Master Sourcing Strategies with GMT Corp Waverly Iowa’s

Introduction: Navigating the Global Market for gmt corp waverly iowa

In the dynamic landscape of global manufacturing, GMT Corporation in Waverly, Iowa, stands out as a pivotal player, particularly for international B2B buyers seeking high-quality machining and fabrication solutions. With nearly five decades of expertise, GMT Corp specializes in the precision machining of large and complex components, serving critical industries such as defense, aerospace, and energy. Their robust capabilities in CNC machining, assembly, and stringent quality control processes make them a trusted partner for Original Equipment Manufacturers (OEMs) across the globe.

This comprehensive guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe—regions characterized by diverse manufacturing needs and growing markets. It explores essential aspects of sourcing from GMT Corp, including the types of services offered, materials used, manufacturing and quality control standards, supplier relationships, cost considerations, and market insights.

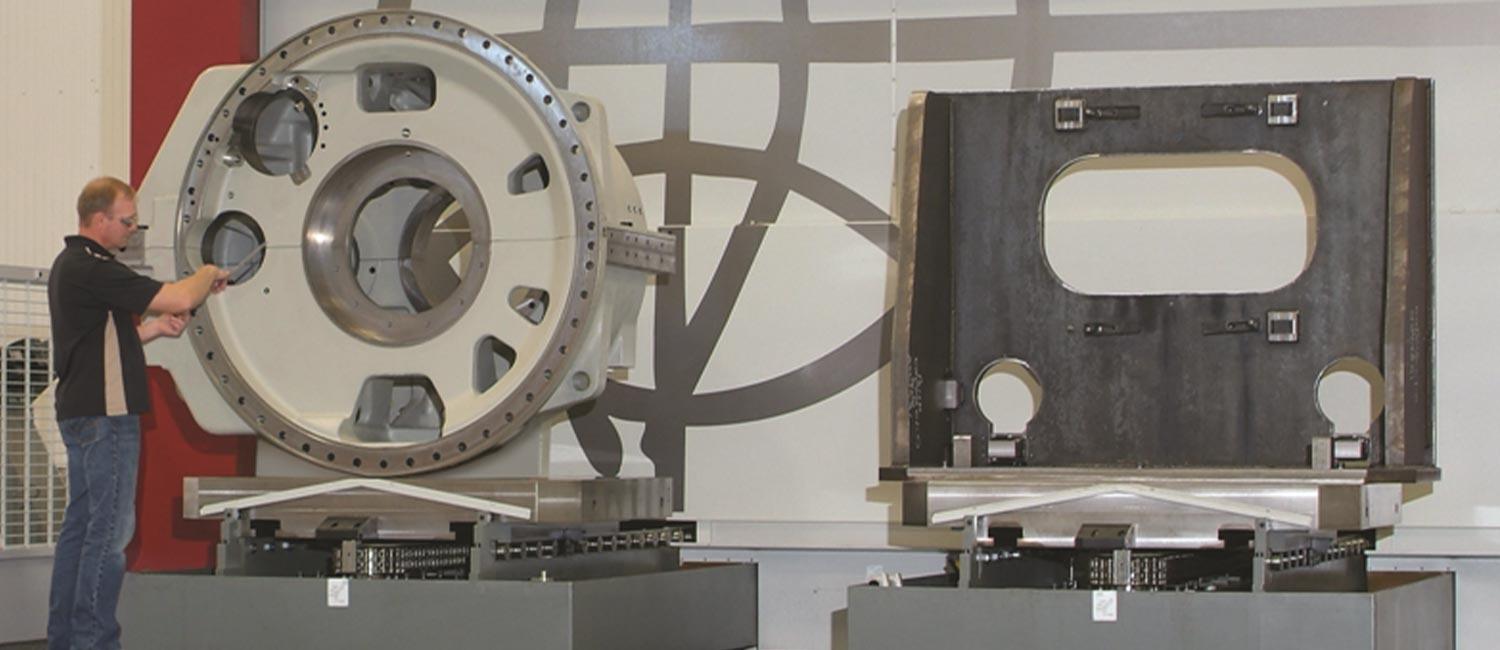

Illustrative Image (Source: Google Search)

