Master Sourcing Strategies for Toroid Transformers: A B2B

Introduction: Navigating the Global Market for toroid transformer

In today’s interconnected global market, the demand for efficient and reliable power solutions has never been more critical. Toroidal transformers stand out as a premier choice for various applications, particularly in industries such as medical, audio, renewable energy, and manufacturing. Their unique design not only enhances energy efficiency but also significantly reduces electromagnetic interference and noise, making them ideal for sensitive environments.

This comprehensive guide serves as an essential resource for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe. It encompasses a wide range of topics, including the different types of toroidal transformers, the materials used in their construction, and the manufacturing and quality control processes that ensure their reliability. Furthermore, this guide provides insights into sourcing strategies, a detailed overview of suppliers, cost considerations, and market trends, along with answers to frequently asked questions.

By leveraging the insights contained within this guide, buyers can make informed sourcing decisions that align with their operational needs and budget constraints. Whether you are seeking to upgrade existing equipment or explore new applications, understanding the nuances of toroidal transformers will empower your organization to enhance performance and drive innovation in a competitive global landscape.

Understanding toroid transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Medical Isolation Transformers | Designed for safety in medical environments; high reliability | Medical equipment (MRI, lab equipment) | Pros: High safety standards; reliable performance. Cons: Higher cost due to safety features. |

| General Purpose Toroidal Transformers | Versatile; suitable for a range of applications; compact design | Industrial machinery, control systems | Pros: Cost-effective; efficient. Cons: May lack specific features needed for specialized applications. |

| Power Supply Transformers | Optimized for power conversion; high efficiency | Audio equipment, renewable energy systems | Pros: Excellent efficiency; lower heat generation. Cons: May require specialized installation. |

| Auto-Transformers | Adjustable voltage output; compact and lightweight | Electrical distribution, voltage regulation | Pros: Flexible voltage options; space-saving design. Cons: Limited to specific voltage applications. |

| Dimmable Lamp Transformers | Designed for lighting applications; noise-free operation | Residential and commercial lighting systems | Pros: Quiet operation; energy-efficient. Cons: Limited to lower power ratings. |

Medical Isolation Transformers

Medical isolation transformers are engineered to ensure the safety of both patients and medical professionals. These transformers are crucial in environments where electrical isolation is required to prevent electrical shock and interference with sensitive medical devices. When purchasing, buyers should consider the transformer’s compliance with medical standards, efficiency ratings, and its ability to handle specific load requirements, as these factors directly impact patient safety and device performance.

General Purpose Toroidal Transformers

General-purpose toroidal transformers are designed for a wide range of applications, making them a versatile choice for many industries, including manufacturing and industrial control. Their compact design allows for easy installation in tight spaces, and they typically offer good efficiency. Buyers should assess the transformer’s power rating and dimensions to ensure compatibility with their equipment, as well as consider the overall cost-effectiveness for their specific use case.

Power Supply Transformers

Power supply transformers are optimized for converting electrical power efficiently, making them ideal for applications such as audio equipment and renewable energy systems. Their high efficiency translates to lower energy losses, resulting in reduced operating costs. B2B buyers should evaluate the transformer’s efficiency rating, thermal performance, and compatibility with the intended load to ensure it meets their operational needs.

Auto-Transformers

Auto-transformers provide adjustable voltage outputs, making them suitable for applications where voltage regulation is necessary. Their lightweight and compact design allows for easy integration into electrical distribution systems. However, buyers should be aware that auto-transformers are typically used for specific voltage applications, so understanding the precise voltage requirements of their systems is essential for effective purchasing.

Dimmable Lamp Transformers

Dimmable lamp transformers are specifically designed for lighting applications, providing a quiet and energy-efficient solution for both residential and commercial environments. These transformers excel in reducing audible noise, enhancing user experience in sound-sensitive areas. When purchasing, buyers should consider the transformer’s power rating and compatibility with dimming systems, as these factors can influence overall lighting performance and energy efficiency.

