Master Sourcing Toroidal Coils: Your Comprehensive Guide

Introduction: Navigating the Global Market for toroidal coil

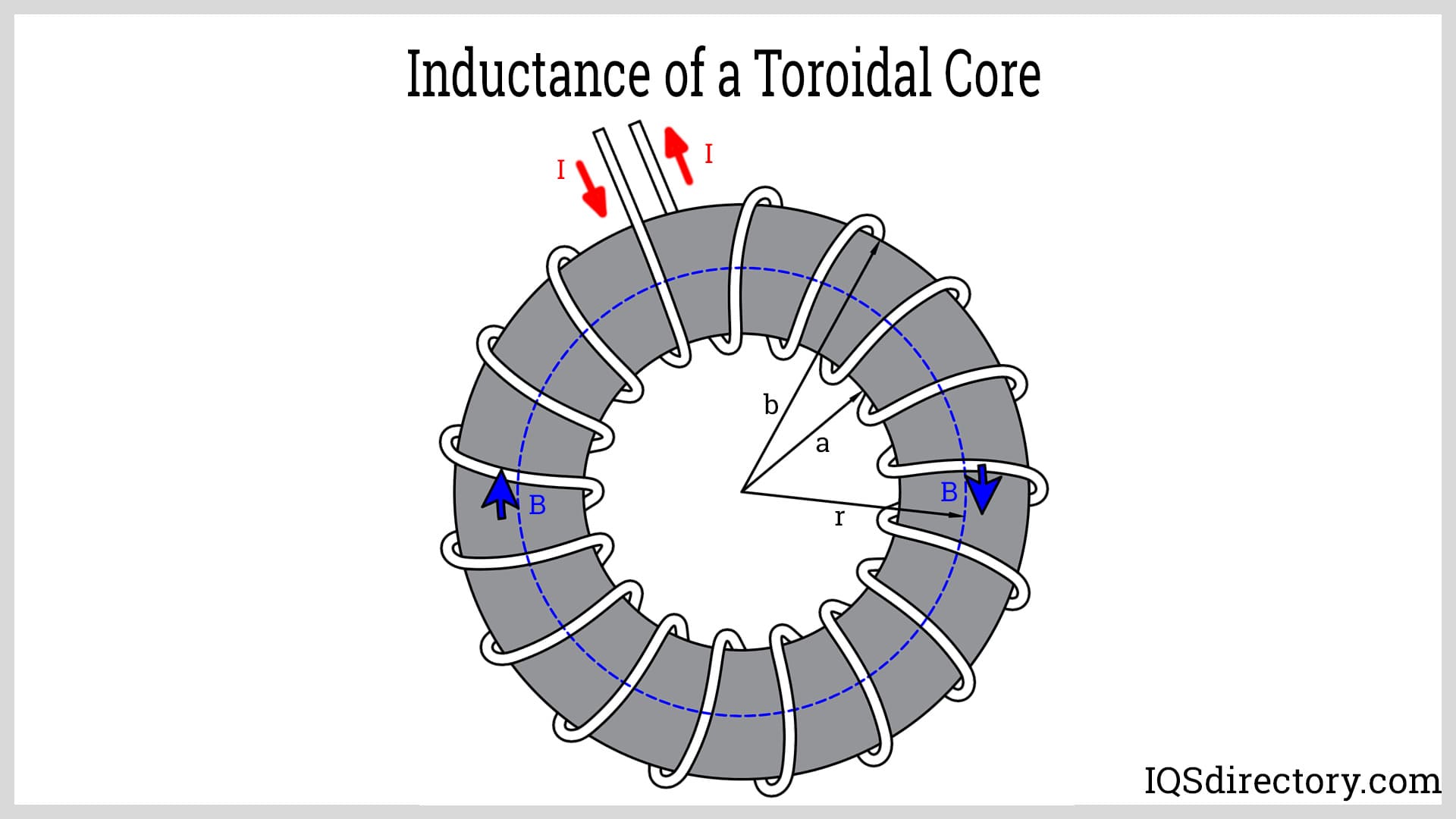

Navigating the global market for toroidal coils is essential for B2B buyers seeking reliable and efficient components for their electronic applications. These doughnut-shaped inductors play a critical role in energy transfer, electromagnetic interference suppression, and overall circuit performance, making them indispensable in industries ranging from telecommunications to medical equipment. As the demand for compact, high-efficiency solutions rises, understanding the intricacies of toroidal coils becomes paramount.

