Master Sourcing Strategies for Tumbling Machines: A B2B

Introduction: Navigating the Global Market for tumbling machine

In an increasingly competitive global landscape, the tumbling machine has emerged as an essential tool for industries seeking efficient surface finishing solutions. From automotive and aerospace to electronics, these machines play a pivotal role in enhancing product quality and operational efficiency. As the demand for high-quality finishes continues to surge, understanding the dynamics of the tumbling machine market is crucial for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

This guide offers a comprehensive exploration of the tumbling machine landscape, covering critical aspects such as types of tumbling machines, materials used, manufacturing and quality control processes, and insights into leading suppliers. Additionally, it delves into cost considerations and market trends, equipping buyers with the knowledge needed to make informed sourcing decisions.

With projected market growth and increasing adoption of advanced technologies, this guide empowers buyers to navigate potential challenges and capitalize on opportunities within the tumbling machine sector. By providing actionable insights tailored to the unique needs of buyers from varied geographical and industrial backgrounds, we aim to facilitate smarter purchasing strategies and foster long-term supplier relationships. Whether you’re in Egypt, Germany, or beyond, understanding the intricacies of the tumbling machine market will position your business for success in the global arena.

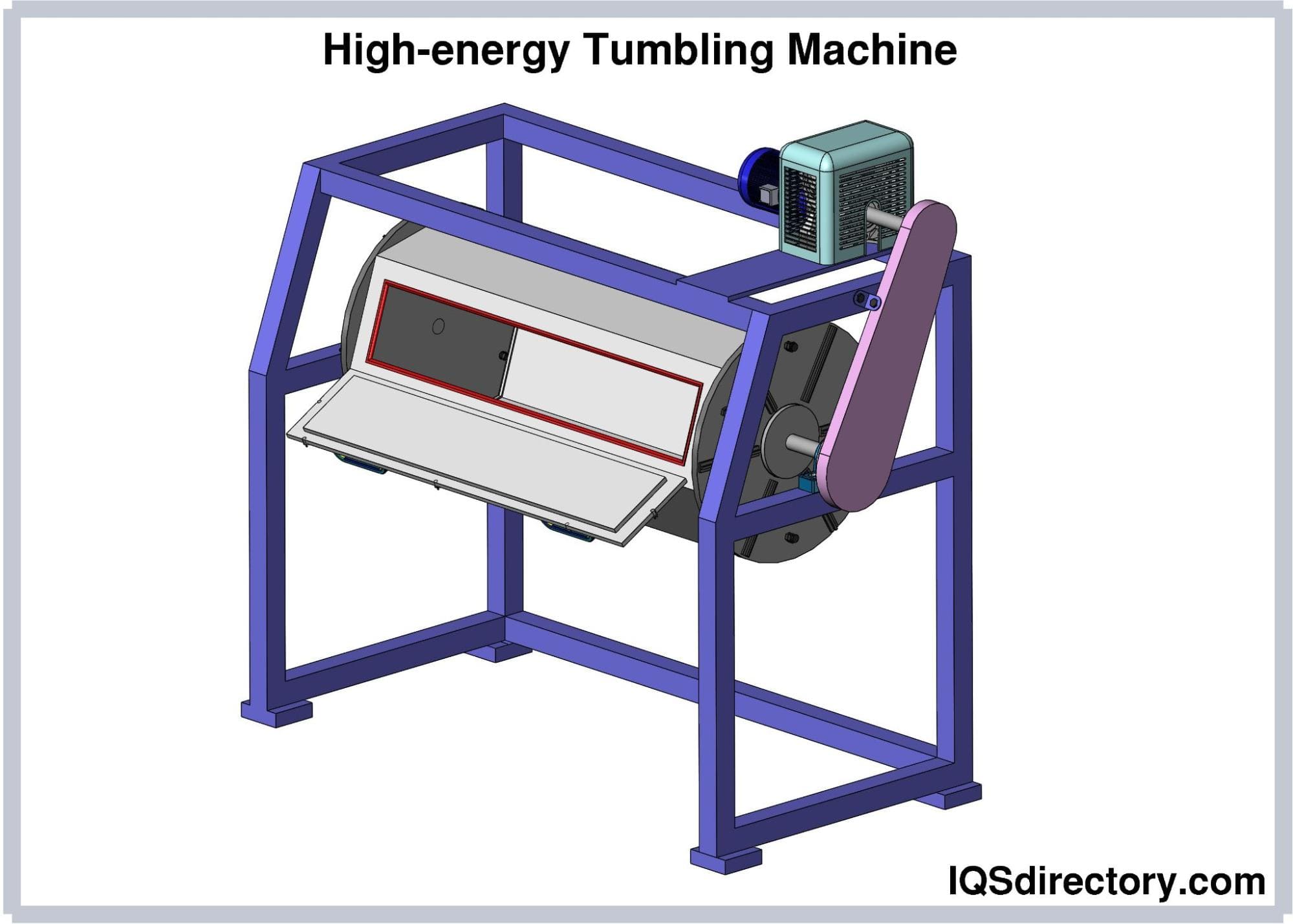

Understanding tumbling machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vibratory Tumblers | Utilizes vibration to agitate media and workpieces. | Automotive parts, jewelry finishing | Pros: Fast processing, versatile; Cons: Can be noisy, may require more maintenance. |

| Barrel Tumblers | Rotating barrel design, suitable for larger batches. | Heavy-duty applications, metal finishing | Pros: Cost-effective for bulk; Cons: Slower processing time, uneven wear. |

| Centrifugal Tumblers | Uses centrifugal force to enhance finishing speed. | Aerospace components, precision parts | Pros: High efficiency, consistent results; Cons: Higher initial investment, complex operation. |

