Master Sourcing Strategies for Motor Suppliers in Global

Introduction: Navigating the Global Market for motor suppliers

Electric motors are the backbone of industrial operations worldwide, silently powering everything from agricultural machinery in Colombia to advanced manufacturing systems in Europe. For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, sourcing the right motor suppliers is not merely a transactional decision—it is a strategic imperative that directly influences operational efficiency, cost management, and compliance with local regulations.

As the global market for electric motors continues to evolve, navigating this complex landscape requires a comprehensive understanding of various motor types, the materials used in their construction, and the intricacies of manufacturing quality control. This guide serves as an invaluable resource, meticulously outlining the essential aspects of motor procurement, including:

- Types of Motors: Detailed analysis of AC, DC, and specialty motors, tailored for different applications.

- Materials and Manufacturing: Insights into the materials that enhance durability and performance, alongside manufacturing processes that ensure quality.

- Supplier Selection: Frameworks for evaluating and qualifying suppliers, managing costs, and negotiating favorable contracts.

- Market Trends: Current intelligence on pricing models, emerging technologies, and regulatory compliance that impact sourcing decisions.

- FAQs: Addressing common challenges faced by B2B buyers in various global markets.

By leveraging this guide, procurement leaders can enhance their sourcing strategies, mitigate risks, and ultimately secure a competitive advantage in their respective industries, ensuring that their operations are powered by the most reliable motor solutions available.

Understanding motor suppliers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| AC Induction Motor | Robust, simple design; operates on AC power | Pumps, compressors, conveyors, fans | Reliable and widely available; less efficient at variable speeds |

| Brushless DC (BLDC) | Electronic commutation; high efficiency; no brushes | Electric vehicles, HVAC, medical equipment | Long lifespan, compact; higher upfront cost, requires electronic control |

| Synchronous Motor | Rotor speed synchronized with supply frequency | Process plants, mills, power factor correction | High efficiency, precise speed; complex start-up, higher cost |

| Servo Motor | Precise position/speed control; closed-loop feedback | Robotics, CNC, high-precision automation | Exceptional accuracy; more expensive, complex commissioning |

| Gear Motor | Integrated gearbox with motor for torque and speed adaptation | Packaging, materials handling, agitators | Simplifies system design; gearbox wear, modest efficiency loss |

AC Induction Motor

AC induction motors are characterized by their simplicity and robustness, making them ideal for various industrial applications such as pumps, compressors, and conveyors. They operate efficiently on alternating current (AC) and are favored for their reliability and adaptability to different voltage levels, which is particularly beneficial in regions with unstable power supply. B2B buyers should prioritize compatibility with local electrical standards and assess the availability of spare parts and support services to minimize operational downtime.

Brushless DC (BLDC) Motor

BLDC motors utilize electronic commutation instead of brushes, leading to high efficiency and reduced maintenance. Their compact design is suitable for applications in electric vehicles, HVAC systems, and medical devices, where space and energy conservation are crucial. For B2B buyers, the long lifespan and operational savings are significant advantages, but it is essential to ensure that local technicians are trained to handle the necessary electronic controls and that supply chains can consistently provide compatible components.

Synchronous Motor

Synchronous motors are designed for applications requiring precise speed control and power factor improvement. Their operation is synchronized with the supply frequency, making them suitable for process plants and critical infrastructure. While they offer high efficiency and performance, buyers must consider the complexity of installation and maintenance, which may necessitate skilled technicians. Ensuring a stable power supply and robust technical support is critical for successful procurement and integration in B2B settings.

Servo Motor

Servo motors provide exceptional precision in position and speed control, making them indispensable in robotics and high-precision automation applications. They operate on closed-loop feedback systems, allowing for real-time adjustments to enhance performance. While their accuracy is unmatched, the higher costs and complexity of commissioning may pose challenges for some buyers. It is vital for B2B purchasers to evaluate their operational needs and ensure they have access to the necessary expertise for installation and maintenance.

Gear Motor

Gear motors combine an electric motor with a gearbox, allowing for efficient torque and speed adaptation in applications such as packaging and materials handling. This integration simplifies system design and enhances performance. However, buyers should be aware of potential gearbox wear and modest efficiency losses over time. When sourcing gear motors, it is crucial to assess the quality of the gearbox and the overall motor construction to ensure long-term reliability and operational efficiency.

