Master Sourcing Strategies for Osborn International Brushes

Introduction: Navigating the Global Market for osborn international brushes

In today’s competitive industrial landscape, Osborn International brushes stand out as essential tools for enhancing manufacturing and maintenance processes across various sectors. Known for their durability and efficiency, these brushes play a critical role in tasks ranging from surface finishing to deburring, making them invaluable to businesses focused on quality and productivity. This guide serves as a comprehensive resource for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, including key markets like the UAE and Brazil.

The scope of this guide covers a wide array of topics designed to empower informed sourcing decisions. Buyers will find detailed insights into the types of brushes available, including power brushes, maintenance brushes, and specialty brushes tailored for unique applications. We will also delve into the materials and manufacturing processes that ensure the quality and longevity of Osborn products, alongside stringent quality control measures that uphold industry standards.

Additionally, this guide provides an overview of reliable suppliers and the cost considerations associated with sourcing Osborn brushes. By addressing common market trends and answering frequently asked questions, we aim to equip buyers with the knowledge necessary to make strategic purchasing decisions. Ultimately, this resource is designed to facilitate seamless access to high-quality Osborn brushes, ensuring that businesses can optimize their operations and achieve superior results in their respective markets.

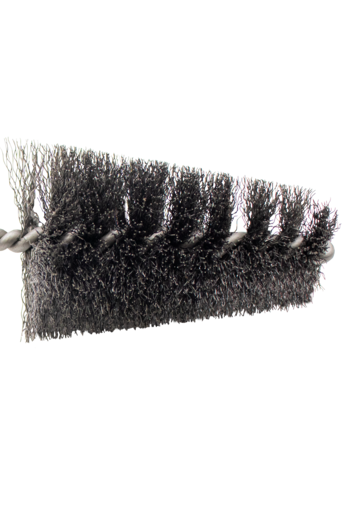

Illustrative Image (Source: Google Search)

Understanding osborn international brushes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Power Brushes | Versatile for cutting, grinding, and deburring; various sizes. | Metalworking, automotive, and manufacturing. | Pros: High efficiency; Cons: Higher initial cost. |

| Strip Brushes | Customizable lengths and shapes; suitable for sealing and cleaning. | Industrial sealing, cleaning, and product handling. | Pros: Tailored solutions; Cons: Longer lead times for custom orders. |

| Maintenance Brushes | Wide range of materials (wire, natural fibers); ergonomic designs. | Facility maintenance and commercial cleaning. | Pros: Diverse applications; Cons: May require frequent replacement. |

| Polishing Tools | Includes compounds and tools for achieving various finishes. | Jewelry making, automotive finishing, and woodworking. | Pros: High-quality finishes; Cons: Requires skill for optimal use. |

| Cylinder Brushes | Designed for cylindrical surfaces; effective at cleaning and deburring. | Pipe manufacturing, automotive, and aerospace. | Pros: Efficient for specific shapes; Cons: Limited to cylindrical applications. |

Power Brushes

Power brushes are essential tools in various industrial applications, particularly in metalworking and automotive sectors. They are designed to perform cutting, grinding, and deburring tasks efficiently. Available in multiple sizes and configurations, these brushes can be adapted to fit various machinery and processes. When purchasing power brushes, buyers should consider the specific material compatibility and the brush’s durability to ensure optimal performance in demanding environments.

Strip Brushes

Strip brushes offer a unique solution for sealing, cleaning, and product handling tasks across multiple industries. Their customizable lengths and shapes make them suitable for a wide range of applications, from industrial sealing to cleaning conveyor systems. Buyers should evaluate the specific application needs, such as the environment (e.g., temperature, exposure to chemicals) when selecting strip brushes to ensure they meet operational requirements effectively.

Maintenance Brushes

Maintenance brushes are versatile tools available in various materials, such as wire and natural fibers, making them suitable for diverse cleaning and maintenance tasks. Their ergonomic designs enhance usability for facility maintenance and commercial cleaning applications. Buyers should assess the frequency of use and the types of surfaces being cleaned to select the most appropriate brush type, as different materials may offer varying levels of durability and effectiveness.