This comprehensive guide delves into various aspects of toroidal coils, including their types—such as ferrite, powdered metal, laminated iron alloy, and tape wound cores—along with the materials used in their construction. We will explore manufacturing processes, quality control measures, and the importance of sourcing from reputable suppliers. Additionally, this guide will offer insights into cost considerations and market trends, equipping buyers with the knowledge to make informed purchasing decisions.

International B2B buyers from Africa, South America, the Middle East, and Europe will find valuable resources in this guide, empowering them to navigate the complexities of sourcing toroidal coils. Whether optimizing for performance, cost, or supplier reliability, the insights provided herein will help streamline procurement strategies and enhance product offerings in a competitive landscape.

Understanding toroidal coil Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ferrite Core Toroids | Made from ceramic materials, low magnetic permeability, cost-effective | Consumer electronics, telecommunications, industrial automation | Pros: High frequency performance, low eddy current losses. Cons: Limited to moderate power applications. |

| Powdered Metal Core Toroids | High saturation flux density, customizable material blends | Switching power supplies, RF circuits, inverters | Pros: Excellent for current spikes, tailored properties. Cons: More expensive than ferrite options. |

| Laminated Iron Alloy Toroids | Constructed from thin sheets to reduce eddy currents | Transformers, audio applications, industrial power conversion | Pros: Efficient at low-to-medium frequencies. Cons: Bulkier than other types, may require more space. |

| Tape Wound Core Toroids | Insulated metallic ribbons, superior magnetic performance at high frequencies | Precision power monitoring, medical instruments | Pros: High stability under load, minimal losses. Cons: More complex manufacturing process, potentially higher cost. |

| Solid Iron Toroids | Made from solid ferromagnetic materials, high inductance | General inductive applications, transformers | Pros: Robust and durable, excellent for low-frequency applications. Cons: Heavier and less efficient at high frequencies. |

Ferrite Core Toroids

Ferrite core toroidal coils are favored in the electronics sector due to their low eddy current losses and cost-effectiveness. They are particularly suitable for applications requiring efficient performance at high frequencies, such as power supplies and EMI filters. When purchasing, consider the specific frequency range and core material, as these can significantly impact performance and suitability for various applications.

Illustrative Image (Source: Google Search)

Powdered Metal Core Toroids

These toroidal coils utilize a blend of metallic powders, offering high saturation flux density ideal for applications that experience current surges. Commonly found in DC-DC converters and RF circuits, they can be customized to meet specific electrical requirements. Buyers should evaluate the material composition and thermal stability, as these factors directly influence performance under varying operational conditions.

Laminated Iron Alloy Toroids

Laminated iron alloy toroids are constructed from thin sheets of iron alloy, which help minimize eddy current losses, making them well-suited for low-to-medium frequency applications like audio transformers and industrial power conversion. When sourcing these coils, it’s essential to assess the core thickness and insulation quality, as these elements affect efficiency and operational reliability.

Tape Wound Core Toroids

Tape wound core toroids are characterized by their construction from insulated metallic ribbons, providing superior magnetic performance at higher frequencies. They are ideal for use in precision instruments and medical applications where stability and low noise are critical. Buyers should consider the manufacturing complexity and associated costs, as these can influence both the lead time and overall investment.

Solid Iron Toroids

Solid iron toroids offer high inductance and durability, making them suitable for general inductive applications, including transformers. While they excel at low frequencies, their weight and bulk can be a disadvantage in compact designs. Buyers should weigh the benefits of robustness against the potential limitations in efficiency at higher frequencies when making purchasing decisions.