Related Video: Attention is all you need (Transformer) – Model explanation (including math), Inference and Training

Key Industrial Applications of toroid transformer

| Industry/Sector | Specific Application of toroid transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical | MRI Machines and Hospital Equipment | Reliable power supply with reduced noise levels for sensitive devices | Compliance with medical standards, custom specifications, and safety certifications |

| Audio | High-Fidelity Audio Amplifiers | Enhanced sound quality with minimal electromagnetic interference | Compatibility with existing audio systems and size constraints |

| Renewable Energy | Solar Power Inverters | Improved efficiency and reduced energy losses | Adaptability to various renewable technologies and environmental standards |

| Manufacturing | Machine Tool Control Systems | Increased operational efficiency and reduced heat generation | Custom sizing and power ratings to match specific machinery requirements |

| Automotive | Electric Vehicle Charging Stations | Fast and efficient charging with minimal energy losses | Durability under varying environmental conditions and regulatory compliance |

Medical Applications

In the medical sector, toroidal transformers are essential for powering equipment such as MRI machines, CAT scan devices, and hospital beds. These transformers provide a reliable power supply while significantly reducing noise levels, which is critical for sensitive medical environments. For international buyers, particularly in regions like Africa and South America, sourcing must prioritize compliance with stringent medical standards and certifications, ensuring that the transformers meet local safety regulations while also being customizable to fit specific equipment needs.

Audio Applications

The audio industry leverages toroidal transformers in high-fidelity amplifiers and other sound equipment. Their design minimizes electromagnetic interference, resulting in superior sound quality without the hum typically associated with standard transformers. Buyers from Europe and the Middle East should consider the compatibility of these transformers with existing audio setups and ensure that they meet the necessary power ratings and physical dimensions for seamless integration.

Renewable Energy Applications

In renewable energy sectors, toroidal transformers are utilized in solar power inverters and control systems. Their efficient design leads to reduced energy losses, making them ideal for sustainable energy solutions. Buyers, especially from regions like Africa, where renewable energy is rapidly growing, need to ensure that the transformers can adapt to various technologies and comply with local environmental standards, enhancing their overall effectiveness in energy conversion.

Manufacturing Applications

Manufacturing operations benefit from toroidal transformers in machine tool control systems, where they enhance efficiency and reduce heat generation. This is crucial for maintaining optimal performance in industrial environments. For businesses in South America and Europe, sourcing considerations should include custom sizing and power ratings tailored to specific machinery requirements, ensuring that the transformers can withstand the demands of heavy-duty applications.

Automotive Applications

In the automotive sector, toroidal transformers are increasingly used in electric vehicle (EV) charging stations. They facilitate fast and efficient charging while minimizing energy losses, which is vital as the demand for EV infrastructure grows. Buyers from the Middle East and Europe should focus on the durability of these transformers under varying environmental conditions and ensure compliance with relevant regulatory standards to guarantee safe and reliable operation in public charging stations.

Related Video: TOROID

Strategic Material Selection Guide for toroid transformer

When selecting materials for toroidal transformers, it is crucial to consider the properties, advantages, disadvantages, and specific applications of each material. Below is an analysis of four common materials used in toroidal transformers, providing actionable insights for international B2B buyers.

1. Silicon Steel

Key Properties: Silicon steel is known for its high magnetic permeability, which enhances the efficiency of transformers. It typically operates effectively at temperatures up to 120°C and can withstand moderate pressures.

Pros & Cons: The primary advantage of silicon steel is its excellent efficiency and low core losses, making it ideal for applications requiring high performance. However, it can be prone to corrosion if not properly coated, and its manufacturing process can be complex, increasing costs.

Impact on Application: Silicon steel is compatible with various electrical applications, particularly in environments where efficiency is paramount, such as renewable energy systems.

Considerations for International Buyers: Buyers must ensure compliance with international standards like ASTM A677 for electrical steel. In regions like Europe and the Middle East, specific corrosion-resistant coatings may be required to meet local regulations.

2. Ferrite

Key Properties: Ferrite materials exhibit high resistivity and low losses at high frequencies, making them suitable for high-frequency applications. They can typically handle temperatures up to 150°C.

Pros & Cons: Ferrite cores are lightweight and compact, which is advantageous for space-constrained designs. However, they can be brittle and may require careful handling during manufacturing and installation, potentially increasing production complexity.

Impact on Application: Ferrite is particularly effective in applications involving audio equipment and RF transformers, where minimizing electromagnetic interference is critical.