| Disc Tumblers | Features a disc-shaped platform for tumbling. | Small precision parts, electronics | Pros: Gentle on delicate items, customizable; Cons: Limited to lighter loads, slower than vibratory. |

| Continuous Tumblers | Designed for uninterrupted processing of materials. | High-volume production lines | Pros: Increased throughput, less labor-intensive; Cons: High upfront costs, space requirements. |

Vibratory Tumblers

Vibratory tumblers are popular for their ability to finish parts quickly using a vibration mechanism to agitate both the media and the workpieces. They are particularly effective for deburring and polishing small to medium-sized components, making them ideal for industries such as automotive and jewelry. Buyers should consider the noise level and maintenance needs, as these machines can require regular upkeep and may produce significant sound during operation.

Barrel Tumblers

Barrel tumblers are characterized by their rotating cylindrical design, which allows for the processing of larger batches of materials. They are often used in heavy-duty applications, such as metal finishing. While barrel tumblers are cost-effective for bulk processing, buyers must be aware of the potential for slower processing times and uneven wear on the media, which can affect the overall finishing quality.

Centrifugal Tumblers

Centrifugal tumblers leverage centrifugal force to enhance the finishing process, providing faster and more consistent results. This type is particularly suitable for industries like aerospace, where precision is critical. While they offer high efficiency, buyers should weigh the higher initial investment and the complexity of operation against the benefits of increased productivity and quality.

Disc Tumblers

Disc tumblers are designed with a disc-shaped platform that gently tumbles parts, making them suitable for delicate items such as small precision components and electronics. Their customizable settings allow for tailored finishing processes. However, they are limited to lighter loads and may operate slower than vibratory tumblers, which buyers should consider based on their production needs.

