Master Sourcing Swing Check Valves: Essential Guide for B2B

Introduction: Navigating the Global Market for swing check valve

In today’s interconnected industrial landscape, the swing check valve stands out as a pivotal component in fluid management systems. Designed to allow the flow of liquids in one direction while preventing backflow, these valves are essential in maintaining system integrity across various applications, from oil and gas to water treatment. For international B2B buyers, particularly those operating in dynamic markets like Africa, South America, the Middle East, and Europe, understanding the nuances of swing check valves is crucial for making informed procurement decisions.

This comprehensive guide will explore various aspects of swing check valves, including their types, materials, manufacturing processes, and quality control standards. We will also delve into supplier options, cost factors, and market trends, providing insights tailored to the needs of buyers in regions such as Brazil and Saudi Arabia. Additionally, a frequently asked questions section will address common concerns, enhancing your understanding of this vital product.

By equipping you with essential knowledge and actionable insights, this guide empowers you to navigate the global market for swing check valves effectively. Whether you are sourcing for a new project or optimizing existing systems, understanding these valves’ operational benefits and specifications will lead to better choices, ensuring efficiency and reliability in your fluid systems.

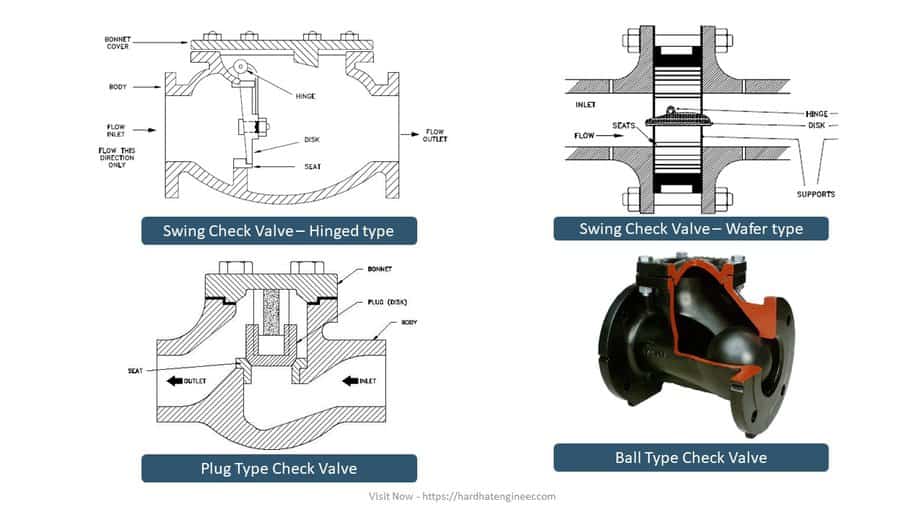

Understanding swing check valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Swing Check Valve | Simple disc design, low-pressure drop | Water supply, HVAC systems | Pros: Cost-effective, easy to install. Cons: Limited to horizontal or vertical installations. |

| Lift Check Valve | Vertical lift mechanism, suitable for high pressure | Oil and gas, industrial applications | Pros: Handles high pressure, minimal backflow. Cons: More complex design, higher cost. |

| Dual Disc Check Valve | Two discs for reduced flow resistance | Power generation, wastewater treatment | Pros: Efficient flow, compact size. Cons: More expensive, requires precise installation. |

| Spring Loaded Check Valve | Spring mechanism for faster closure | Chemical processing, food and beverage | Pros: Quick response, prevents water hammer. Cons: Higher maintenance, potential for spring fatigue. |

| Wafer Check Valve | Compact design, fits between flanges | Piping systems, HVAC | Pros: Space-saving, lightweight. Cons: Limited to certain pressure ranges, may require specific flanges. |

Standard Swing Check Valve

The Standard Swing Check Valve is characterized by its straightforward disc design, which operates effectively in low-pressure environments. It is commonly used in water supply and HVAC systems, where reliability and cost-effectiveness are paramount. When considering this type, buyers should evaluate the installation requirements, as it typically functions best in horizontal or vertical pipelines.

