Master Sourcing Strategies for Perforated Metal Mesh: A B2B

Introduction: Navigating the Global Market for perforated metal mesh

Perforated metal mesh has emerged as a pivotal component across various industries, serving a multitude of applications ranging from architectural design to industrial filtration. This versatile material not only enhances functionality but also elevates aesthetics, making it a preferred choice for B2B buyers globally. As businesses increasingly seek sustainable and efficient solutions, understanding the nuances of perforated metal mesh becomes essential for informed sourcing decisions.

In this comprehensive guide, we will delve into the critical aspects of perforated metal mesh, covering various types and materials available in the market, including aluminum, stainless steel, and carbon steel. We will also explore manufacturing processes and quality control measures that ensure the integrity and performance of these products. Additionally, our guide will provide insights into selecting reliable suppliers, assessing cost structures, and navigating the market trends that influence pricing and availability.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, this guide empowers you to make knowledgeable decisions tailored to your specific requirements. Whether you are looking to enhance ventilation systems, create acoustic panels, or design visually stunning architectural features, understanding perforated metal mesh will enable you to leverage its benefits effectively. Prepare to navigate the global market with confidence, equipped with actionable insights and expert guidance that will streamline your procurement process.

Understanding perforated metal mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Hole Perforated | Holes are circular and arranged in staggered patterns. | Architectural facades, sound panels | Pros: Strong structure, versatile applications. Cons: Limited aesthetic options compared to other shapes. |

| Square Hole Perforated | Square holes provide a unique aesthetic and strength. | Decorative panels, filtration systems | Pros: Offers a modern look, good airflow. Cons: May not be as strong as round hole variants. |

| Slotted Perforated | Holes are elongated, allowing for specific airflow. | Ventilation systems, machinery guarding | Pros: Excellent for airflow, customizable sizes. Cons: Strength may vary based on slot orientation. |

| Hexagonal Hole Perforated | Holes are hexagonal, combining aesthetics and function. | Architectural design, acoustic panels | Pros: Unique appearance, good strength-to-weight ratio. Cons: More complex to manufacture. |

| Custom Perforated | Tailored hole shapes and patterns based on client needs. | Specialized industrial applications | Pros: Fully customizable to specific requirements. Cons: Higher costs and longer lead times. |

Round Hole Perforated

Round hole perforated metal is characterized by circular holes arranged in staggered patterns, which maximize strength and airflow. This type is widely used in architectural facades and sound panels, making it ideal for both functional and aesthetic applications. When purchasing, buyers should consider the thickness and material, as these factors significantly influence strength and durability. Round holes are prevalent in the market, ensuring availability and competitive pricing.

Square Hole Perforated

Square hole perforated metal features square openings that provide a distinct modern aesthetic while maintaining structural integrity. Commonly utilized in decorative panels and filtration systems, this type can enhance visual appeal without compromising functionality. Buyers should assess the pitch and thickness of the material to ensure it meets specific project requirements. While aesthetically pleasing, square perforations may not offer the same strength as traditional round holes.

Slotted Perforated

Slotted perforated metal is defined by elongated holes that facilitate specific airflow patterns, making it ideal for ventilation systems and machinery guarding. This type allows for customized hole sizes and arrangements, catering to various industrial needs. Buyers should consider the orientation of the slots, as this can affect the material’s overall strength. Slotted perforated metal is an excellent choice for applications requiring enhanced airflow and visibility.

Hexagonal Hole Perforated

Hexagonal hole perforated metal combines a unique design with functional benefits, making it suitable for architectural design and acoustic panels. This configuration offers a good strength-to-weight ratio while providing a visually striking appearance. When purchasing, buyers should evaluate the material’s thickness and hexagon size to ensure it meets performance criteria. Although more complex to manufacture, its aesthetic and functional qualities can justify the investment.

Custom Perforated

Custom perforated metal allows buyers to specify unique hole shapes and patterns tailored to their specific applications. This flexibility makes it a go-to option for specialized industrial needs where standard products may not suffice. However, buyers should be aware of potential higher costs and longer lead times associated with custom orders. When considering custom perforated metal, it is essential to clearly communicate design specifications to the manufacturer for optimal results.

