Master Sourcing Strategies for Motor Drive Shaft Coupling

Introduction: Navigating the Global Market for motor drive shaft coupling

In the realm of industrial machinery, motor drive shaft couplings play an indispensable role, acting as the vital link that connects motor shafts to driven equipment. These components ensure the smooth transmission of torque while accommodating unavoidable misalignments, thereby safeguarding machinery from premature wear and catastrophic failures. For international B2B buyers—especially those operating in diverse markets across Africa, South America, the Middle East, and Europe—understanding the intricacies of motor drive shaft couplings is crucial for optimizing operational efficiency and reducing downtime.

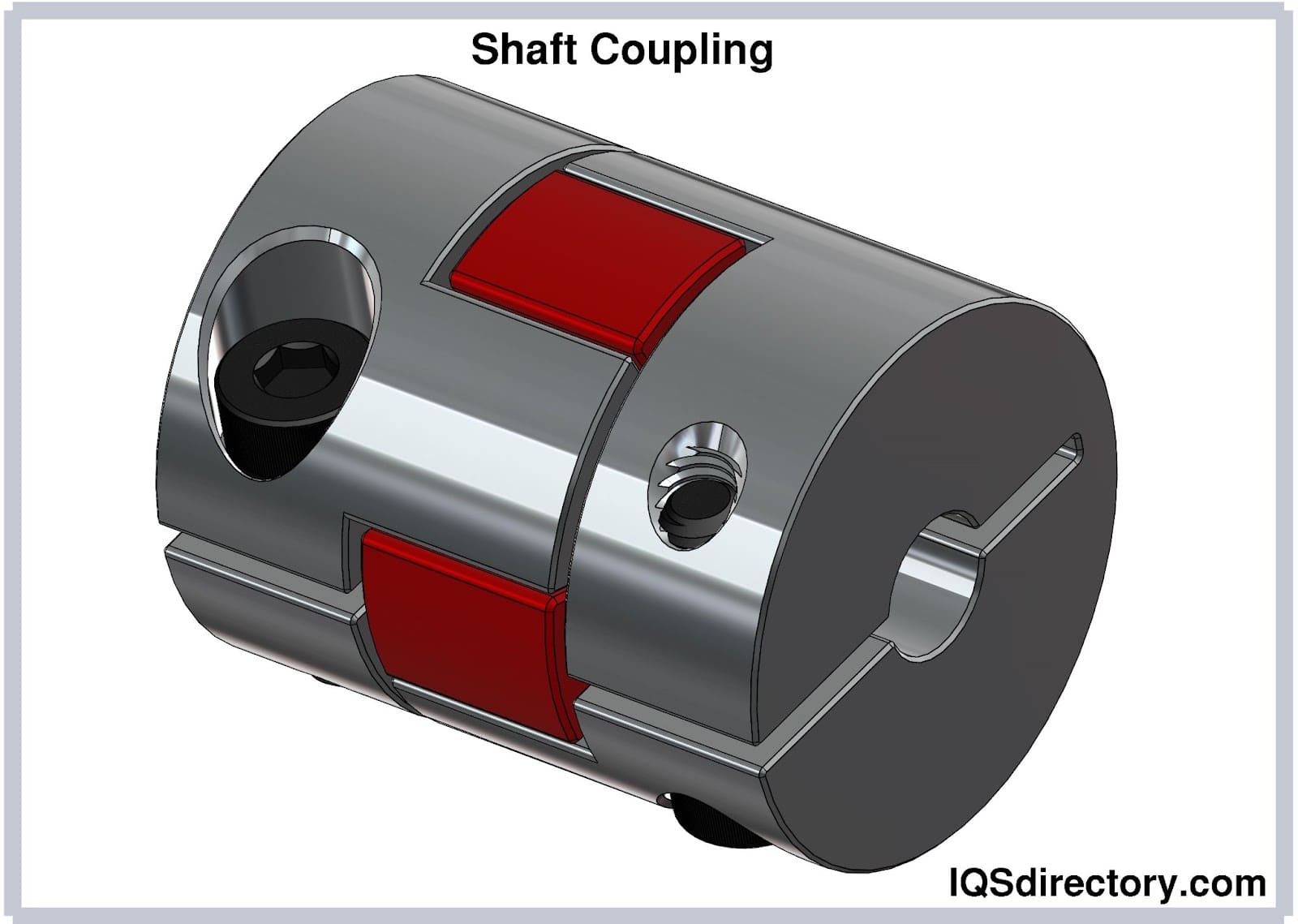

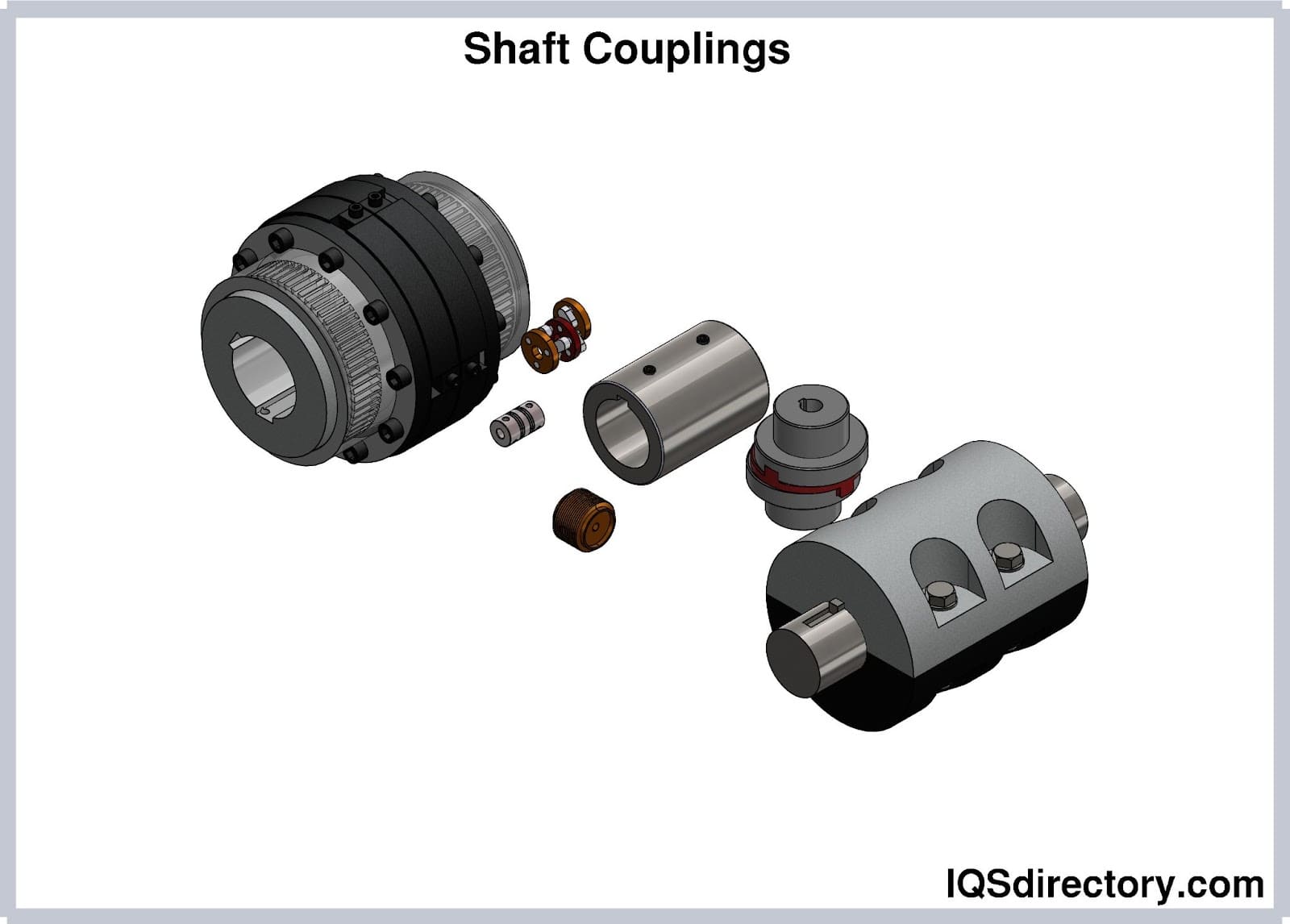

Illustrative Image (Source: Google Search)

This comprehensive guide delves into the various types of motor drive shaft couplings, their material compositions, and the critical aspects of manufacturing and quality control. It also provides insights into identifying reliable suppliers, understanding cost implications, and navigating the global market landscape. By addressing frequently asked questions, this guide empowers buyers with the knowledge needed to make informed sourcing decisions tailored to their specific operational needs.

As the global market evolves, the demand for high-quality, durable couplings continues to rise. Whether you are sourcing for a manufacturing plant in Argentina or a robotics facility in the UK, this guide is designed to equip you with actionable insights that enhance your procurement strategies and ensure the reliability of your mechanical systems.