By delving into frequently asked questions and providing actionable insights, this guide equips decision-makers with the knowledge necessary to navigate their sourcing journeys effectively. Whether you are looking to optimize production costs or ensure product reliability, understanding the capabilities of GMT Corporation will enable you to make informed decisions that align with your business objectives. Explore the potential of partnering with GMT Corp to elevate your manufacturing operations and achieve competitive advantages in the global market.

Understanding gmt corp waverly iowa Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Machining Services | High precision, large-scale machining capabilities | Aerospace, defense, heavy machinery | Pros: Precision, efficiency; Cons: Costly for small runs. |

| Assembly and Fabrication | In-house assembly of complex components | Construction, automotive, industrial equipment | Pros: Streamlined processes; Cons: Limited flexibility in design changes. |

| Inspection and Quality Control | Advanced CMM technology for precise measurement | Quality assurance in manufacturing | Pros: Ensures product reliability; Cons: Increased lead times. |

| Custom Machining Solutions | Tailored machining processes for specific client needs | Custom parts for various industries | Pros: Flexibility, tailored solutions; Cons: Longer development time. |

| Structural Components Manufacturing | Production of heavy-duty components | Construction, energy sectors | Pros: Robustness, durability; Cons: Heavy logistics and shipping costs. |

CNC Machining Services

CNC (Computer Numerical Control) machining is a cornerstone of GMT Corporation’s offerings. This service is characterized by its ability to produce complex parts with high precision and repeatability. Ideal for industries such as aerospace and defense, CNC machining allows for the efficient production of large-scale components. Buyers should consider the initial investment and cost-per-part, particularly for low-volume runs, as the technology can be more expensive compared to traditional machining methods.

Assembly and Fabrication

The assembly and fabrication services provided by GMT Corporation leverage their in-house capabilities to bring together various components into finished products. This service is particularly beneficial for sectors like construction and automotive, where complex assemblies are common. While this approach streamlines production and reduces lead times, buyers must be aware that it can limit flexibility in making design changes once production is underway.

Inspection and Quality Control

GMT Corporation employs advanced Coordinate Measuring Machines (CMM) to ensure that all produced components meet stringent quality standards. This inspection service is crucial for maintaining reliability in manufacturing, especially for industries where safety is paramount. Buyers should appreciate the value of rigorous quality control, but they must also consider that enhanced inspection processes can lead to longer lead times due to the additional checks involved.

Custom Machining Solutions

Custom machining solutions at GMT Corporation are designed to meet specific client requirements, ensuring that unique parts are produced to exact specifications. This flexibility makes it suitable for various industries looking for tailored solutions. However, buyers should be prepared for potentially longer development times and increased costs associated with custom projects, as they often require more intricate planning and setup.

Structural Components Manufacturing

This service focuses on the production of heavy-duty structural components, which are essential in industries such as construction and energy. The robustness and durability of these components make them ideal for demanding applications. Buyers should weigh the advantages of high-quality materials and reliable performance against the potential challenges of logistics and shipping costs, especially for large-scale orders.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of gmt corp waverly iowa

| Industry/Sector | Specific Application of GMT Corp Waverly Iowa | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Defense | Precision machining of components for military vehicles and equipment | Ensures operational reliability and performance | Compliance with military standards, lead time, and volume requirements |

| Agriculture | Fabrication of heavy-duty agricultural machinery components | Enhances durability and efficiency in farming | Material specifications, custom designs, and scalability |

| Wind Energy | Machining of large wind turbine components | Supports renewable energy initiatives and reduces costs | Quality assurance processes, precision requirements, and delivery timelines |

| Aerospace | Manufacturing of aircraft structural components | Increases safety and performance of aircraft | Certification requirements, traceability of materials, and testing protocols |

| Oil and Gas | Production of heavy-duty parts for drilling and extraction equipment | Improves operational efficiency and reduces downtime | Material certifications, supply chain reliability, and cost-effectiveness |

GMT Corporation in Waverly, Iowa, is a key player in the defense sector, providing precision machining for military vehicles and equipment. Their expertise ensures that components meet stringent operational standards, thereby enhancing reliability and performance in critical defense applications. For international buyers, especially from regions such as Africa and the Middle East, understanding the compliance with military standards and the importance of lead time is essential when sourcing these components.