Polishing Tools

Polishing tools from Osborn are designed to achieve high-quality finishes on various materials, including metals and wood. This category includes both solid and liquid polishing compounds, alongside the tools required to apply them. For B2B buyers, understanding the specific finish required for their applications—whether matte or high-gloss—is crucial. Additionally, skill levels within the workforce should be considered, as optimal use of these tools often requires training and experience.

Cylinder Brushes

Cylinder brushes are specifically engineered for cleaning and deburring cylindrical surfaces, making them particularly useful in industries such as pipe manufacturing and aerospace. Their design allows for effective cleaning of hard-to-reach areas, improving overall process efficiency. When sourcing cylinder brushes, buyers should consider the diameter and length necessary for their specific applications, as well as the type of bristle material that will best suit their cleaning needs.

Related Video: Osborn ATB™ Brushes

Key Industrial Applications of osborn international brushes

| Industry/Sector | Specific Application of osborn international brushes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Deburring and surface finishing of automotive parts | Enhances product quality and reduces defects, leading to cost savings. | Ensure compatibility with specific materials and processes. |

| Metal Fabrication | Cleaning and polishing of metal surfaces | Improves surface finish and prepares for coating, enhancing durability. | Consider brush type and size for specific machinery and tasks. |

| Electronics | ESD-safe cleaning solutions for circuit boards | Prevents damage to sensitive components, increasing reliability. | Verify ESD compliance and suitability for delicate applications. |

| Construction | Maintenance of heavy machinery and tools | Reduces downtime through effective cleaning and maintenance. | Assess durability and effectiveness for various construction materials. |

| Aerospace | Precision cleaning of aircraft components | Ensures safety and compliance with stringent industry standards. | Focus on high-performance materials and specialized brushes. |

Automotive Manufacturing

In the automotive sector, Osborn international brushes are widely utilized for deburring and surface finishing of various components. These brushes help remove sharp edges and burrs from machined parts, ensuring smooth surfaces that meet quality standards. For international buyers, particularly in regions like Europe and the Middle East, sourcing brushes that are compatible with specific automotive materials—such as aluminum and steel—is crucial to avoid production delays and enhance efficiency.

Metal Fabrication

In metal fabrication, Osborn brushes are essential for cleaning and polishing metal surfaces. They effectively remove contaminants and prepare surfaces for further processing, such as painting or coating. This application is vital in South America, where industries are expanding rapidly. Buyers must consider the specific brush type—whether wire, nylon, or abrasive—based on their machinery and desired finish to optimize productivity.

Electronics

For the electronics industry, Osborn offers ESD-safe brushes designed for cleaning circuit boards and sensitive components. These brushes prevent electrostatic discharge, which can damage delicate electronic parts. B2B buyers from Africa and South America should prioritize sourcing brushes that comply with ESD standards to ensure the reliability of their electronic products. Additionally, understanding the specific brush design that suits their assembly line can significantly enhance operational efficiency.

Construction

In the construction industry, Osborn brushes play a critical role in the maintenance of heavy machinery and tools. Regular cleaning with these brushes helps prevent buildup of debris and corrosion, reducing downtime and extending equipment lifespan. For buyers in the Middle East, where construction is booming, it’s essential to select durable brushes that can withstand harsh working conditions and various materials, ensuring consistent performance.

Aerospace

Precision cleaning of aircraft components is another key application for Osborn brushes in the aerospace sector. These brushes ensure that parts are free from contaminants, which is essential for safety and compliance with industry regulations. Buyers from Europe must focus on high-performance brushes that meet stringent aerospace standards, considering factors such as brush material and design to achieve the required level of cleanliness and performance.

Related Video: Osborn Crimped Wire Cup Brush – Paint Stripping

Strategic Material Selection Guide for osborn international brushes

When selecting materials for Osborn International brushes, understanding the properties, advantages, and limitations of each material is essential for optimizing performance and ensuring suitability for specific applications. Below, we analyze four common materials used in Osborn brushes, providing actionable insights for B2B buyers, particularly from Africa, South America, the Middle East, and Europe.