Key Industrial Applications of toroidal coil

| Industry/Sector | Specific Application of toroidal coil | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Power Electronics | Switch-mode power supplies (SMPS) | High efficiency and reduced electromagnetic interference | Ensure low core losses, high inductance, and appropriate voltage ratings. |

| Telecommunications | EMI filters and signal transformers | Enhanced signal integrity and noise reduction | Focus on high-frequency performance and material quality. |

| Medical Equipment | MRI machines and diagnostic imaging systems | Precision and reliability in critical applications | Look for components with low noise and excellent EMC properties. |

| Industrial Automation | Inverters and motor drives | Improved energy efficiency and system reliability | Select suppliers with robust testing and quality assurance processes. |

| Consumer Electronics | Audio devices and home appliances | Compact design and high performance | Consider cost-effectiveness and availability of diverse designs. |

In the power electronics sector, toroidal coils are essential components in switch-mode power supplies (SMPS). Their design minimizes electromagnetic interference (EMI) while maximizing efficiency, making them ideal for sensitive electronic devices. For international buyers, particularly from regions like Africa and South America, sourcing requires a focus on low core losses and high inductance to ensure optimal performance under varying voltage conditions.

Within telecommunications, toroidal coils serve critical roles in EMI filters and signal transformers, enhancing signal integrity and reducing noise. These coils are engineered for high-frequency applications, which is vital for maintaining communication quality. Buyers should prioritize sourcing from manufacturers that offer high-quality materials and proven performance in their product lines to meet the stringent requirements of this industry.

In the medical equipment field, toroidal coils are utilized in MRI machines and diagnostic imaging systems. Their ability to provide low noise levels and maintain electromagnetic compatibility (EMC) is crucial for the accurate functioning of these devices. International B2B buyers must ensure that the suppliers they choose can deliver components that meet rigorous medical standards and provide reliable performance under critical conditions.

For industrial automation, toroidal coils are integral to inverters and motor drives, significantly improving energy efficiency and system reliability. The ability to handle current spikes and surges makes these coils indispensable in industrial applications. Buyers should focus on sourcing from reputable manufacturers that can provide robust testing and quality assurance to ensure the longevity and reliability of these components.

In the realm of consumer electronics, toroidal coils are widely used in audio devices and home appliances, where their compact design and high performance are highly valued. These coils not only enhance audio quality but also contribute to the overall efficiency of electronic devices. Buyers should consider cost-effectiveness alongside the availability of diverse designs to meet their specific product requirements, especially in competitive markets in Europe and Australia.

Related Video: How a Toroidal Transformer Works ⚡ What is a Toroidal Transformer

Strategic Material Selection Guide for toroidal coil

When selecting materials for toroidal coils, several factors influence performance, durability, and cost. Understanding the properties of various materials can help international B2B buyers make informed decisions tailored to their specific applications. Below is an analysis of four common materials used in the manufacturing of toroidal coils, focusing on their key properties, advantages, disadvantages, and implications for buyers in diverse regions.

Ferrite Core Materials

Key Properties: Ferrite cores are made from ceramic materials mixed with metal oxides, offering low magnetic permeability and high electrical resistivity. They perform well at high frequencies, making them suitable for applications like power supplies and EMI filters.

Pros & Cons: The primary advantage of ferrite cores is their cost-effectiveness and efficiency in reducing eddy current losses. However, they have a lower saturation flux density, which may limit their use in high-power applications. Additionally, ferrite materials can be brittle, posing risks during manufacturing and handling.

Impact on Application: Ferrite cores are ideal for consumer electronics and telecommunications, where space is limited, and performance is critical. They are compatible with a wide range of media, including air and various insulating materials.

Considerations for Buyers: International buyers should ensure compliance with standards such as ASTM and DIN for ferrite materials. Additionally, sourcing from reputable manufacturers is essential to guarantee product quality, particularly in regions with varying material specifications.

Powdered Metal Core Materials

Key Properties: Powdered metal cores, typically made from iron or permalloy, exhibit high saturation flux density and can be tailored for specific applications through material blending.

Pros & Cons: These cores excel in applications requiring stable inductance and minimal core losses, such as inverters and RF circuits. However, the manufacturing process can be more complex and costly compared to ferrite cores, impacting overall pricing.