Lift Check Valve

The Lift Check Valve features a vertical lift mechanism that allows it to manage high-pressure applications effectively. It is ideal for sectors like oil and gas, where robust performance is critical. Buyers should consider the complexity of installation and potential maintenance costs, as this valve type can be more intricate compared to standard models.

Dual Disc Check Valve

Known for its two-disc design, the Dual Disc Check Valve minimizes flow resistance and is well-suited for power generation and wastewater treatment applications. This design allows for efficient fluid flow while maintaining a compact size. B2B buyers should assess the cost implications and the precision required during installation, as improper fitting can lead to operational issues.

Spring Loaded Check Valve

The Spring Loaded Check Valve utilizes a spring mechanism to ensure rapid closure, making it suitable for applications in chemical processing and the food and beverage industry. Its quick response helps prevent water hammer, a common issue in fluid systems. Buyers must weigh the benefits of quick operation against potential maintenance challenges, such as spring fatigue over time.

Wafer Check Valve

The Wafer Check Valve stands out due to its compact design, fitting snugly between flanges in piping systems. This valve is commonly used in HVAC applications where space is limited. While its lightweight nature is advantageous, buyers should be aware of the specific pressure ranges it can handle and ensure compatibility with the flanges in their systems to avoid installation issues.

Related Video: How Swing Check Valves work | Check Valve Assembly | Check Valve working principle

Key Industrial Applications of swing check valve

| Industry/Sector | Specific Application of Swing Check Valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water and Wastewater | Preventing backflow in sewage systems | Protects against contamination and system damage | Ensure compliance with local regulations and standards |

| Oil and Gas | Flow control in pipelines | Enhances safety by preventing reverse flow | Materials suitable for high pressure and corrosive fluids |

| Food and Beverage | Liquid transfer in processing plants | Maintains product integrity and hygiene | Compliance with food safety standards (e.g., FDA, EU) |

| Power Generation | Steam and water systems | Increases operational efficiency and safety | High-temperature resistance and durability of materials |

| HVAC Systems | Preventing backflow in heating systems | Ensures efficient operation and energy savings | Compatibility with various pipe sizes and materials |

Water and Wastewater

In water and wastewater management, swing check valves are crucial for preventing backflow in sewage systems. This application is vital as it protects treatment facilities from contamination, which can lead to significant operational disruptions and public health risks. International buyers should ensure that the valves meet local regulations and standards, particularly in regions where water quality is heavily monitored.

Oil and Gas

In the oil and gas sector, swing check valves are used extensively for flow control in pipelines. They enhance safety by preventing reverse flow, which can cause spills or leaks. Buyers in this sector should consider sourcing valves made from materials that can withstand high pressure and corrosive fluids, ensuring longevity and reliability in harsh environments.

Food and Beverage

In the food and beverage industry, swing check valves play a critical role in liquid transfer processes within processing plants. They help maintain product integrity and hygiene by preventing contamination from backflow. B2B buyers must ensure that the valves comply with food safety standards, such as those set by the FDA or EU regulations, to guarantee safe operations.

Power Generation

Swing check valves are employed in steam and water systems within power generation facilities. Their role is to increase operational efficiency and safety by ensuring that fluids flow in the correct direction, preventing potential hazards. Buyers should focus on high-temperature resistance and durability of materials when sourcing valves for this application, as they must withstand extreme operational conditions.

HVAC Systems

In HVAC systems, swing check valves are utilized to prevent backflow in heating systems, ensuring that water circulates efficiently. This application is essential for maintaining energy savings and operational efficiency. When sourcing these valves, buyers should consider their compatibility with various pipe sizes and materials to ensure seamless integration into existing systems.

Strategic Material Selection Guide for swing check valve

When selecting materials for swing check valves, it is crucial for B2B buyers to consider the properties and performance characteristics of each material. Below, we analyze four common materials used in swing check valves, focusing on their key properties, advantages and disadvantages, application impacts, and considerations for international buyers, particularly in Africa, South America, the Middle East, and Europe.

1. Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and the ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 600°F (315°C) and can handle pressures exceeding 1500 psi.

Pros & Cons:

Stainless steel is highly durable and suitable for a wide range of applications, including those involving aggressive media. However, it is more expensive than other materials and can be complex to manufacture due to its hardness.

Impact on Application:

Stainless steel is ideal for applications involving water, steam, and various chemicals, making it suitable for industries like oil and gas, food processing, and pharmaceuticals.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A351 and DIN 17440. Countries like Brazil and Saudi Arabia may have specific regulations regarding material certifications.

2. Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and ability to withstand high pressures, typically rated up to 300 psi. However, it is less effective in high-temperature applications, generally limited to 400°F (204°C).

Pros & Cons:

The material is cost-effective and easy to manufacture, making it a popular choice for many applications. On the downside, cast iron is prone to corrosion and may require protective coatings, which can add to maintenance costs.

Impact on Application:

Cast iron is commonly used in water supply and wastewater applications. Its compatibility with non-corrosive media makes it a reliable choice for municipal systems.

Considerations for International Buyers:

Buyers should be aware of local standards such as JIS G5502 for cast iron valves. In regions like Africa, where infrastructure may be less developed, the durability of cast iron can be advantageous.

3. PVC (Polyvinyl Chloride)

Key Properties:

PVC is lightweight, resistant to corrosion, and can handle temperatures up to 140°F (60°C) and pressures around 150 psi. It is an excellent choice for non-pressurized applications.

Pros & Cons:

The primary advantage of PVC is its low cost and ease of installation. However, it has limited temperature and pressure ratings compared to metals, which can restrict its use in high-demand applications.

Impact on Application:

PVC is often used in irrigation, drainage, and chemical processing where media compatibility is essential. It is particularly suitable for transporting corrosive fluids.

Considerations for International Buyers:

Compliance with ASTM D1784 is essential for PVC products. Buyers in Europe and South America should verify local regulations regarding chemical compatibility and environmental impact.

4. Bronze

Key Properties:

Bronze offers good corrosion resistance, especially in marine environments, and can handle temperatures up to 400°F (204°C) with pressure ratings of around 200 psi.

Pros & Cons:

Bronze is durable and has excellent wear resistance, making it suitable for high-performance applications. However, it is generally more expensive than cast iron and can be susceptible to dezincification if not properly formulated.

Impact on Application:

Bronze is often used in applications involving seawater or other corrosive environments, such as marine and offshore industries.

Considerations for International Buyers:

Buyers should ensure compliance with ASTM B62 and similar standards. In regions like the Middle East, where marine applications are prevalent, the use of bronze can be particularly advantageous.

Summary Table

| Material | Typical Use Case for swing check valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Oil and gas, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Cast Iron | Water supply, wastewater | Cost-effective and durable | Prone to corrosion, requires coatings | Low |

| PVC | Irrigation, drainage | Lightweight and easy to install | Limited temperature and pressure ratings | Low |

| Bronze | Marine applications | Good corrosion resistance in marine environments | More expensive than cast iron, risk of dezincification | Medium |

By understanding the properties and implications of each material, international B2B buyers can make informed decisions that align with their specific application needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for swing check valve

Manufacturing Processes for Swing Check Valves

Material Preparation

The production of swing check valves begins with the careful selection of materials, which are critical for ensuring durability and performance. Common materials include stainless steel, cast iron, and bronze, each chosen based on the specific application and environmental conditions.

Key Techniques:

– Material Sourcing: Suppliers should provide certifications for materials used, ensuring they meet standards such as ASTM or EN for mechanical properties and corrosion resistance.

– Pre-processing: Materials undergo treatments such as heat treatment or surface hardening to enhance strength and resistance to wear and corrosion.

Forming

After preparing the materials, the next stage involves shaping them into the components of the swing check valve. This includes the body, disc, and seat.

Key Techniques:

– Casting: Commonly used for the valve body, casting allows for complex shapes and robust structures. Ensure that suppliers use quality molds and follow standards like ISO 9001 for manufacturing processes.