1. Nylon

Key Properties: Nylon is known for its excellent abrasion resistance, flexibility, and resilience under varying temperatures, typically rated from -40°C to 120°C. It also exhibits good chemical resistance, making it suitable for a variety of cleaning and finishing applications.

Pros & Cons: Nylon brushes are durable and can withstand high-speed applications, making them ideal for industrial use. However, they can be more expensive than natural fiber alternatives. Manufacturing complexity is moderate, as nylon can be molded into various shapes and sizes.

Impact on Application: Nylon is compatible with a wide range of media, including solvents and oils, which makes it versatile for different industrial cleaning tasks.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers should also consider the availability of nylon brushes in their region, as sourcing may vary.

2. Steel

Key Properties: Steel brushes are characterized by their high strength and durability, with excellent resistance to heat and wear. They can operate effectively at elevated temperatures, often exceeding 300°C.

Pros & Cons: Steel brushes are highly effective for heavy-duty applications, such as deburring and surface preparation. However, they are prone to corrosion unless treated, which can limit their lifespan in humid or corrosive environments. The manufacturing process can be complex due to the need for precise engineering.

Impact on Application: Steel is particularly effective for abrasive applications and is commonly used in metalworking industries. It is essential to ensure compatibility with the specific metals being processed to avoid damage.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of steel in industrial applications, particularly in regions with stringent environmental laws. Compliance with standards like JIS may also be necessary.

3. Brass

Key Properties: Brass brushes offer good corrosion resistance and are suitable for applications requiring non-sparking tools. They typically perform well in temperatures up to 200°C.

Pros & Cons: Brass is softer than steel, which makes it less abrasive and ideal for delicate surfaces. However, it has a shorter lifespan in heavy-duty applications and can be more expensive than steel. The manufacturing process is straightforward, but sourcing quality brass can be a challenge.

Impact on Application: Brass brushes are particularly effective for cleaning non-ferrous metals and delicate components, making them suitable for industries such as jewelry and electronics.

Considerations for International Buyers: Buyers should verify the brass quality and its compliance with international standards. Additionally, understanding the local market for brass materials can impact procurement strategies.

4. Natural Fibers

Key Properties: Natural fibers, such as horsehair or tampico, are biodegradable and offer good flexibility. They generally perform well in temperatures up to 80°C and have moderate chemical resistance.

Pros & Cons: Natural fiber brushes are excellent for gentle cleaning applications and provide a softer touch, making them suitable for sensitive surfaces. However, they are less durable than synthetic options and may require more frequent replacement. Manufacturing is less complex, but sourcing quality fibers can be inconsistent.

Impact on Application: These brushes are ideal for applications in the food industry or for delicate finishes, where a softer touch is necessary.

Considerations for International Buyers: Buyers should consider the sustainability of sourcing natural fibers and ensure compliance with environmental regulations. Preferences for biodegradable materials are increasing, particularly in Europe.

Summary Table

| Material | Typical Use Case for osborn international brushes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Industrial cleaning and finishing | Excellent abrasion resistance | Higher cost compared to natural fibers | Medium |

| Steel | Heavy-duty deburring and surface preparation | High strength and durability | Prone to corrosion | Medium |

| Brass | Cleaning non-ferrous metals and delicate surfaces | Non-sparking and corrosion resistant | Shorter lifespan in heavy use | High |

| Natural Fibers | Gentle cleaning applications | Biodegradable and soft touch | Less durable and frequent replacement | Low |

This guide provides a strategic overview for international buyers to make informed decisions regarding material selection for Osborn International brushes, ensuring compatibility with their specific industrial needs and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for osborn international brushes

Osborn International Brushes are renowned for their high-quality manufacturing and stringent quality assurance processes. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can greatly enhance procurement decisions. Below is a detailed exploration of the manufacturing stages, quality assurance standards, and best practices for verifying supplier quality.