Related Video: Different Types of Motorcycles | Explained

Key Industrial Applications of motor suppliers

| Industry/Sector | Specific Application of motor suppliers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Increased efficiency and reduced labor costs | Compatibility with existing systems and local voltage standards |

| Agriculture | Irrigation Pumps | Enhanced crop yield and water management | Durability in harsh environments and availability of spare parts |

| Water Treatment | Submersible Pumps | Improved water quality and compliance with regulations | Energy efficiency and reliability in continuous operation |

| Logistics and Warehousing | Automated Guided Vehicles (AGVs) | Streamlined operations and cost savings | Precision in motor control and integration with automation systems |

| Renewable Energy | Wind Turbines | Sustainable energy production and reduced costs | Compliance with local regulations and availability of technical support |

Manufacturing: Conveyor Systems

In manufacturing, electric motors are integral to conveyor systems that transport materials and products throughout the production line. By employing efficient motors, businesses can significantly increase throughput, reduce manual labor, and minimize operational costs. International buyers should focus on sourcing motors that are compatible with local electrical standards and can withstand the demands of continuous operation. Ensuring the availability of replacement parts and service support is also crucial to maintain uptime in production environments.

Agriculture: Irrigation Pumps

Electric motors power irrigation pumps that are essential in agriculture, particularly in regions with variable rainfall. These motors enable efficient water management, ultimately leading to improved crop yields. For buyers in Africa and South America, sourcing motors that are rugged and capable of operating in harsh conditions is vital. Additionally, considering energy-efficient models can help reduce operational costs, making it essential to evaluate local infrastructure and service networks to support ongoing maintenance.

Water Treatment: Submersible Pumps

In the water treatment sector, submersible pumps powered by electric motors play a critical role in ensuring the supply of clean water. These motors help in the efficient management of water quality and compliance with environmental regulations. Buyers should prioritize sourcing energy-efficient models that can operate continuously and reliably. Understanding local regulations and the availability of skilled technicians for installation and maintenance can greatly influence procurement decisions in this sector.

Logistics and Warehousing: Automated Guided Vehicles (AGVs)

Electric motors are essential for the operation of Automated Guided Vehicles (AGVs) in logistics and warehousing. These systems enhance operational efficiency by automating material handling processes, leading to significant cost savings. Buyers should consider motors that provide precise control and can seamlessly integrate with existing automation systems. Additionally, evaluating the supplier’s ability to provide ongoing technical support is crucial, especially in rapidly evolving logistics environments.

Renewable Energy: Wind Turbines

In the renewable energy sector, electric motors are critical components of wind turbines, converting wind energy into electricity. This application not only supports sustainability goals but also helps reduce energy costs in the long run. For international buyers, especially in Europe, compliance with local regulations and standards is essential when sourcing motors for wind energy applications. Ensuring that suppliers can provide technical support and maintenance services will also contribute to the long-term success of renewable energy projects.

Related Video: Brushless Motor – How they work BLDC ESC PWM

Strategic Material Selection Guide for motor suppliers

When selecting materials for electric motors, international B2B buyers must consider various factors that influence performance, durability, and cost. Here, we analyze four common materials used in motor manufacturing: copper, steel, aluminum, and insulation materials. Each material has distinct properties and implications for application, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe.

Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It can operate effectively in a wide range of temperatures, making it suitable for various motor applications.

Pros & Cons: The primary advantage of copper is its superior conductivity, which leads to improved energy efficiency and reduced heat generation in motors. However, copper is relatively expensive compared to other conductive materials, and its sourcing can be affected by global market fluctuations. Additionally, copper components may require more complex manufacturing processes, increasing production costs.

Impact on Application: Copper is essential in windings and electrical connections within motors. Its high conductivity ensures efficient energy transfer, which is crucial for applications in industries such as manufacturing and transportation.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM B170 and consider the availability of copper in local markets. In regions like Nigeria and Colombia, where copper prices can be volatile, it is advisable to establish reliable supply chains to mitigate cost risks.

Steel

Key Properties: Steel is characterized by its high tensile strength, durability, and resistance to wear and deformation. It can withstand high pressures and is often treated for corrosion resistance.

Pros & Cons: Steel’s strength and durability make it an ideal choice for motor frames and shafts, providing structural integrity. However, the weight of steel can be a disadvantage in applications where weight reduction is critical. Additionally, the manufacturing process for steel components can be complex and energy-intensive.

