Master Sourcing Sun and Planet Gear: Key Insights for B2B

Introduction: Navigating the Global Market for sun and planet gear

In today’s dynamic global marketplace, sun and planet gears play a pivotal role across various industries, from manufacturing and automotive to renewable energy solutions. These gears, known for their compact design and high torque efficiency, are essential in optimizing machinery performance and enhancing operational productivity. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of sun and planet gears is crucial for making informed sourcing decisions.

This comprehensive guide delves deep into the world of sun and planet gears, offering insights into different types, materials, and manufacturing processes. Buyers will gain a clear understanding of quality control measures and how to evaluate potential suppliers effectively. Additionally, the guide covers critical factors influencing cost and the latest market trends to help buyers navigate pricing strategies.

Furthermore, a dedicated FAQ section addresses common queries, empowering decision-makers with the knowledge they need to select the right gear solutions for their specific applications. Whether you are sourcing for heavy machinery or precision engineering, this guide is designed to equip you with the tools necessary for successful procurement. By leveraging the insights provided, you can enhance your supply chain efficiency and ensure that your operations remain competitive in an ever-evolving market landscape.

Understanding sun and planet gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Planetary Gear | Consists of sun gear, planet gears, and ring gear; offers high torque density and compact design. | Automotive transmissions, industrial machinery | Pros: High efficiency and durability. Cons: Complexity in design may lead to higher costs. |

| Epicyclic Gear Train | Allows for multiple input and output configurations; can change speed and torque ratios. | Robotics, aerospace applications | Pros: Versatile and adaptable. Cons: Requires precise assembly and alignment. |

| Single Stage Planetary Gear | Simple structure with one set of planet gears; ideal for low-speed applications. | Conveyors, low-speed motors | Pros: Cost-effective and easy to install. Cons: Limited torque and speed capabilities. |

| Multi-stage Planetary Gear | Incorporates several gear stages for higher torque and reduced speed; suitable for heavy-duty applications. | Heavy machinery, wind turbines | Pros: Greater torque output. Cons: More complex and larger footprint. |

| Fixed Gear Planetary System | One gear is held stationary while others rotate; ideal for specific torque and speed outputs. | Marine applications, construction equipment | Pros: Reliable performance for specific tasks. Cons: Limited flexibility in applications. |

Standard Planetary Gear

Standard planetary gears are characterized by their arrangement of a central sun gear, surrounding planet gears, and an outer ring gear. These systems are renowned for their high torque density and compact design, making them ideal for automotive transmissions and various industrial machinery. When considering a purchase, buyers should note that while they offer exceptional efficiency and durability, the complexity of their design can lead to increased costs and maintenance requirements.

Epicyclic Gear Train

Epicyclic gear trains are unique in their ability to allow multiple input and output configurations, which can change speed and torque ratios depending on the application. This versatility makes them particularly suitable for robotics and aerospace applications. Buyers should consider that while these systems are adaptable, they require precise assembly and alignment, which may increase installation time and costs.

Single Stage Planetary Gear

Single-stage planetary gears feature a straightforward structure with only one set of planet gears, making them ideal for low-speed applications such as conveyors and low-speed motors. Their cost-effectiveness and ease of installation are significant advantages for businesses looking to streamline operations. However, buyers should be aware that these systems have limited torque and speed capabilities compared to more complex gear systems.

Multi-stage Planetary Gear

Multi-stage planetary gears consist of several gear stages, allowing for higher torque output and reduced speed, making them suitable for heavy-duty applications like heavy machinery and wind turbines. While these systems provide significant advantages in torque performance, buyers must consider the increased complexity and larger footprint, which could impact installation and operational costs.

Fixed Gear Planetary System

Fixed gear planetary systems involve one gear being held stationary while others rotate, allowing for specific torque and speed outputs. This design is particularly effective in marine applications and construction equipment. Buyers should recognize that while these systems offer reliable performance for designated tasks, their limited flexibility may restrict adaptability in various operational environments.