Illustrative Image (Source: Google Search)

Manufacturing Processes

The manufacturing of Osborn International Brushes involves several key stages, each designed to ensure the final product meets the highest industry standards.

Material Preparation

The first stage of manufacturing involves sourcing high-quality raw materials, which may include various types of bristles (such as natural fibers or synthetic materials), metal for brush bases, and other components. Osborn emphasizes the importance of selecting materials that not only meet performance specifications but also comply with environmental and safety regulations.

- Material Selection: Choosing durable and resilient materials that enhance the brush’s lifespan.

- Pre-Processing: This may include treatments such as sterilization or chemical processing to prepare fibers for use.

Forming

Once materials are prepared, the forming stage begins. This involves shaping the brush components into their final forms. Osborn employs advanced techniques to ensure precision and consistency.

- Machining: Utilizing CNC machines for precise cutting and shaping of brush bases.

- Bristle Insertion: Using automated systems to insert bristles into the base, ensuring uniformity and strength.

Assembly

The assembly process integrates all components into a finished brush. This stage is critical for achieving the desired functionality and durability.

- Manual and Automated Assembly: Depending on the complexity of the brush, both automated systems and skilled labor are utilized.

- Integration of Custom Features: For specialized brushes, customization options are integrated during assembly.

Finishing

The finishing stage enhances both the aesthetic and functional qualities of the brushes.

- Surface Treatment: Processes such as coating, polishing, or applying protective layers to improve durability and performance.

- Final Inspection: Each brush undergoes a final inspection before packaging to ensure it meets quality standards.

Quality Assurance

Quality assurance is integral to the manufacturing process at Osborn. The company adheres to several international standards, ensuring that products are consistently reliable and effective.

International Standards

Osborn complies with ISO 9001, a globally recognized quality management standard that emphasizes process consistency and continuous improvement. Additionally, industry-specific certifications may apply, such as:

- CE Marking: Indicates compliance with EU safety and health requirements.

- API Certification: For brushes used in oil and gas applications, ensuring they meet specific performance and safety standards.

Quality Control Checkpoints

Osborn implements a multi-tiered quality control system, including:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing ensures adherence to quality standards at every stage.

- Final Quality Control (FQC): The final product is rigorously tested before packaging, assessing functionality and performance.

Common Testing Methods

To ensure that each brush meets its performance criteria, Osborn employs various testing methods, including:

- Durability Tests: Assessing the lifespan and resilience of brushes under simulated operational conditions.

- Performance Tests: Evaluating cleaning efficiency, abrasion resistance, and other functional characteristics.

- Dimensional Checks: Ensuring that all specifications for size and shape are met.

Verifying Supplier Quality

For international B2B buyers, particularly those from diverse markets, verifying the quality assurance processes of suppliers like Osborn is crucial. Here are actionable steps to ensure confidence in product quality:

Conducting Audits

- Supplier Audits: Perform regular audits of the manufacturing facilities to assess adherence to quality standards and operational practices.

- Certification Verification: Request documentation of certifications (ISO, CE, etc.) and ensure they are current and relevant.

Reviewing Reports

- Quality Reports: Ask suppliers for detailed quality assurance reports that outline their testing methodologies, results, and corrective actions taken.

- Traceability Documents: Ensure that all products can be traced back to their manufacturing batch to confirm quality consistency.

Engaging Third-Party Inspectors

- Independent Inspections: Consider hiring third-party inspection agencies to conduct unbiased evaluations of the manufacturing processes and final products.

- Sample Testing: Obtain samples of products for independent testing to verify performance claims.

Conclusion

Understanding the manufacturing processes and quality assurance measures employed by Osborn International Brushes is essential for B2B buyers in making informed purchasing decisions. By focusing on the key stages of manufacturing, the rigorous quality control checkpoints, and actionable verification strategies, international buyers can ensure they procure reliable and high-quality brushes that meet their specific needs.

Comprehensive Cost and Pricing Analysis for osborn international brushes Sourcing

When sourcing Osborn International brushes, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis focuses on the cost components and price influencers that can significantly affect purchasing decisions.