Impact on Application: Steel is widely used in heavy-duty motors, particularly in industrial applications where robustness is essential. Its ability to handle high torque and pressure makes it suitable for pumps, compressors, and conveyor systems.

Considerations for International Buyers: Buyers should be aware of regional standards such as DIN EN 10025 for structural steel. In Europe, compliance with environmental regulations regarding steel production and recycling may also impact sourcing decisions.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is also non-magnetic, which is beneficial in certain motor applications.

Pros & Cons: The main advantage of aluminum is its low weight, which can enhance the efficiency of motors by reducing overall mass. However, aluminum has lower strength compared to steel, which may limit its use in high-stress applications. Additionally, while aluminum is less expensive than copper, it can still incur significant costs depending on the alloy used.

Impact on Application: Aluminum is often used in motor housings and components where weight reduction is critical, such as in electric vehicles and portable machinery. Its corrosion resistance makes it suitable for outdoor applications or environments with high humidity.

Considerations for International Buyers: Buyers should consider the availability of aluminum alloys that meet specific performance requirements. Standards like ASTM B221 for aluminum extrusions should be adhered to, especially in regions with strict quality regulations.

Insulation Materials

Key Properties: Insulation materials, such as epoxy resins and thermoplastics, provide electrical insulation and thermal stability. They are essential for preventing short circuits and ensuring motor longevity.

Pros & Cons: High-quality insulation materials enhance motor reliability and efficiency. However, they can add to the overall cost and complexity of manufacturing. Some insulation materials may also have limitations in extreme temperature environments.

Impact on Application: Insulation is crucial for all types of motors, particularly in applications involving high voltages or temperatures. Proper insulation ensures safety and compliance with electrical standards.

Considerations for International Buyers: Buyers should verify that insulation materials comply with international standards such as IEC 60085. In regions like the Middle East, where high temperatures are common, selecting insulation materials designed for thermal stability is vital.

Summary Table

| Material | Typical Use Case for motor suppliers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Electrical windings and connections | Superior electrical conductivity | High cost and market volatility | High |

| Steel | Motor frames and shafts | High strength and durability | Heavy and complex manufacturing process | Medium |

| Aluminum | Motor housings and lightweight components | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Insulation Materials | Electrical insulation for motors | Enhances reliability and efficiency | Can increase manufacturing costs | Medium |

This analysis provides a comprehensive overview of the materials critical to motor suppliers, equipping international B2B buyers with the insights needed to make informed procurement decisions.