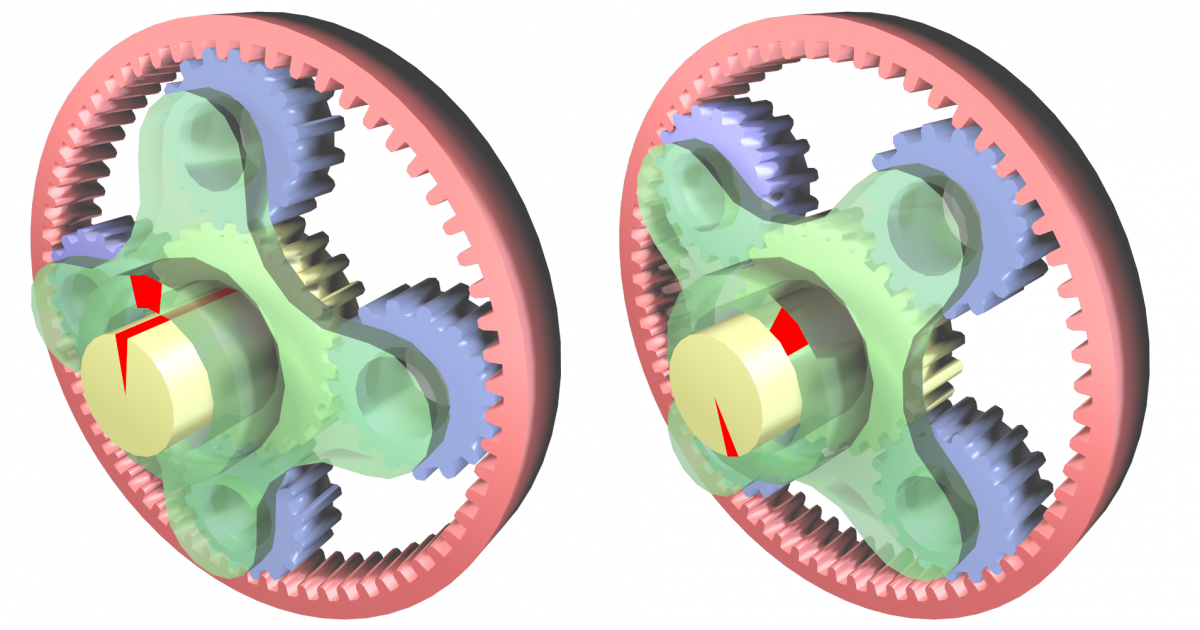

Illustrative Image (Source: Google Search)

Key Industrial Applications of sun and planet gear

| Industry/Sector | Specific Application of sun and planet gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | CNC Machines | High precision and torque management for machining | Supplier reliability and quality certifications are crucial. |

| Agriculture | Tractors and Harvesters | Efficient power transmission for heavy loads | Consider local sourcing for reduced lead times and costs. |

| Mining | Conveyor Systems | Enhanced durability and torque in harsh conditions | Look for gear sets with high wear resistance materials. |

| Automotive | Electric Vehicles | Compact design for lightweight and efficient drives | Ensure compatibility with existing systems and regulations. |

| Renewable Energy | Wind Turbines | Reliable energy conversion and efficiency | Focus on suppliers with experience in high-stress applications. |

Manufacturing

In the manufacturing sector, sun and planet gears are integral to CNC (Computer Numerical Control) machines. They provide high precision and effective torque management, allowing for intricate machining processes. This application helps businesses reduce downtime and improve production efficiency. For international buyers, sourcing from manufacturers that offer quality certifications and robust after-sales support is vital to ensure operational continuity.

Agriculture

In agriculture, sun and planet gears are commonly used in tractors and harvesters. They facilitate efficient power transmission, enabling these machines to handle heavy loads and challenging terrains. This results in improved productivity during planting and harvesting seasons. Buyers should consider local sourcing options to mitigate shipping costs and ensure timely deliveries, especially during peak agricultural periods.