Cost Components

-

Materials: The choice of materials directly impacts the cost of Osborn brushes. High-quality bristles, durable backing, and specialized coatings increase material costs but enhance product lifespan and performance. Buyers should assess the type of materials used for their specific applications to ensure they are getting value for their investment.

-

Labor: Labor costs are a significant component of the manufacturing process. Osborn’s commitment to quality often involves skilled labor, particularly for custom brushes. Understanding the labor cost in the production region can provide insights into overall pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help keep these costs down, which may be reflected in the pricing of the brushes.

-

Tooling: For custom or specialized brush designs, tooling costs can be substantial. These costs are usually amortized over the production volume, meaning that higher order quantities can lead to lower per-unit costs.

-

Quality Control (QC): Ensuring that each batch of brushes meets stringent quality standards incurs costs related to testing and inspection. Osborn’s rigorous QC processes add to the overall cost but are essential for maintaining product integrity.

-

Logistics: Shipping and handling costs can vary widely based on geographic location, shipping method, and freight terms. International buyers should consider these costs when evaluating total expenses.

-

Margin: Manufacturer margins can vary based on competition, brand positioning, and market demand. Understanding the manufacturer’s pricing strategy can provide insight into potential negotiation leeway.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly influence pricing. Larger orders often qualify for volume discounts, making it economically advantageous for buyers who can commit to higher quantities.

-

Specifications/Customization: Customization requests will typically increase costs due to added tooling and material expenses. Buyers should clearly define their specifications to avoid unexpected costs.

-

Materials: The choice between standard and premium materials can affect pricing. Assessing the performance needs versus material costs is essential for cost-effective purchasing.

-

Quality/Certifications: Products with recognized certifications (e.g., ISO, ANSI) may command higher prices due to the assurance of quality and compliance. Buyers should weigh the importance of certifications against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and service levels can influence pricing. Established suppliers like Osborn may have premium pricing due to their brand equity and service offerings.

-

Incoterms: The terms of trade (Incoterms) dictate the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers manage costs related to shipping, insurance, and customs.

Buyer Tips

-

Negotiation: Leverage order size and long-term relationships to negotiate better pricing. Engaging in open discussions about pricing structures can lead to mutually beneficial agreements.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial purchase price, maintenance, and potential downtime. Investing in higher-quality brushes may reduce overall costs over time.

-

Pricing Nuances: International buyers should be aware of fluctuations in currency and global market trends that may affect pricing. Keeping abreast of these changes can aid in strategic planning and purchasing decisions.

Disclaimer

Prices for Osborn brushes can vary widely based on the factors outlined above. It is advisable to request quotes directly from suppliers for the most accurate and current pricing tailored to specific needs.

Spotlight on Potential osborn international brushes Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘osborn international brushes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for osborn international brushes

Understanding the technical properties and trade terminology associated with Osborn International brushes is crucial for international B2B buyers. This knowledge helps ensure that procurement decisions align with specific operational needs, optimizing performance and cost-effectiveness.

Key Technical Properties of Osborn International Brushes

-

Material Grade

– Osborn brushes are constructed from various materials such as nylon, steel, and natural fibers. The material grade affects durability, flexibility, and effectiveness in different applications. Selecting the right material is essential for maximizing the brush’s lifespan and performance, especially in demanding environments. -

Bristle Density

– The density of bristles in a brush impacts its cleaning efficiency and surface finish quality. A higher bristle density typically provides more cleaning power and a smoother finish, which is crucial for industries requiring precision, such as automotive and electronics. -

Filament Type

– Different types of filaments (e.g., synthetic vs. natural) offer distinct advantages. For instance, nylon filaments are often chosen for their resistance to chemicals and wear, making them suitable for harsh environments. Understanding filament types helps buyers select the right brush for specific applications. -

Size and Dimensions

– Brushes come in various sizes and shapes, tailored for specific tasks. The diameter, length, and width of the brush must be compatible with the equipment and processes involved. Accurate sizing ensures efficient operation and reduces the risk of damage to both the brush and the workpiece. -