In agriculture, GMT Corp fabricates heavy-duty machinery parts designed to withstand harsh operational conditions. The durability of these components directly impacts the efficiency of farming operations, which is crucial in regions like South America, where agricultural productivity is vital. Buyers should consider material specifications and the ability to accommodate custom designs to meet specific agricultural needs.

The wind energy sector benefits significantly from GMT’s machining of large wind turbine components. As countries aim to increase their renewable energy capacity, GMT’s ability to produce high-quality parts helps lower costs and supports sustainability efforts. International buyers should focus on the company’s quality assurance processes and precision requirements to ensure optimal performance of these components.

In the aerospace industry, GMT manufactures critical structural components for aircraft. The safety and performance of these components are paramount, making GMT’s adherence to rigorous certification requirements a key selling point. Buyers from Europe, particularly in countries like Spain, need to prioritize traceability of materials and thorough testing protocols when sourcing from GMT.

Lastly, in the oil and gas sector, GMT produces heavy-duty parts for drilling and extraction equipment. The reliability and efficiency of these components can significantly reduce operational downtime, a crucial factor in this high-stakes industry. Buyers should be aware of the importance of material certifications and the overall reliability of the supply chain when considering GMT as a sourcing partner.

Related Video: LBO Model Tutorial: Sources & Uses and Financial Forecast

Strategic Material Selection Guide for gmt corp waverly iowa

Material Analysis for GMT Corp, Waverly Iowa

When selecting materials for manufacturing processes at GMT Corp, it is crucial to consider the properties, advantages, disadvantages, and specific application impacts of commonly used materials. Below are analyses of four prevalent materials utilized in the machining and fabrication sectors.

1. Gray Iron

Key Properties:

Gray iron is known for its excellent castability and machinability. It has good wear resistance, moderate tensile strength, and can withstand high temperatures, making it suitable for various applications.

Pros & Cons:

The durability of gray iron is a significant advantage, particularly in heavy machinery components. However, it is brittle, which can lead to cracking under certain stress conditions. The cost is relatively low, but its manufacturing complexity increases with intricate designs.

Impact on Application:

Gray iron is compatible with various media, including water and oil, making it ideal for engine blocks and pump housings. Its thermal conductivity aids in heat dissipation, which is beneficial in high-temperature applications.

International Considerations:

For buyers from regions like Africa and South America, understanding ASTM standards for gray iron (e.g., ASTM A48) is essential for compliance. European buyers should be aware of EN standards, ensuring the material meets local regulations.

2. Ductile Iron

Key Properties:

Ductile iron, also known as nodular cast iron, offers enhanced strength and ductility compared to gray iron. It exhibits excellent corrosion resistance and fatigue strength, making it suitable for dynamic applications.

Pros & Cons:

The key advantage of ductile iron is its ability to absorb shock and resist deformation, which is critical in applications like automotive components. However, it is more expensive than gray iron and requires more complex manufacturing processes.

Impact on Application:

Ductile iron is particularly effective in applications involving high-stress environments, such as gears and crankshafts. Its corrosion resistance makes it suitable for environments exposed to moisture or chemicals.

International Considerations:

B2B buyers should ensure that ductile iron complies with relevant international standards, such as ASTM A536. Buyers from the Middle East and Europe may also need to consider specific local regulations regarding material properties.

3. Aluminum

Key Properties:

Aluminum is lightweight, has high corrosion resistance, and excellent thermal and electrical conductivity. It can be easily machined and formed, making it a versatile choice for various applications.