Impact on Application: Powdered metal cores are particularly effective in environments with frequent current spikes. Their ability to handle higher power levels makes them suitable for industrial applications, but they may not perform as well in high-frequency scenarios compared to ferrite cores.

Considerations for Buyers: Buyers from Africa and South America should be aware of local suppliers’ capabilities in producing powdered metal cores. Additionally, understanding the specific electrical parameters and temperature stability requirements is crucial for ensuring compatibility with existing systems.

Laminated Iron Alloy Materials

Key Properties: Laminated iron alloy cores are made from thin sheets of iron alloy, which are insulated from each other to reduce eddy current losses. They are particularly effective in low-to-medium frequency applications.

Pros & Cons: The laminated structure enhances efficiency in power transfer, making these cores suitable for transformers. However, they can be heavier and bulkier than other options, which may not be ideal for compact designs.

Impact on Application: Laminated cores are commonly used in audio and distribution transformers, where low losses are essential. Their design allows for better heat dissipation, which is critical in high-load scenarios.

Considerations for Buyers: Buyers in Europe and the Middle East should consider the availability of laminated iron alloys that meet local standards. Understanding the insulation quality and core thickness is vital for ensuring optimal performance in specific applications.

Tape Wound Core Materials

Key Properties: Tape wound cores are created from insulated metallic ribbons, offering superior magnetic performance at higher frequencies.

Pros & Cons: These cores provide excellent efficiency and stability under load, making them ideal for precision applications. However, the manufacturing process can be more labor-intensive and expensive, which may drive up costs.

Impact on Application: Tape wound cores are particularly suited for medical and scientific instrumentation, where precision is paramount. Their design minimizes losses, ensuring reliable operation in sensitive environments.

Considerations for Buyers: International buyers should evaluate manufacturers’ capabilities in producing tape wound cores, particularly in regions where advanced technology is required. Compliance with health and safety standards is also crucial, especially in medical applications.

Summary Table

| Material | Typical Use Case for toroidal coil | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ferrite Core | Power supplies, EMI filters | Cost-effective, efficient | Brittle, lower saturation flux | Low |

| Powdered Metal | Inverters, RF circuits | High saturation flux density | Complex manufacturing process | Medium |

| Laminated Iron Alloy | Audio transformers, distribution | Low eddy current losses | Heavier, bulkier | Medium |

| Tape Wound | Medical instrumentation | Superior magnetic performance | Labor-intensive, higher cost | High |

This strategic material selection guide provides valuable insights for B2B buyers in diverse regions, helping them choose the right toroidal coil materials based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for toroidal coil

The manufacturing processes and quality assurance (QA) for toroidal coils are critical for ensuring the reliability and performance of these essential components in various applications. For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding these processes can facilitate informed sourcing decisions. This section outlines the main stages of manufacturing, key techniques, and international quality standards that govern the production of toroidal coils.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing of toroidal coils involves the selection and preparation of materials. Typically, the core materials include ferrite, powdered iron, or laminated iron alloys, each chosen based on specific application requirements. The conductive wire, commonly made from copper, is also prepared during this stage.

Illustrative Image (Source: Google Search)

Key Techniques:

– Material Sourcing: Ensure that suppliers provide high-quality raw materials compliant with international standards.

– Pre-Processing: Materials may undergo treatments such as annealing to enhance their magnetic properties and reduce impurities, thereby improving overall performance.

2. Forming

In this stage, the raw materials are shaped into the desired form. For ferrite cores, this involves pressing powdered materials into toroidal shapes, while laminated cores are produced by stacking and insulating thin sheets of metal.

Key Techniques:

– Pressing and Molding: Precision presses are used to form cores, ensuring uniformity and adherence to specifications.

– Winding: The copper wire is wound around the core using automated winding machines, which maintain consistent tension and spacing to optimize inductance.

3. Assembly

Once the cores are formed, the assembly process integrates the core with the wound wire. This stage is crucial for ensuring that the magnetic and electrical properties are preserved.

Key Techniques:

– Soldering and Connections: Electrical connections are made with soldering techniques that ensure minimal resistance and maximum conductivity.

– Insulation: Proper insulation materials are applied to prevent short circuits and enhance durability.