Considerations for International Buyers: Buyers should be aware of the varying quality standards across regions. Compliance with JIS standards in Japan or DIN standards in Europe may be necessary, depending on the application.

3. Amorphous Steel

Key Properties: Amorphous steel has a non-crystalline structure that provides excellent magnetic properties and low core losses. It can operate effectively at temperatures up to 130°C.

Pros & Cons: The main advantage of amorphous steel is its superior energy efficiency, which can lead to lower operating costs. However, it is more expensive than traditional silicon steel and may require specialized manufacturing processes.

Impact on Application: This material is particularly beneficial in applications focused on energy conservation, such as smart grids and energy-efficient transformers.

Considerations for International Buyers: Buyers should consider the higher upfront costs against long-term savings in energy consumption. Compliance with energy efficiency standards, such as those set by the EU, is essential.

4. Copper Wire

Key Properties: Copper wire is commonly used for windings in toroidal transformers due to its excellent conductivity and resistance to corrosion. It typically operates well at temperatures up to 200°C.

Pros & Cons: Copper offers high electrical conductivity, which enhances transformer performance. However, it is more expensive than alternatives like aluminum, and its weight can be a consideration in design.

Impact on Application: Copper is suitable for high-performance applications where efficiency and reliability are crucial, such as in industrial machinery and high-end audio equipment.

Considerations for International Buyers: Buyers must ensure that the copper used meets international standards, such as ASTM B170 for copper wire. In regions like South America, where copper theft can be an issue, ensuring traceability and security in supply chains is vital.

Summary Table

| Material | Typical Use Case for toroid transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Renewable energy systems | High efficiency and low core losses | Prone to corrosion, complex mfg | Medium |

| Ferrite | Audio equipment, RF transformers | Lightweight and compact | Brittle, requires careful handling | Medium |

| Amorphous Steel | Smart grids, energy-efficient transformers | Superior energy efficiency | Higher cost, specialized mfg | High |

| Copper Wire | Industrial machinery, high-end audio | Excellent electrical conductivity | Expensive, heavier than alternatives | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with specific application needs and regional compliance requirements.

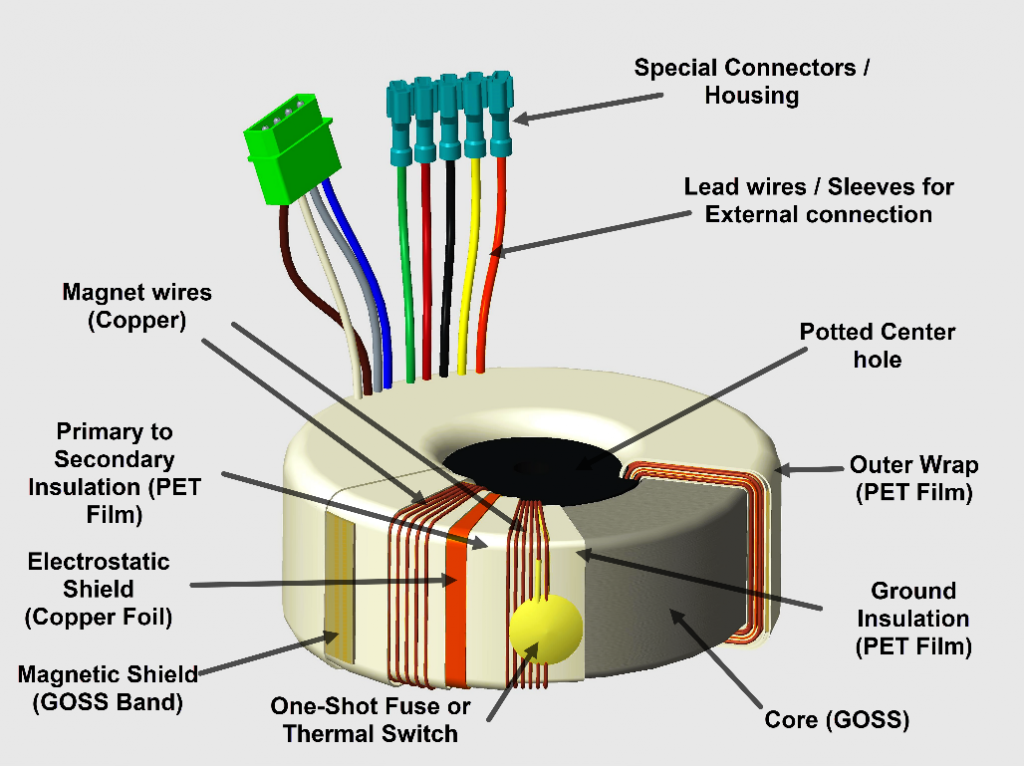

In-depth Look: Manufacturing Processes and Quality Assurance for toroid transformer