Continuous Tumblers

Continuous tumblers are engineered for uninterrupted processing, allowing for high-volume production lines. They are ideal for manufacturers looking to increase throughput while minimizing labor costs. However, the high upfront investment and space requirements can be significant barriers for smaller businesses. Buyers must evaluate their production capacity and operational needs when considering this option.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of tumbling machine

| Industry/Sector | Specific Application of tumbling machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Deburring and polishing of engine components | Enhances surface finish, reduces friction, and improves durability of parts. | Look for machines with adjustable speed and media options to accommodate various materials. |

| Aerospace | Surface finishing of turbine blades | Increases efficiency and performance, critical for safety standards in aviation. | Ensure compliance with industry regulations and certifications for aerospace applications. |

| Electronics | Cleaning and polishing of electronic housings | Improves aesthetic appeal and functionality, crucial for consumer satisfaction. | Select machines that allow for precision control to prevent damage to sensitive components. |

| Medical Devices | Deburring of surgical instruments | Ensures safety and hygiene, as well as compliance with stringent medical standards. | Consider sourcing machines that offer advanced automation features for consistent results. |

| Jewelry and Accessories | Polishing and finishing of metal jewelry | Enhances visual appeal and value, critical for market competitiveness. | Look for tumbling machines with customizable media for different metal types and finishes. |

Automotive Industry

In the automotive sector, tumbling machines are primarily used for deburring and polishing engine components. This process enhances the surface finish, which not only improves the aesthetic quality but also reduces friction, leading to increased durability and performance of the parts. For international buyers, especially from regions like Africa and South America, sourcing machines that offer adjustable speeds and a variety of media types is crucial. This flexibility allows manufacturers to adapt to different materials and production needs, ensuring optimal results.

Aerospace Sector

In aerospace applications, tumbling machines are vital for the surface finishing of turbine blades. The precision finishing achieved through tumbling enhances the blades’ efficiency and performance, which is critical for meeting stringent safety standards in aviation. Buyers from Europe and the Middle East should prioritize machines that comply with industry regulations and certifications, ensuring that their products meet the high safety and quality benchmarks required in this sector.

Electronics Industry

The electronics industry utilizes tumbling machines for cleaning and polishing electronic housings. This application is essential for improving both aesthetic appeal and functionality, which directly impacts consumer satisfaction. Buyers, particularly in technologically advanced regions like Europe and South America, should seek machines with precision control capabilities. Such features help prevent damage to sensitive electronic components during the finishing process, ensuring high-quality outcomes.

Medical Devices Sector

In the medical devices sector, tumbling machines are employed for deburring surgical instruments. This application is crucial for ensuring safety and hygiene, as well as compliance with strict medical standards. International buyers, especially from regions with emerging healthcare markets, should consider sourcing machines that incorporate advanced automation features. This technology can enhance consistency in results, a key factor in the production of medical devices where precision is paramount.

Jewelry and Accessories Industry

For the jewelry and accessories industry, tumbling machines play a significant role in polishing and finishing metal jewelry. This application enhances the visual appeal and value of the products, which is critical for maintaining competitiveness in the market. Buyers should look for tumbling machines that offer customizable media options, allowing them to work with different metal types and achieve various finishes. This adaptability is particularly beneficial for businesses operating in diverse markets across Africa and Europe.

Related Video: The KD-6808 Multi-Purpose Mini Rotary Tumbler Machine Review.

Strategic Material Selection Guide for tumbling machine

When selecting materials for tumbling machines, it is crucial for B2B buyers to understand the properties, advantages, and limitations of various media. The right material can significantly affect the performance, durability, and cost-effectiveness of the tumbling process. Below is an analysis of four common materials used in tumbling machines, focusing on their key properties, pros and cons, and considerations for international buyers.

1. Plastic Media

Key Properties:

Plastic media is lightweight and non-abrasive, making it suitable for delicate parts. It is resistant to corrosion and can withstand a range of temperatures, typically up to 80°C (176°F).

Pros & Cons:

Plastic media is durable and cost-effective, especially for softer materials. However, it may not be suitable for heavy-duty applications due to its lower hardness compared to ceramic or steel. The manufacturing complexity is relatively low, making it widely available.

Impact on Application:

Plastic media is ideal for deburring and polishing softer metals and plastics. It is compatible with various finishing compounds, enhancing the quality of the surface finish.

Considerations for International Buyers:

Buyers should ensure compliance with local environmental regulations regarding plastic use. Standards such as ASTM and DIN may apply, particularly in Europe, where sustainability is a growing concern.