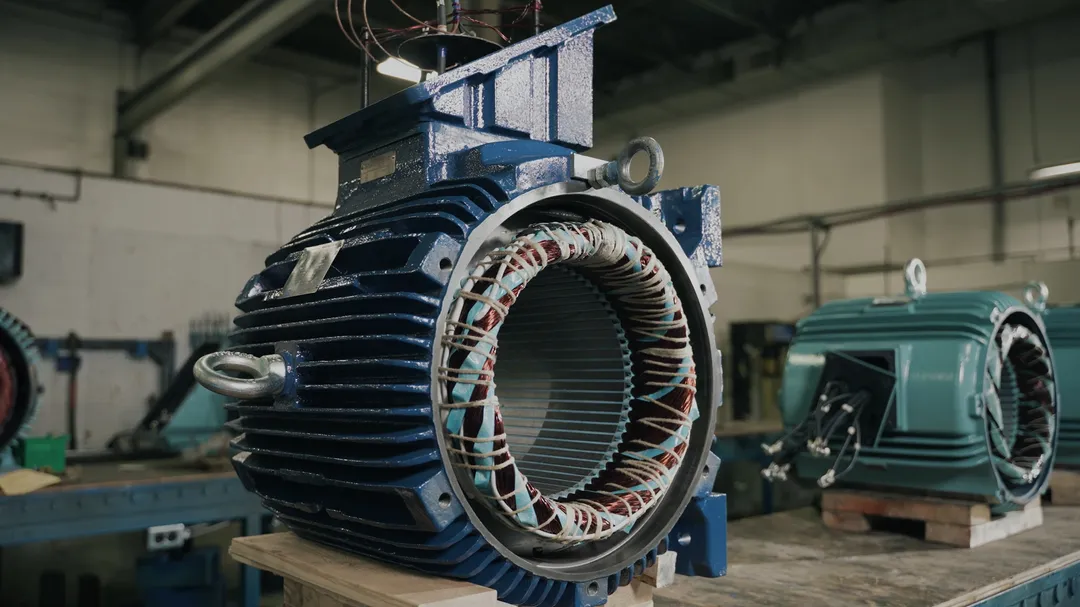

In-depth Look: Manufacturing Processes and Quality Assurance for motor suppliers

Manufacturing Processes for Motor Suppliers

The manufacturing of electric motors involves several critical stages, each contributing to the overall quality and performance of the final product. Understanding these processes is vital for B2B buyers, particularly when sourcing motors for diverse applications in regions like Africa, South America, the Middle East, and Europe.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The first step in motor manufacturing is selecting high-quality raw materials, such as steel for the motor casing, copper for windings, and insulation materials. The choice of materials significantly affects the motor’s performance and durability.

– Material Testing: Before processing, materials undergo rigorous testing to ensure they meet industry specifications. This may include checking for tensile strength, conductivity, and resistance to environmental factors. -

Forming

– Machining Components: Key components like the stator, rotor, and end bells are machined using CNC (Computer Numerical Control) technology. This ensures precision and consistency across all parts, which is essential for effective motor operation.

– Stamping and Winding: Stamping involves creating the core laminations for the stator and rotor. Winding copper wire around the core is done meticulously to ensure optimal electromagnetic properties. -

Assembly

– Component Assembly: After individual parts are prepared, they are assembled. This involves placing the rotor within the stator and securing it with appropriate fasteners. Alignment is crucial to minimize friction and wear during operation.

– Installation of Bearings and Shafts: Bearings are installed to support the rotor, while shafts are integrated to facilitate the motor’s connection to machinery. -

Finishing

– Surface Treatment: To enhance durability and corrosion resistance, motors often undergo surface treatments such as painting, plating, or powder coating. This step is especially important in regions with harsh environmental conditions.

– Final Assembly and Quality Checks: The motor is completed with the addition of any necessary electronic components or controls, and a final inspection is performed before packaging.

Quality Assurance in Motor Manufacturing

Quality assurance (QA) is integral to the motor manufacturing process, ensuring that products meet both international and industry-specific standards. For B2B buyers, understanding these QA processes can aid in selecting reliable suppliers.

International and Industry-Specific Standards

- ISO 9001: This international standard focuses on quality management systems (QMS). Suppliers who adhere to ISO 9001 demonstrate a commitment to quality through systematic processes and continuous improvement.

- CE Marking: Particularly relevant in Europe, the CE mark indicates compliance with health, safety, and environmental protection standards. Buyers in Europe should prioritize suppliers with CE certification.

- API Standards: For motors used in oil and gas applications, adherence to American Petroleum Institute (API) standards is essential. These standards ensure reliability and safety in demanding environments.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Material Inspection: Upon receiving raw materials, suppliers conduct IQC to verify that they meet specified standards. This may involve visual inspections and laboratory testing. -

In-Process Quality Control (IPQC)

– Monitoring During Production: Throughout the manufacturing process, IPQC measures key parameters such as dimensions, electrical resistance, and assembly integrity. This ongoing assessment helps identify defects early. -

Final Quality Control (FQC)

– Comprehensive Testing: Before shipment, motors undergo FQC, which includes functional testing, performance assessments, and safety checks. Testing methods may involve temperature rise tests, noise level assessments, and vibration analysis.

Verification of Supplier Quality Control

B2B buyers can adopt several strategies to verify the quality control measures of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes and quality control practices directly. This assessment can include reviewing documentation, inspecting facilities, and interviewing staff.

- Quality Reports: Requesting detailed quality reports can provide insights into a supplier’s QA processes and track record. These documents should detail test results, compliance certifications, and any corrective actions taken in the past.

- Third-Party Inspections: Engaging third-party inspection services adds an extra layer of assurance. These independent firms can conduct thorough evaluations and provide unbiased reports on the supplier’s quality standards.

Quality Control Nuances for International Buyers

International buyers must be aware of specific nuances when it comes to quality control in motor procurement:

- Regulatory Compliance: Different regions have varying compliance requirements. For instance, motors intended for the European market must meet CE standards, while products for the U.S. may require adherence to NEMA (National Electrical Manufacturers Association) standards.

- Cultural Considerations: Communication styles and business practices can vary significantly across regions. Understanding local customs and expectations can facilitate smoother negotiations and foster stronger supplier relationships.