Mining

The mining industry relies on sun and planet gears for conveyor systems. These gears enhance durability and torque management under extreme conditions, ensuring the safe and efficient transport of mined materials. Buyers in this sector should prioritize sourcing gear sets made from high wear-resistant materials to withstand harsh operational environments, thus reducing maintenance costs and downtime.

Automotive

In the automotive industry, particularly with the rise of electric vehicles (EVs), sun and planet gears are utilized for their compact design and efficiency in power transmission. This application is crucial for optimizing space and weight in vehicle design, contributing to better energy efficiency. Buyers should ensure that the gears are compatible with existing systems and adhere to relevant safety regulations.

Renewable Energy

Sun and planet gears are increasingly used in wind turbines, where they play a key role in converting wind energy into electrical energy. Their reliability and efficiency make them ideal for this application, supporting sustainable energy initiatives. When sourcing for this application, buyers should focus on suppliers with a proven track record in high-stress applications, ensuring the longevity and performance of the gear systems in variable wind conditions.

Related Video: How Epicyclic Sun And Planet Gear Box train Works

Strategic Material Selection Guide for sun and planet gear

When selecting materials for sun and planet gears, international B2B buyers must consider various factors, including mechanical properties, environmental resistance, manufacturing complexity, and cost. Here, we analyze four common materials used in the production of sun and planet gears: steel, aluminum, cast iron, and composite materials. Each material presents unique advantages and challenges that can significantly impact performance and application suitability.

Steel

Key Properties: Steel offers high tensile strength, excellent wear resistance, and good thermal stability, making it suitable for high-load applications. It typically has a temperature rating up to 300°C and can withstand high pressures.

Pros & Cons: Steel’s durability and strength make it ideal for demanding environments. However, it can be prone to corrosion if not properly treated, which may require additional surface coatings. The manufacturing process can be complex and costly, particularly for precision components.

Impact on Application: Steel gears are compatible with various media and can be used in automotive, aerospace, and industrial machinery applications. They perform well in high-torque situations but may require lubrication to reduce wear.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100. Corrosion resistance treatments may be necessary, especially in humid or corrosive environments, common in regions like Africa and South America.

Aluminum

Key Properties: Aluminum is lightweight, with good corrosion resistance and thermal conductivity. It typically has a lower tensile strength compared to steel but compensates with lower density.

Pros & Cons: The primary advantage of aluminum is its weight, which can lead to reduced energy consumption in applications like electric vehicles. However, its lower strength limits its use in high-load applications. Manufacturing processes can be simpler, but the cost of high-quality aluminum alloys can be high.

Impact on Application: Aluminum gears are suitable for applications where weight savings are critical, such as in aerospace and automotive sectors. They are also resistant to oxidation, making them ideal for outdoor applications.

Considerations for International Buyers: Compliance with standards like ASTM B221 or DIN 1725 is crucial. Buyers should consider the specific aluminum alloy used, as different alloys have varying mechanical properties.

Cast Iron

Key Properties: Cast iron is known for its excellent wear resistance and good machinability. It can withstand high temperatures and pressures, typically rated up to 600°C.

Pros & Cons: Its durability and ability to absorb vibrations make cast iron a popular choice for heavy machinery. However, it is brittle and can fracture under impact loads. The manufacturing process is generally less complex, but the material can be heavy and costly to transport.

Impact on Application: Cast iron gears are commonly used in industrial applications where vibration dampening is beneficial. They perform well in moderate to high-load situations but may not be suitable for highly dynamic applications.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM A48 or JIS G5501. The weight of cast iron can impact shipping costs, particularly for buyers in remote regions.

Composite Materials

Key Properties: Composites, such as reinforced plastics, offer excellent corrosion resistance and low weight. They can be engineered to provide specific mechanical properties, including high tensile strength.

