Master Sourcing Strategies for Type 1 Power Plug in Global

Introduction: Navigating the Global Market for type 1 power plug

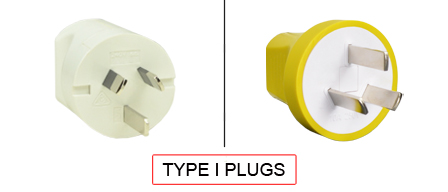

In an increasingly interconnected world, the Type 1 power plug stands out as a critical component in the global electrical landscape. As industries across Africa, South America, the Middle East, and Europe strive for operational efficiency and sustainability, understanding the nuances of this essential connector is vital for B2B buyers. The Type 1 power plug, known for its unique design and compatibility with various electrical devices, plays a pivotal role in facilitating reliable power distribution in numerous applications, from consumer electronics to industrial machinery.

This comprehensive guide is tailored specifically for international B2B buyers, providing an in-depth exploration of Type 1 power plugs. It covers a spectrum of topics, including the different types and materials available, manufacturing processes, and quality control measures that ensure safety and reliability. Additionally, the guide delves into supplier selection, cost considerations, and prevailing market trends, equipping buyers with the knowledge needed to make informed sourcing decisions.

Illustrative Image (Source: Google Search)

By addressing frequently asked questions and offering actionable insights, this resource empowers businesses to navigate the complexities of the Type 1 power plug market with confidence. As companies from diverse regions seek to enhance their supply chains and foster long-term partnerships, understanding the intricacies of Type 1 power plugs will be pivotal in achieving competitive advantage and operational excellence.

Understanding type 1 power plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A Plug | Two flat parallel pins | Household appliances, lighting | Pros: Widely available; Cons: Limited to low power. |

| Type B Plug | Two flat parallel pins with a grounding pin | Commercial equipment, computers | Pros: Enhanced safety; Cons: Requires compatible sockets. |

| Type C Plug | Two round pins | Travel adapters, small devices | Pros: Versatile; Cons: Not grounded, lower safety. |

| Type D Plug | Three round pins | Heavy machinery, industrial tools | Pros: High durability; Cons: Bulkier, less portable. |

| Type E Plug | Two round pins with a grounding hole | Electrical appliances in Europe | Pros: Secure connection; Cons: Limited global compatibility. |

Type A Plug

The Type A plug is characterized by its two flat parallel pins and is predominantly used in household appliances and lighting systems. Its widespread availability makes it a practical choice for low-power applications, particularly in residential settings. However, B2B buyers must consider the limitations regarding power capacity and the need for adapters in regions where this plug is not standard. Additionally, compliance with regional safety standards is crucial when sourcing these plugs for commercial use.

Type B Plug

The Type B plug features two flat parallel pins along with a grounding pin, enhancing safety for commercial applications. This type is commonly used for computers and sensitive electronic equipment, making it essential for businesses prioritizing operational safety. When purchasing, B2B buyers should ensure compatibility with existing sockets and understand the importance of grounding for equipment protection. Investing in Type B plugs can significantly enhance the reliability of business operations.

Type C Plug

Known for its two round pins, the Type C plug is widely utilized in Europe and is favored for travel adapters and small devices. Its versatility allows it to be used across various applications; however, it lacks a grounding feature, which may pose safety concerns for high-power devices. Buyers should assess the intended use and carefully evaluate the risks associated with ungrounded connections when sourcing this plug type, especially for equipment that requires higher safety standards.

Type D Plug

The Type D plug is distinguished by its three round pins and is primarily designed for heavy machinery and industrial tools. Its robust design ensures reliability in environments where operational continuity is critical. B2B buyers should be mindful of its bulkiness, which can limit portability and ease of installation. When sourcing Type D plugs, it is essential to consider the specific power requirements of the equipment and its suitability for the intended industrial application.

Type E Plug

Featuring two round pins and a grounding hole, the Type E plug is a secure option for electrical appliances in Europe. Its design promotes a stable connection, which enhances safety during operation. However, its limited compatibility outside Europe may restrict its use in international trade. Buyers should evaluate the compatibility with local electrical systems and consider potential sourcing challenges when opting for Type E plugs, particularly for businesses engaged in cross-border operations.