Operating Speed

– Each brush type has a recommended operating speed, which is vital for ensuring optimal performance. Exceeding these speeds can lead to premature wear or failure of the brush. Buyers should align the brush specifications with their machinery capabilities to avoid costly downtimes. -

Tolerance Levels

– Tolerance refers to the acceptable variation in dimensions. High tolerance levels are critical in applications where precision is paramount. Understanding the required tolerance can help buyers ensure that the brushes meet their operational standards.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of brushes, knowing if the product is OEM can assure buyers of quality and compatibility with their existing equipment. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory and budget constraints effectively. -

RFQ (Request for Quotation)

– An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It is crucial for buyers to prepare a detailed RFQ to ensure they receive accurate pricing and terms that meet their needs. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping, insurance, and delivery obligations, reducing risks in cross-border trade. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. Knowledge of lead times is essential for planning and ensuring that production schedules are met without delays. -

Custom Solutions

– Many suppliers, including Osborn, offer custom brush solutions tailored to specific applications. Understanding the process for requesting custom solutions can lead to more effective procurement strategies and better product performance.

By mastering these technical properties and trade terms, international B2B buyers can make informed decisions when procuring Osborn International brushes, ensuring they meet operational requirements while optimizing costs and efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the osborn international brushes Sector

Market Overview & Key Trends

The global market for industrial brushes, including those produced by Osborn International, is experiencing significant growth driven by various factors. Key drivers include the expanding manufacturing sector, increasing automation in industries, and the rising demand for efficient surface finishing solutions. In regions such as Africa, South America, the Middle East, and Europe, buyers are increasingly focused on sourcing high-quality, durable products that enhance operational efficiency.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are revolutionizing the sourcing landscape. B2B buyers are leveraging data analytics to assess supplier performance, optimize procurement processes, and ensure timely delivery. Furthermore, the trend towards customization is gaining momentum, with buyers seeking tailored solutions that meet specific operational needs.

International buyers must also navigate fluctuating raw material prices and geopolitical factors that affect supply chains. Establishing robust relationships with suppliers like Osborn International can mitigate these risks. It’s crucial for buyers to conduct thorough market research and engage in strategic sourcing to identify the most reliable partners who can provide innovative solutions and maintain competitive pricing.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of B2B purchasing decisions. As global awareness of environmental issues grows, buyers are increasingly demanding products that minimize ecological impact. Osborn International is committed to sustainability, employing eco-friendly materials and processes in the manufacturing of its brushes.

Buyers should prioritize suppliers that adopt ethical sourcing practices, ensuring that raw materials are obtained responsibly and that production methods are environmentally sound. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a supplier’s commitment to sustainability. Additionally, using recycled materials in products can enhance sustainability credentials and appeal to environmentally conscious customers.

Moreover, transparency in the supply chain is critical. Buyers should seek partners who provide clear information about their sourcing practices and environmental impact, fostering trust and ensuring compliance with international sustainability standards.

Brief Evolution/History

Founded in 1887, Osborn International has a rich history as a leader in the brush manufacturing industry. The company has continually evolved, embracing innovation and technological advancements to meet the changing needs of its global clientele. With a strong emphasis on quality and customer service, Osborn has developed a diverse product range, including power brushes and specialty brushes, tailored for various industrial applications. This long-standing commitment to excellence has solidified its reputation as a reliable supplier for B2B buyers worldwide.

In conclusion, international B2B buyers must focus on market dynamics, sustainability, and the historical context of suppliers like Osborn International to make informed sourcing decisions that align with both operational goals and ethical standards.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of osborn international brushes

-

What should I consider when vetting suppliers for Osborn International brushes?

When vetting suppliers, prioritize their industry experience and reputation. Look for suppliers with certifications such as ISO 9001, which indicates a commitment to quality management. Request references and case studies from previous clients, particularly those in your region, to gauge their reliability. Additionally, evaluate their customer support capabilities, response times, and willingness to provide product samples. Establishing a strong partnership with a vetted supplier can lead to more favorable terms and better service. -

Can I customize Osborn brushes to meet specific requirements?