2. Ceramic Media

Key Properties:

Ceramic media is known for its high hardness and durability, withstanding temperatures up to 1200°C (2192°F). It is highly resistant to wear and tear, making it suitable for heavy-duty applications.

Pros & Cons:

The key advantage of ceramic media is its effectiveness in achieving a high-quality finish on tough materials. However, it is more expensive than plastic and can be brittle, leading to breakage under certain conditions. The manufacturing process can also be more complex.

Impact on Application:

Ceramic media is particularly effective for grinding and polishing hard metals and is widely used in the automotive and aerospace industries for finishing components.

Considerations for International Buyers:

Buyers must be aware of the specific ceramic materials that comply with local standards, such as JIS in Japan or DIN in Germany. The higher cost may be justified by the superior finish quality and durability.

3. Steel Media

Key Properties:

Steel media offers excellent hardness and durability, withstanding high temperatures and pressures. It is resistant to corrosion when properly maintained and can last for many cycles.

Pros & Cons:

Steel media is highly effective for aggressive deburring and surface conditioning. However, it is heavier and more expensive than plastic, and improper use can lead to surface scratches on softer materials. The manufacturing complexity is moderate.

Impact on Application:

Steel media is suitable for heavy-duty applications, particularly in the automotive and manufacturing sectors. It is effective for both ferrous and non-ferrous metals.

Considerations for International Buyers:

Compliance with safety standards and regulations regarding the use of steel is essential, especially in regions with stringent environmental laws. Buyers should also consider the cost implications of shipping heavier materials.

4. Natural Media (e.g., Walnut Shells)

Key Properties:

Natural media is biodegradable and non-toxic, making it an environmentally friendly option. It is effective for polishing and cleaning without damaging the substrate.

Pros & Cons:

The primary advantage of natural media is its eco-friendliness and suitability for delicate finishes. However, it may not be as durable as synthetic options and can degrade over time, leading to more frequent replacements.

Impact on Application:

Natural media is ideal for finishing delicate parts in industries such as jewelry and electronics, where a gentle touch is required.

Considerations for International Buyers:

Buyers should ensure that the natural media meets local environmental standards. In regions like Europe, where sustainability is prioritized, natural media may be favored.

Summary Table

| Material | Typical Use Case for tumbling machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic Media | Deburring soft metals and plastics | Lightweight and non-abrasive | Not suitable for heavy-duty use | Low |

| Ceramic Media | Grinding and polishing hard metals | High hardness and durability | Brittle and more expensive | High |

| Steel Media | Aggressive deburring and surface conditioning | Excellent hardness and durability | Heavier and can scratch softer materials | Medium |

| Natural Media | Polishing delicate parts | Eco-friendly and biodegradable | Less durable and degrades over time | Low |

This guide provides essential insights for international B2B buyers in selecting the appropriate materials for tumbling machines, ensuring they make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for tumbling machine

Manufacturing Processes for Tumbling Machines

The manufacturing of tumbling machines involves a series of precise steps that ensure the final product meets the rigorous demands of various industries, including automotive, aerospace, and electronics. Understanding these processes can help B2B buyers evaluate potential suppliers more effectively.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The first step involves selecting appropriate materials, typically high-quality steel or aluminum, which offer durability and resistance to wear. The choice often depends on the machine’s intended use and the specific requirements of the industry.

– Cutting and Shaping: Raw materials are cut into manageable sizes and shapes using techniques like laser cutting or plasma cutting. This step ensures that the components will fit together correctly in subsequent stages. -

Forming

– Machining: This stage involves processes such as milling, turning, and drilling to achieve precise dimensions and surface finishes. CNC (Computer Numerical Control) machines are commonly employed to enhance accuracy and repeatability.

– Welding: Components are welded together using techniques like MIG or TIG welding, ensuring structural integrity and durability. This process is critical for the machine’s frame and any load-bearing components. -

Assembly

– Component Assembly: Individual parts, including motors, gears, and control systems, are assembled. Attention to detail is crucial to ensure that all components function harmoniously.