Manufacturing toroidal transformers requires a detailed understanding of both the production processes and the stringent quality assurance measures necessary to ensure reliability and efficiency. This section outlines the typical stages involved in manufacturing toroidal transformers, key techniques employed, and the quality assurance standards that international B2B buyers should be aware of.

Manufacturing Processes

The manufacturing of toroidal transformers can be broken down into several key stages:

1. Material Preparation

The first step involves selecting high-quality materials, primarily copper for windings and steel for cores. The choice of materials significantly affects the transformer’s efficiency and performance.

- Copper Wire: High-purity copper is used for winding to minimize resistive losses.

- Core Material: High-grade silicon steel or ferrite materials are commonly employed to enhance magnetic properties.

2. Forming

In this stage, the core is formed into a toroidal shape.

- Core Production: The steel is cut and shaped into a ring, often through a process called “punching,” which creates a seamless toroidal core. This is crucial as it reduces air gaps that can cause energy losses.

- Winding: The copper wire is wound around the core in a precise manner. Automated winding machines are typically used to ensure consistent tension and alignment, which are vital for performance.

3. Assembly

Once the winding is complete, the transformer is assembled.

- Connection: The ends of the copper wire are connected to terminals, ensuring secure and reliable electrical connections.

- Insulation: Insulating materials are applied to prevent short circuits and to enhance safety. This can include varnishing the windings or using insulating sleeves.

4. Finishing

The final stage involves several processes to prepare the toroidal transformer for shipping.

- Testing: Preliminary testing is conducted to check for electrical integrity and performance specifications.

- Packaging: The transformers are packaged carefully to prevent damage during transport. This often includes protective materials that cushion the product against shocks and vibrations.

Key Techniques

Manufacturers employ various techniques to enhance efficiency and reduce losses:

- Precision Winding: Automated machines maintain consistent winding patterns and tension.

- Vacuum Impregnation: This process helps eliminate air pockets in the insulation, enhancing the transformer’s durability and performance.

- Thermal Management: Techniques such as using heat sinks or designing for better airflow can help manage operating temperatures.

Quality Assurance

Quality assurance is critical in ensuring that toroidal transformers meet international standards and customer expectations.

Relevant International Standards

B2B buyers should ensure that their suppliers adhere to recognized quality standards, including:

- ISO 9001: This certification ensures that manufacturers have a quality management system in place, focusing on continuous improvement and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adherence to API standards can be crucial.

Quality Control Checkpoints

Quality control is typically structured around several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early. This can involve regular audits of machinery and processes.

- Final Quality Control (FQC): The final inspection checks the completed transformers for performance against specifications. This includes electrical testing and visual inspections.

Common Testing Methods

Manufacturers utilize various testing methods to ensure product quality:

- Electrical Testing: This includes measuring resistance, inductance, and insulation resistance.

- Thermal Testing: Evaluates how the transformer performs under load and its ability to dissipate heat.

- Environmental Testing: Assesses the transformer’s performance under different environmental conditions, such as humidity and temperature extremes.

Verification of Supplier Quality Control

B2B buyers can implement several strategies to verify the quality control practices of their suppliers:

- Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards and operational practices.

- Requesting Quality Reports: Buyers should ask for documentation of quality tests, including certificates of compliance with ISO and other relevant standards.

- Third-Party Inspections: Engaging independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes.

Quality Assurance Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of specific nuances in quality assurance:

- Cultural Differences: Understanding the local manufacturing culture can help in assessing the reliability and transparency of suppliers.

- Logistics and Transportation: Quality assurance also extends to how products are handled during shipping. Buyers should inquire about the packaging and transport methods used by suppliers.