Related Video: Fine Tuning LLM Models – Generative AI Course

Key Industrial Applications of perforated metal mesh

| Industry/Sector | Specific Application of Perforated Metal Mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Façade cladding and decorative panels | Enhances aesthetic appeal while ensuring structural integrity | Material type (e.g., aluminum, stainless steel), corrosion resistance, custom hole patterns |

| Automotive | Sound dampening in vehicle interiors | Reduces noise pollution, improving passenger comfort | Acoustic performance specifications, thickness, and durability under varying temperatures |

| Food Processing | Filtration in production lines | Ensures product purity and compliance with health standards | Material safety certifications, mesh size for specific filtration needs, ease of cleaning |

| Mining and Minerals | Ventilation systems in underground operations | Improves air quality and worker safety | Strength and thickness for heavy-duty applications, resistance to harsh environments |

| Electronics | EMI shielding for sensitive components | Protects electronic devices from interference | Electrical conductivity, mesh size, and compatibility with other materials used in assembly |

Construction

In the construction sector, perforated metal mesh is widely utilized for façade cladding and decorative panels. This application not only enhances the aesthetic appeal of buildings but also provides structural integrity and durability. Buyers should consider the material type, such as aluminum or stainless steel, and ensure it has adequate corrosion resistance, especially in coastal or humid environments. Custom hole patterns can also be specified to meet unique design requirements.

Automotive

Perforated metal mesh plays a crucial role in automotive applications, particularly for sound dampening in vehicle interiors. By strategically placing perforated panels, manufacturers can significantly reduce noise pollution, thus improving passenger comfort and overall driving experience. International buyers must focus on acoustic performance specifications, ensuring the material thickness can withstand varying temperatures and conditions prevalent in their operating regions.

Food Processing

In the food processing industry, perforated metal mesh is essential for filtration in production lines. It ensures product purity and compliance with stringent health standards, which is critical for maintaining consumer safety and regulatory compliance. Buyers should prioritize material safety certifications and the specific mesh size required for effective filtration, as well as the ease of cleaning to maintain hygiene standards.

Mining and Minerals

Perforated metal mesh is extensively used in ventilation systems within underground mining operations. It improves air quality, which is vital for worker safety and operational efficiency. When sourcing for this application, businesses must consider the strength and thickness of the mesh to withstand heavy-duty conditions and the harsh environments typical of mining sites.

Electronics

In the electronics sector, perforated metal mesh serves as an effective solution for EMI shielding, protecting sensitive components from electromagnetic interference. This is particularly important in high-performance electronic devices. Buyers should ensure the mesh has appropriate electrical conductivity and a suitable mesh size that aligns with the specific requirements of their products, as well as compatibility with other materials used in assembly.

Related Video: Solidworks Quick Tips 03 – Perforated Sheet Metal

Strategic Material Selection Guide for perforated metal mesh

When selecting the appropriate material for perforated metal mesh, international B2B buyers must consider several factors, including performance properties, application suitability, and regional compliance standards. Below is an analysis of four common materials used in perforated metal mesh, focusing on their key properties, advantages and disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand extreme temperatures. It typically has a temperature rating of up to 870°C (1600°F) and is resistant to rust and staining, making it ideal for both indoor and outdoor applications.

Pros & Cons:

Stainless steel offers durability and longevity, which can justify its higher cost. However, its manufacturing process can be complex, leading to higher production costs. This material is suitable for applications requiring high strength and corrosion resistance, such as in food processing and chemical industries.

Impact on Application:

Stainless steel is compatible with various media, including water, chemicals, and food products. Its non-reactive nature makes it a preferred choice in sanitary applications.

Considerations for Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 and DIN 1.4301. In regions like Europe, certifications for food safety may also be required.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It typically has a temperature rating of up to 400°C (752°F), making it suitable for various applications.

Pros & Cons:

Aluminum’s lightweight nature makes it easy to handle and install, reducing overall project costs. However, it may not be as strong as stainless steel, which can limit its use in heavy-duty applications. Its cost is generally lower than stainless steel, making it an attractive option for budget-conscious projects.

Impact on Application:

Aluminum is ideal for applications requiring good ventilation and aesthetic appeal, such as architectural facades and decorative panels. Its corrosion resistance makes it suitable for outdoor use.

Considerations for Buyers:

Buyers should consider compliance with standards such as ASTM B209 and EN 573. In regions like Africa and South America, local sourcing may affect availability and pricing.