Pros & Cons:

The primary advantage of aluminum is its low weight, which is crucial for applications in aerospace and automotive sectors. However, its lower strength compared to steel can limit its use in high-stress applications. The cost of aluminum is generally medium, depending on the alloy.

Impact on Application:

Aluminum is compatible with a wide range of media and is often used in applications requiring weight reduction without sacrificing performance, such as in aircraft components and automotive parts.

International Considerations:

International buyers should be aware of the various aluminum alloy standards (e.g., ASTM B221). Compliance with local regulations in Europe and South America regarding recycling and environmental impact is also essential.

4. Steel

Key Properties:

Steel is renowned for its high tensile strength and versatility. It can be alloyed with various elements to enhance specific properties, such as corrosion resistance or hardness.

Pros & Cons:

Steel’s durability and strength make it suitable for heavy-duty applications. However, it is heavier than aluminum and may require additional corrosion protection, which can increase costs. The relative cost of steel is typically medium to high, depending on the grade.

Impact on Application:

Steel is widely used in construction and heavy machinery, where high strength and durability are required. Its compatibility with various coatings can enhance its performance in harsh environments.

International Considerations:

B2B buyers should ensure steel complies with international standards like ASTM A36 or EN 10025. Buyers from Africa and South America should consider local sourcing options to reduce costs and ensure compliance with regional regulations.

Summary Table

| Material | Typical Use Case for GMT Corp Waverly Iowa | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Gray Iron | Engine blocks, pump housings | Excellent castability and machinability | Brittle under stress | Low |

| Ductile Iron | Gears, crankshafts | High strength and ductility | More expensive and complex to manufacture | Medium |

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Lower strength compared to steel | Medium |

| Steel | Construction, heavy machinery | High tensile strength | Heavier and requires corrosion protection | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for gmt corp waverly iowa

GMT Corporation in Waverly, Iowa, is a prominent contract manufacturer specializing in high-precision machining and assembly solutions. With nearly five decades of experience, their operations are characterized by a robust manufacturing process and stringent quality assurance protocols, making them a reliable partner for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

Manufacturing Processes

Understanding the manufacturing processes employed by GMT Corporation is crucial for B2B buyers seeking reliable and efficient production partners. The primary stages of their manufacturing process include:

1. Material Preparation

The initial stage involves the selection and preparation of raw materials, which include gray iron castings, aluminum, nodular castings, and steel. GMT ensures that materials meet specific industry standards, which is essential for the quality of the final product. Buyers should inquire about the sourcing and certification of these materials to ensure they align with their quality expectations.

2. Forming

The forming stage encompasses various machining processes, including CNC (Computer Numerical Control) machining. GMT utilizes advanced CNC technology to achieve high-precision components. This technology allows for intricate designs and tight tolerances, which are critical for industries such as aerospace and defense. B2B buyers should assess the capabilities of GMT’s CNC machines and the expertise of their operators.

3. Assembly

Once components are machined, they proceed to the assembly phase. GMT specializes in assembling large parts, a process that requires meticulous attention to detail and coordination. The company employs skilled technicians who follow strict assembly protocols to ensure that all components fit together seamlessly. Buyers should verify GMT’s assembly capabilities and inquire about the experience of the assembly team.

4. Finishing

Finishing processes may include surface treatments, coatings, and polishing to enhance the durability and aesthetic appeal of the components. GMT’s finishing capabilities ensure that products meet both functional and visual standards. B2B buyers should request information about the finishing techniques used and any certifications that may apply.

Quality Assurance

Quality assurance is integral to GMT Corporation’s operations, ensuring that products meet the highest standards before they reach the customer. The company adheres to various international and industry-specific quality standards, including:

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system, ensuring consistent quality in products and services. GMT’s adherence to ISO 9001 signifies their commitment to quality and customer satisfaction.

- API Certification: For buyers in the oil and gas sector, GMT’s compliance with API standards indicates that their products meet rigorous safety and performance criteria.