- Legal Compliance: Familiarize yourself with the legal requirements in your region concerning electrical products, as these can vary significantly between countries.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for toroidal transformers is essential for international B2B buyers. By focusing on high-quality materials, precise manufacturing techniques, and stringent quality control, buyers can ensure that they procure reliable and efficient transformers that meet their specific needs.

Related Video: Rotel Toroidal Transformer Manufacturing Process

Comprehensive Cost and Pricing Analysis for toroid transformer Sourcing

Understanding the Cost Structure of Toroidal Transformers

Sourcing toroidal transformers involves a multifaceted cost structure that international B2B buyers must navigate. Key components of this cost structure include:

-

Materials: The choice of core materials (such as silicon steel or ferrite) significantly affects pricing. Higher quality materials typically lead to better performance and longer life, but at a higher initial cost.

-

Labor: Labor costs can vary based on geographic location and local wage standards. Skilled labor is often required for precision manufacturing, particularly for custom designs.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Initial tooling expenses can be substantial, especially for custom transformers. The amortization of these costs over larger production runs can make them more manageable.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet specifications and safety standards. While this adds to upfront costs, it can prevent costly returns and warranty claims.

-

Logistics: Transportation and warehousing costs can fluctuate based on distance, shipping methods, and tariffs. Understanding these costs is crucial for international sourcing.

-

Margin: Suppliers will typically include a profit margin that varies based on market conditions and competition. Buyers should be aware of these margins when assessing overall costs.

Influencers of Pricing

Several factors influence the pricing of toroidal transformers, which B2B buyers should consider:

-

Volume/MOQ: Suppliers often provide better pricing for larger orders. Understanding Minimum Order Quantities (MOQs) can help buyers negotiate favorable terms.

-

Specifications/Customization: Custom designs tailored to specific applications can significantly impact cost. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Higher-grade materials and certifications (such as ISO 9001) can drive up prices but are essential for applications requiring reliability, such as medical or industrial uses.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can all affect pricing. Engaging with established manufacturers with a track record of quality may come at a premium but often ensures better service and reliability.

-

Incoterms: Understanding Incoterms can clarify who bears responsibility for shipping costs and risks, impacting overall pricing. Familiarity with these terms can help buyers negotiate better deals.

Buyer Tips for Cost-Efficiency

To maximize value when sourcing toroidal transformers, consider the following strategies:

-

Negotiation: Leverage competitive bids from multiple suppliers to negotiate better pricing. Highlighting your purchasing volume and potential for long-term business can strengthen your position.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the purchase price. Consider factors such as energy efficiency, maintenance costs, and expected lifespan to make informed decisions.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local market conditions that can affect overall costs. Establishing contracts in stable currencies can mitigate some risks.

-

Research and Development: Engage with suppliers who invest in R&D, as they may offer innovative designs that improve performance and reduce long-term costs.

Disclaimer on Pricing

Prices for toroidal transformers can vary widely based on the above factors and market conditions. It is advisable to conduct thorough market research and obtain multiple quotes to ensure competitive pricing. Always consider the specific needs of your application and the reliability of the supplier when making purchasing decisions.

Spotlight on Potential toroid transformer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘toroid transformer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for toroid transformer

Key Technical Properties of Toroidal Transformers

Understanding the essential specifications of toroidal transformers is critical for B2B buyers, particularly those from diverse international markets. Here are some of the most significant technical properties that influence purchasing decisions:

Illustrative Image (Source: Google Search)

-

Core Material: Toroidal transformers typically utilize high-grade silicon steel or ferrite materials for their cores. The choice of core material significantly affects the transformer’s efficiency, magnetic performance, and operational temperature. Buyers should prioritize suppliers that offer cores with low hysteresis and eddy current losses to ensure optimal performance.

-

Power Rating (kVA): The power rating indicates the maximum load the transformer can handle, usually expressed in kilovolt-amperes (kVA). For B2B buyers, understanding the power rating is crucial to ensure compatibility with their equipment. Most toroidal transformers are rated up to 15 kVA, making them ideal for low-power applications in sectors such as medical and audio.

-

Efficiency: Efficiency ratings for toroidal transformers typically range from 90% to 95%. This metric is vital for businesses looking to minimize energy costs and reduce heat generation. Higher efficiency translates to lower operational costs, making it a key consideration for long-term investments.