– Machining: Components are machined to precise tolerances. CNC (Computer Numerical Control) machining is prevalent for achieving high accuracy, particularly for the disc and seat. Verification of the machining process can be performed through dimensional inspection.

Assembly

The assembly stage is crucial, as it determines the valve’s functionality and reliability. Each component is carefully assembled to ensure proper sealing and operation.

Key Techniques:

– Manual and Automated Assembly: Depending on the scale of production, assembly can be done manually or through automated processes. Automated assembly lines often reduce human error and improve consistency.

– Sealing Methods: Gaskets or O-rings are installed to prevent leakage. It’s essential that these seals are compatible with the fluid they will be exposed to.

Finishing

Once assembled, the swing check valves undergo finishing processes to enhance their appearance and performance.

Key Techniques:

– Surface Treatment: Processes such as electroplating, powder coating, or painting can be applied to enhance corrosion resistance and aesthetic appeal.

– Final Inspection: A thorough visual inspection is performed to check for surface defects, proper assembly, and finishing quality.

Quality Assurance for Swing Check Valves

Quality assurance is essential to ensure that swing check valves meet international standards and perform reliably in their intended applications.

International Standards

B2B buyers should be aware of the following relevant standards:

– ISO 9001: This quality management standard ensures that suppliers maintain consistent quality through established processes.

– CE Marking: For products sold in the European Union, CE marking indicates compliance with health, safety, and environmental protection standards.

– API Standards: The American Petroleum Institute (API) provides standards relevant to valves used in oil and gas applications, ensuring safety and performance.

Quality Control Checkpoints

To maintain high-quality standards, manufacturers implement several checkpoints throughout the production process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify they meet specifications before entering production.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing ensure that each stage adheres to quality standards, allowing for immediate corrective actions if needed.

- Final Quality Control (FQC): The completed valves undergo rigorous testing, including pressure testing and leakage tests, to confirm they function as intended.

Common Testing Methods

B2B buyers should be familiar with standard testing methods employed during the quality assurance process:

– Hydrostatic Testing: Measures the valve’s ability to withstand pressure without leaking.

– Functional Testing: Ensures that the valve opens and closes properly under specified conditions.

– Material Testing: Includes tensile strength and hardness tests to confirm that materials meet specified requirements.

Illustrative Image (Source: Google Search)

Verifying Supplier Quality Control

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial.

Strategies for Verification

- Audits: Conduct regular audits of suppliers to assess their adherence to quality standards. An on-site visit can provide insight into their manufacturing processes and capabilities.

- Quality Reports: Request detailed quality reports that document testing results, compliance with international standards, and any corrective actions taken.

- Third-Party Inspection: Engage independent inspection agencies to conduct thorough evaluations of the manufacturing process and final products, providing an unbiased assessment of quality.

QC and Certification Nuances for International Buyers

When sourcing swing check valves, international buyers must navigate specific nuances related to quality control and certification:

- Regional Standards: Understand the specific standards required in your region. For instance, CE marking is mandatory for products sold in the EU, while API standards are crucial for the oil and gas industry.

- Documentation: Ensure that suppliers provide complete documentation for all certifications and compliance reports. This is vital for customs and regulatory approvals in your home country.

- Language Barriers: When dealing with suppliers from diverse regions, language differences can lead to miscommunication regarding quality requirements. It is advisable to have clear, written specifications in both parties’ languages.

By understanding the manufacturing processes and quality assurance protocols for swing check valves, B2B buyers can make informed purchasing decisions, ensuring they source reliable, high-quality products suitable for their applications.

Related Video: Check Valve | Non Return Valve

Comprehensive Cost and Pricing Analysis for swing check valve Sourcing

Understanding the Cost Structure of Swing Check Valves

When sourcing swing check valves, international B2B buyers must consider various cost components that contribute to the overall pricing. The primary elements include:

-

Materials: The choice of materials significantly impacts cost. Common materials include stainless steel, cast iron, and PVC, each varying in price based on market conditions and quality. Higher-grade materials often lead to increased durability and reliability, justifying a higher initial investment.