Understanding motor drive shaft coupling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Elastic Couplings | Use elastomeric materials to absorb shock and vibration | Pumps, conveyors, and moderate-load systems | Pros: Vibration damping, moderate misalignment tolerance. Cons: Limited torque capacity. |

| Rigid Couplings | Provide a solid, inflexible connection | Precision machinery requiring exact alignment | Pros: High torque transmission, no backlash. Cons: Cannot accommodate misalignment. |

| Universal Joints | Allow for significant angular misalignment | Automotive and heavy machinery | Pros: Flexibility in alignment, robust design. Cons: May require more maintenance. |

| Gear Couplings | Feature interlocking gears for high torque applications | Heavy-duty industrial equipment | Pros: High torque transmission, durable. Cons: More complex installation. |

| Disc Couplings | Utilize flexible metal discs to handle misalignment | Robotics and high-speed applications | Pros: High precision, accommodates misalignment. Cons: Sensitive to overloads. |

Elastic Couplings

Elastic couplings are designed with elastomeric materials that absorb shock and vibration, making them ideal for applications involving moderate misalignment. They are particularly useful in pumps and conveyors where damping vibrations is crucial. Buyers should consider the load capacity, as while these couplings offer excellent vibration absorption, they have limitations on torque transmission. Their ease of installation and maintenance further enhance their appeal for many B2B applications.

Rigid Couplings

Rigid couplings create a solid connection between shafts, ensuring precise alignment. They are commonly used in applications where exact shaft alignment is critical, such as in precision machinery. While they excel at transmitting high torque without backlash, buyers must be cautious, as these couplings do not accommodate misalignment. Therefore, it’s essential to assess the alignment conditions before choosing a rigid coupling to avoid premature wear or failure.

Universal Joints

Universal joints (U-joints) are designed to accommodate significant angular misalignment, making them suitable for automotive and heavy machinery applications. They allow for flexibility in shaft alignment, which is particularly valuable in dynamic environments. However, buyers should be aware that while U-joints are robust, they may require more frequent maintenance due to their moving parts. Understanding the operational environment and alignment needs is crucial for effective purchasing decisions.

Gear Couplings

Gear couplings consist of interlocking gears that facilitate high torque transmission, making them well-suited for heavy-duty industrial equipment. Their durability and ability to handle high torque loads make them a preferred choice in demanding applications. However, the complexity of installation can be a drawback for some buyers. It is essential to evaluate the specific torque requirements and installation capabilities when considering gear couplings for B2B applications.

Disc Couplings

Disc couplings utilize flexible metal discs to accommodate misalignment and are often employed in robotics and high-speed applications. They provide high precision and are effective in situations where precise shaft alignment is necessary. However, buyers should be cautious of their sensitivity to overloads, which can lead to premature failure. When selecting disc couplings, it’s important to consider the operational conditions and potential load scenarios to ensure optimal performance.

Related Video: Types of Shaft Coupling, Animation, Machine Design | Solidworks

Key Industrial Applications of motor drive shaft coupling

| Industry/Sector | Specific Application of motor drive shaft coupling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to conveyor systems | Ensures efficient material handling and reduced downtime | Compatibility with existing machinery and load capacity |

| Automotive | Power transmission in assembly lines | Enhances production speed and reliability | Torque requirements and misalignment tolerance |

| HVAC Systems | Integration in fan and pump systems | Improves energy efficiency and reduces vibrations | Environmental resistance and ease of maintenance |

| Oil & Gas | Connecting pumps in drilling operations | Increases operational safety and equipment longevity | Durability under extreme conditions and corrosion resistance |

| Robotics | Linkage in robotic arms and automation systems | Facilitates precision movement and task execution | Lightweight materials and high torque capacity |

Manufacturing

In the manufacturing sector, motor drive shaft couplings are pivotal in connecting motors to conveyor systems. They ensure the seamless transfer of power, which is essential for efficient material handling. By accommodating misalignment and reducing vibrations, these couplings minimize wear and tear on machinery, significantly reducing downtime. For international buyers, especially in regions like Africa and South America, sourcing couplings that are compatible with existing machinery while meeting specific load capacities is crucial for maintaining operational efficiency.

Automotive

In automotive manufacturing, motor drive shaft couplings are used for power transmission along assembly lines. These couplings enhance production speed and reliability by ensuring that motors operate in sync with machinery. The ability to handle varying torque requirements and misalignment is vital for maintaining continuous workflow. Buyers from Europe and the Middle East should focus on sourcing couplings that align with the specific torque and load conditions of their assembly processes to optimize production efficiency.