Related Video: USB Cable Types: How to Identify and Use Different USB Connectors

Key Industrial Applications of type 1 power plug

| Industry/Sector | Specific Application of type 1 power plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and production lines | Ensures consistent operations and minimizes downtime | Compatibility with local voltage standards, durability, and safety certifications |

| Healthcare | Medical equipment power supply | Critical for patient safety and operational reliability | Compliance with health regulations, reliability under varying loads |

| Construction | Temporary power for construction sites | Facilitates quick setup and flexibility in project timelines | Portability, robustness against environmental conditions, and local regulations |

| Telecommunications | Power supply for network infrastructure | Supports uninterrupted service delivery and network reliability | Voltage stability, supplier reliability, and service support |

| Transportation | Electric vehicle charging stations | Enhances infrastructure for EV adoption and sustainability | Compatibility with EV standards, installation requirements, and safety certifications |

Manufacturing

In the manufacturing sector, type 1 power plugs are essential for powering machinery and production lines. These plugs ensure consistent operations, which is critical for maintaining productivity and minimizing downtime. International B2B buyers must consider the compatibility of these plugs with local voltage standards and the durability of the components, especially in high-demand environments. Safety certifications are also crucial to ensure compliance with local regulations and to protect workers and equipment.

Healthcare

In healthcare, type 1 power plugs are vital for the operation of medical equipment, from diagnostic machines to life-support systems. The reliability of power supply is critical for patient safety and operational efficiency. B2B buyers in this sector must ensure that the plugs meet stringent health regulations and can handle varying electrical loads without failure. Additionally, sourcing from reputable suppliers with proven reliability is essential to mitigate risks associated with equipment downtime.

Construction

The construction industry frequently employs type 1 power plugs for temporary power setups on job sites. This flexibility allows for rapid deployment of power sources as projects evolve. B2B buyers should focus on sourcing plugs that are portable and robust enough to withstand harsh environmental conditions. Compliance with local regulations regarding electrical installations is also a significant consideration to avoid legal and safety issues during construction activities.

Telecommunications

In telecommunications, type 1 power plugs are used to supply power to network infrastructure, including routers, switches, and communication towers. Reliable power is crucial for uninterrupted service delivery and maintaining network reliability. Buyers in this sector should emphasize sourcing plugs that provide voltage stability and come from suppliers known for their reliability and service support. This ensures that network operations remain stable and efficient.

Transportation

Type 1 power plugs are increasingly being utilized in electric vehicle (EV) charging stations, playing a key role in enhancing infrastructure for EV adoption. This application supports sustainability initiatives and meets the growing demand for electric transportation. B2B buyers should ensure compatibility with existing EV standards, consider installation requirements, and prioritize safety certifications to provide safe and efficient charging solutions.

Related Video: Type 1 and type 2 SPD : installation and rules

Strategic Material Selection Guide for type 1 power plug

When selecting materials for Type 1 power plugs, international B2B buyers must consider various factors that influence product performance, durability, and compliance with regional standards. Below is an analysis of four common materials used in the manufacturing of Type 1 power plugs, focusing on their properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic known for its excellent electrical insulation properties and resistance to moisture. It can typically withstand temperatures up to 75°C and has moderate resistance to chemicals.

Pros & Cons: PVC is cost-effective and easy to mold, making it a popular choice for mass production. However, it has lower durability compared to other materials and may degrade under prolonged exposure to UV light. Additionally, its flexibility can be a disadvantage in high-stress applications.

Impact on Application: PVC is suitable for low to moderate power applications, such as household appliances and light-duty electrical devices. However, it may not be ideal for environments with extreme temperatures or exposure to harsh chemicals.

Considerations for International Buyers: Buyers should ensure that PVC materials comply with local standards such as ASTM or DIN. In regions like Kenya or Germany, where environmental regulations are stringent, sourcing PVC from certified suppliers is essential to avoid compliance issues.

Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering excellent flexibility, resilience, and temperature resistance, typically ranging from -40°C to 100°C.