-

Dimensions and Weight: The compact design of toroidal transformers results in smaller dimensions and lower weight compared to standard transformers. This feature is particularly advantageous for manufacturers aiming to save space in equipment layouts. Understanding the physical specifications can help buyers optimize their product designs and installations.

-

Voltage Rating: This specification defines the maximum voltage the transformer can handle. It is essential for ensuring that the transformer can operate safely within the voltage limits of the application. Buyers should verify that the voltage rating aligns with their operational requirements to prevent equipment failure.

-

Temperature Rating: The operational temperature rating indicates the range within which the transformer can function without performance degradation. This property is crucial for applications in extreme environments. Buyers should consider this specification to ensure reliability and longevity in their equipment.

Common Trade Terminology in Toroidal Transformers

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms relevant to toroidal transformers:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers ensure they are sourcing quality components that meet their specifications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ is essential for buyers to manage inventory and budget constraints, particularly for smaller businesses or startups.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, sending RFQs is a critical step in sourcing toroidal transformers, as it allows for comparison of prices, delivery times, and terms across different suppliers.

-

Incoterms (International Commercial Terms): These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for buyers to understand shipping costs, risk transfer, and delivery obligations.

-

Lead Time: This term indicates the time required for a supplier to fulfill an order. Understanding lead times can help buyers plan their production schedules and manage customer expectations effectively.

-

Certification Standards: Many transformers, including toroidal types, must meet specific industry standards (such as ISO, CE, or UL). Buyers should ensure that suppliers provide documentation proving compliance with relevant safety and quality certifications to mitigate risks in their operations.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational needs and contribute to the success of their projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toroid transformer Sector

Market Overview & Key Trends

The global market for toroidal transformers is witnessing significant growth driven by increasing demand for energy-efficient solutions across various industries. Key sectors such as medical equipment, audio technology, and renewable energy are adopting toroidal transformers due to their compact design, high efficiency, and low electromagnetic interference. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their operational efficiencies, they are increasingly gravitating towards suppliers who can provide customized solutions tailored to specific applications.

Emerging technologies, including IoT and smart grid systems, are reshaping sourcing trends in the toroidal transformer sector. Buyers are now prioritizing suppliers that can integrate advanced manufacturing techniques, such as automation and AI-driven design, to ensure precision and scalability. Moreover, as global supply chains become more interconnected, the ability to source locally is becoming a critical factor, particularly for regions like Africa and South America, where logistics can pose challenges.

Furthermore, the sustainability movement is influencing market dynamics. Buyers are not only looking for high-performance products but are also concerned about the environmental impact of their sourcing decisions. This trend is especially pronounced in Europe, where regulatory frameworks encourage the adoption of greener technologies. Hence, B2B buyers are expected to engage with manufacturers who can demonstrate compliance with international environmental standards and provide transparency in their production processes.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere buzzword; it is a fundamental criterion for B2B transactions in the toroidal transformer sector. The production of toroidal transformers can have a significant environmental impact, from resource extraction to energy consumption during manufacturing. As such, international buyers are increasingly focused on ethical sourcing practices that prioritize environmental stewardship and social responsibility.

Buyers should look for suppliers that utilize eco-friendly materials and comply with relevant environmental certifications, such as ISO 14001. This certification indicates a commitment to effective environmental management systems, which is vital for companies aiming to reduce their carbon footprint. Additionally, using green materials, such as recyclable cores and insulation, can further minimize environmental impact.

Ethical supply chains are essential for building trust and ensuring compliance with local and international regulations. Companies that prioritize sustainability not only enhance their brand reputation but also attract environmentally conscious clients. By fostering relationships with suppliers who share these values, B2B buyers can contribute to a more sustainable future while securing high-quality products.