4. Finishing

The final stage involves the application of protective coatings and additional treatments to enhance the coil’s durability and performance under operational conditions.

Key Techniques:

– Coating: Coatings such as epoxy or varnish are applied to protect against environmental factors.

– Final Shaping: Any necessary adjustments are made to ensure the coils meet strict dimensional tolerances.

Quality Assurance

Relevant International Standards

Quality assurance in toroidal coil manufacturing is governed by various international standards, which ensure that products meet specific performance criteria. Some of the key standards include:

– ISO 9001: This standard focuses on quality management systems, ensuring that companies maintain consistent quality in their manufacturing processes.

– CE Marking: Required in Europe, this indicates compliance with safety and environmental protection standards.

– API Standards: For applications in the oil and gas industry, adherence to American Petroleum Institute (API) standards may be necessary.

QC Checkpoints

Quality control is implemented at several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Initial inspections of raw materials to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to verify compliance with all specifications.

Common Testing Methods

Testing methods are vital for ensuring that toroidal coils perform as expected. Common methods include:

– Tan-Delta Testing: Measures insulation quality and integrity.

– Impulse Testing: Evaluates the coil’s ability to withstand voltage surges.

– Thermal Imaging: Assesses heat distribution during operation to identify potential failure points.

Verifying Supplier Quality Control

For B2B buyers, particularly those sourcing from international markets, verifying the quality control processes of suppliers is essential. Here are some actionable steps:

-

Conduct Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and QA systems. Look for suppliers with ISO certifications and a proven track record in quality assurance.

-

Request Documentation: Ask for quality assurance reports, certificates of compliance, and testing results. These documents should detail their adherence to international standards and internal QC processes.

-

Utilize Third-Party Inspectors: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s manufacturing and quality control capabilities. This is particularly important when dealing with suppliers from regions with varying compliance standards.

-

Assess QC Nuances: Be aware of specific regional regulations and certifications that might apply to your industry. For instance, products entering the EU must comply with CE marking, while those in the oil sector may require API certification.

Conclusion

Understanding the manufacturing processes and quality assurance practices for toroidal coils is crucial for B2B buyers looking to source these components effectively. By focusing on material preparation, forming, assembly, and finishing stages, along with robust quality control measures, buyers can ensure they select suppliers that deliver high-quality, reliable products. Engaging in thorough audits, requesting detailed documentation, and leveraging third-party inspections can further enhance confidence in supplier capabilities, ultimately leading to successful procurement outcomes.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for toroidal coil Sourcing

In the realm of sourcing toroidal coils, understanding the comprehensive cost structure and pricing landscape is crucial for international B2B buyers. This analysis delves into the key components that influence costs, pricing strategies, and actionable insights tailored for buyers from Africa, South America, the Middle East, and Europe.

Cost Components

-

Materials: The primary cost driver in toroidal coil manufacturing is the raw materials used. Core materials such as ferrite, powdered metal, and laminated iron alloys significantly impact the price. For instance, ferrite cores are generally less expensive compared to powdered metal cores, which may incur higher costs due to their specialized production processes.

-

Labor: Labor costs vary by region and production complexity. Highly skilled labor is often required for precise winding and assembly processes, particularly for custom coils. Countries with lower labor costs may offer a competitive advantage, but this must be balanced against quality considerations.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, equipment maintenance, and general administrative expenses. Suppliers with advanced manufacturing capabilities and automation may pass on savings to buyers, influencing overall pricing.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. Buyers should consider these costs when evaluating suppliers, as they can affect the pricing of lower-volume orders.

-

Quality Control (QC): Ensuring high-quality production involves rigorous testing and inspection processes. Suppliers with established quality assurance protocols may charge a premium, but this investment can lead to long-term savings by reducing failure rates and warranty claims.

-

Logistics: Shipping and handling costs are crucial, especially for international buyers. Factors such as distance, shipping method, and customs duties can add substantial costs. Buyers should assess the total logistics costs when comparing supplier quotes.

-

Margin: Suppliers typically add a margin to cover their costs and ensure profitability. Understanding a supplier’s pricing strategy can provide insight into their cost structure and help in negotiations.