HVAC Systems

Motor drive shaft couplings are integral to HVAC systems, particularly in connecting motors to fans and pumps. These couplings help improve energy efficiency and reduce vibrations, which can lead to noise reduction and enhanced system longevity. For buyers, especially in regions with high humidity or temperature variations, it is essential to consider couplings with environmental resistance. Ease of maintenance is another critical factor, as it can directly affect operational uptime.

Oil & Gas

In the oil and gas industry, motor drive shaft couplings are vital for connecting pumps used in drilling operations. These couplings increase operational safety by accommodating misalignment and reducing the risk of equipment failure. Given the extreme conditions often encountered in this sector, sourcing durable couplings that can withstand high torque and resist corrosion is essential. Buyers in this industry should prioritize suppliers who offer couplings designed for harsh environments to ensure long-term reliability.

Robotics

Motor drive shaft couplings are crucial in robotics, linking motors within robotic arms and automation systems. They facilitate precise movement, essential for executing intricate tasks. Lightweight materials that can handle high torque are particularly important for enhancing the efficiency of robotic systems. International buyers, especially in technologically advanced regions, should ensure that the couplings sourced meet specific performance criteria to maintain the precision and reliability of their robotic applications.

Related Video: Selecting a Coupling for a Shaft

Strategic Material Selection Guide for motor drive shaft coupling

When selecting materials for motor drive shaft couplings, it is crucial to consider their properties, advantages, disadvantages, and suitability for specific applications. Below is an analysis of four common materials used in the manufacture of motor drive shaft couplings, focusing on their performance characteristics and implications for international B2B buyers.

Steel

Key Properties: Steel couplings are known for their high strength and durability. They can withstand high torque and pressure ratings, making them suitable for heavy-duty applications. Steel also offers excellent wear resistance and can operate effectively in a wide temperature range.

Pros & Cons: The primary advantage of steel is its robustness, which translates to longer service life and lower maintenance costs. However, steel is prone to corrosion if not properly treated, which can be a significant drawback in humid or corrosive environments. Additionally, steel couplings tend to be heavier, which may not be ideal for applications where weight is a critical factor.

Impact on Application: Steel couplings are widely used in industries such as manufacturing and automotive, where high torque transmission is essential. However, they may not be suitable for applications involving corrosive media unless treated with protective coatings.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for material quality. In regions like Africa and South America, where humidity may be high, selecting corrosion-resistant steel options is advisable.

Aluminum

Key Properties: Aluminum couplings are lightweight and possess good corrosion resistance. They typically have lower temperature and pressure ratings compared to steel but are excellent for applications requiring reduced weight.

Pros & Cons: The key advantage of aluminum is its lightweight nature, which facilitates easier handling and installation. However, aluminum is less durable than steel, making it less suitable for high-torque applications. Additionally, its lower strength can lead to higher wear rates under heavy loads.

Impact on Application: Aluminum couplings are ideal for high-speed applications in industries like robotics and HVAC, where weight savings are crucial. However, they may not perform well in heavy-duty environments or where high torque is required.

Considerations for International Buyers: Buyers in Europe and the Middle East should be aware of the specific alloy grades that meet local standards for strength and corrosion resistance. Ensuring compliance with JIS standards is also essential for quality assurance.

Elastomers

Key Properties: Elastomeric couplings are made from flexible materials that provide excellent vibration damping and misalignment compensation. They can operate effectively in moderate temperature ranges and are resistant to wear and tear.

Pros & Cons: The primary advantage of elastomers is their ability to absorb shocks and vibrations, leading to smoother operation. However, they may not withstand high temperatures or heavy loads, limiting their use in certain applications. Additionally, their lifespan can be shorter compared to metal couplings.

Impact on Application: Elastomeric couplings are widely used in applications with moderate misalignment and vibration, such as in pumps and compressors. They are particularly effective in reducing noise and extending the life of connected equipment.

Considerations for International Buyers: Buyers should consider the specific elastomer compounds used, as they must be compatible with the media they will encounter. Compliance with local standards for material safety and performance is also crucial.

Composite Materials

Key Properties: Composite couplings combine materials like fiberglass and resin, offering a balance of strength and weight. They are resistant to corrosion and can operate effectively in a variety of environmental conditions.