Pros & Cons: The main advantage of composites is their versatility and resistance to environmental factors. However, they may not handle high temperatures or loads as well as metals. The manufacturing process can be complex and may require specialized techniques.

Impact on Application: Composite gears are suitable for applications requiring lightweight and corrosion-resistant components, such as in marine or chemical processing industries. They can also reduce noise and vibration.

Considerations for International Buyers: Compliance with standards like ASTM D638 or ISO 527 is essential. Buyers should evaluate the specific composite material used, as performance can vary significantly.

| Material | Typical Use Case for sun and planet gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength and durability | Prone to corrosion | High |

| Aluminum | Aerospace, electric vehicles | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Cast Iron | Industrial machinery | Excellent wear resistance | Brittle under impact loads | Medium |

| Composite Materials | Marine, chemical processing | Corrosion resistance and low weight | Limited high-load capacity | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for sun and planet gear

The manufacturing of sun and planet gears is a complex process that requires precision and attention to quality. For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, understanding these processes and the quality assurance measures in place is crucial for making informed purchasing decisions.

Manufacturing Processes for Sun and Planet Gear

1. Material Preparation

The first step in the manufacturing process involves selecting the appropriate materials. Common materials for sun and planet gears include high-carbon steel, alloy steel, and sometimes plastic composites for specific applications. The choice of material affects the gear’s durability, performance, and resistance to wear.

- Material Testing: Before manufacturing begins, raw materials undergo rigorous testing to ensure they meet specified mechanical and chemical properties.

- Cutting and Shaping: The selected materials are cut into blanks using techniques such as laser cutting or water jet cutting, ensuring precise dimensions for subsequent processes.

2. Forming

Forming processes are essential for shaping the gears into their required geometries. This may involve several techniques, including:

- Forging: Hot or cold forging processes are often used to improve the strength and grain structure of the material.

- Machining: Precision machining, including CNC (Computer Numerical Control) milling and turning, is employed to achieve the exact tooth profile and dimensions necessary for proper meshing with other gears.

3. Assembly

Once the individual components (sun gear, planet gears, and ring gear) are manufactured, they must be assembled. This process is critical for ensuring that all parts fit together seamlessly.

- Alignment and Fitting: Careful alignment is necessary to prevent premature wear or failure. The assembly process might include the use of fixtures and jigs to maintain precision.

- Lubrication: Proper lubrication systems are integrated at this stage to reduce friction and wear during operation.

4. Finishing

The finishing stage enhances the surface quality and performance characteristics of the gears.

- Heat Treatment: Processes such as quenching and tempering are used to enhance hardness and toughness.

- Surface Treatment: Techniques like grinding, shot peening, or coating can be applied to improve surface finish and wear resistance.

Quality Assurance for Sun and Planet Gear

Quality assurance is integral to the manufacturing of sun and planet gears, ensuring that products meet international standards and customer specifications.

Relevant International Standards

B2B buyers should be aware of the standards that govern the quality of gear manufacturing:

- ISO 9001: This standard outlines the requirements for a quality management system and is fundamental for manufacturers seeking to ensure consistent quality.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards may be required.

Quality Control Checkpoints

Quality control is performed at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, checks are performed to monitor critical dimensions and tolerances.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection verifies that the final product meets all design and performance criteria.

Common Testing Methods

Several testing methods are utilized to ensure the quality of sun and planet gears:

- Dimensional Inspection: Using tools like calipers and micrometers to verify that components meet specified dimensions.

- Material Testing: Hardness tests (e.g., Rockwell, Brinell) and tensile strength tests are conducted to ensure material properties are within acceptable limits.

- Functional Testing: Gears may undergo operational testing to ensure they perform under expected loads and speeds.

Verifying Supplier Quality Control

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliability and compliance with industry standards.

- Supplier Audits: Conducting audits of potential suppliers can provide insights into their quality management systems and manufacturing capabilities. This includes reviewing their certifications, processes, and facilities.

- Quality Assurance Reports: Requesting detailed QA reports can help buyers assess the supplier’s commitment to quality and consistency.