Price Influencers

-

Volume/MOQ: Pricing is often tiered based on order volume. Larger orders may qualify for significant discounts, making it essential for buyers to evaluate their purchasing strategy.

-

Specifications/Customization: Custom-designed coils can lead to increased costs due to specialized materials or manufacturing processes. Buyers should clearly communicate their specifications to avoid unexpected costs.

-

Materials and Quality Certifications: Higher-grade materials or certifications (e.g., ISO, RoHS) can increase costs but also enhance reliability and performance. Buyers should weigh the benefits of quality against potential price increases.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers with a track record of quality and reliability may command higher prices.

-

Incoterms: Understanding the terms of delivery can impact total costs. Different Incoterms (e.g., FOB, CIF) define responsibilities and liabilities that can affect shipping costs and timelines.

Buyer Tips

-

Negotiation: Leverage volume purchasing and long-term contracts to negotiate better pricing. Establishing a relationship with suppliers can also yield favorable terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, maintenance, and potential downtime costs. Opting for higher-quality coils may reduce long-term operational costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and regional economic conditions that can impact pricing. Engage with suppliers who can provide transparent pricing models and support in navigating these complexities.

-

Disclaimer for Indicative Prices: Pricing can vary significantly based on market conditions, material availability, and supplier specifics. Buyers should obtain detailed quotes from multiple suppliers to ensure competitive pricing.

By understanding these components and factors, international B2B buyers can make informed decisions when sourcing toroidal coils, ultimately enhancing their procurement strategy and operational efficiency.

Spotlight on Potential toroidal coil Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘toroidal coil’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for toroidal coil

When sourcing toroidal coils, it is crucial for B2B buyers to understand key technical specifications and industry terminology. This knowledge not only aids in evaluating suppliers but also ensures the selected components meet application requirements efficiently.

Critical Specifications for Toroidal Coils

-

Core Material

– Definition: The material from which the toroidal coil’s core is made (e.g., ferrite, powdered metal, laminated iron).

– Importance: The choice of core material affects the coil’s magnetic properties, efficiency, and suitability for specific applications. For instance, ferrite cores are excellent for high-frequency applications due to their low eddy current losses. -

Inductance

– Definition: The measure of a coil’s ability to store energy in a magnetic field, expressed in henries (H).

– Importance: Inductance values directly impact the performance of electrical circuits. Understanding the inductance required for a specific application helps buyers select the right coil and avoid under or over-specification. -

Saturation Flux Density

– Definition: The maximum magnetic flux density a core can handle before it becomes saturated.

– Importance: This property is critical for applications where current spikes may occur. Choosing a coil with an appropriate saturation flux density ensures reliable operation and prevents component failure under peak loads. -

Tolerance

– Definition: The allowable variation in the coil’s inductance or physical dimensions.

– Importance: Tolerance affects the performance consistency and quality of the coil. Tight tolerances are essential for precision applications, while looser tolerances may be acceptable for less critical uses. -

Temperature Coefficient

– Definition: The rate at which a coil’s inductance changes with temperature, usually expressed in parts per million (ppm) per degree Celsius.

– Importance: Understanding the temperature coefficient is vital for applications subjected to varying environmental conditions. Coils with a low temperature coefficient maintain stable performance, which is crucial in sensitive electronic devices. -

Quality Factor (Q)

– Definition: A measure of the coil’s efficiency, representing the ratio of inductive reactance to resistance at a specific frequency.

– Importance: A higher Q factor indicates lower energy losses and better performance in high-frequency applications. Buyers should prioritize coils with a high Q factor for applications requiring efficiency.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships is crucial for buyers seeking reliable suppliers and ensuring compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers assess inventory needs and negotiate purchasing terms, especially when working with budget constraints or specific project requirements. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting a price quote for specific products or services.

– Relevance: Crafting a clear RFQ can streamline the procurement process and ensure that all suppliers provide comparable offers, enhancing decision-making. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law.

– Relevance: Understanding Incoterms is essential for buyers to clarify shipping responsibilities, risk, and costs involved in international transactions, minimizing disputes. -

Lead Time

– Definition: The amount of time from placing an order to receiving the goods.