3. Mild Steel

Key Properties:

Mild steel is known for its high tensile strength and affordability. However, it has lower corrosion resistance compared to stainless steel and aluminum, typically requiring protective coatings for outdoor applications.

Pros & Cons:

Mild steel is cost-effective and easy to machine, making it a popular choice for various industrial applications. The main disadvantage is its susceptibility to rust and corrosion, which can limit its lifespan without proper treatment.

Impact on Application:

Mild steel is suitable for structural applications, such as support frameworks and industrial screens. However, it may not be suitable for environments with high humidity or exposure to corrosive substances.

Considerations for Buyers:

Buyers should ensure that mild steel products comply with standards such as ASTM A36 and EN 10025. In regions with high humidity, additional protective measures may be necessary.

4. Copper

Key Properties:

Copper is known for its excellent conductivity and antimicrobial properties. It can withstand temperatures up to 200°C (392°F) and is highly resistant to corrosion, particularly in non-oxidizing environments.

Pros & Cons:

Copper’s antimicrobial properties make it ideal for applications in healthcare and food processing. However, it is more expensive than mild steel and aluminum, which can be a limiting factor for some projects. Its softness can also make it less suitable for high-stress applications.

Impact on Application:

Copper is particularly effective in applications requiring electrical conductivity or antimicrobial surfaces, such as in hospitals or food processing facilities.

Considerations for Buyers:

Buyers should verify compliance with standards such as ASTM B152 and EN 1976. In regions like the Middle East, the availability of copper may vary, impacting sourcing decisions.

Summary Table

| Material | Typical Use Case for perforated metal mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, chemical industries | Excellent corrosion resistance | Higher cost, complex manufacturing | High |

| Aluminum | Architectural facades, decorative panels | Lightweight, easy to handle | Lower strength than stainless steel | Medium |

| Mild Steel | Structural frameworks, industrial screens | Cost-effective, high tensile strength | Susceptible to corrosion | Low |

| Copper | Healthcare, food processing | Antimicrobial properties | Expensive, less suitable for high-stress applications | High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding perforated metal mesh, ensuring that they choose the right material for their specific applications while considering regional compliance and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for perforated metal mesh

Perforated metal mesh is a vital component in various industries, known for its versatility and functionality. Understanding the manufacturing processes and quality assurance protocols is essential for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe. This section provides a comprehensive overview of the typical manufacturing stages and quality control measures associated with perforated metal mesh.

Manufacturing Processes

The production of perforated metal mesh involves several key stages, each contributing to the final product’s quality and performance. Here’s a breakdown of the main stages:

1. Material Preparation

The first step in manufacturing perforated metal mesh is selecting the appropriate raw materials, typically stainless steel, aluminum, or mild steel. The choice of material depends on the intended application, environmental conditions, and required durability.

- Material Sourcing: Ensure that suppliers can provide certificates of compliance to relevant material standards (e.g., ASTM, ISO).

- Cutting: The sheets are cut to size based on the specifications provided by the buyer. Precision cutting is crucial to avoid any material wastage and ensure uniformity.

2. Forming

Forming is the critical stage where holes are created in the metal sheets. This is typically achieved through two primary methods:

- Punching: The most common technique, where a punch press applies force to create holes in a predetermined pattern. Variations in hole size and spacing can be customized to meet specific needs.

- Laser Cutting: For applications requiring intricate designs or non-standard hole shapes, laser cutting offers high precision and flexibility.

3. Assembly

While perforated sheets may not require extensive assembly, some applications involve combining multiple sheets or integrating additional components.

- Welding or Joining: If the design necessitates, sheets can be welded together or attached to frames to enhance structural integrity.

- Finishing Options: Depending on the application, additional treatments such as bending or forming into specific shapes may be conducted at this stage.

4. Finishing

The final stage involves surface treatment to enhance aesthetics and performance:

- Coating: Options include galvanization, powder coating, or anodizing, which protect against corrosion and improve durability.

- Cleaning: Removing any residual debris or contaminants is essential, especially for applications in food processing or pharmaceuticals.