– Integration of Automation: Modern tumbling machines often include automated features for enhanced efficiency. This may involve integrating sensors and control systems that allow for real-time monitoring and adjustments during operation. -

Finishing

– Surface Treatment: After assembly, the machine undergoes surface treatments such as powder coating or anodizing to improve resistance to corrosion and wear. This enhances the longevity of the machine.

– Final Inspection: The completed machine is subjected to a thorough inspection to ensure it meets design specifications and quality standards.

Quality Assurance in Manufacturing

Quality assurance (QA) is critical in the manufacturing of tumbling machines. It ensures that products not only meet customer expectations but also comply with international standards.

Relevant International Standards

- ISO 9001: This is a globally recognized standard for quality management systems. Compliance ensures that manufacturers have processes in place for consistent quality and continuous improvement.

- CE Marking: For manufacturers targeting the European market, CE marking indicates compliance with European safety, health, and environmental protection standards.

- API Certification: For tumbling machines used in the oil and gas industry, compliance with American Petroleum Institute (API) standards is essential.

Key Quality Control Checkpoints

-

Incoming Quality Control (IQC):

– Raw materials are inspected upon arrival to ensure they meet specified quality standards. This may include checks for material properties, dimensions, and certifications. -

In-Process Quality Control (IPQC):

– Throughout the manufacturing process, various checkpoints are established to monitor quality. This includes evaluating dimensional accuracy during machining and checking weld integrity. -

Final Quality Control (FQC):

– Before shipping, the finished product undergoes a comprehensive inspection. This includes functional testing and verification against design specifications.

Common Testing Methods

- Dimensional Inspection: Using calipers, micrometers, and gauges to ensure all parts meet specified tolerances.

- Functional Testing: Operating the machine to verify that it performs as intended under various conditions.

- Stress Testing: Subjecting components to stress to assess their durability and performance under load.

Verifying Supplier Quality Control

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial.

-

Supplier Audits:

– Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and quality management systems firsthand. This can provide insight into the supplier’s commitment to quality. -

Quality Assurance Reports:

– Requesting detailed QA reports can help buyers understand the supplier’s QC protocols, including documentation of past inspections and test results. -

Third-Party Inspections:

– Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s processes and products. This can be particularly beneficial for buyers unfamiliar with local manufacturing practices.

Illustrative Image (Source: Google Search)

Quality Control and Certification Nuances for International Buyers

When sourcing tumbling machines, international buyers should be aware of specific certification nuances:

- Local Regulations: Different countries may have unique regulatory requirements. Buyers should ensure that suppliers comply with both local and international standards.

- Cultural Differences: Understanding cultural approaches to quality and business practices can facilitate smoother negotiations and collaborations. For instance, European suppliers may have different expectations regarding documentation and process transparency compared to those in Africa or South America.

- Sustainability Practices: Increasingly, buyers are looking for suppliers that adhere to environmentally sustainable practices. This includes using eco-friendly materials and processes that minimize waste and energy consumption.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for tumbling machines is vital for international B2B buyers. By focusing on key manufacturing stages, relevant standards, and effective verification methods, buyers can make informed decisions that ensure they procure high-quality machinery tailored to their specific industry needs. This approach not only mitigates risks but also fosters long-term partnerships with reliable suppliers.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for tumbling machine Sourcing

To effectively analyze the cost structure and pricing for sourcing tumbling machines, it is essential to break down the various cost components, understand the price influencers, and provide actionable tips for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost component involves the raw materials used in manufacturing tumbling machines, such as steel, plastics, and electronic components. The choice of materials significantly impacts durability and performance. Notably, the market is trending towards more sustainable materials due to regulatory pressures and consumer preferences.

-

Labor: Labor costs can vary significantly based on geographic location and the skill level required for assembly and quality control. For instance, labor costs in Europe may be higher compared to South America or Africa, affecting the overall price of the machine.

Illustrative Image (Source: Google Search)

-

Manufacturing Overhead: This includes costs related to the factory’s operation, such as utilities, rent, and maintenance. It is important to evaluate the efficiency of the manufacturing process, as higher efficiency can lead to reduced overhead costs.