-

Labor: Labor costs can fluctuate based on the manufacturing location. Regions with lower labor costs, such as parts of Asia, may offer competitive pricing. However, it’s crucial to assess the skill level of the workforce, as it directly affects product quality.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative costs associated with the manufacturing facility. Efficient manufacturing processes can help minimize these overheads, thus reducing the overall price of the valve.

-

Tooling: Custom tooling for specific valve designs can be a significant upfront cost. However, investing in high-quality tooling can enhance production efficiency and product consistency over time.

-

Quality Control (QC): Ensuring that swing check valves meet international quality standards is vital. The costs associated with QC processes can vary, but they are essential for maintaining product integrity and customer satisfaction.

-

Logistics: Transportation costs depend on the distance between the supplier and the buyer, as well as the chosen Incoterms. Buyers should be aware of potential additional costs related to customs duties and tariffs, particularly when importing from overseas.

-

Margin: Suppliers typically apply a profit margin on top of their costs. Understanding the average margins in the industry can aid buyers in negotiating better prices.

Key Price Influencers

Several factors can affect the pricing of swing check valves beyond the basic cost structure:

-

Volume/MOQ: Purchasing in larger quantities often leads to bulk discounts. Establishing a minimum order quantity (MOQ) can also help in negotiating better prices.

-

Specifications/Customization: Customized valves tailored to specific applications can incur additional costs. Buyers should clarify their requirements upfront to get accurate quotes.

-

Quality and Certifications: Valves that meet stringent industry certifications (e.g., ISO, API) may carry a premium price tag. However, investing in certified products can reduce long-term risks and maintenance costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better warranties and after-sales support, which can be worth the extra cost.

-

Incoterms: The choice of Incoterms (e.g., FOB, CIF) affects the final price by determining who is responsible for shipping costs and risks during transportation.

Buyer Tips for Cost-Efficiency

To maximize value when sourcing swing check valves, international buyers should consider the following strategies:

-

Negotiate Effectively: Establish clear communication with suppliers regarding pricing structures. Don’t hesitate to negotiate based on volume, loyalty, or the potential for long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operation, and potential downtime costs associated with the valves. Selecting higher-quality valves may result in lower TCO.

-

Understand Pricing Nuances: Be aware of regional price variations. For instance, suppliers in Europe may have different pricing structures compared to those in South America or Africa due to local manufacturing costs and market demand.

-

Research Supplier Backgrounds: Investigate suppliers’ histories, customer reviews, and their ability to meet delivery timelines. A reliable supplier can save costs in the long run through timely deliveries and quality assurance.

Disclaimer on Pricing

Prices for swing check valves can vary widely based on the aforementioned factors. It is advisable for buyers to obtain multiple quotes and conduct thorough market research to establish a fair price for their specific needs.

Spotlight on Potential swing check valve Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘swing check valve’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for swing check valve

Critical Technical Properties of Swing Check Valves

When selecting a swing check valve for your industrial applications, understanding the key technical properties is vital. Here are some essential specifications to consider:

-

Material Grade

Swing check valves are typically made from materials such as stainless steel, cast iron, or bronze. The choice of material affects durability, corrosion resistance, and suitability for different fluids. For instance, stainless steel is ideal for corrosive environments, while cast iron is often used in water and sewage applications. Selecting the right material ensures long-term reliability and reduces maintenance costs. -

Pressure Rating

This specification indicates the maximum pressure the valve can withstand while functioning properly, usually expressed in PSI (pounds per square inch). Common ratings include 150, 300, and 600 PSI. Understanding pressure ratings is crucial for ensuring the valve can handle the demands of your system without risk of failure, which can lead to costly downtime and repairs. -

Size and Connection Type

Swing check valves come in various sizes, measured in inches, and can have different connection types such as threaded, flanged, or welded. Choosing the correct size and connection type is essential for compatibility with existing piping systems and ensuring optimal flow rates. -

Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions. This is critical for ensuring proper sealing and preventing leaks. A valve with precise tolerance levels will perform better under varying pressures and temperatures, enhancing operational efficiency and safety. -

Flow Coefficient (Cv)

The flow coefficient measures the valve’s capacity to allow fluid to flow through it. A higher Cv indicates better flow efficiency. Understanding the Cv value is important for calculating the pressure drop across the valve and ensuring that the system maintains adequate flow rates. -

Operating Temperature

This specification indicates the range of temperatures within which the valve can operate effectively. It is crucial for applications involving hot or cold fluids, as exceeding these limits can lead to material degradation or valve failure.