Quality Assurance

Quality assurance is critical in ensuring that the perforated metal mesh meets international standards and customer expectations. Here’s an overview of the relevant quality control measures:

International Standards

International standards such as ISO 9001 play a significant role in defining quality management systems. Compliance with these standards ensures that manufacturers have robust processes for maintaining product quality. Additionally, industry-specific certifications such as CE marking or API (for oil and gas applications) may also be required, depending on the end-use.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter production. Buyers should ensure that suppliers conduct thorough checks against specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring ensures that production parameters remain within acceptable limits. This may include checking hole sizes, spacing, and material integrity.

- Final Quality Control (FQC): After production, the final product undergoes inspection to verify compliance with specifications, including visual inspections and dimensional checks.

Common Testing Methods

Various testing methods are employed to ensure the quality of perforated metal mesh:

- Tensile Strength Testing: This assesses the material’s strength and durability under load.

- Corrosion Resistance Testing: Essential for determining the longevity of the material in various environments, especially for outdoor applications.

- Acoustic Testing: For applications involving sound absorption, testing ensures that the mesh meets acoustic performance requirements.

Verifying Supplier Quality Control

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, it is crucial to verify the quality control processes of suppliers. Here are some actionable insights:

- Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into their quality management systems and adherence to international standards.

- Request Quality Reports: Buyers should request detailed reports on IQC, IPQC, and FQC processes, as well as test results for products.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s capabilities and compliance with quality standards.

Quality Control Nuances for International Buyers

When sourcing perforated metal mesh from international suppliers, several nuances must be considered:

- Understanding Regional Standards: Different regions may have specific standards and regulations. Buyers should familiarize themselves with these to ensure compliance.

- Cultural and Language Barriers: Effective communication is crucial. Buyers should ensure that they have a clear understanding of product specifications and quality expectations with their suppliers.

- Shipping and Handling: Quality can be compromised during transportation. Buyers should discuss packaging standards and handling procedures with suppliers to minimize risks.

By understanding the manufacturing processes and quality assurance protocols associated with perforated metal mesh, B2B buyers can make informed decisions that align with their project requirements and ensure the reliability of their supply chain.

Related Video: Amazing Scale! Process of Making I-Beam with Metal Scrap. Korean Steel Factory

Comprehensive Cost and Pricing Analysis for perforated metal mesh Sourcing

Cost Components in Perforated Metal Mesh Sourcing

Understanding the cost structure for perforated metal mesh is essential for B2B buyers to make informed purchasing decisions. The primary components influencing the cost include:

-

Materials: The type of metal used (stainless steel, aluminum, carbon steel, etc.) significantly affects the base cost. Stainless steel, for instance, typically has a higher price point due to its durability and corrosion resistance.

-

Labor: Labor costs can vary by region and the complexity of the perforation process. Skilled labor may be required for intricate designs, impacting overall pricing.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and machinery maintenance. Efficient manufacturing processes can lower these overheads.

-

Tooling: The cost of designing and maintaining custom tooling for specific perforation patterns can be substantial. Custom orders often incur additional costs due to the need for specialized equipment.

-

Quality Control (QC): Implementing rigorous QC measures ensures that the perforated metal meets industry standards and specifications. This can add to the overall cost but is crucial for maintaining product integrity.

-

Logistics: Transportation costs depend on the distance from the manufacturer to the buyer, as well as the chosen shipping method. Import duties and tariffs should also be considered, particularly for international buyers.

-

Margin: Suppliers will typically add a profit margin to cover their costs and ensure profitability. This margin can vary widely based on market conditions and competition.

Price Influencers

Several factors can influence the pricing of perforated metal mesh:

-

Volume/MOQ: Larger orders often result in lower per-unit costs. Suppliers may provide discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications/Customization: Custom designs, hole shapes, and sizes can increase costs. Standard products are generally more economical than bespoke options.

-

Materials: The choice of material not only affects the initial cost but also the long-term value and performance of the product. For instance, aluminum is lightweight and resistant to corrosion, which might justify a higher upfront cost due to lower maintenance needs.

-

Quality and Certifications: Products that meet specific quality standards or certifications (e.g., ISO) often carry a premium. Buyers should weigh the benefits of these certifications against their project requirements.

-

Supplier Factors: The reputation, reliability, and service level of the supplier can impact pricing. Established suppliers may charge more due to their reliability and experience.

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms (e.g., FOB, CIF) can shift the cost burden and risk from the supplier to the buyer, affecting the total cost of ownership.

Buyer Tips for Cost-Efficiency

-

Negotiate Wisely: Leverage the competitive landscape. Engage multiple suppliers to compare offers and negotiate better terms. Highlight potential for repeat business to strengthen your position.