- Third-Party Inspection: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and the final product.

Quality Control and Certification Nuances for International Buyers

When dealing with suppliers from different regions, understanding the nuances of quality control and certification is vital:

- Local Standards vs. International Standards: Some suppliers may follow local standards that differ from international ones. It’s essential for buyers to clarify which standards their suppliers adhere to and whether they are recognized in their target markets.

- Communication and Documentation: Clear communication regarding quality expectations and thorough documentation of certifications and testing results can help bridge any gaps in understanding between buyers and suppliers.

- Cultural Considerations: Different regions may have varying approaches to quality assurance. Building strong relationships and understanding local practices can facilitate smoother transactions.

By comprehensively understanding the manufacturing processes and quality assurance measures associated with sun and planet gears, B2B buyers can make more informed decisions, ensuring that they select reliable suppliers who can deliver high-quality products tailored to their specific needs.

Related Video: How 1 Million Chocolate Bars Are Made in Factory | Surprising Chocolate Production Process

Comprehensive Cost and Pricing Analysis for sun and planet gear Sourcing

When sourcing sun and planet gears, B2B buyers must navigate a complex cost structure influenced by various components and pricing factors. Understanding these elements can lead to more informed purchasing decisions and improved negotiations with suppliers.

Cost Components

-

Materials: The cost of raw materials, such as steel or aluminum, is a significant factor in the overall price of sun and planet gears. High-quality materials may increase initial costs but can enhance durability and performance, leading to long-term savings.

-

Labor: Labor costs can vary significantly based on the region where manufacturing occurs. In regions with lower labor costs, such as parts of Africa or South America, the overall cost of production may be reduced, but this can impact quality if not managed properly.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can minimize overhead, thus lowering the final price.

-

Tooling: The investment in specialized tooling for production can affect pricing. Custom tooling may be required for unique specifications, which can add to initial costs but may offer greater precision and efficiency in the long run.

-

Quality Control (QC): Implementing robust QC measures ensures that the gears meet required specifications and standards, which is essential for operational reliability. However, rigorous QC processes can add to costs, especially if third-party certifications are needed.

-

Logistics: Shipping and handling fees can vary based on the distance from the supplier and the selected Incoterms. Understanding these costs is crucial, particularly for international buyers who may face tariffs or additional taxes.

-

Margin: Supplier margins will vary depending on their operational efficiencies and market positioning. Buyers should expect a markup that reflects the supplier’s investment in quality, service, and innovation.

Price Influencers

-

Volume/MOQ: Larger orders often come with discounts, making it beneficial for buyers to consolidate their purchases. Minimum order quantities (MOQs) can also influence pricing strategies.

-

Specifications/Customization: Custom-designed gears will generally incur higher costs due to the additional engineering and manufacturing processes involved. Buyers should weigh the necessity of customization against potential cost increases.

-

Material Quality/Certifications: Higher quality materials and certifications (such as ISO standards) typically command higher prices. However, they can lead to lower maintenance and operational costs over time.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer competitive pricing to build their market presence.

-

Incoterms: Understanding Incoterms is essential for international buyers as they dictate the responsibilities of buyers and sellers regarding shipping and logistics, which can affect overall costs.

Buyer Tips

-

Negotiation: Engage in negotiations with suppliers to explore potential discounts, especially for bulk purchases or long-term contracts. Being prepared with market research can strengthen your position.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes initial costs, maintenance, and operational efficiency. Investing in higher-quality gears may reduce long-term expenses.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and their impact on costs. Additionally, tariffs and import duties may affect the final price, so consider these in budgeting.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and service. Open communication about expectations can foster a collaborative environment that benefits both parties.