Pros & Cons: TPEs provide superior durability and can withstand repeated flexing without cracking, making them ideal for applications requiring flexibility. However, they can be more expensive than PVC and may require specialized manufacturing processes.

Impact on Application: TPE is particularly effective for applications that involve frequent movement or bending, such as power cords for portable devices. Its excellent insulation properties make it suitable for outdoor use as well.

Considerations for International Buyers: Buyers must check for compliance with international safety standards, especially in Europe, where regulations regarding materials used in electrical products are stringent. Understanding the specific grades of TPE that meet these requirements is crucial.

Nylon

Key Properties: Nylon is a robust thermoplastic known for its high tensile strength and excellent abrasion resistance. It can operate effectively in temperatures ranging from -40°C to 120°C.

Pros & Cons: The durability and strength of nylon make it suitable for heavy-duty applications. However, it can be more expensive than PVC and may require more complex manufacturing techniques, which can increase lead times.

Impact on Application: Nylon is ideal for industrial applications where plugs are subject to mechanical stress or harsh environments. Its resistance to wear makes it suitable for use in machinery and equipment.

Considerations for International Buyers: Buyers should ensure that the nylon used complies with relevant international standards and certifications. In regions like South America, where infrastructure can vary, understanding the local market’s material preferences is essential for successful sourcing.

Metal (Copper)

Key Properties: Copper is a highly conductive metal with excellent thermal and electrical properties. It can withstand high temperatures and has good corrosion resistance when properly treated.

Pros & Cons: Copper’s superior conductivity makes it the preferred choice for electrical connections, ensuring efficient power transfer. However, it is more expensive than plastic materials and can be prone to corrosion if not properly coated.

Impact on Application: Copper is essential for the conductive parts of Type 1 power plugs, ensuring reliable performance in high-power applications. Its conductivity is particularly beneficial in industrial settings where power efficiency is critical.

Considerations for International Buyers: Buyers must be aware of the regulatory standards regarding the use of metals in electrical components. In Europe, for instance, compliance with RoHS (Restriction of Hazardous Substances) is mandatory, which impacts sourcing decisions.

Summary Table

| Material | Typical Use Case for type 1 power plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Household appliances, light-duty devices | Cost-effective and easy to mold | Lower durability, UV degradation | Low |

| Thermoplastic Elastomer | Portable power cords, outdoor use | Excellent flexibility and durability | Higher cost, specialized manufacturing | Medium |

| Nylon | Industrial applications, machinery | High strength and abrasion resistance | More expensive, complex manufacturing | High |

| Copper | Electrical connections, high-power applications | Superior conductivity | Higher cost, potential corrosion | High |

This analysis provides a comprehensive overview of material considerations for Type 1 power plugs, empowering international B2B buyers to make informed decisions that align with their operational requirements and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for type 1 power plug

Manufacturing Processes for Type 1 Power Plug

The manufacturing of Type 1 power plugs involves several critical stages that ensure the final product meets safety and performance standards. Understanding these processes helps B2B buyers assess the reliability and quality of the plugs they intend to procure.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The primary materials used in Type 1 power plugs typically include thermoplastics for insulation and copper or brass for the conductive pins. Buyers should ensure that suppliers use materials compliant with international standards to prevent issues related to conductivity and heat resistance.

– Material Testing: Before manufacturing begins, raw materials undergo rigorous testing for electrical and thermal properties, ensuring they meet specifications. This step is crucial for minimizing defects and ensuring safety. -

Forming

– Injection Molding: The insulating body of the plug is usually formed through injection molding, where molten thermoplastic is injected into molds. This method allows for high precision and consistency in producing large quantities.

– Pin Fabrication: Conductive pins are typically stamped from metal sheets and then plated with nickel or tin to enhance corrosion resistance. This step may involve various techniques such as die-casting or machining, depending on the required specifications. -

Assembly

– Component Assembly: Once the individual components are prepared, they are assembled. This can be done manually or through automated processes, depending on the scale of production. Quality control during this stage is critical, as improper assembly can lead to electrical failures.