-

Assess Total Cost of Ownership: Consider not just the purchase price but also factors like maintenance, durability, and operational efficiency. Investing in higher-quality perforated metal can lead to savings over time.

-

Understand Pricing Nuances: Be aware that international shipping, tariffs, and currency fluctuations can affect costs. Factor these into your budget, especially when sourcing from regions like Europe or the Middle East.

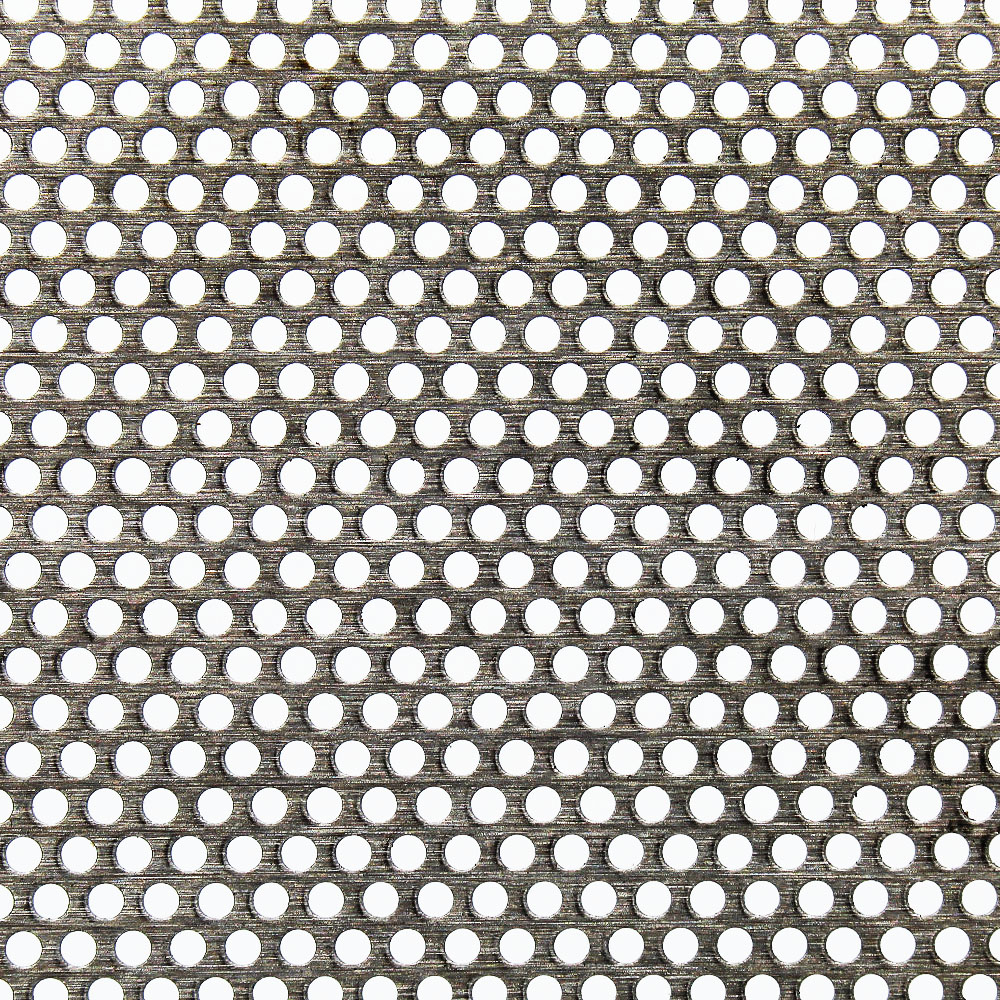

Illustrative Image (Source: Google Search)

-

Evaluate Customization Needs: Only opt for customization when necessary. If standard products meet your requirements, they are typically more cost-effective.

-

Consider Local Suppliers: For buyers in Africa or South America, sourcing from local manufacturers may reduce shipping costs and lead times, potentially offsetting higher material costs.

Disclaimer on Indicative Prices

Pricing for perforated metal mesh can vary significantly based on the factors outlined above. It is essential for buyers to request quotes tailored to their specific needs and to factor in all associated costs for a comprehensive understanding of their investment. Always consult with multiple suppliers to ensure competitive pricing and optimal purchasing decisions.