Disclaimer

Prices for sun and planet gears can fluctuate based on market conditions, raw material costs, and supplier pricing strategies. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Spotlight on Potential sun and planet gear Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘sun and planet gear’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for sun and planet gear

Key Technical Properties of Sun and Planet Gears

When considering sun and planet gears for various industrial applications, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

-

Material Grade

– Common materials for sun and planet gears include steel, aluminum, and cast iron. The choice of material directly affects durability, weight, and resistance to wear. For instance, high-carbon steel is often used for its strength and ability to withstand high torque loads. Selecting the appropriate material can enhance the lifespan of the gears, reduce maintenance costs, and ensure optimal performance in harsh environments. -

Gear Ratio

– The gear ratio defines the relationship between the number of teeth on the sun gear and the planet gears. This ratio is critical as it determines the output speed and torque. A higher gear ratio typically results in increased torque and reduced speed, which is essential in applications like heavy machinery. Understanding gear ratios helps buyers align their equipment needs with operational requirements. -

Tolerance Levels

– Tolerance refers to the allowable deviation in gear dimensions. Tight tolerances ensure smoother operation and better engagement between gears, which can enhance efficiency and reduce noise. Buyers should pay attention to tolerance specifications to avoid costly operational issues that arise from poor fitting. -

Load Capacity

– The load capacity of sun and planet gears specifies the maximum load they can handle without failure. This property is crucial for ensuring that the gears can withstand the operational demands of the machinery they will be used in. Buyers must assess load capacity to prevent premature gear wear or catastrophic failures. -

Efficiency

– Efficiency is a measure of how effectively the gear system transmits power. High-efficiency gear systems minimize energy losses due to friction and heat. When selecting gears, buyers should consider efficiency ratings to ensure that their systems operate economically and sustainably. -

Lubrication Requirements

– Proper lubrication is essential for maintaining the performance and longevity of sun and planet gears. Different materials and designs may have specific lubrication needs, impacting maintenance schedules and operational costs. Buyers should inquire about recommended lubricants and maintenance practices to optimize gear performance.

Common Trade Terminology in the Gear Industry

Familiarity with industry jargon can significantly streamline communication and negotiation processes for B2B buyers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM status is important for buyers seeking reliability and compatibility in replacement parts. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Buyers must consider MOQs to ensure they meet production needs without overcommitting financially. This is particularly relevant for startups or companies looking to scale. -

RFQ (Request for Quotation)

– An RFQ is a standard business process where buyers invite suppliers to submit price quotations for specific products or services. Issuing an RFQ can help buyers compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international transactions. Understanding Incoterms helps buyers clarify responsibilities and risks associated with shipping, delivery, and insurance. -

Lead Time

– Lead time refers to the time taken from placing an order to delivery. For B2B buyers, understanding lead times is essential for inventory planning and ensuring that production schedules are met. -

After-Sales Support

– This term encompasses services provided after the sale, including installation, maintenance, and repairs. Buyers should evaluate after-sales support offerings to ensure they have access to necessary resources for optimal equipment performance.

By grasping these technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing sun and planet gears more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the sun and planet gear Sector

Market Overview & Key Trends

The sun and planet gear sector is witnessing robust growth driven by several global factors. The increasing demand for high-efficiency systems in industries such as renewable energy, automotive, and manufacturing is propelling the adoption of planetary gear systems. The shift towards electric vehicles (EVs) and automation is particularly notable, as these applications require compact and efficient gear solutions that enhance performance while minimizing space and weight.

Emerging technologies such as Industry 4.0 and IoT are reshaping sourcing trends. B2B buyers are increasingly seeking suppliers who offer smart gear systems capable of real-time monitoring and predictive maintenance, which enhances operational efficiency and reduces downtime. Additionally, the integration of advanced materials and manufacturing techniques, such as additive manufacturing, is becoming more prevalent. This trend not only improves performance characteristics but also allows for greater customization to meet specific operational needs.