- Logistics and Supply Chain: Buyers should consider the logistical challenges of sourcing motors internationally, including shipping times, tariffs, and the potential for supply chain disruptions. Having clear agreements on quality expectations and delivery timelines can mitigate risks.

Conclusion

For international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures of motor suppliers is crucial. By focusing on material quality, manufacturing precision, adherence to international standards, and proactive verification strategies, buyers can ensure they are sourcing reliable motors that meet their operational needs. This comprehensive approach not only enhances productivity but also contributes to long-term cost savings and operational efficiency.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for motor suppliers Sourcing

Understanding the cost structure and pricing dynamics of motor suppliers is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This analysis highlights key cost components, price influencers, and actionable buyer tips to navigate the complexities of motor procurement effectively.

Cost Components

-

Materials: The primary cost driver in electric motor manufacturing includes raw materials such as copper, steel, and magnets. The quality of these materials significantly impacts the durability and efficiency of the motors. For example, motors made from high-grade stainless steel or aluminum tend to be more expensive due to their enhanced performance and longevity.

-

Labor: Labor costs can vary widely depending on the region and the skill level required for assembly and quality control. In countries with lower labor costs, such as some parts of Africa and South America, manufacturers might achieve lower overall production costs. However, the expertise required for high-precision motors may necessitate skilled labor, which can elevate costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, equipment maintenance, and utilities. Efficient manufacturing processes can reduce overhead, but initial investments in technology and automation may be substantial.

-

Tooling: Custom tooling for specific motor designs can represent a significant upfront investment. Buyers should consider whether suppliers can utilize existing tooling or if new investments will be required for specialized motor specifications.

-

Quality Control (QC): Rigorous quality assurance processes ensure that motors meet industry standards and customer specifications. The costs associated with QC can be substantial, but they are vital for minimizing defects and enhancing reliability.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors like shipping methods, distance, and Incoterms can all influence final pricing. The choice of air freight versus sea freight can drastically affect costs and delivery timelines.

-

Margin: Supplier profit margins can vary based on the market segment and competition. Larger suppliers might offer lower margins due to economies of scale, while niche manufacturers may have higher margins due to specialized products.

Illustrative Image (Source: Google Search)

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their needs without incurring excess inventory costs.

-

Specifications/Customization: Custom motors designed to meet specific application requirements often come at a premium. Buyers must balance the need for customization with cost considerations.

-

Quality and Certifications: Motors that comply with international quality standards (e.g., ISO, IEC) may command higher prices. Buyers should assess whether the additional cost is justified by the motor’s performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived quality and service levels, whereas emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of sale (e.g., FOB, CIF) is crucial for cost management. These terms dictate who bears the shipping costs and risks, directly impacting the total procurement cost.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing structures, discounts for larger orders, and potential cost-saving opportunities. Establishing a solid relationship can lead to better terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also installation, maintenance, and energy consumption over the motor’s lifecycle. Energy-efficient motors may have higher upfront costs but yield significant savings in operational expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and tariffs that may affect pricing. Building relationships with local suppliers can mitigate risks associated with international shipping and customs.

Disclaimer

Prices for electric motors can vary widely based on specifications, region, and supplier dynamics. The indicative price range for small to medium-sized motors typically falls between USD 100 and USD 500, while industrial-grade motors can range from several hundred to several thousand USD. Always conduct thorough market research and supplier evaluations to ensure the best procurement decisions.

Spotlight on Potential motor suppliers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘motor suppliers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for motor suppliers

Key Technical Properties for Motor Suppliers

Understanding the technical specifications of electric motors is essential for B2B buyers to make informed procurement decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade refers to the quality of the materials used in the motor’s construction, including the housing, windings, and components. Common materials include aluminum, cast iron, and stainless steel. B2B Importance: Higher-grade materials enhance durability and resistance to environmental factors, which is crucial for operations in diverse climates found in regions like Africa and South America.

2. Efficiency Rating

Electric motors are classified by their efficiency ratings, typically represented by the International Electrotechnical Commission (IEC) standards such as IE2, IE3, and IE4. B2B Importance: A higher efficiency rating translates into lower energy consumption and operational costs, making it particularly relevant for businesses focused on sustainability and energy savings, especially in energy-sensitive markets.

3. Power Rating

This specification indicates the motor’s output power, typically measured in horsepower (HP) or kilowatts (kW). It determines the motor’s capability to perform specific tasks. B2B Importance: Selecting the appropriate power rating is critical for ensuring that the motor meets the operational demands of machinery, preventing underperformance or failure.