Illustrative Image (Source: Google Search)

Common Trade Terminology in Swing Check Valve Transactions

Navigating the procurement landscape requires familiarity with specific industry terms. Here are some common jargon and their meanings:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are used as components in another company’s product. In the context of swing check valves, knowing whether a supplier is an OEM can ensure that you are getting genuine parts that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for international buyers who may need to meet specific volume requirements. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specified goods or services. It is a standard practice in B2B transactions, allowing buyers to compare pricing, terms, and conditions before making purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, duties, and other logistics. Familiarity with Incoterms can help avoid misunderstandings and disputes during the procurement process. -

Lead Time

Lead time refers to the amount of time from placing an order to the receipt of the goods. This is a critical factor for planning and scheduling in manufacturing and construction projects. Understanding lead times can help buyers manage their supply chains more effectively. -

Certification Standards

These are industry-specific benchmarks that products must meet to ensure quality and safety, such as ISO or API certifications. Knowledge of relevant certifications can provide assurance about the product’s reliability and performance, especially in regulated industries.

By familiarizing yourself with these properties and terms, you can make more informed purchasing decisions, ultimately leading to improved operational efficiency and cost savings in your projects.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the swing check valve Sector

Market Overview & Key Trends

The swing check valve market is witnessing robust growth, driven by several global factors. The increasing demand for efficient fluid control systems across various sectors—including oil and gas, water treatment, and manufacturing—positions swing check valves as critical components. In regions like Africa and South America, infrastructure development and urbanization are accelerating the demand for reliable piping solutions. Additionally, the Middle East’s expanding energy sector is further propelling market dynamics, with countries investing heavily in pipeline systems.

Emerging technologies are reshaping sourcing trends in the swing check valve sector. Digital procurement platforms are becoming essential for international B2B buyers, facilitating real-time market insights and streamlined purchasing processes. Moreover, the integration of IoT in valve systems is enhancing operational efficiency and predictive maintenance capabilities, which are crucial for reducing downtime in industrial applications. Buyers should also be aware of regional compliance requirements, as they can vary significantly, influencing sourcing strategies.

As sustainability becomes a priority for businesses globally, the demand for eco-friendly products is rising. B2B buyers are increasingly sourcing valves made from sustainable materials and those that minimize environmental impact. This trend is particularly pronounced in Europe, where regulations regarding energy efficiency and emissions are stringent. By aligning with suppliers that prioritize sustainability, buyers can not only meet compliance standards but also enhance their corporate social responsibility (CSR) profiles.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a luxury but a necessity in the sourcing of swing check valves. The environmental impact of manufacturing processes, material selection, and end-of-life disposal is under scrutiny. Buyers should consider suppliers who utilize sustainable practices, such as using recycled materials or energy-efficient manufacturing processes. The adoption of materials like stainless steel and other alloys that are durable and recyclable can significantly reduce the ecological footprint of valve production.

Ethical sourcing is equally important. B2B buyers must ensure that their suppliers adhere to fair labor practices and responsible sourcing of raw materials. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Additionally, the trend towards transparency in supply chains is gaining momentum, with buyers increasingly demanding information about the sourcing of materials and the environmental policies of their suppliers. By partnering with ethically responsible manufacturers, buyers can mitigate risks associated with reputational damage and regulatory compliance.