– Relevance: Knowledge of lead times is vital for project planning and inventory management, especially in industries with strict timelines. -

EMI (Electromagnetic Interference)

– Definition: Disruption that electromagnetic energy can cause to electronic devices.

– Relevance: Buyers must consider EMI performance when selecting toroidal coils, particularly in sensitive applications like telecommunications and medical devices, where interference can lead to malfunctions.

Understanding these technical properties and trade terms equips international B2B buyers with the insights needed for informed purchasing decisions regarding toroidal coils, ultimately enhancing their operational efficiency and product reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the toroidal coil Sector

Market Overview & Key Trends

The global market for toroidal coils is experiencing significant growth, driven by the increasing demand for efficient energy solutions across various sectors. Key drivers include the rise of renewable energy technologies, the expansion of electric vehicle (EV) infrastructure, and the growing need for compact, lightweight electronic components. In regions like Africa and South America, the push for sustainable energy solutions and local manufacturing is creating new opportunities for B2B buyers to source high-quality toroidal coils from regional suppliers.

Current and emerging B2B sourcing trends indicate a shift towards digital procurement platforms that enhance transparency and efficiency. Many buyers are leveraging these platforms to compare suppliers, assess product quality, and facilitate faster transactions. Additionally, the integration of Industry 4.0 technologies, such as IoT and AI, is revolutionizing manufacturing processes, allowing for more precise production of toroidal coils tailored to specific applications. This technological advancement is particularly relevant for buyers in Europe and the Middle East, where innovation is a priority.

Market dynamics are also influenced by geopolitical factors and trade agreements. Buyers should stay informed about tariffs, import/export regulations, and local market conditions, especially when sourcing from diverse regions. Establishing partnerships with manufacturers who prioritize quality assurance and rapid delivery can provide a competitive edge. As the demand for toroidal coils continues to rise, B2B buyers must strategically navigate these dynamics to secure reliable, high-performance components for their applications.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a crucial consideration in the sourcing of toroidal coils. The environmental impact of manufacturing processes, particularly regarding energy consumption and waste management, is under scrutiny. B2B buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon emissions and minimizing material waste.

Ethical supply chains are essential for fostering trust and accountability. Buyers should prioritize partnerships with manufacturers who adhere to internationally recognized standards for labor practices and environmental stewardship. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) can serve as indicators of a supplier’s commitment to sustainability.

In terms of materials, the use of ‘green’ certifications is gaining traction. Sourcing toroidal coils made from recycled or sustainably sourced materials not only minimizes environmental impact but also aligns with corporate social responsibility goals. Moreover, engaging with suppliers who implement life cycle assessments can provide insights into the environmental footprint of their products, allowing buyers to make informed decisions that support sustainability initiatives.

Brief Evolution/History

The development of toroidal coils can be traced back to the early 20th century, when engineers sought to improve the efficiency of electromagnetic devices. The toroidal design, characterized by its doughnut shape, was revolutionary as it allowed for more efficient magnetic field containment and reduced electromagnetic interference. Over the decades, advancements in materials science and manufacturing techniques have led to the production of various types of toroidal coils, including ferrite, powdered metal, and laminated designs.

As the demand for compact, high-performance electronic components has surged, the toroidal coil sector has evolved to meet the needs of modern applications. Today, these components are integral in power supplies, telecommunications, and medical equipment, showcasing their versatility and essential role in contemporary technology. For B2B buyers, understanding this evolution is vital for making informed purchasing decisions that align with current market demands.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of toroidal coil

-

What criteria should I use to vet toroidal coil suppliers?

When vetting toroidal coil suppliers, consider their industry experience, production capabilities, and certifications such as ISO 9001. Look for suppliers with a proven track record of reliability and quality assurance. Request references from past clients and review their product quality through samples. Additionally, assess their ability to meet your specific requirements regarding lead times, customization options, and after-sales support. Conducting site visits or audits can also provide insight into their manufacturing processes and quality control measures. -

Can I customize toroidal coils to meet specific requirements?