– Soldering and Connections: Pins are soldered to the internal wiring in the plug. This connection must be secure to ensure electrical safety and performance. Automated soldering techniques may be employed for consistency. -

Finishing

– Surface Treatment: After assembly, plugs may undergo surface treatments such as coating to enhance durability and aesthetic appeal. This step can also include applying anti-static coatings to prevent damage during handling.

– Final Inspection: The finished products are inspected for visual defects, dimensional accuracy, and overall quality. Any defective items are removed from the production line to maintain high standards.

Quality Assurance Processes

Quality assurance is integral to the manufacturing process of Type 1 power plugs, ensuring compliance with international and industry-specific standards. B2B buyers should be familiar with these processes to evaluate potential suppliers effectively.

Relevant International Standards

-

ISO 9001: This is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Suppliers adhering to ISO 9001 demonstrate a commitment to consistent quality and customer satisfaction.

-

CE Marking: This indicates that the product meets European Union safety, health, and environmental protection requirements. For buyers in Europe, CE marking is essential for compliance and market access.

-

UL Certification: In North America, Underwriters Laboratories (UL) certification ensures the product has been tested for safety. It is crucial for buyers sourcing plugs for use in the U.S. and Canada.

Quality Control Checkpoints

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival at the manufacturing facility. The inspection ensures that materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): During manufacturing, random samples are taken to monitor the production process. This includes checking dimensions, electrical properties, and assembly quality to catch defects early.

-

Final Quality Control (FQC): Once production is complete, the finished products undergo thorough testing. This may include electrical testing to ensure proper functionality and safety under load conditions.

Common Testing Methods

- Electrical Testing: This assesses the plug’s ability to conduct electricity safely. Tests typically include insulation resistance, continuity, and dielectric strength.

- Mechanical Testing: This evaluates the physical durability of the plug, including tests for impact resistance, tensile strength, and thermal stability.

- Environmental Testing: These tests simulate real-world conditions, including exposure to humidity, temperature extremes, and corrosive environments, to ensure long-term reliability.

Verifying Supplier Quality Control

For B2B buyers, verifying a supplier’s quality control processes is essential to mitigate risks associated with poor product quality. Here are several strategies:

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control measures, and adherence to standards. This firsthand assessment can reveal potential issues that may not be apparent from documentation alone.

-

Quality Reports: Requesting quality assurance reports and testing certifications from suppliers can provide insights into their adherence to industry standards and the results of various tests conducted on the products.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s manufacturing processes and quality assurance practices. These inspections often include detailed reporting on compliance with international standards.

Considerations for International B2B Buyers

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be mindful of several factors when sourcing Type 1 power plugs:

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that the plugs meet local standards to avoid compliance issues.

- Supply Chain Reliability: Assessing the reliability of suppliers in terms of lead times, production capacity, and responsiveness is crucial for maintaining operational continuity.

- Cultural and Language Barriers: When dealing with international suppliers, consider potential challenges related to communication and cultural differences. Establishing clear channels of communication can facilitate smoother transactions.

By understanding the manufacturing processes and quality assurance measures associated with Type 1 power plugs, B2B buyers can make informed decisions that enhance operational efficiency and product safety.

Related Video: 18650 Cell Manufacturing Process, Automatic Production Line

Comprehensive Cost and Pricing Analysis for type 1 power plug Sourcing

Understanding the cost structure and pricing dynamics of sourcing Type 1 power plugs is essential for international B2B buyers, especially those operating in diverse markets across Africa, South America, the Middle East, and Europe. This analysis will help buyers make informed decisions, ensuring they achieve both quality and cost-efficiency in their procurement strategies.

Cost Components

The total cost of sourcing Type 1 power plugs can be broken down into several key components:

-

Materials: The primary materials used in manufacturing power plugs include high-grade plastics, copper for conductors, and sometimes metal for grounding features. The choice of materials significantly impacts the durability and safety of the plugs.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. In regions with higher labor costs, such as parts of Europe, buyers may encounter higher product prices.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help keep these costs down.

-

Tooling: Initial tooling costs can be significant, especially for customized or specialized plugs. Buyers should consider these costs when evaluating suppliers who offer customization options.

-

Quality Control (QC): Ensuring compliance with international standards requires robust QC processes, which can add to the overall cost. Certifications like ISO or IEC can enhance the perceived value and price of the plugs.