Spotlight on Potential perforated metal mesh Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘perforated metal mesh’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for perforated metal mesh

Understanding the technical properties and trade terminology of perforated metal mesh is crucial for B2B buyers, especially those engaged in industries across Africa, South America, the Middle East, and Europe. This knowledge aids in making informed purchasing decisions, ensuring that the selected materials meet specific project requirements.

Key Technical Properties of Perforated Metal Mesh

-

Material Grade

– Definition: Refers to the specific type of metal used, such as stainless steel, aluminum, or mild steel.

– Importance: The material grade affects the mesh’s strength, corrosion resistance, and suitability for various applications. For example, stainless steel is ideal for environments prone to moisture, while aluminum is lightweight and corrosion-resistant, making it suitable for architectural applications. -

Hole Size

– Definition: The diameter of the holes punched in the metal sheet, which can vary widely.

– Importance: Hole size directly impacts the mesh’s functionality, including airflow, light transmission, and filtration capabilities. Buyers must choose an appropriate hole size based on the intended use, such as sound absorption or aesthetic design. -

Pitch

– Definition: The distance between the centers of two adjacent holes.

– Importance: The pitch determines the open area of the mesh, influencing airflow and weight. A larger pitch can provide better ventilation, while a tighter pitch may offer more structural support. -

Thickness

– Definition: The gauge or thickness of the metal sheet used for perforation.

– Importance: Thickness affects the durability and load-bearing capacity of the mesh. Thicker materials can withstand heavier loads, making them suitable for structural applications, whereas thinner materials may be used for decorative elements. -

Tolerance

– Definition: The allowable deviation from specified dimensions in the manufacturing process.

– Importance: Tolerance ensures that the perforated mesh fits precisely within the intended application, reducing the risk of installation issues and enhancing overall performance. High tolerance levels are critical in applications requiring exact specifications, such as filtration systems. -

Open Area Percentage

– Definition: The ratio of the total area of the holes to the overall area of the mesh.

– Importance: This metric is vital for applications involving airflow, sound absorption, or fluid filtration. A higher open area percentage allows for better ventilation and sound reduction, making it an essential consideration for design engineers.

Common Trade Terms in Perforated Metal Mesh

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify reliable suppliers who can provide customized solutions and ensure product compatibility. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Buyers should be aware of MOQ requirements to manage costs and inventory effectively. Smaller businesses or projects may need to negotiate lower MOQs or seek suppliers with flexible terms. -

RFQ (Request for Quotation)

– Definition: A standard business process where buyers invite suppliers to bid on specific products or services.

– Relevance: An RFQ helps buyers gather pricing information and compare different suppliers, facilitating informed decision-making.

-

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers.

– Relevance: Familiarity with Incoterms is essential for international B2B transactions, as they outline who bears the risk and costs during shipping and delivery. -

Lead Time

– Definition: The time taken from placing an order to its delivery.

– Relevance: Understanding lead times is critical for project planning and ensuring that materials are available when needed. Delays can impact project timelines and costs.

By familiarizing themselves with these properties and terms, international B2B buyers can enhance their purchasing strategies, ensuring that they acquire the right perforated metal mesh for their specific applications while navigating the complexities of global trade.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the perforated metal mesh Sector

Market Overview & Key Trends

The perforated metal mesh market is experiencing significant growth driven by various global factors. Increasing urbanization and infrastructure development, particularly in Africa and South America, are creating heightened demand for versatile materials like perforated metal. These materials are widely used in architectural applications, industrial equipment, and environmental solutions due to their functionality and aesthetic appeal.

Emerging technologies, including advanced perforation techniques and digital manufacturing, are reshaping sourcing trends. Buyers can now access custom designs with improved precision, leading to enhanced product performance in applications such as sound absorption and ventilation systems. Furthermore, the rise of e-commerce platforms allows international B2B buyers to source materials more efficiently, streamlining procurement processes and reducing lead times.

In Europe and the Middle East, regulatory pressures are pushing for higher standards in construction and manufacturing. This creates opportunities for suppliers who can demonstrate compliance with stringent quality and safety regulations. Notably, the growing trend towards sustainable and eco-friendly materials is compelling manufacturers to innovate, leading to a surge in demand for perforated metal made from recycled or sustainable materials.

