projects. Evaluate their production capabilities, including technology and maintenance practices. Additionally, consider the supplier’s certifications (ISO, CE, etc.) to ensure quality assurance. A site visit can also provide insights into their operations and workforce capabilities, allowing you to gauge their reliability in meeting your specific needs. -

Can mixing equipment be customized to meet my specific requirements?

Yes, many manufacturers offer customization options for mixing equipment based on the unique needs of your operation. This can include modifications to size, mixing speed, and material compatibility. When discussing customization, provide detailed specifications and desired outcomes to ensure the manufacturer understands your requirements. Be prepared for potential additional costs and longer lead times associated with custom solutions. -

What are the typical minimum order quantities (MOQs) and lead times for mixing equipment?

Minimum order quantities vary significantly among suppliers and depend on the type of equipment. Generally, larger, more specialized equipment may have higher MOQs. Lead times can range from a few weeks to several months, influenced by factors such as production schedules, customization needs, and shipping logistics. It’s advisable to discuss these details upfront with suppliers to align expectations and ensure timely delivery for your production schedule. -

What payment terms should I negotiate with international suppliers?

Payment terms can vary widely, so it’s crucial to negotiate terms that protect your interests. Common practices include partial upfront payments (20-50%) with the balance due upon delivery or installation. Consider using letters of credit for larger transactions to mitigate risk. Additionally, clarify any potential additional costs, such as tariffs or shipping fees, to avoid unexpected expenses that could impact your budget. -

How can I ensure quality assurance and compliance with international standards?

To ensure quality, request that suppliers provide documentation of their quality assurance processes and certifications. Establish clear expectations for testing protocols and compliance with relevant standards (e.g., ASTM, ISO). Involve third-party inspectors if necessary, especially for large orders, to verify that equipment meets specifications before shipment. Regular communication with the supplier during production can also help address potential issues proactively. -

What logistics considerations should I keep in mind when sourcing mixing equipment?

Logistics play a critical role in sourcing mixing equipment internationally. Assess the supplier’s shipping capabilities and discuss options for freight forwarding, customs clearance, and delivery timelines. Determine the best shipping method based on cost and urgency, and consider potential delays due to customs regulations or local logistics challenges in your region. It’s advisable to work with a logistics partner familiar with international shipping to streamline the process. -

How should I handle disputes with suppliers over equipment quality or delivery issues?

Establish a clear dispute resolution process in your contract, outlining steps for addressing issues related to equipment quality or delivery. Document all communications and maintain records of agreements and expectations. Open dialogue with suppliers can often resolve disputes amicably; however, if necessary, consider mediation or arbitration as alternatives to litigation. Knowing your rights under international trade laws can also provide leverage in negotiations. -

What ongoing support and maintenance should I expect from my mixing equipment supplier?

Ensure that your supplier provides comprehensive after-sales support, including installation, training, and maintenance services. Discuss warranty terms and what they cover, as well as the availability of spare parts and technical support. A good supplier should also offer periodic maintenance checks and be responsive to your operational needs, ensuring that your equipment remains efficient and minimizes downtime in your production processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for mixing equipment

In today’s dynamic landscape, strategic sourcing of mixing equipment is essential for B2B buyers aiming to enhance operational efficiency and product quality. The variety of mixing technologies—from open mill to continuous mixing—offers distinct advantages tailored to diverse industrial needs. Buyers should prioritize partnerships with manufacturers that provide comprehensive testing services, ensuring that equipment is suited to their specific processes and material requirements.

Key takeaways for international buyers include:

– Understand Your Needs: Assess the specific mixing requirements of your industry to select the most appropriate technology.

– Quality Control: Focus on suppliers who uphold rigorous quality standards and can demonstrate a track record of successful implementations.

– Cost Management: Consider the total cost of ownership, including maintenance and operational efficiency, rather than just the initial purchase price.

As the global market evolves, the demand for innovative and efficient mixing solutions will only increase. Buyers from Africa, South America, the Middle East, and Europe are encouraged to leverage this opportunity to rethink their sourcing strategies. By doing so, they can position themselves for long-term success and resilience in a competitive marketplace. Embrace the future of mixing equipment—invest strategically to unlock greater value and drive your business forward.