-

Logistics: Shipping costs, including freight and insurance, are critical for international sourcing. Factors such as distance, mode of transport, and local tariffs can significantly affect overall costs.

-

Margin: Supplier margins can vary widely based on their business model, market positioning, and the level of competition. Understanding these margins helps buyers negotiate better pricing.

Price Influencers

Several factors can influence the pricing of Type 1 power plugs:

-

Volume/MOQ: Bulk purchasing can lead to significant cost savings. Suppliers often provide discounts for larger orders, making it beneficial for buyers to assess their needs and optimize order sizes.

-

Specifications/Customization: Custom features or specific technical requirements can increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials: Higher quality materials may lead to increased costs but can enhance product longevity and safety, offering better value in the long run.

-

Quality and Certifications: Products that meet stringent quality standards often command higher prices. Buyers should prioritize suppliers who can provide certifications that align with their operational requirements.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind regarding product performance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect overall costs. Buyers should carefully evaluate terms to understand their responsibilities regarding shipping and insurance.

Buyer Tips

To maximize value when sourcing Type 1 power plugs, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing and terms. Leverage volume commitments to negotiate better rates.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and potential downtime costs. Opting for higher quality plugs may reduce long-term expenses.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and local economic conditions that can impact pricing. Understanding regional market dynamics is crucial when sourcing from different parts of the world.

-

Local Market Insights: Buyers in regions like Kenya or Germany should familiarize themselves with local suppliers and market conditions to make informed decisions that balance cost and quality effectively.

Disclaimer

Prices for Type 1 power plugs can vary significantly based on the factors mentioned above. It is essential for buyers to conduct thorough market research and obtain multiple quotes to ensure they are receiving competitive pricing that reflects the quality and specifications required for their applications.

Spotlight on Potential type 1 power plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘type 1 power plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for type 1 power plug

Understanding the technical specifications and trade terminology related to the Type 1 power plug is crucial for international B2B buyers. This knowledge enables better sourcing decisions, enhances negotiation power, and ensures compliance with local standards. Below are key technical properties and essential trade terms that buyers should be familiar with.

Critical Technical Specifications

-

Material Grade

– The Type 1 power plug is typically constructed from materials such as thermoplastics for the housing and copper for the pins. Material grade affects durability, heat resistance, and overall safety. For buyers, selecting plugs made from high-quality materials can prevent failures and enhance longevity, particularly in demanding environments. -

Current Rating

– This specification indicates the maximum current the plug can safely handle, typically measured in amperes (A). For Type 1 plugs, the common ratings are 10A or 15A. Understanding current ratings is vital for ensuring compatibility with the intended electrical load, preventing overheating, and maintaining operational safety. -

Voltage Rating

– The voltage rating defines the maximum voltage the plug can accommodate, usually around 125V for Type 1 plugs. Buyers must ensure that the voltage rating aligns with their regional electrical standards to avoid equipment damage and ensure compliance with local regulations. -

Pin Configuration and Dimensions

– Type 1 plugs feature two flat parallel pins that are standardized in size and spacing. Understanding these dimensions is essential for ensuring compatibility with sockets, especially when sourcing plugs for use in different countries or regions. -

Temperature Rating

– This specification indicates the maximum operating temperature the plug can withstand without compromising performance. It’s critical for buyers to consider temperature ratings, especially in environments subject to high temperatures, to ensure safety and reliability. -

Tolerance Levels

– Tolerance levels refer to the permissible deviation from specified dimensions. For electrical components like plugs, tight tolerances can prevent connectivity issues. Buyers should prioritize suppliers who adhere to strict manufacturing tolerances to ensure product reliability and performance.