Pros & Cons: The main advantage of composite materials is their lightweight nature and corrosion resistance, making them suitable for a wide range of applications. However, they can be more expensive to manufacture and may not offer the same torque transmission capabilities as metal couplings.

Impact on Application: Composite couplings are ideal for applications in corrosive environments, such as chemical processing and marine applications. Their lightweight nature also makes them suitable for portable equipment.

Considerations for International Buyers: Buyers should ensure that composite materials meet relevant international standards for safety and performance. In regions like the Middle East, where exposure to harsh conditions is common, selecting high-quality composite options is essential.

Summary Table

| Material | Typical Use Case for motor drive shaft coupling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications in manufacturing | High strength and durability | Prone to corrosion | Medium |

| Aluminum | High-speed applications in robotics | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Elastomers | Pumps and compressors with moderate misalignment | Excellent vibration damping | Limited temperature and load capacity | Low |

| Composite | Chemical processing and marine applications | Corrosion-resistant and lightweight | Higher manufacturing cost | High |

This guide should assist international B2B buyers in making informed decisions regarding material selection for motor drive shaft couplings, ensuring optimal performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for motor drive shaft coupling

When considering the procurement of motor drive shaft couplings, understanding the manufacturing processes and quality assurance protocols is crucial for B2B buyers. This knowledge not only helps in selecting reliable suppliers but also ensures that the products meet international standards. Below is a detailed breakdown of the typical manufacturing processes, quality assurance measures, and how buyers can verify supplier credentials.

Manufacturing Processes

The manufacturing of motor drive shaft couplings typically involves several key stages:

1. Material Preparation

The first stage involves selecting the appropriate materials based on the application requirements. Common materials include:

- Steel: Known for its strength and durability, suitable for heavy-duty applications.

- Aluminum: Lightweight and corrosion-resistant, ideal for high-speed environments.

- Elastomers: Used for flexible couplings to absorb shock and vibration.

Once selected, the materials are cut and shaped into preliminary forms, ensuring they meet dimensional specifications.

2. Forming

This stage involves various techniques depending on the coupling type:

-

Machining: Precision machining processes like turning, milling, and grinding are used to achieve the exact dimensions and tolerances required for the coupling. CNC (Computer Numerical Control) machines are often employed for their high accuracy.

-

Casting and Forging: For specific designs, components may be cast or forged. Casting allows for complex shapes while forging enhances material strength.

-

Heat Treatment: Some couplings undergo heat treatment to improve mechanical properties, such as hardness and tensile strength, crucial for high-torque applications.

3. Assembly

After forming, the components are assembled. This may involve:

- Joining Techniques: Welding, bolting, or using adhesive methods to connect different parts securely.

- Alignment: Ensuring proper alignment during assembly is critical for operational efficiency and to minimize wear and tear.

4. Finishing

The final stage includes surface treatments and coatings to enhance durability and resistance to environmental factors. Common processes include:

- Polishing: Improves surface finish and reduces friction.

- Coating: Application of protective coatings such as zinc plating or powder coating to prevent corrosion.

Quality Assurance

Quality assurance is vital in ensuring that motor drive shaft couplings perform reliably in demanding environments. Key aspects include:

International Standards

Buyers should look for compliance with relevant international standards such as:

- ISO 9001: This standard outlines the criteria for a quality management system, ensuring consistent quality and continuous improvement.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: For couplings used in the oil and gas industry, API (American Petroleum Institute) standards may apply.

Quality Control Checkpoints

Quality control is typically performed at several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch any deviations from quality standards early.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify performance and reliability.

Common Testing Methods

Several testing methods are employed to ensure quality, including:

- Torque Testing: Measures the coupling’s ability to transmit torque without failure.

- Vibration Testing: Assesses the coupling’s ability to dampen vibrations and maintain operational stability.

- Dimensional Inspection: Uses precision measuring tools to ensure that all parts meet specified tolerances.

Verifying Supplier Quality Control

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies to verify supplier quality control:

Supplier Audits

Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This includes:

- Facility Tours: Visiting the manufacturing site to observe processes and quality checks in real-time.

- Document Review: Examining quality control reports, compliance certificates, and inspection records.

Third-Party Inspection

Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control measures. These agencies can conduct:

- Pre-shipment Inspections: Ensuring products meet specified quality standards before they are shipped.

- Random Sampling: Testing a sample of products from a batch to ensure consistency in quality.

Certification Verification

Buyers should request copies of certifications and confirm their validity with the issuing organizations. This includes checking for:

- ISO Certification: Validating the supplier’s ISO 9001 status.