Brief Evolution/History

The swing check valve has evolved significantly since its inception in the 19th century. Initially designed for simple applications, advancements in materials and engineering have led to improved designs that enhance durability and performance. The introduction of new materials, such as high-performance polymers and composites, has expanded the valve’s applicability across various industries, including food processing and pharmaceuticals. Today, swing check valves are recognized for their reliability in preventing backflow, making them essential in modern fluid control systems. This evolution highlights the importance of continuous innovation in meeting the diverse needs of international B2B buyers.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of swing check valve

-

What should I consider when vetting suppliers of swing check valves?

When vetting suppliers, prioritize their industry experience and reputation. Check for certifications relevant to your region (such as ISO, API, or CE) to ensure compliance with quality standards. Request references from previous clients to assess reliability. Evaluate their financial stability and production capacity to meet your demand. Consider their responsiveness and customer service as these factors will influence your purchasing experience. -

Can I customize swing check valves to meet specific requirements?

Yes, many manufacturers offer customization options for swing check valves. This can include size, material, pressure rating, and design features tailored to your application. When requesting customization, provide detailed specifications and application context. Ensure that the supplier has the capability and experience in producing custom solutions to avoid delays and ensure compatibility with your systems. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities for swing check valves can vary significantly by supplier, typically ranging from 50 to several hundred units. Lead times often depend on the complexity of the order and the supplier’s production capacity, generally spanning from 2 to 12 weeks. When negotiating, inquire about bulk order discounts and ensure the lead times align with your project schedules to avoid disruptions. -

What payment terms are common in international B2B transactions?

Common payment terms include letters of credit, wire transfers, and payment upon delivery. Many suppliers require a deposit (often 30% to 50%) upfront, with the balance due upon completion or delivery. It’s crucial to clarify payment terms in advance to avoid misunderstandings. Consider using escrow services for added security in high-value transactions, especially when dealing with new suppliers. -

How can I ensure quality assurance and certifications for swing check valves?

Request documentation of quality assurance processes and certifications from your supplier. This may include test reports, material certificates, and compliance with international standards. Conducting factory audits can also be beneficial, especially for larger orders. Additionally, consider third-party inspection services to verify product quality before shipment, ensuring that the valves meet your specifications and standards. -

What logistics considerations should I keep in mind when importing swing check valves?

Logistics is critical in international trade. Assess the supplier’s shipping capabilities and options for freight forwarding. Understand the customs regulations in your country to avoid delays or penalties. It’s advisable to work with a logistics partner experienced in handling industrial goods to navigate potential challenges. Additionally, clarify the Incoterms (like FOB or CIF) to define responsibilities for shipping costs and risks. -

How should disputes with suppliers be handled?

Disputes can arise from quality issues, delivery delays, or payment disagreements. Establish clear communication channels and documentation practices to address issues promptly. It’s beneficial to have a contract detailing terms and conditions, including a dispute resolution clause. Consider mediation or arbitration as alternative dispute resolution methods to avoid lengthy legal battles, especially when dealing with international suppliers. -

What are the common applications for swing check valves in various industries?

Swing check valves are widely used in water and wastewater treatment, oil and gas, chemical processing, and HVAC systems. They prevent backflow, protecting equipment and maintaining system integrity. Understanding the specific application requirements—such as fluid type, temperature, and pressure—will help you select the right valve. Engage with suppliers who can provide insights into the best practices for your industry to enhance performance and reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for swing check valve

In conclusion, strategic sourcing of swing check valves presents a vital opportunity for international B2B buyers to enhance operational efficiency and ensure reliability in fluid systems. Key takeaways include the importance of selecting durable materials, understanding the operational mechanics of swing check valves, and recognizing their benefits, such as low-pressure drops and backflow prevention.

Buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who offer not only competitive pricing but also robust support and compliance with regional standards. Establishing long-term partnerships with reputable manufacturers can lead to better pricing, improved product quality, and enhanced supply chain resilience.

As we look to the future, the demand for high-quality swing check valves is poised to grow, driven by expanding industries such as energy, water management, and manufacturing. Now is the time to leverage strategic sourcing initiatives that align with your operational goals. Engage with trusted suppliers, stay informed about market trends, and make informed decisions to secure your competitive edge in the evolving global landscape.