Buyers should also be aware of fluctuating raw material prices, particularly steel and aluminum, which can impact procurement strategies. Understanding local market dynamics, including supply chain logistics and regional production capabilities, is critical for international buyers to secure competitive pricing and reliable supply.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a key consideration for B2B buyers in the perforated metal mesh sector. The environmental impact of metal production, including energy consumption and emissions, necessitates a shift towards greener practices. Ethical sourcing of materials is increasingly important, as buyers are motivated to partner with suppliers who prioritize sustainable practices and transparency in their supply chains.

Buyers should look for manufacturers that hold certifications such as ISO 14001, which indicates a commitment to effective environmental management systems. Additionally, sourcing perforated metal mesh made from recycled materials can significantly reduce the carbon footprint of projects. Many suppliers are now offering eco-friendly alternatives that not only meet functional requirements but also align with corporate sustainability goals.

Another important aspect is the lifecycle assessment of products. Buyers should evaluate the durability and recyclability of perforated metal mesh options, which can contribute to waste reduction and resource conservation over time. By prioritizing sustainability in procurement decisions, B2B buyers can enhance their brand reputation and fulfill corporate social responsibility objectives, ultimately fostering long-term partnerships with environmentally conscious suppliers.

Brief Evolution/History

The use of perforated metal dates back centuries, originally employed in applications such as architectural facades and agricultural equipment. Over time, advancements in manufacturing technologies have significantly enhanced the precision and versatility of perforated metal mesh. The introduction of CNC (computer numerical control) machinery has revolutionized production processes, allowing for intricate designs and customized solutions tailored to specific industry needs.

In recent decades, the focus on aesthetics and functionality has driven the adoption of perforated metal in various sectors, including construction, automotive, and electronics. Today, it is recognized not only for its structural benefits but also for its design potential, making it a staple material in modern architecture and industrial applications. As sustainability becomes a focal point in global manufacturing, the evolution of perforated metal mesh continues, aligning with the demands of a more environmentally conscious market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of perforated metal mesh

-

What should I consider when vetting suppliers of perforated metal mesh?

When vetting suppliers, focus on their industry reputation, experience, and customer reviews. Verify if they have certifications such as ISO 9001, which indicates quality management systems. Assess their production capabilities and whether they can meet your specific requirements, such as material types and perforation patterns. Establish communication to gauge responsiveness and support. Finally, request samples to evaluate the quality of their products before making a commitment. -

Can perforated metal mesh be customized for specific applications?

Yes, perforated metal mesh can be highly customized to meet specific project needs. You can specify hole size, shape, pitch, and sheet dimensions. Additionally, materials like stainless steel, aluminum, or carbon steel can be selected based on environmental conditions and desired durability. Communicate your requirements clearly with the supplier to ensure they can deliver a product that fits your intended application, whether it’s for architectural, industrial, or acoustic purposes. -

What are typical minimum order quantities (MOQs) and lead times for perforated metal mesh?

Minimum order quantities can vary significantly between suppliers, often ranging from 100 to 1,000 square feet, depending on the complexity of the design and materials used. Lead times can also differ, typically spanning from 2 to 6 weeks. To ensure timely delivery, discuss these factors upfront and consider ordering in bulk if you anticipate future needs, which can also help reduce costs. -

What payment options are available when sourcing perforated metal mesh internationally?

International transactions can involve various payment methods, including letters of credit, wire transfers, and online payment platforms. Discuss payment terms with your supplier to understand any upfront deposits or credit options they may offer. Be cautious of currency exchange rates and transaction fees. It’s advisable to establish clear terms in a contract to protect against potential disputes and ensure both parties are aligned on payment expectations. -

How can I ensure quality assurance and certifications for perforated metal mesh?

To ensure quality, request documentation for certifications like ISO 9001 or specific industry standards relevant to your application. Inquire about the supplier’s quality control processes and if they conduct regular inspections of their products. Consider asking for test results on material properties, such as tensile strength and corrosion resistance, to validate that the mesh meets your specifications. Establishing a clear QA agreement can further safeguard your interests. -

What logistics considerations should I keep in mind when importing perforated metal mesh?