- CE Certification: Ensuring compliance with relevant European standards.

Conclusion

For international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for motor drive shaft couplings is essential. By focusing on material selection, manufacturing techniques, and rigorous quality control protocols, buyers can ensure they procure reliable and durable couplings that meet their specific application needs. Verifying supplier quality through audits, third-party inspections, and certification checks further enhances the confidence in the purchasing decision, leading to improved operational efficiency and reduced risks.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for motor drive shaft coupling Sourcing

When sourcing motor drive shaft couplings, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis provides a breakdown of the various cost components, price influencers, and tips for effective negotiation, particularly tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials:

The choice of materials significantly impacts costs. Common materials for couplings include steel, aluminum, and elastomers. High-strength steel is typically more expensive but offers durability for heavy-duty applications, whereas aluminum provides a lightweight alternative at a moderate price. -

Labor:

Labor costs can vary based on the region and the complexity of manufacturing processes. Skilled labor in regions with higher living costs may increase the overall price of the coupling. -

Manufacturing Overhead:

This includes costs associated with utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs, affecting the final pricing. -

Tooling:

The initial investment in tooling can be substantial, especially for customized couplings. Buyers should consider whether the supplier has the necessary equipment to produce specific designs, as this can influence the tooling costs. -

Quality Control (QC):

Implementing strict QC processes ensures product reliability and safety. However, this adds to the overall cost. Certifications such as ISO or industry-specific standards can also impact pricing, reflecting the supplier’s commitment to quality. -

Logistics:

Transportation and shipping costs must be factored into the total cost. This includes local distribution and international freight, which can vary widely depending on the shipping terms agreed upon (Incoterms). -

Margin:

Suppliers typically add a margin to cover their costs and ensure profitability. This margin can be influenced by competition, demand, and the supplier’s market position.

Price Influencers

-

Volume/MOQ:

Pricing often improves with higher order volumes. Minimum Order Quantities (MOQ) can impact initial costs, so negotiating for lower MOQs can yield better pricing for smaller businesses. -

Specifications/Customization:

Custom designs tailored to specific applications can lead to higher costs. Buyers should weigh the necessity of customization against standard options, which are usually more cost-effective. -

Materials and Quality/Certifications:

The choice of materials and the presence of quality certifications can significantly influence pricing. Premium materials and certified products often justify higher costs due to their enhanced performance and longevity. -

Supplier Factors:

The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may charge more but can offer better service and quality assurance. -

Incoterms:

Understanding the implications of different Incoterms (e.g., FOB, CIF) is vital. These terms dictate the responsibilities of buyers and sellers regarding shipping costs and risks, which can alter the total cost of ownership.

Buyer Tips

-

Negotiation:

Engage in open discussions with suppliers to negotiate pricing. Leverage multiple quotes to create competitive tension, which can lead to better pricing. -

Cost-Efficiency:

Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and potential downtime. A slightly higher upfront cost may result in lower long-term expenses if the coupling is more durable. -

Pricing Nuances for International Buyers:

Be aware of currency fluctuations, import duties, and taxes when sourcing from international suppliers. These factors can significantly affect the final price and should be included in your budgeting. -

Disclaimer on Indicative Prices:

Prices can vary widely based on the factors mentioned above. Always seek updated quotes and consider the specific requirements of your application to obtain the most accurate pricing.

In summary, understanding the intricate cost structure and pricing dynamics associated with motor drive shaft couplings is essential for making informed purchasing decisions. By considering the various components and influencers outlined above, buyers can enhance their sourcing strategy and achieve better value.

Spotlight on Potential motor drive shaft coupling Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘motor drive shaft coupling’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for motor drive shaft coupling

Motor drive shaft couplings are critical components in mechanical systems, and understanding their technical properties and relevant trade terminology is essential for international B2B buyers. Below are key specifications and terms that can influence purchasing decisions.

Key Technical Properties

-

Material Grade

– Definition: Refers to the specific type of material used in the coupling, such as steel, aluminum, or elastomers.

– B2B Importance: Different materials offer varying levels of strength, corrosion resistance, and weight. For instance, steel couplings are suited for heavy-duty applications, while aluminum is preferred in high-speed systems due to its lightweight nature. -

Torque Rating

– Definition: The maximum amount of torque that the coupling can transmit without failure.

– B2B Importance: Selecting a coupling with an appropriate torque rating is crucial to avoid equipment failure. Inadequate torque ratings can lead to premature wear or catastrophic failures, resulting in costly downtime. -

Misalignment Tolerance

– Definition: The extent to which a coupling can accommodate misalignment between connected shafts.