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. In Africa and South America, there is a significant push towards local manufacturing to reduce reliance on imports, driven by economic policies favoring local production. Meanwhile, the Middle East is focusing on diversifying its economy, where investments in automation and robotics are creating new opportunities for gear manufacturers. In Europe, sustainability regulations are influencing procurement choices, encouraging buyers to prioritize suppliers who adhere to eco-friendly practices.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing processes in the sun and planet gear sector cannot be overlooked. As global awareness of sustainability increases, B2B buyers are prioritizing suppliers that demonstrate commitment to reducing carbon footprints and waste. Ethical sourcing is becoming a key criterion, with companies increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly and sustainably.

Buyers should look for suppliers offering “green” certifications, which indicate adherence to environmental standards. Materials such as recycled metals and bio-based composites are gaining traction, offering sustainable alternatives without compromising performance. Furthermore, engaging with suppliers who have transparent supply chains can help mitigate risks associated with unethical labor practices and environmental degradation.

Investing in sustainable gear solutions is not merely a compliance issue; it can also enhance brand reputation and customer loyalty. Companies that prioritize sustainability often find that their products resonate more with environmentally conscious consumers, leading to increased market share. As such, B2B buyers must ensure that sustainability is integrated into their sourcing strategies to meet both regulatory demands and customer expectations.

Brief Evolution/History

The evolution of sun and planet gears dates back to the early 20th century, with significant advancements that have shaped their applications today. Initially used in early automotive transmissions, these gears have evolved into critical components in various industries, including aerospace, robotics, and renewable energy systems.

The design of sun and planet gears allows for compact configurations that deliver high torque and efficiency, making them ideal for applications requiring robust performance in limited spaces. The continuous innovation in materials and manufacturing processes has further enhanced their capabilities, positioning them as a preferred choice for modern engineering solutions. As industries move towards automation and sustainable practices, the relevance of sun and planet gears is set to grow, providing ample opportunities for B2B buyers to capitalize on.

Related Video: Exim Trade Conclave 2025 LIVE | Finance Minister Nirmala Sitharaman Delivers Keynote Address | N18L

Frequently Asked Questions (FAQs) for B2B Buyers of sun and planet gear

-

What should I consider when vetting suppliers of sun and planet gears?

When vetting suppliers, prioritize their industry experience, technical expertise, and production capabilities. Request references from previous clients and evaluate their track record in delivering quality products. Ensure they have the necessary certifications (e.g., ISO 9001) and quality assurance processes in place. Additionally, assess their ability to provide customization based on your specific needs, which is crucial for applications in diverse industries. -

Can I customize sun and planet gears to meet my specific requirements?

Yes, many manufacturers offer customization options for sun and planet gears. When discussing your needs, provide detailed specifications, including size, material, gear ratio, and application requirements. Be clear about the intended use, as this will help the supplier recommend the best design. Keep in mind that customization may affect lead times and pricing, so it’s wise to inquire about these aspects upfront. -

What are the typical minimum order quantities (MOQs) and lead times for sun and planet gears?

MOQs can vary significantly between suppliers, often ranging from a few pieces to several hundred units. Lead times typically depend on the complexity of the order and the supplier’s production capacity. On average, expect lead times of 4-12 weeks for standard products, while customized gears may take longer. It’s advisable to discuss these details during initial negotiations to align expectations and avoid delays. -

What payment terms should I expect when sourcing sun and planet gears internationally?

Payment terms can vary widely based on the supplier’s policies and your negotiation. Common terms include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Ensure that all payment terms are clearly outlined in the purchase agreement to avoid any misunderstandings. -

How can I ensure quality assurance and compliance with industry standards?

Request documentation of the supplier’s quality assurance processes and certifications. It is beneficial to conduct a factory audit or request third-party inspections to verify compliance with relevant industry standards. Additionally, ask for sample products before placing a large order to assess quality firsthand. Establishing a clear quality agreement that specifies acceptable tolerances and testing methods can also help ensure that the products meet your expectations. -

What logistics considerations should I keep in mind when importing sun and planet gears?