Essential Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding the distinction between OEM and aftermarket products is crucial for buyers to ensure quality and compatibility. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ can significantly impact inventory management and cash flow, especially when sourcing Type 1 plugs. -

RFQ (Request for Quotation)

– An RFQ is a document that buyers use to solicit price quotes from suppliers. This process helps in comparing costs and terms from multiple vendors, ensuring competitive pricing for Type 1 plugs. -

Incoterms (International Commercial Terms)

– These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for understanding shipping responsibilities and costs. -

Certification Standards

– Certification standards (e.g., UL, CE) indicate that products have been tested for safety and performance. Buyers should verify that Type 1 plugs meet relevant certification standards in their market to ensure compliance and reduce liability. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. Understanding lead times is crucial for effective supply chain management, especially in regions where electrical components are in high demand.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their sourcing strategies for Type 1 power plugs align with operational needs and market standards. This knowledge not only enhances supplier negotiations but also mitigates risks associated with product failures and regulatory compliance.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the type 1 power plug Sector

Market Overview & Key Trends

The global market for type 1 power plugs is currently influenced by several dynamic factors, particularly relevant for international B2B buyers from Africa, South America, the Middle East, and Europe. Key drivers include the rapid expansion of renewable energy initiatives, the growth of electric vehicle (EV) infrastructure, and the increasing need for standardized power solutions across regions. In many developing regions, such as parts of Africa and South America, demand for reliable and efficient power sources is rising, leading to a focus on plugs that can support both traditional and alternative energy systems.

Emerging sourcing trends reflect a shift towards digital procurement platforms that facilitate easier access to suppliers and comparative product analysis. This trend is particularly important for buyers in regions with less established supply chains. Additionally, the emphasis on supplier reliability and compliance with international standards is paramount, ensuring that products meet safety and quality benchmarks. As businesses seek to streamline operations and reduce costs, there is a growing preference for suppliers who offer comprehensive support, including installation and maintenance services.

International buyers must also navigate market dynamics such as fluctuating raw material costs and varying regional regulations that can impact sourcing decisions. Understanding local market conditions, such as demand peaks during infrastructure projects or seasonal shifts in energy consumption, can help buyers optimize their procurement strategies. By leveraging insights into these trends, B2B buyers can enhance their competitive advantage and ensure sustainable operations.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers in the type 1 power plug sector. The environmental impact of production processes, from raw material extraction to manufacturing, necessitates a focus on ethical sourcing practices. Buyers are increasingly aware of the implications of their supply chain decisions, seeking suppliers who prioritize sustainability and compliance with environmental regulations.

The use of green certifications and sustainable materials is gaining traction. Suppliers who can demonstrate their commitment to reducing carbon footprints through energy-efficient manufacturing processes or the use of recyclable materials will stand out in a competitive market. For instance, sourcing plugs made from eco-friendly plastics or those that comply with international sustainability standards can not only enhance a company’s reputation but also align with corporate social responsibility goals.

Moreover, engaging with suppliers that have transparent supply chains fosters trust and collaboration. This is especially crucial in regions where regulatory environments may vary. By prioritizing ethical sourcing, B2B buyers can mitigate risks associated with environmental compliance and contribute positively to global sustainability efforts, reinforcing their brand’s commitment to responsible business practices.

Brief Evolution/History

The type 1 power plug has evolved significantly since its inception, adapting to the changing technological landscape and energy needs. Originally designed for low-power applications, these plugs have undergone enhancements to meet the demands of modern electrical systems. The introduction of safety features, such as grounding pins and higher voltage capacities, reflects a response to the increasing complexity of electrical infrastructure globally.

As international trade expanded, standardization efforts emerged to ensure compatibility across regions. This evolution not only facilitated easier cross-border transactions but also supported the global transition towards renewable energy solutions. Today, the type 1 power plug stands as a testament to innovation in electrical engineering, emphasizing safety, reliability, and sustainability in a rapidly changing market. For B2B buyers, understanding this historical context is essential for making informed sourcing decisions that align with current and future market demands.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of type 1 power plug

-

What should I consider when vetting suppliers for Type 1 power plugs?

When vetting suppliers, focus on their experience in manufacturing Type 1 power plugs and their compliance with international safety standards. Check for certifications such as ISO 9001 and IEC standards relevant to electrical components. Request references from existing clients and assess their reliability in terms of delivery schedules and product quality. It’s also beneficial to consider suppliers who offer post-sale support and have a strong presence in your target markets, ensuring they understand local regulations and requirements. -

Can Type 1 power plugs be customized for specific applications?