– B2B Importance: Different couplings handle misalignment differently; understanding this tolerance helps buyers select a coupling that can effectively reduce vibration and wear in their specific applications. -

Operating Speed

– Definition: The maximum rotational speed at which the coupling can function safely.

– B2B Importance: Buyers must consider the operational speed of their machinery to ensure the coupling can handle the demands of high-speed applications without failure. -

Temperature Range

– Definition: The range of temperatures within which the coupling can operate without degrading.

– B2B Importance: Understanding the temperature range is vital for applications in extreme environments, as material properties can change significantly under different thermal conditions. -

Ease of Maintenance

– Definition: The design features that facilitate the inspection, installation, and replacement of the coupling.

– B2B Importance: Couplings designed for easy maintenance can reduce downtime and maintenance costs, making them more appealing to buyers focused on operational efficiency.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– B2B Importance: Understanding OEM specifications is crucial for buyers to ensure compatibility with existing machinery and to maintain warranties. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– B2B Importance: Knowing the MOQ helps buyers plan their inventory and budget accordingly. Larger orders may also lead to cost savings. -

RFQ (Request for Quotation)

– Definition: A formal document requesting a price quote from suppliers for specific products.

– B2B Importance: An RFQ helps buyers obtain competitive pricing and terms from multiple suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms used to clarify the costs, risks, and responsibilities involved in shipping goods.

– B2B Importance: Familiarity with Incoterms is essential for international buyers to understand shipping liabilities, customs duties, and delivery obligations. -

Lead Time

– Definition: The time it takes from placing an order to the delivery of the product.

– B2B Importance: Knowing the lead time is critical for project planning and ensures that buyers can meet their operational timelines.

Illustrative Image (Source: Google Search)

- Certification Standards

– Definition: Standards that products must meet to ensure quality and safety, such as ISO or ASTM certifications.

– B2B Importance: Certifications provide assurance regarding the quality and reliability of the couplings, which is especially important for industries with stringent safety regulations.

Understanding these technical properties and trade terms empowers B2B buyers to make informed decisions, ensuring they select the right motor drive shaft couplings for their applications.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the motor drive shaft coupling Sector

Market Overview & Key Trends

The motor drive shaft coupling sector is witnessing significant growth driven by the increasing demand for efficient power transmission across various industries, including manufacturing, automotive, and energy. Global drivers such as industrial automation, the rise of renewable energy sources, and the expansion of manufacturing capabilities in developing regions are propelling this market forward. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of these trends is essential for strategic sourcing.

Current and emerging B2B sourcing trends include the adoption of advanced manufacturing technologies, such as 3D printing and IoT-enabled devices. These technologies enhance the precision and customization of couplings, allowing for better alignment with specific application needs. Moreover, buyers are increasingly gravitating towards suppliers that offer integrated solutions, combining couplings with monitoring and maintenance services to improve operational efficiency.

Market dynamics are also influenced by regional factors. In Africa and South America, the focus is on cost-effective solutions that can withstand challenging environmental conditions. In contrast, European buyers are often more inclined towards high-precision, high-performance couplings that comply with stringent regulatory standards. Understanding these regional preferences can provide B2B buyers with a competitive edge in sourcing decisions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration in the sourcing of motor drive shaft couplings. The environmental impact of manufacturing processes, including resource consumption and waste generation, necessitates a shift towards sustainable practices. B2B buyers should prioritize suppliers that adhere to sustainable manufacturing processes, such as using recyclable materials and minimizing energy consumption during production.

The importance of ethical supply chains cannot be overstated. Buyers should seek partnerships with manufacturers who are transparent about their sourcing practices, ensuring that materials are obtained from responsible sources. Certifications such as ISO 14001 for environmental management and materials with green certifications (e.g., recycled aluminum or environmentally-friendly elastomers) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, adopting sustainable practices not only enhances corporate responsibility but can also lead to long-term cost savings and improved brand reputation. B2B buyers should engage with suppliers who are willing to invest in sustainable technologies and practices, thereby fostering a more resilient supply chain.

Brief Evolution/History

The evolution of motor drive shaft couplings has been shaped by advancements in engineering and materials science. Originally, couplings were simple mechanical devices designed primarily for torque transmission. However, as machinery became more complex and the demand for precision increased, the coupling designs evolved to accommodate various misalignment types and to enhance vibration damping.