4. Tolerance

Tolerance refers to the allowable deviation in dimensions and performance characteristics of motor components. It is crucial for ensuring compatibility and performance consistency. B2B Importance: Tight tolerances are essential in precision applications, such as robotics and CNC machinery, where deviations can lead to operational inefficiencies or equipment damage.

5. Operating Temperature Range

This specification defines the range of temperatures within which the motor can operate effectively. Motors may be rated for specific environments, such as high temperatures in industrial settings or colder climates. B2B Importance: Understanding the operating temperature range helps buyers select motors suitable for their environmental conditions, minimizing the risk of overheating or failure.

Common Trade Terminology

Familiarizing yourself with industry jargon is vital for effective communication and negotiation with suppliers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Importance: Knowing whether a supplier is an OEM can inform buyers about the quality and compatibility of the motors with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Importance: Understanding the MOQ helps buyers plan their purchases and manage inventory effectively, especially in regions with limited storage capacity.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request pricing and terms from suppliers for specific products or services. Importance: Sending an RFQ allows buyers to compare offers from multiple suppliers, ensuring they get the best value for their procurement.

Illustrative Image (Source: Google Search)

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international transactions. Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother cross-border transactions.

5. VFD (Variable Frequency Drive)

A VFD is a type of motor controller that adjusts the frequency and voltage supplied to an electric motor. Importance: Using VFDs can enhance energy efficiency and control in applications requiring variable speed, making them increasingly relevant for modern industrial applications.

By understanding these technical properties and trade terms, B2B buyers can navigate the complexities of motor procurement more effectively, ensuring they select the right products for their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the motor suppliers Sector

Market Overview & Key Trends

The global electric motor market is witnessing transformative growth driven by advancements in technology, rising energy efficiency demands, and increased automation across various industries. For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The adoption of Industry 4.0 practices is accelerating, with smart factories and IoT-enabled systems requiring highly efficient and responsive electric motors. This trend is particularly relevant for sectors such as agritech in Colombia and manufacturing in Nigeria, where operational efficiency directly impacts productivity and profitability.

Emerging sourcing trends highlight the importance of flexible supply chains. Buyers are increasingly favoring suppliers who can provide tailored solutions that accommodate local infrastructure and regulatory requirements. Digital sourcing platforms are gaining traction, allowing for streamlined procurement processes and enhanced visibility into supplier capabilities. Additionally, the ongoing shift towards energy-efficient motors, such as IE4-rated products, is not just a regulatory requirement in many regions but also a strategic move to reduce operational costs. Buyers should consider these factors when evaluating suppliers, ensuring they align with both current and future industry needs.

Furthermore, global material costs are fluctuating, influenced by geopolitical tensions and supply chain disruptions. Buyers must remain vigilant and informed about these changes to negotiate effectively and secure competitive pricing. Establishing strong relationships with suppliers in key manufacturing hubs like Germany, China, and Mexico can provide leverage and access to high-quality products.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a core consideration for B2B buyers in the electric motor sector. The environmental impact of motor manufacturing, from raw material extraction to energy consumption during operation, necessitates a focus on sustainable practices. Buyers should prioritize suppliers who adopt sustainable manufacturing processes and demonstrate a commitment to reducing their carbon footprint. This can include utilizing renewable energy sources in production, minimizing waste, and implementing recycling initiatives.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing of raw materials, particularly in regions where labor practices may be questionable. Ensuring that suppliers adhere to ethical standards and can provide transparency in their supply chains is essential for maintaining corporate social responsibility and brand integrity.

Investing in green certifications is another vital aspect for buyers seeking sustainability in motor procurement. Certifications such as ISO 14001 for environmental management and Energy Star for energy efficiency can serve as indicators of a supplier’s commitment to sustainable practices. Additionally, sourcing materials that are recyclable or derived from sustainable sources can help mitigate environmental impact and align with global sustainability goals.

Brief Evolution/History

The electric motor industry has evolved significantly since its inception in the late 19th century. Initially dominated by simple AC and DC motors, technological advancements have led to the development of more sophisticated motor types, including brushless DC and servo motors. The evolution has been driven by the need for greater efficiency, precision, and adaptability to various applications.