-

Tooling: Tooling costs are incurred in the initial setup for production. Custom designs may require specialized tools, which can escalate costs.

-

Quality Control (QC): Ensuring that tumbling machines meet industry standards involves QC costs. Advanced QC processes may add to the price but are vital for ensuring product reliability, especially in sectors like aerospace and automotive.

-

Logistics: The cost of shipping and handling can vary based on the destination. International buyers should consider freight costs, customs duties, and insurance, which can collectively add a significant amount to the final cost.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margin. This can vary based on the supplier’s market positioning and competitive strategy.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounts. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications/Customization: Custom specifications can lead to increased costs due to additional labor and materials. Buyers should assess whether customization is necessary or if off-the-shelf solutions suffice.

-

Material Selection: The choice of materials directly influences the machine’s cost and performance. Eco-friendly materials may incur a premium but could align with sustainability goals.

-

Quality and Certifications: Machines certified to specific industry standards may command higher prices. Buyers should weigh the importance of certifications against their operational needs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better warranties and support, justifying a higher price.

-

Incoterms: The agreed terms of shipment (e.g., FOB, CIF) affect the total landed cost. Understanding these terms is crucial for effective budgeting.

Buyer Tips

-

Negotiate: Leverage volume purchasing and long-term relationships to negotiate better prices. Establishing rapport with suppliers can lead to favorable terms.

-

Focus on Cost-Efficiency: Beyond the initial purchase price, consider the Total Cost of Ownership (TCO), which includes operational costs, maintenance, and potential downtime.

-

Understand Pricing Nuances: Be aware of regional pricing trends and the economic factors influencing them. For instance, fluctuations in raw material prices can lead to sudden price increases.

-

Conduct Market Research: Stay informed about industry trends and competitor pricing to better position your negotiation strategy.

-

Engage Multiple Suppliers: Solicit quotes from several suppliers to compare pricing and service offerings. This not only aids in negotiation but also helps identify the best value.

Disclaimer

The prices mentioned in this analysis are indicative and subject to change based on market dynamics, supplier negotiations, and other external factors. It is advisable for buyers to conduct due diligence and obtain updated quotes before making purchasing decisions.

Spotlight on Potential tumbling machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘tumbling machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for tumbling machine

Tumbling machines are essential tools in various industries, particularly for processes like deburring, polishing, and surface finishing. Understanding their technical properties and trade terminology is crucial for international B2B buyers to make informed purchasing decisions.

Key Technical Properties of Tumbling Machines

-

Material Grade

– Definition: Refers to the quality and composition of materials used in manufacturing the tumbling machine.

– Importance: Higher-grade materials improve durability and resistance to wear, which is critical in high-demand environments. For example, machines constructed from stainless steel are more resistant to corrosion, making them ideal for industries like aerospace and automotive. -

Tumbling Capacity

– Definition: The maximum weight and volume of materials that the machine can process in a single cycle.

– Importance: Understanding capacity is vital for efficiency. Buyers must match the machine’s capacity with their operational needs to avoid bottlenecks in production. -

Speed and RPM (Revolutions Per Minute)

– Definition: The rotational speed at which the tumbling machine operates.

– Importance: Different materials require different speeds for optimal finishing. A higher RPM can enhance finishing quality but may lead to faster wear of the machine, impacting long-term operational costs. -

Tolerance Levels

– Definition: The allowable deviation from a specified dimension or measurement.

– Importance: High tolerance levels ensure that the finished product meets quality standards. This is particularly important in precision industries like electronics and medical devices, where even minor deviations can lead to product failures. -

Automation Features

– Definition: The extent to which the tumbling machine incorporates automated controls and features.

– Importance: Automation can significantly enhance operational efficiency, reduce labor costs, and minimize human error. For buyers in regions like Europe and North America, where labor costs are high, investing in automated systems can lead to substantial long-term savings. -

Energy Efficiency

– Definition: The machine’s ability to perform its tasks while minimizing energy consumption.