Logistics involves several aspects, including shipping methods, costs, and customs clearance. Choose a reliable freight forwarder familiar with international shipping regulations to avoid delays. Understand the import duties and taxes applicable in your country, as these can affect overall costs. Clearly communicate packaging requirements with your supplier to ensure the product arrives in good condition. Track your shipment closely to manage any unexpected issues during transit. -

How can disputes be resolved when sourcing perforated metal mesh?

To minimize disputes, establish clear terms in your purchase agreement, including specifications, delivery timelines, and payment conditions. If a dispute arises, first attempt to resolve it directly with the supplier through open communication. If that fails, consider mediation or arbitration as less adversarial options before pursuing legal action. Familiarize yourself with international trade laws and regulations that may apply, as they can influence how disputes are handled. -

What are the common applications for perforated metal mesh in various industries?

Perforated metal mesh is versatile and used across multiple sectors. In architecture, it serves as façade cladding, decorative panels, and sunshades, enhancing aesthetics while providing functionality. In industrial settings, it is utilized for filtration, ventilation systems, and sound absorption in auditoriums. Additionally, its lightweight yet durable nature makes it suitable for security applications and structural reinforcements. Understanding these applications can guide your sourcing decisions based on your industry needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for perforated metal mesh

As the global market for perforated metal mesh continues to expand, strategic sourcing becomes increasingly vital for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Understanding the diverse applications and benefits of perforated metal mesh—from enhancing ventilation and sound absorption to providing aesthetic value in architectural designs—allows buyers to make informed decisions that align with their project requirements.

By prioritizing suppliers with a proven track record and a comprehensive product range, buyers can secure high-quality materials that meet specific performance standards. Additionally, leveraging insights from industry resources can guide purchasing strategies and improve cost efficiency.

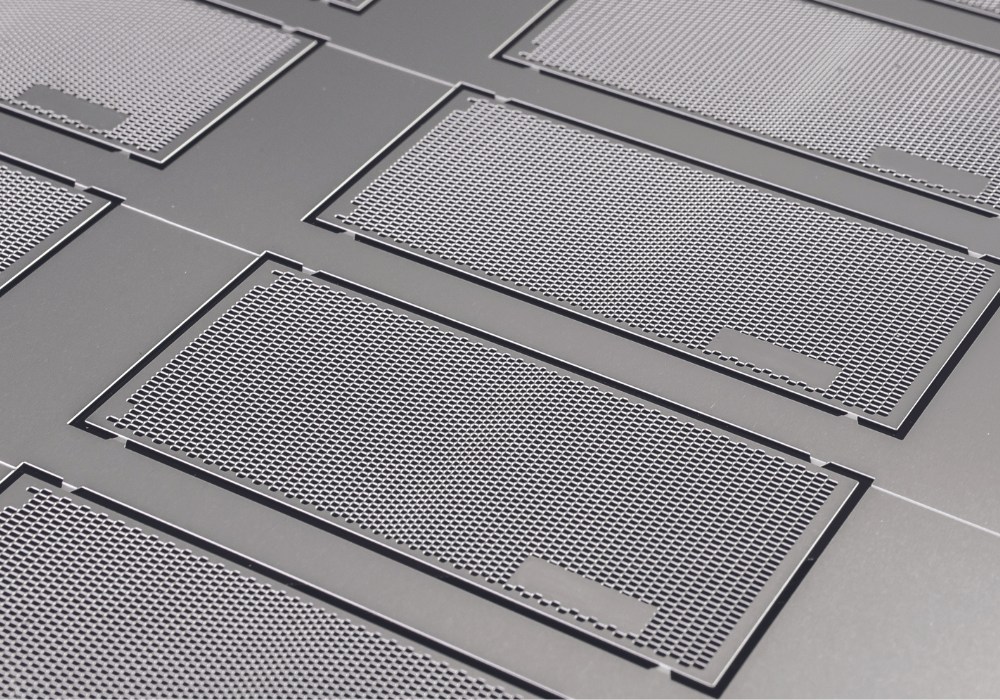

Illustrative Image (Source: Google Search)

Looking ahead, the demand for custom perforated solutions is likely to grow, driven by advancements in manufacturing technologies and a heightened focus on sustainability in design. Buyers are encouraged to engage actively with suppliers, exploring innovative applications and sustainable practices. This proactive approach will not only enhance project outcomes but also foster long-term partnerships in an evolving marketplace. Embrace the opportunities in perforated metal mesh sourcing to elevate your projects and drive success in your operations.