In recent decades, the push for energy efficiency and environmental sustainability has reshaped the industry. Regulatory frameworks, particularly in Europe and North America, have established standards that compel manufacturers to innovate continuously. This historical context is critical for B2B buyers, as it highlights the importance of staying abreast of technological advancements and regulatory changes that influence procurement decisions today. Understanding this evolution can aid buyers in making informed choices that align with both current market demands and future trends.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of motor suppliers

-

How can I effectively vet motor suppliers in international markets?

When vetting motor suppliers, focus on their industry reputation, customer reviews, and financial stability. Request references from previous clients, particularly those in your region, to gauge their reliability. Additionally, assess their production capabilities by visiting their facilities if possible or reviewing audits and certifications. Ensuring compliance with international standards (like ISO) can also indicate their commitment to quality and reliability. -

What customization options should I consider when sourcing motors?

Many suppliers offer customization to meet specific operational needs. Consider factors such as voltage, power ratings, and mounting configurations. Communicate your requirements clearly and inquire about the supplier’s ability to accommodate modifications without significant lead times or cost increases. Additionally, assess their past experiences with custom orders to ensure they can deliver tailored solutions effectively. -

What are typical minimum order quantities (MOQ) and lead times for electric motors?

MOQs can vary significantly among suppliers, generally ranging from a few units to several hundred based on the motor type and customization. Lead times typically span from a few weeks to several months, influenced by the complexity of the order and the supplier’s production capacity. Always confirm these details upfront and consider negotiating terms that suit your procurement schedule and inventory management needs. -

What quality assurance measures and certifications should I look for?

Key quality assurance measures include adherence to international standards such as ISO 9001 for quality management and ISO 14001 for environmental management. Request documentation for testing procedures and certifications from recognized bodies. Understanding their quality control processes will help you assess the reliability and durability of the motors, which is crucial for minimizing downtime and ensuring operational efficiency. -

How can I manage logistics and shipping when sourcing motors internationally?

Logistics can be complex when dealing with international suppliers. Establish clear shipping terms (Incoterms) to define responsibilities for costs and risks. Collaborate with logistics providers familiar with the regions involved to ensure efficient transportation. Moreover, consider customs regulations and duties, as these can impact the total cost and delivery timelines. It’s advisable to have contingency plans for potential delays. -

What should I do in case of disputes with my motor supplier?

Disputes can arise from various issues, including product quality and delivery delays. To mitigate risks, establish clear contractual terms outlining expectations, responsibilities, and dispute resolution processes. If conflicts occur, initiate communication with the supplier to resolve issues amicably. If necessary, consider mediation or arbitration as cost-effective alternatives to litigation. Document all communications for reference during dispute resolution. -

How can I ensure after-sales support and spare parts availability?

Inquire about the supplier’s after-sales support policies, including warranty terms and service agreements. Ensure they have a robust system for providing spare parts, particularly in your region, to avoid prolonged downtime. Establishing a reliable line of communication with the supplier for technical support can also be beneficial. Assess their historical performance regarding after-sales service through customer feedback and case studies. -

What payment terms are commonly used in international B2B motor transactions?

Payment terms can vary, but common practices include advance payments, letter of credit, or payment upon delivery. Assess the supplier’s payment flexibility and negotiate terms that mitigate risk while maintaining cash flow. Be cautious of suppliers requiring full payment upfront, especially if they are unfamiliar. Utilizing escrow services for large transactions can also enhance security for both parties during the procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for motor suppliers

In navigating the complexities of motor procurement, international B2B buyers must prioritize strategic sourcing to ensure optimal operational efficiency and cost-effectiveness. Key takeaways include understanding the diverse types of electric motors available, assessing the impact of local regulatory frameworks, and recognizing the importance of supplier reliability and after-sales support. By aligning motor specifications with operational requirements, buyers can mitigate risks associated with downtime and maintenance costs.

As the demand for energy-efficient and sustainable solutions grows, leveraging insights into emerging technologies and market trends will be crucial. Buyers in regions like Africa, South America, the Middle East, and Europe should actively engage with suppliers who not only meet quality standards but also align with their sustainability goals.

Looking ahead, the landscape of motor suppliers is set to evolve, driven by innovations in manufacturing and a heightened focus on energy efficiency. Now is the time for international buyers to harness these insights, build strong supplier partnerships, and make informed decisions that will propel their businesses forward. Embrace strategic sourcing as a pathway to unlocking greater value and resilience in your operations.