Yes, many manufacturers offer customization options for Type 1 power plugs to meet specific application needs. Customizations may include variations in pin configurations, materials, or additional features like weatherproofing for outdoor use. When discussing customization, clearly communicate your technical requirements and application context to ensure the supplier can meet your needs. Be prepared for potential changes in lead times and minimum order quantities (MOQs) based on the complexity of the customizations. -

What are the typical minimum order quantities (MOQs) and lead times for Type 1 power plugs?

MOQs for Type 1 power plugs can vary significantly depending on the supplier and the specifics of your order. Generally, MOQs range from 500 to 1,000 units for standard products, while customized orders may have higher MOQs. Lead times can also differ, typically ranging from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production capacity. Always confirm these details upfront to avoid delays and ensure your project timelines are met. -

What quality assurance measures should I look for in Type 1 power plugs?

When sourcing Type 1 power plugs, ensure the supplier implements rigorous quality assurance (QA) protocols. Look for suppliers who conduct comprehensive testing, including electrical safety tests and durability assessments. Verify that they have certifications from recognized organizations, such as UL or CE, which indicate adherence to international safety standards. Additionally, consider requesting a sample batch for testing before placing a larger order to evaluate the product’s performance and reliability. -

How do I manage logistics and shipping for international orders of Type 1 power plugs?

Effective logistics management is crucial when sourcing Type 1 power plugs internationally. Work with suppliers who have experience in exporting goods to your region and understand the customs regulations. Ensure that shipping terms are clearly defined, including Incoterms, to clarify responsibilities for costs and risks during transit. Additionally, consider using freight forwarders who specialize in electrical components, as they can streamline the process and help mitigate potential delays or issues at customs.

-

What steps can I take to resolve disputes with suppliers of Type 1 power plugs?

To resolve disputes effectively, start by maintaining clear and open communication with your supplier. Document all agreements and communications to have a reference point. If issues arise, attempt to negotiate a resolution directly, focusing on the specific terms of the contract. If necessary, escalate the matter to higher management within the supplier’s organization. Consider including arbitration or mediation clauses in your contracts to provide a structured approach for resolving disputes amicably without resorting to legal action. -

What payment terms are typically offered by suppliers of Type 1 power plugs?

Payment terms can vary widely among suppliers of Type 1 power plugs, but common options include upfront payment, partial payment upon order confirmation, and balance upon delivery. Some suppliers may also offer letter of credit arrangements for larger transactions. Assess the payment terms carefully, considering your cash flow needs and the supplier’s credibility. Establishing mutually agreeable terms upfront can help foster a strong business relationship and reduce the risk of payment disputes. -

How can I ensure compliance with local regulations when sourcing Type 1 power plugs?

To ensure compliance with local regulations, familiarize yourself with the specific electrical standards and safety requirements in your country or region. Engage with local regulatory bodies or industry associations to gain insights into compliance issues related to Type 1 power plugs. When sourcing, work exclusively with suppliers who provide documentation of compliance with relevant standards, such as certification marks. Conduct regular audits and inspections to ensure that the products meet local safety and quality regulations before deploying them in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type 1 power plug

In conclusion, strategic sourcing of Type 1 power plugs is essential for international B2B buyers seeking to optimize their operations across diverse markets. By understanding the various plug types, their applications, and regional compliance standards, buyers can make informed decisions that enhance safety and efficiency in their electrical systems.

Illustrative Image (Source: Google Search)

Key takeaways include the importance of assessing supplier reliability, evaluating total cost of ownership, and ensuring compatibility with local infrastructure. Prioritizing quality control measures can significantly mitigate risks associated with equipment failure and operational downtime.

As global energy demands continue to evolve, the landscape for power plug sourcing will also shift, driven by technological advancements and sustainability goals. Therefore, it is crucial for buyers from regions such as Africa, South America, the Middle East, and Europe to stay ahead of market trends and foster strategic partnerships with reputable suppliers.

Take action today: Evaluate your sourcing strategies for Type 1 power plugs, engage with industry experts, and leverage this guide to enhance your procurement processes. Embrace the opportunity to future-proof your operations and drive competitive advantage in your respective markets.