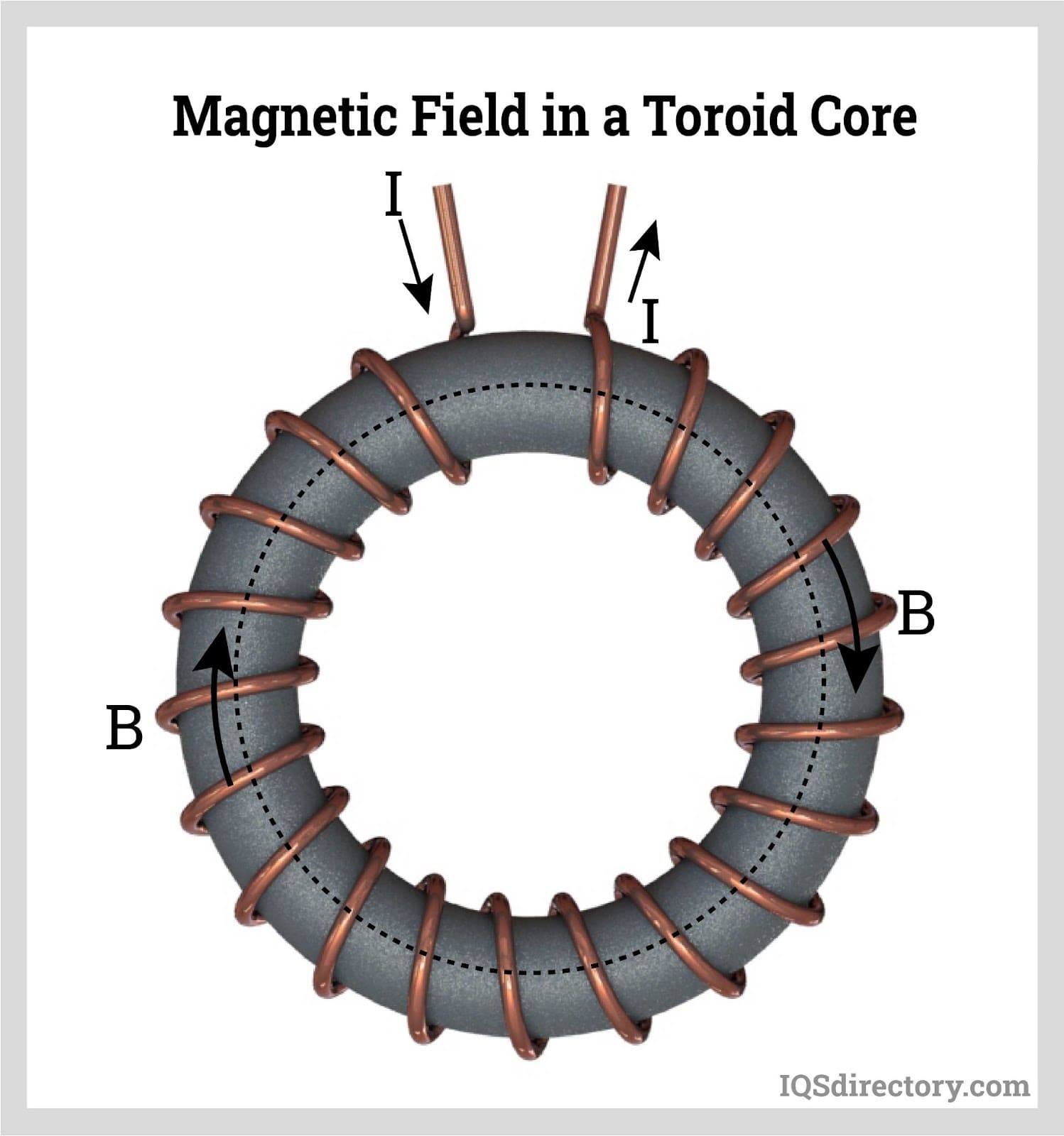

Brief Evolution/History

The evolution of toroidal transformers can be traced back to the mid-20th century when advancements in electrical engineering led to the development of more efficient and compact transformer designs. Unlike traditional laminated transformers, which are bulky and generate more noise, toroidal transformers feature a doughnut-shaped core that allows for reduced electromagnetic interference and enhanced efficiency.

Over the decades, the adoption of toroidal transformers has expanded across various industries, including medical, audio, and renewable energy sectors. This growth is attributed to their superior performance characteristics and the ability to meet the stringent demands of modern applications. As technology continues to advance, the role of toroidal transformers in energy-efficient solutions is expected to grow, making them a staple in the evolving landscape of electrical engineering.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of toroid transformer

-

How do I vet suppliers of toroidal transformers?