Quality Control Checkpoints

GMT Corporation implements a comprehensive quality control (QC) process that includes several checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, real-time monitoring and inspections are conducted to identify any deviations from quality standards. This proactive approach minimizes defects and ensures that issues are addressed promptly.

- Final Quality Control (FQC): Before products are shipped, they undergo a final inspection to verify that all specifications and quality standards have been met.

Common Testing Methods

GMT employs various testing methods to validate the quality of its products:

– Coordinate Measuring Machine (CMM) Inspections: Utilizing one of the largest CMMs in North America, GMT performs precise measurements of completed components, ensuring they meet dimensional tolerances.

– Non-Destructive Testing (NDT): This includes methods like ultrasonic testing and magnetic particle inspection to detect internal flaws without damaging the components.

– Functional Testing: Components are subjected to operational tests to ensure they perform as expected under real-world conditions.

Verifying Supplier Quality Control

International B2B buyers should take proactive steps to verify the quality control measures of their suppliers. Here are several strategies:

- Conduct Audits: Regular audits of the manufacturing facility can provide insights into the operational processes and quality management practices. Buyers can request audit reports to assess compliance with international standards.

- Request Quality Control Reports: Suppliers should provide detailed QC reports that outline inspection results, testing methods, and any corrective actions taken.

- Third-Party Inspections: Engaging independent third-party inspectors can add an additional layer of assurance. These professionals can evaluate the manufacturing processes and provide unbiased assessments of quality.

QC Certification Nuances for International Buyers

When dealing with international suppliers like GMT Corporation, buyers should be aware of specific nuances related to quality certifications:

- Regulatory Compliance: Different regions have varying regulatory requirements. Buyers from Africa, South America, and the Middle East should ensure that GMT’s certifications are recognized in their respective countries.

- Language Barriers: Documentation may be in English, which could pose challenges for non-English speaking buyers. It’s advisable to request translations of critical quality documents.

- Cultural Considerations: Understanding the cultural context of business practices can facilitate smoother negotiations and partnerships. Buyers should be aware of GMT’s operational culture to foster effective communication and collaboration.

In conclusion, GMT Corporation’s comprehensive manufacturing processes and rigorous quality assurance measures position it as a strong partner for international B2B buyers. By understanding these processes and implementing effective verification strategies, buyers can ensure they receive high-quality products tailored to their specific needs.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for gmt corp waverly iowa Sourcing

Understanding Cost Components for GMT Corp, Waverly Iowa

When sourcing from GMT Corp in Waverly, Iowa, it’s crucial for international B2B buyers to grasp the various cost components that contribute to the total pricing structure. Understanding these components can help in budgeting and negotiation processes.

Key Cost Components

-

Materials: The cost of raw materials is often the most significant part of the overall cost structure. GMT Corp specializes in machining various materials such as gray iron, aluminum, and steel. Prices fluctuate based on market conditions, availability, and sourcing strategies. Buyers should consider long-term contracts for better pricing stability.

-

Labor: Labor costs are influenced by the skill level required for precision machining and assembly. GMT Corp employs a skilled workforce, which can be reflected in the pricing. Understanding local labor rates in Iowa and comparing them with those in your home country can provide insights into labor cost competitiveness.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. GMT Corp operates a large facility, which may lead to economies of scale. Buyers should inquire about how overhead costs are allocated to specific projects.

-

Tooling: Custom tooling can significantly affect pricing. Depending on the complexity and specifications of the parts being manufactured, tooling costs can vary widely. Buyers should discuss tooling requirements upfront to understand how these costs will impact the overall price.

-

Quality Control (QC): Given GMT Corp’s commitment to quality, investments in QC processes are essential. The costs associated with inspections, testing, and compliance with industry standards contribute to the overall price. Buyers should ask for details on the QC measures in place to ensure they align with their quality expectations.