Yes, many manufacturers offer customization options for toroidal coils, including variations in core materials, wire gauge, and winding configurations. When discussing customization, clearly outline your technical specifications, such as inductance values, dimensions, and operating frequencies. Be prepared to collaborate with the supplier’s engineering team to optimize the design for your application. Additionally, inquire about the supplier’s prototyping capabilities to evaluate the custom coils before full-scale production. -

What are the typical minimum order quantities (MOQs) and lead times for toroidal coils?

Minimum order quantities for toroidal coils can vary significantly between suppliers and are often influenced by the complexity of the design and materials used. Typically, MOQs can range from a few dozen to several hundred units. Lead times may also differ based on the supplier’s production capacity, with standard lead times often between 4 to 12 weeks. Always confirm these details upfront and consider negotiating terms that align with your project timelines and budget constraints. -

What quality assurance practices should I expect from toroidal coil suppliers?

Reputable toroidal coil suppliers should adhere to strict quality assurance practices, including routine testing and inspections throughout the manufacturing process. Look for suppliers that perform electrical testing, such as tan-delta and impulse tests, to ensure compliance with relevant specifications. Request documentation of their quality control processes, and certifications, and consider suppliers who are ISO-certified as they typically maintain higher standards. Transparency in quality assurance practices is crucial for building trust and ensuring product reliability. -

What payment terms are commonly offered for international orders?

Payment terms can vary widely among suppliers, but common practices include options like advance payment, net 30 or net 60 days, and letter of credit arrangements for larger orders. It’s essential to discuss payment methods that align with your company’s financial policies and risk tolerance. Consider using escrow services for significant transactions to ensure that funds are released only upon satisfactory receipt of goods. Always clarify any additional fees, such as currency conversion or transaction fees, upfront to avoid surprises. -

How do logistics and shipping work for international toroidal coil orders?

Logistics for international orders typically involve coordination between the supplier and freight forwarders to manage shipping. Discuss your preferred shipping method, whether air or sea, as it will impact delivery times and costs. Ensure that the supplier provides proper packaging to protect the coils during transit. Additionally, confirm that they can handle customs documentation and duties. It’s advisable to work with suppliers who have experience in international trade to streamline the logistics process and mitigate potential delays. -

What should I do if I encounter a dispute with a toroidal coil supplier?

In the event of a dispute, first, attempt to resolve the issue directly with the supplier through clear communication. Document all correspondences and agreements to provide a record of your interactions. If the issue remains unresolved, review the contract for any dispute resolution clauses, such as mediation or arbitration. Engaging a legal professional with experience in international trade can also provide guidance. Maintaining a professional demeanor throughout the process can often lead to a more amicable resolution. -

Are there specific certifications or standards I should look for in toroidal coils?

Yes, look for suppliers whose toroidal coils comply with international standards relevant to your industry, such as IEC, UL, or RoHS certifications. These certifications indicate adherence to safety, environmental, and quality standards, which can be crucial for applications in sectors like telecommunications, automotive, or medical devices. Request certification documentation to verify compliance and ensure that the coils meet the necessary performance criteria for your specific applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for toroidal coil

In conclusion, strategic sourcing of toroidal coils is essential for international B2B buyers looking to enhance efficiency and performance in their electrical applications. Understanding the diverse types of toroidal coils—such as ferrite, powdered metal, laminated iron alloy, and tape wound—allows procurement professionals to select components that align with specific operational needs.

Key takeaways include:

- Quality Assurance: Partner with manufacturers who adhere to rigorous quality standards to ensure reliability and performance.

- Customization: Engage suppliers that offer tailored solutions to meet unique project specifications, particularly in industries like telecommunications and medical equipment.

- Supply Chain Efficiency: Leverage suppliers with robust logistics capabilities to minimize lead times and ensure timely delivery.

As the demand for innovative electrical solutions grows across Africa, South America, the Middle East, and Europe, embracing a strategic sourcing approach will position buyers to capitalize on emerging opportunities. Now is the time to assess your sourcing strategies and build strong partnerships with reputable toroidal coil manufacturers to drive future success. Your commitment to quality sourcing will not only enhance operational efficiency but also contribute to sustainable growth in a competitive marketplace.