When sourcing toroidal transformers, it’s crucial to conduct thorough supplier vetting. Start by verifying their industry certifications, such as ISO 9001, which indicates adherence to quality management standards. Request references from previous clients, focusing on those within your industry. Additionally, assess their production capacity and technological capabilities. For international suppliers, check their experience in exporting to your region, as this can impact compliance with local regulations and standards. -

Can toroidal transformers be customized for specific applications?

Yes, toroidal transformers can often be customized to meet specific requirements, such as voltage ratings, power ratings, and physical dimensions. When discussing customization, provide detailed specifications, including your application needs and environmental conditions. Collaborate closely with the manufacturer’s engineering team to ensure that the design meets both performance and safety standards. Be aware that customization may affect pricing and lead times, so factor this into your planning. -

What are the minimum order quantities (MOQ) and lead times for toroidal transformers?

Minimum order quantities for toroidal transformers vary by supplier and can range from a few units to several hundred, depending on the complexity of the order. Lead times typically range from 4 to 12 weeks, influenced by factors such as customization, production capacity, and logistics. For large orders, suppliers may offer better pricing and shorter lead times, so it’s advisable to discuss your projected needs upfront to negotiate favorable terms. -

What payment terms should I expect when sourcing internationally?

Payment terms for international transactions typically include options such as advance payment, letter of credit, or payment against documents. Discuss these terms with your supplier early in the negotiation process to avoid misunderstandings. Ensure that the payment method aligns with your cash flow requirements and risk tolerance. For large orders, consider escrow services to protect both parties until the goods are delivered and inspected. -

What quality assurance measures should suppliers provide?

Quality assurance is essential when sourcing toroidal transformers. Suppliers should provide documentation of their quality control processes, including inspection protocols and testing procedures. Request certifications that demonstrate compliance with international safety standards, such as UL or CE markings. It’s also beneficial to ask for a sample unit prior to bulk ordering to evaluate performance and build quality, ensuring that the products meet your specifications. -

How can I manage logistics and shipping for international orders?

Managing logistics effectively is crucial for international orders of toroidal transformers. Coordinate with your supplier to choose the best shipping method based on cost and delivery time. Familiarize yourself with customs regulations in your country to avoid delays. Consider working with a freight forwarder who can assist with documentation, tariffs, and insurance. It’s also wise to track your shipment closely and communicate with your supplier throughout the shipping process to address any issues promptly. -

What steps should I take in case of a dispute with a supplier?

In the event of a dispute with a supplier, maintaining clear communication is key. Start by documenting all interactions, agreements, and discrepancies. Attempt to resolve the issue amicably through direct negotiation. If this fails, refer to the terms outlined in your contract regarding dispute resolution processes, which may include mediation or arbitration. Engaging legal counsel familiar with international trade can provide additional support if the situation escalates. -

What certifications should I look for in toroidal transformers?

When sourcing toroidal transformers, look for certifications that ensure compliance with safety and performance standards. Common certifications include ISO 9001 for quality management, UL for safety in North America, and CE marking for compliance in Europe. Additionally, industry-specific certifications may be relevant, such as medical-grade certifications for transformers used in healthcare applications. These certifications not only assure product quality but also facilitate smoother customs clearance and regulatory compliance in your region.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toroid transformer

In conclusion, strategic sourcing of toroidal transformers offers significant advantages for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. The unique design of toroidal transformers allows for enhanced efficiency, reduced noise, and lower thermal output compared to traditional transformers. These factors can lead to long-term cost savings and improved performance in various applications, from medical equipment to renewable energy systems.

Buyers should prioritize partnerships with manufacturers who uphold rigorous quality standards, such as ISO certifications, and who can provide custom designs to meet specific needs. Understanding the nuances of toroidal transformer specifications—like power ratings, size, and intended applications—will enable buyers to make informed decisions that align with their operational goals.

As the global demand for energy-efficient solutions continues to rise, the market for toroidal transformers is expected to expand. International B2B buyers should seize this opportunity to invest in cutting-edge technology that not only meets current demands but also positions their businesses for future growth. Engage with suppliers today to explore tailored solutions that will elevate your operations in an increasingly competitive landscape.