-

Logistics: Shipping costs can vary based on destination, shipping method, and Incoterms agreed upon. International buyers should consider these costs when calculating total expenses. Understanding the logistics network GMT Corp utilizes can also provide insights into potential delays or additional charges.

-

Margin: Finally, the profit margin that GMT Corp adds to its pricing is influenced by market conditions and competition. Buyers should be aware that margins may vary based on the volume of orders and long-term relationships.

Price Influencers

Several factors can influence pricing when engaging with GMT Corp:

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs. Buyers should evaluate their needs and consider placing bulk orders to maximize cost efficiency.

-

Specifications/Customization: Custom parts or complex specifications may incur additional costs. Providing clear and concise specifications can help minimize misunderstandings and additional charges.

-

Quality/Certifications: International buyers may require specific certifications (e.g., ISO) that can affect pricing. Ensure that the required certifications are discussed upfront to avoid surprises.

-

Supplier Factors: The relationship with GMT Corp can also influence pricing. Building a strong partnership may lead to more favorable terms over time.

-

Incoterms: Understanding the agreed-upon Incoterms is essential as they dictate the responsibilities of buyers and sellers regarding shipping and logistics costs.

Buyer Tips for International Sourcing

-

Negotiation: Engage in discussions early to clarify expectations and explore pricing flexibility. Consider leveraging volume or long-term commitments as negotiation tools.

-

Cost-Efficiency: Assess the Total Cost of Ownership (TCO) rather than just the initial price. This includes considering logistics, potential tariffs, and maintenance costs associated with the products.

-

Pricing Nuances: Be aware that international payments may incur additional fees. Discuss payment methods and terms upfront to ensure clarity.

-

Research: Conduct thorough market research to understand regional pricing norms and the competitive landscape. This knowledge can empower you during negotiations.

Disclaimer

Pricing can vary significantly based on specific project requirements and market fluctuations. It is advisable to consult directly with GMT Corp for indicative pricing tailored to your needs.

Spotlight on Potential gmt corp waverly iowa Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘gmt corp waverly iowa’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for gmt corp waverly iowa

Key Technical Properties

When engaging with GMT Corporation in Waverly, Iowa, understanding specific technical properties and specifications is crucial for B2B buyers, especially when dealing with large, complex machining projects. Here are some essential properties:

-

Material Grade

Material grade refers to the classification of materials based on their mechanical properties and composition. Common materials used by GMT include gray iron, nodular casting, aluminum, and steel. Selecting the appropriate material grade is vital as it directly affects durability, weight, and cost, which are critical factors in industries such as defense and aerospace. -

Tolerance

Tolerance indicates the permissible limit of variation in a physical dimension. For high-precision machining, GMT often operates within tight tolerances, which can be as narrow as ±0.001 inches. Understanding tolerance is essential for ensuring that parts fit together correctly and perform as intended, significantly reducing the risk of failure in high-stakes applications. -

Surface Finish

Surface finish refers to the texture of a surface, which can influence performance and aesthetics. GMT provides various finishes, including rough, smooth, or polished, depending on the application. A proper surface finish can enhance fatigue resistance and corrosion protection, making it a key consideration for B2B buyers in sectors like oil and gas. -

Dimensional Stability

This property measures the ability of a material to maintain its dimensions under varying conditions such as temperature and humidity. For industries like aerospace, where components must operate under extreme conditions, dimensional stability is critical. Buyers should assess how GMT ensures this stability throughout its manufacturing process. -

Machining Capability

This refers to the range of machining processes that can be executed, including CNC machining, assembly, and inspection. GMT’s ability to provide these services in-house allows for greater quality control and efficiency, which can lead to significant cost savings for buyers.

Common Trade Terminology

Familiarity with industry terminology can streamline communication and negotiation processes. Here are some key terms relevant to GMT Corporation:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for international buyers looking to source components or materials efficiently. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Recognizing MOQ is important for buyers to manage inventory costs and ensure they meet their production needs without over-committing resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to request price quotes for specific products or services. This process helps buyers compare costs and services effectively, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that describe the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for international buyers to clarify shipping, insurance, and risk management responsibilities. -

CMM (Coordinate Measuring Machine)

CMM is a device used for measuring the physical geometrical characteristics of an object. GMT’s investment in one of the largest CMMs in North America underscores its commitment to precision and quality control, which is crucial for buyers seeking high-standard manufacturing.