Yes, Osborn International offers customization options to cater to specific industrial applications. Discuss your needs with the supplier, including dimensions, materials, and specific performance characteristics. Custom solutions may include unique brush configurations or modifications to existing products. Ensure that you communicate your requirements clearly and confirm the feasibility of the customization with technical specifications. This collaboration can lead to improved efficiency in your processes and optimal product performance. -

What are the minimum order quantities (MOQs) and lead times for Osborn brushes?

MOQs and lead times can vary based on the product type and customization requirements. Typically, standard products may have lower MOQs, while customized items could require larger orders. Lead times generally range from a few weeks to several months, depending on manufacturing schedules and shipping logistics. It’s advisable to inquire directly with the supplier to get accurate information based on your specific order. Planning your orders well in advance can help mitigate delays in your production schedule. -

What payment options are available for purchasing Osborn brushes?

Payment options for international purchases may include wire transfers, credit cards, or payment through trade finance solutions. Many suppliers also offer letters of credit for larger orders, which can provide additional security for both parties. Discuss payment terms upfront to ensure alignment with your financial processes and cash flow management. Be aware of any potential foreign exchange rates and transaction fees, especially when dealing with suppliers across different currencies. -

What quality assurance measures and certifications should I expect?

Osborn International brushes typically adhere to stringent quality assurance protocols. Look for suppliers that provide documentation of compliance with international standards such as ISO 9001 or industry-specific certifications. Request details about their testing procedures, including performance testing and materials verification. Understanding these quality assurance measures can help ensure that the products you receive meet your specifications and are suitable for your applications. -

How does logistics work for importing Osborn brushes to my region?

Logistics for importing Osborn brushes involves coordinating shipping methods, customs clearance, and delivery to your location. Discuss logistics options with your supplier, including freight options such as air or sea transport, which may vary in cost and delivery time. Ensure that the supplier provides necessary shipping documentation and guidance on customs requirements for your region. Understanding local regulations and potential tariffs can help you avoid unexpected costs and delays. -

What steps should I take if I encounter a dispute with my supplier?

In case of a dispute, first, attempt to resolve the issue directly with the supplier through open communication. Document all communications and agreements for reference. If a resolution cannot be reached, consider escalating the matter to a formal dispute resolution process, which may include mediation or arbitration. Review your contract for any clauses related to dispute resolution and jurisdiction. Engaging legal counsel familiar with international trade can provide additional support if needed. -

Are there any specific considerations for buyers in Africa, South America, the Middle East, and Europe?

Buyers in these regions should be mindful of local regulations and import duties that may affect the cost of procurement. Additionally, consider the logistical challenges unique to your region, such as shipping times and customs processes. Establishing clear communication channels with suppliers can facilitate smoother transactions and better service. Networking with local industry associations can also provide insights into best practices and potential partners in your area, enhancing your procurement strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for osborn international brushes

The strategic sourcing of Osborn International brushes presents a unique opportunity for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By leveraging Osborn’s extensive product range—encompassing industrial brushes, surface finishing solutions, and customized applications—businesses can significantly enhance their operational efficiency and product quality.

Key Takeaways:

– Quality Assurance: Osborn’s commitment to innovation and rigorous testing ensures that buyers receive high-performance products tailored to their specific needs.

– Customization: The ability to develop bespoke solutions allows businesses to address unique challenges, fostering greater operational flexibility.

– Global Support: With a robust network of sales and service professionals, Osborn offers unparalleled customer service, ensuring that buyers receive timely assistance and expert guidance.

As you consider your sourcing strategies, remember that investing in high-quality industrial brushes can lead to long-term cost savings and improved productivity. Now is the time to engage with Osborn International, explore their offerings, and seize the opportunity to elevate your business operations to new heights. Embrace the future of industrial cleaning and finishing solutions with confidence.