– Importance: Energy-efficient machines not only lower operational costs but also align with global sustainability initiatives. Buyers from environmentally conscious regions may prioritize these features to comply with regulations and enhance corporate responsibility.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers identify reliable suppliers and assess the quality and compatibility of components for their tumbling machines. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Buyers need to be aware of MOQs to manage inventory effectively and ensure that they are not overcommitting resources, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

– Definition: A document that solicits price offers from suppliers for specific products or services.

– Importance: Initiating an RFQ allows buyers to compare pricing and terms from multiple suppliers, ensuring competitive procurement. -

Incoterms (International Commercial Terms)

– Definition: A series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers.

– Importance: Familiarity with Incoterms is essential for international transactions, as they dictate who is responsible for shipping, insurance, and tariffs, affecting overall cost calculations. -

Lead Time

– Definition: The amount of time from the initiation of a process until its completion, particularly in manufacturing and delivery.

– Importance: Understanding lead times is crucial for planning production schedules and ensuring timely delivery of components, especially in just-in-time manufacturing environments. -

Warranty and Service Agreements

– Definition: Contracts that outline the terms under which repairs or replacements will be provided for equipment.

– Importance: Buyers should carefully review warranty terms to ensure they are receiving adequate protection for their investment, which can mitigate potential future costs.

By grasping these essential properties and terminologies, B2B buyers can enhance their decision-making processes, ensuring they select the most suitable tumbling machines for their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the tumbling machine Sector

Market Overview & Key Trends

The tumbling machine sector is undergoing notable transformation, driven by the increasing demand for efficient surface finishing solutions across various industries such as automotive, aerospace, and electronics. Key factors propelling market growth include the rise of automated processes, which enhance operational efficiency and reduce labor costs, and a projected CAGR of approximately 5% between 2025 and 2033. Buyers from regions like Africa, South America, the Middle East, and Europe should pay attention to the evolving dynamics of this market.

Emerging trends include the integration of smart manufacturing technologies that facilitate data acquisition and process optimization, allowing manufacturers to respond more effectively to market demands. Furthermore, the shift toward just-in-time manufacturing is reshaping supply chain strategies, necessitating suppliers to adopt flexible manufacturing practices. The growing focus on sustainability is driving the adoption of eco-friendly materials and processes, with a rising demand for biodegradable and recyclable tumbling media to comply with stringent environmental regulations. International buyers must stay informed about these trends to leverage them in procurement strategies, ensuring they select suppliers who align with their operational needs and sustainability goals.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical factor in sourcing decisions within the tumbling machine sector. The environmental impact of manufacturing processes and materials used for tumbling machines is under scrutiny, as regulations around waste disposal and hazardous materials tighten. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainability.

The importance of an ethical supply chain cannot be overstated. Sourcing from suppliers that utilize renewable resources and sustainable practices not only enhances a company’s brand image but also mitigates risks associated with supply chain disruptions. Buyers should look for certifications like ISO 14001 for environmental management and the use of sustainable materials, such as biodegradable plastics or recycled ceramics, in tumbling media. By prioritizing these factors, companies can contribute to a more sustainable future while meeting the growing demand for responsible manufacturing practices in their industries.

Brief Evolution/History

The tumbling machine sector has evolved significantly since its inception in the early 20th century. Initially developed for simple mass finishing tasks, tumbling machines have transformed through technological advancements, incorporating automated systems and sophisticated materials. Early machines primarily utilized steel media for surface finishing, but the introduction of plastic and ceramic alternatives has broadened applications and improved sustainability. Today, the focus is not only on efficiency and cost-effectiveness but also on the environmental impact of manufacturing processes. As industries continue to innovate, the tumbling machine sector is set to play a pivotal role in achieving high-quality surface finishes while adhering to ethical and sustainable practices.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of tumbling machine

-

What key factors should I consider when vetting suppliers of tumbling machines?