By grasping these technical properties and industry terms, international B2B buyers can navigate their engagements with GMT Corporation more effectively, ensuring they meet their specific needs while maximizing the potential for successful partnerships.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the gmt corp waverly iowa Sector

Market Overview & Key Trends

The landscape of international B2B sourcing, particularly in the machining and fabrication sectors, is rapidly evolving. A few global drivers are shaping this transformation. First, the ongoing demand for high-precision, large-scale components is being driven by industries such as defense, agriculture, and renewable energy, notably in the Middle East and South America. Countries like Spain and Colombia are increasingly investing in infrastructure, leading to a surge in demand for reliable suppliers like GMT Corporation.

Emerging technologies are also influencing sourcing trends. Digitalization and automation are becoming essential, with many companies adopting advanced manufacturing techniques such as CNC machining and real-time monitoring systems. For buyers, this translates into improved quality control and reduced lead times. Additionally, the integration of Industry 4.0 technologies is enabling manufacturers to provide tailored solutions, enhancing collaboration and transparency throughout the supply chain.

Market dynamics are also shifting towards sustainability and ethical sourcing. As international buyers become more environmentally conscious, there is a growing emphasis on suppliers who prioritize sustainable practices. This trend is particularly pronounced in Europe, where regulations around emissions and waste are becoming stricter. For buyers from Africa and South America, establishing partnerships with manufacturers like GMT Corp, which emphasizes quality and sustainability, can be a competitive advantage.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a choice but a necessity for B2B buyers and suppliers alike. The environmental impact of manufacturing processes is significant, and companies are increasingly held accountable for their carbon footprints. GMT Corporation in Waverly, Iowa, is taking steps to align with these sustainability goals by integrating eco-friendly practices into its operations.

Ethical sourcing is crucial in ensuring that the supply chain is not only efficient but also responsible. Buyers should look for manufacturers that prioritize the use of sustainable materials and possess certifications that demonstrate their commitment to environmental stewardship. For instance, certifications such as ISO 14001, which focuses on effective environmental management systems, can indicate a supplier’s dedication to minimizing their ecological impact.

Moreover, the use of recyclable materials and energy-efficient technologies in machining processes can significantly reduce the environmental footprint. Buyers from Africa, South America, the Middle East, and Europe can enhance their brand reputation and meet regulatory requirements by partnering with suppliers who share their commitment to sustainability.

Brief Evolution/History

GMT Corporation has nearly 50 years of experience in the manufacturing sector, particularly in machining and fabrication. Founded in Waverly, Iowa, the company has established itself as a leader in providing complex machining solutions. Over the years, GMT has expanded its capabilities to serve a diverse range of industries, including defense, agriculture, and renewable energy.

The company’s focus on quality and innovation has allowed it to adapt to changing market demands, making it a trusted partner for OEMs across various sectors. As global sourcing trends continue to evolve, GMT is well-positioned to meet the needs of international buyers looking for reliable and sustainable manufacturing solutions.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of gmt corp waverly iowa

-

What should I consider when vetting GMT Corp as a supplier?

When vetting GMT Corp, consider their extensive experience in the industry, which spans nearly 50 years. Review their portfolio to assess the variety of industries they serve, including defense, agriculture, and aerospace. Additionally, verify their certifications and compliance with international standards, which are crucial for quality assurance. Engaging with previous clients for testimonials can provide insights into their reliability and service quality. It’s also advisable to evaluate their manufacturing capabilities, such as their advanced CNC machining and in-house assembly processes. -

Can I customize my order with GMT Corp?