In the late 20th century, the introduction of flexible couplings marked a significant shift, allowing for greater tolerance to misalignment and shock loads. This evolution has continued into the 21st century with the integration of smart technologies, enabling real-time monitoring and predictive maintenance. Understanding this historical context helps B2B buyers appreciate the technological advancements that inform current sourcing strategies and product offerings.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of motor drive shaft coupling

-

What should I look for when vetting suppliers of motor drive shaft couplings?

When vetting suppliers, prioritize their industry experience, customer reviews, and product range. Ensure they have a proven track record in supplying motor drive shaft couplings specifically tailored to your industry needs. Request references and check their certifications, such as ISO 9001, to confirm quality management standards. Additionally, assess their manufacturing capabilities and inquire about their ability to handle custom orders, as this can be crucial for specialized applications. -

Can I customize motor drive shaft couplings to fit my specific requirements?

Yes, many suppliers offer customization options for motor drive shaft couplings. This can include alterations in size, material, and design to meet specific torque, misalignment, or environmental conditions. When discussing customization, provide detailed specifications and operational parameters to ensure the coupling performs effectively in your application. Confirm the supplier’s experience with custom projects to gauge their capability in delivering your unique requirements. -

What are the typical minimum order quantities (MOQ) and lead times for motor drive shaft couplings?

MOQs can vary significantly depending on the supplier and the type of coupling required. Generally, standard products may have a lower MOQ, while custom designs could require larger orders. Lead times typically range from a few weeks to several months, influenced by factors such as complexity, production schedules, and shipping logistics. Always clarify these details before placing an order to avoid unexpected delays. -

What payment terms and methods are commonly accepted by suppliers?

Payment terms can differ widely among suppliers. Common methods include wire transfers, letters of credit, and payment through online platforms. Some suppliers may offer flexible terms like net 30 or net 60, while others might require upfront payment, especially for custom orders. It’s advisable to negotiate payment terms that align with your cash flow and ensure they are documented in the purchase agreement to prevent disputes later. -

How can I ensure quality assurance and certifications for the couplings I purchase?

To ensure quality, request documentation of the supplier’s quality assurance processes and relevant certifications. Look for suppliers who adhere to international standards such as ISO 9001 or industry-specific certifications. Ask for test reports or certificates of compliance for the couplings you intend to purchase. If possible, visit the supplier’s facility or request third-party inspections to verify the quality of their products before finalizing the order. -

What logistics considerations should I keep in mind when sourcing couplings internationally?

When sourcing internationally, consider the logistics of shipping, including freight costs, customs duties, and delivery times. Work with suppliers who have experience in international shipping and can provide reliable logistics solutions. Understand the import regulations in your country and ensure that the products comply with local standards. Additionally, factor in potential delays due to customs clearance and plan accordingly to minimize disruptions in your operations. -

How can I resolve disputes with suppliers effectively?

To resolve disputes effectively, maintain clear communication with the supplier and document all interactions. Start by addressing the issue directly with the supplier, providing evidence and details of the problem. If a resolution isn’t reached, refer to the terms outlined in your contract regarding dispute resolution methods, such as mediation or arbitration. Establishing a good relationship with suppliers can also facilitate smoother negotiations in case of issues. -

What are the common applications for motor drive shaft couplings in different industries?

Motor drive shaft couplings are utilized across various industries, including manufacturing, automotive, HVAC, and robotics. In manufacturing, they connect motors to conveyors and mixers, ensuring smooth operation. In automotive applications, they are vital for connecting the engine to the drivetrain. Understanding the specific needs of your industry can help in selecting the right type of coupling, whether it be for high-torque applications, vibration damping, or accommodating misalignment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for motor drive shaft coupling

In summary, effective strategic sourcing for motor drive shaft couplings can significantly enhance operational efficiency and equipment longevity across various industries. Key takeaways include the importance of selecting the right type of coupling based on torque requirements, misalignment tolerance, and environmental factors. By prioritizing durability and ease of maintenance, businesses can minimize downtime and reduce costs associated with equipment failure.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it is crucial to engage with reputable suppliers who understand the specific needs of your market. Leveraging local insights and global expertise can lead to smarter purchasing decisions and stronger supplier relationships.

Looking ahead, the demand for advanced coupling solutions will continue to grow as industries evolve. Investing in high-quality motor drive shaft couplings is not just a procurement decision; it is a strategic move towards ensuring operational excellence and competitive advantage. Act now to align your sourcing strategies with market trends and secure reliable, high-performance components for your applications.