Logistics play a crucial role in international sourcing. Consider shipping options, customs clearance, and the potential for tariffs or duties that may apply to your order. Work with a reliable logistics partner who understands the nuances of importing machinery components. Ensure that the supplier provides all necessary shipping documents, including a bill of lading and customs declarations, to facilitate a smooth import process. -

How should disputes be handled in international transactions?

Dispute resolution should be addressed in your contract. Common approaches include mediation, arbitration, or litigation, depending on the agreed terms. Specify the governing law and jurisdiction to avoid confusion later. Having a clear dispute resolution process can save time and costs. Additionally, maintain open communication with your supplier to resolve minor issues before they escalate into disputes. -

What are the best practices for maintaining a long-term relationship with suppliers?

Building strong relationships with suppliers is key to successful international sourcing. Regular communication, timely payments, and feedback on product performance can foster trust and collaboration. Consider conducting periodic performance reviews to discuss quality, pricing, and service levels. Engaging suppliers in joint development initiatives or sharing forecasts can also enhance partnership longevity and mutual growth.

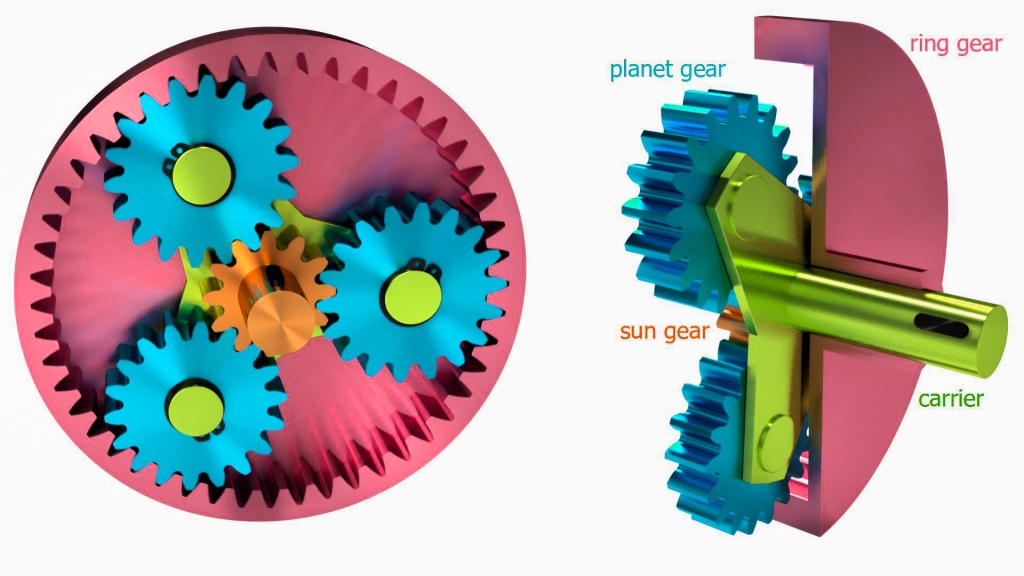

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for sun and planet gear

In conclusion, strategic sourcing of sun and planet gears is not just about procurement; it’s about building sustainable, competitive advantages in your operations. Understanding the intricacies of planetary gear systems—such as their design, functionality, and application—enables international B2B buyers to make informed decisions that enhance efficiency and reduce operational costs.

Key takeaways include the importance of selecting high-quality manufacturers who can provide tailored solutions that meet specific industry needs. By fostering strong relationships with suppliers, businesses can secure favorable terms, gain insights into emerging technologies, and ensure timely delivery of essential components.

Looking ahead, the demand for advanced gearing solutions will only increase, driven by innovations in industries such as renewable energy, automotive, and manufacturing. As buyers from Africa, South America, the Middle East, and Europe navigate this evolving landscape, embracing strategic sourcing practices will be crucial.

Take action today: Evaluate your current sourcing strategies and consider how investing in high-quality sun and planet gears can propel your business forward in a competitive marketplace. The future is bright for those who prioritize efficiency and innovation in their supply chains.