Yes, GMT Corp offers customization options tailored to your specific project needs. They collaborate closely with clients during the development stage to recommend the most efficient machining processes. Discuss your requirements early in the project to ensure that the design and manufacturing processes align with your specifications. This collaborative approach not only helps in achieving desired outcomes but also optimizes costs, making it a strategic advantage for international buyers looking for tailored solutions. -

What are the minimum order quantities (MOQ) and lead times for orders?

The minimum order quantities at GMT Corp can vary based on the complexity and type of machining or assembly required. It’s best to discuss your needs directly with their sales team to determine the MOQ that applies to your specific project. Lead times are also contingent on the project’s scope and the current production schedule. Generally, GMT Corp aims to provide timely deliveries, but international buyers should factor in additional time for logistics and customs clearance when planning their schedules. -

What payment terms does GMT Corp offer for international buyers?

GMT Corp typically offers flexible payment terms for international buyers, which can include options such as letters of credit or advance payments depending on the order size and history of the business relationship. It’s essential to discuss payment terms upfront to avoid any misunderstandings later. Ensure that you are aware of any additional fees related to international transactions, including currency exchange rates and banking charges, which can impact the overall cost of your order.

Illustrative Image (Source: Google Search)

-

How does GMT Corp ensure quality assurance and certifications?

Quality assurance at GMT Corp is a top priority, supported by rigorous quality control processes throughout the manufacturing cycle. They utilize advanced technologies, including one of the largest Coordinate Measuring Machines (CMM) in North America, to ensure precision in every component. Additionally, they employ Advanced Product Quality Planning (APQP) methodologies to assess quality at every stage. Buyers should inquire about specific certifications that GMT Corp holds, such as ISO standards, which affirm their commitment to quality and reliability. -

What logistics options are available for shipping products internationally?

GMT Corp collaborates with various logistics partners to facilitate efficient shipping options for international clients. They can assist in arranging transportation based on your preferences, whether by air or sea. It’s advisable to discuss your logistics requirements early to ensure seamless coordination, especially for larger shipments. Additionally, be aware of potential customs duties and taxes that may apply upon arrival in your country, as these can affect your total cost. -

How does GMT Corp handle disputes or issues that may arise during the procurement process?

GMT Corp is committed to maintaining strong relationships with their clients and has established protocols for addressing disputes. Should issues arise, it’s best to communicate directly with your account manager to seek a resolution. They emphasize transparency and collaboration in resolving conflicts, which can include adjustments to orders or compensation where applicable. Understanding their dispute resolution process can help mitigate concerns and ensure a smoother transaction experience. -

What are the best practices for communicating with GMT Corp as an international buyer?

Effective communication is crucial when working with GMT Corp, especially as an international buyer. Ensure that you clearly articulate your project requirements, timelines, and any specific concerns upfront. Utilize their preferred communication channels, whether it be email, phone, or video calls, to maintain clarity. Regular updates and feedback loops can foster a collaborative relationship, allowing for timely adjustments and ensuring that your needs are met throughout the project lifecycle.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for gmt corp waverly iowa

The strategic sourcing landscape at GMT Corporation in Waverly, Iowa, presents a compelling opportunity for international B2B buyers. With nearly five decades of experience in high-precision machining and assembly, GMT Corp stands out as a reliable partner capable of meeting diverse needs across industries such as defense, agriculture, and aerospace. Their commitment to quality assurance through rigorous inspection processes ensures that all products maintain the highest standards, offering buyers peace of mind.

By leveraging GMT’s single-source capabilities, businesses can significantly reduce lead times and streamline their supply chains, resulting in both time and cost savings. The company’s advanced manufacturing engineering expertise further enhances their ability to collaborate closely with clients during the design and development stages, driving down costs while optimizing product performance.

As international buyers from Africa, South America, the Middle East, and Europe seek to enhance their procurement strategies, partnering with GMT Corporation could be a pivotal decision. Embrace the opportunity to innovate and elevate your supply chain—consider GMT Corp as a strategic ally in your journey towards operational excellence and sustainable growth.