When vetting suppliers, assess their industry experience, reputation, and client testimonials. Check for certifications that indicate adherence to international standards, such as ISO 9001. Request detailed product specifications and performance data to ensure the machines meet your quality requirements. Additionally, consider the supplier’s ability to provide after-sales support, spare parts availability, and their responsiveness to inquiries, which are crucial for long-term partnerships. -

Can I customize tumbling machines to fit my specific needs?

Yes, many suppliers offer customization options for tumbling machines. You can specify features such as size, capacity, and additional functionalities tailored to your production processes. When discussing customization, ensure you clearly communicate your requirements and ask for design prototypes or case studies of previous customizations. This will help you gauge the supplier’s capability and experience in meeting unique specifications. -

What are the typical minimum order quantities (MOQs) and lead times for tumbling machines?

MOQs for tumbling machines can vary widely based on the supplier and the complexity of the machine. Generally, suppliers may require a minimum order of one unit for standard machines, while custom models might have higher MOQs. Lead times can range from a few weeks to several months depending on production schedules and customization complexity. Always clarify these details upfront to align expectations and plan your procurement timeline effectively. -

What payment terms should I expect when purchasing a tumbling machine?

Payment terms can differ among suppliers, but common practices include a deposit upon order confirmation (often 30-50%) and the balance due prior to shipping. Some suppliers may offer financing options or letter of credit arrangements, especially for larger orders. It’s crucial to discuss payment methods upfront, as well as any potential discounts for early payment or bulk orders, to optimize your cash flow. -

What quality assurance measures should I look for in tumbling machines?

Ensure that the supplier implements rigorous quality assurance (QA) protocols throughout the manufacturing process. This includes inspections at various production stages and testing of final products. Ask for certificates of compliance with international standards and any relevant industry-specific certifications. Additionally, inquire about warranty terms and post-sale support, which are essential for maintaining machine performance and reliability. -

How do logistics and shipping impact the procurement of tumbling machines?

Logistics play a vital role in the procurement process, especially for international buyers. Consider the supplier’s location, shipping methods, and potential customs duties or tariffs that could affect the total cost. Discuss shipping timelines and options for tracking shipments to ensure timely delivery. Additionally, evaluate the supplier’s experience in handling international shipments, as this can significantly impact the efficiency of the procurement process. -

What steps should I take if I encounter disputes with a supplier?

In the event of a dispute, first, attempt to resolve the issue amicably through direct communication. Document all correspondence and agreements to provide a clear record. If the issue persists, refer to the terms outlined in the contract, which should include dispute resolution mechanisms, such as mediation or arbitration. Engaging legal counsel familiar with international trade laws can also be beneficial, especially for cross-border disputes. -

What role do environmental regulations play in the selection of tumbling machines?

Environmental regulations are increasingly important in the selection of tumbling machines, particularly in regions with stringent compliance standards. Look for suppliers that provide eco-friendly machines and media, such as those made from recyclable materials. Inquire about the supplier’s commitment to sustainability, including their waste disposal practices and adherence to local regulations. This not only helps in compliance but also enhances your company’s reputation as a socially responsible entity.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for tumbling machine

The tumbling machine market presents a significant opportunity for international B2B buyers, particularly in Africa, South America, the Middle East, and Europe. With a projected 5% CAGR from 2025 to 2033, the demand for efficient surface finishing solutions across industries such as automotive, aerospace, and electronics is on the rise. Strategic sourcing is essential for buyers to capitalize on this growth, allowing them to identify reliable suppliers, negotiate favorable terms, and ensure access to the latest technological advancements.

Buyers should prioritize suppliers that demonstrate innovation in sustainable practices and automation, as these factors will increasingly define competitive advantage in the marketplace. Additionally, understanding the regional dynamics and market concentration will enable buyers to make informed decisions that align with their operational goals.

As the industry evolves, staying ahead of trends such as smart manufacturing and eco-friendly materials will be crucial. International buyers are encouraged to engage with suppliers who are not only responsive to current demands but are also proactive in anticipating future needs. By doing so, they can enhance their competitive edge and contribute to a more sustainable manufacturing landscape. Embrace the opportunities within the tumbling machine market and position your business for success in the coming years.