Master the Art of Selecting the Right Heating Element Type

Introduction: Navigating the Global Market for heating element type

In today’s dynamic global market, understanding the intricacies of heating element types is paramount for international B2B buyers, especially those from Africa, South America, the Middle East, and Europe. Heating elements are essential components in numerous industries, from manufacturing to food processing, influencing operational efficiency, safety, and product quality. The right choice can enhance energy efficiency, reduce operational costs, and extend equipment lifespan, making it a critical area for informed sourcing.

This comprehensive guide delves into the various heating element types, including resistive wire, ceramic, and specialized industrial applications. It examines key materials, manufacturing processes, and quality control measures that impact performance and durability. Additionally, the guide provides insights into supplier selection, cost considerations, and market trends, equipping buyers with the knowledge needed to navigate this complex landscape.

To further empower decision-making, we address frequently asked questions that cover common challenges faced by buyers in different regions. By leveraging this information, you can confidently choose heating elements that align with your operational requirements and environmental conditions, ensuring both reliability and efficiency in your applications. This guide is designed to support your strategic sourcing decisions, helping you stay competitive in an increasingly interconnected marketplace.

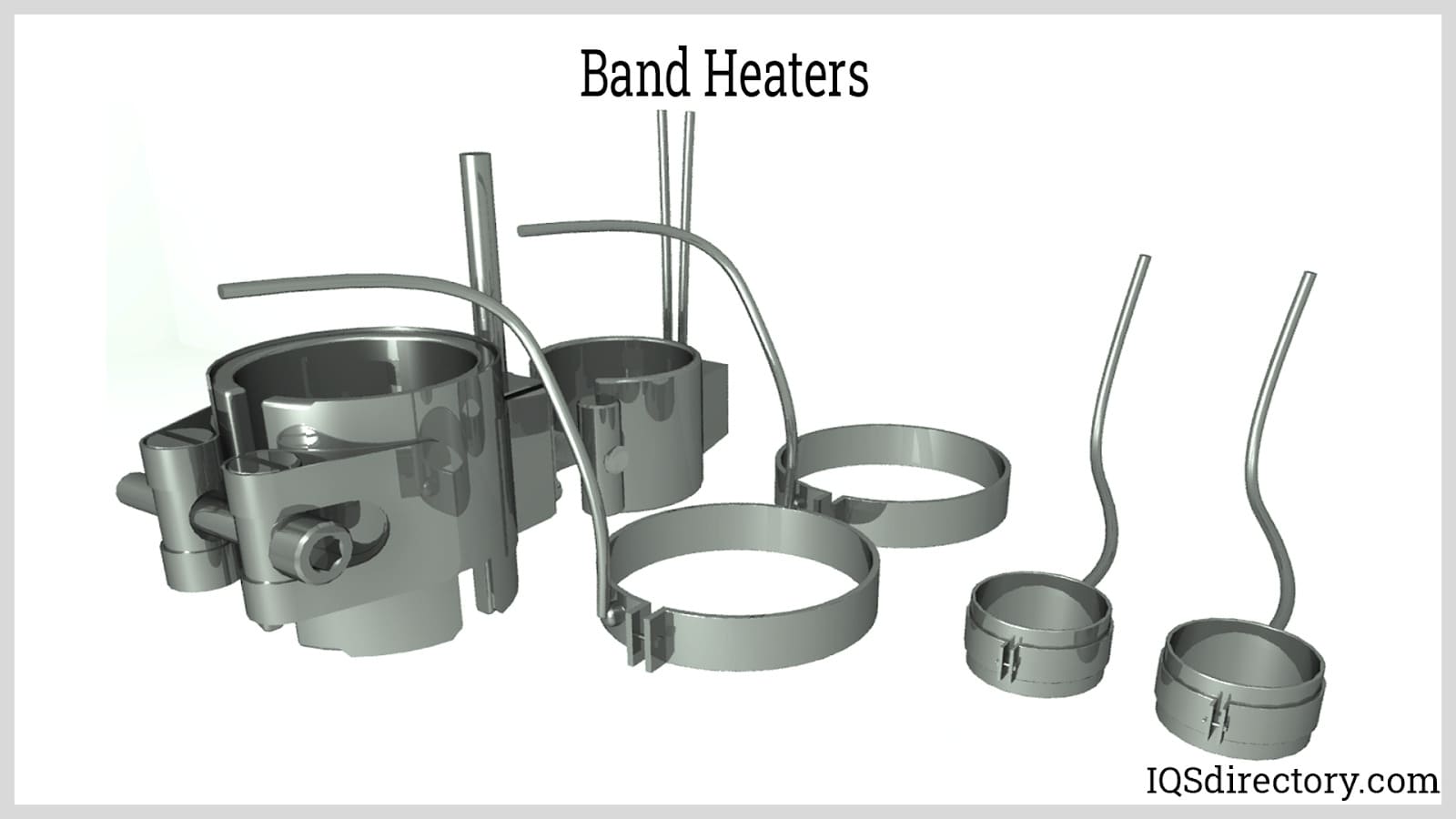

Understanding heating element type Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resistance Wire Elements | Made from alloys like nichrome; efficient heat generation | Industrial furnaces, laboratory equipment | Pros: High efficiency, good longevity; Cons: Limited to specific temperature ranges (up to 1,200°C) |

| Ceramic Heating Elements | Composed of materials like molybdenum disilicide; withstands high temperatures | Glass manufacturing, high-temperature kilns | Pros: Excellent thermal shock resistance; Cons: Generally more expensive and fragile |

| Tubular Heating Elements | Encased in metal sheaths; versatile design | Heating liquids, air, and industrial ovens | Pros: Customizable; Cons: Installation can be complex |

| Infrared Heating Elements | Emit infrared radiation; instant heat generation | Food processing, drying applications | Pros: Fast heating, energy-efficient; Cons: Limited penetration depth |

| Flexible Heating Elements | Thin, adaptable designs; often silicone-based | Medical devices, automotive applications | Pros: Lightweight, easy to install; Cons: Limited heat capacity |

Resistance Wire Elements

Resistance wire elements utilize high-resistivity alloys such as nichrome and Kanthal to generate heat through electrical resistance. These elements are ideal for industrial furnaces and laboratory equipment that operate at moderate temperatures (up to 1,200°C). Buyers should consider the specific operational temperature and the element’s longevity, as these factors can directly impact energy efficiency and maintenance costs.

Ceramic Heating Elements

Ceramic heating elements are designed for high-temperature applications, often using materials like molybdenum disilicide or silicon carbide. They excel in environments that exceed 1,800°C, making them suitable for glass manufacturing and high-temperature kilns. While they provide excellent thermal shock resistance, buyers should weigh their higher cost and potential fragility against the benefits of durability and efficiency.

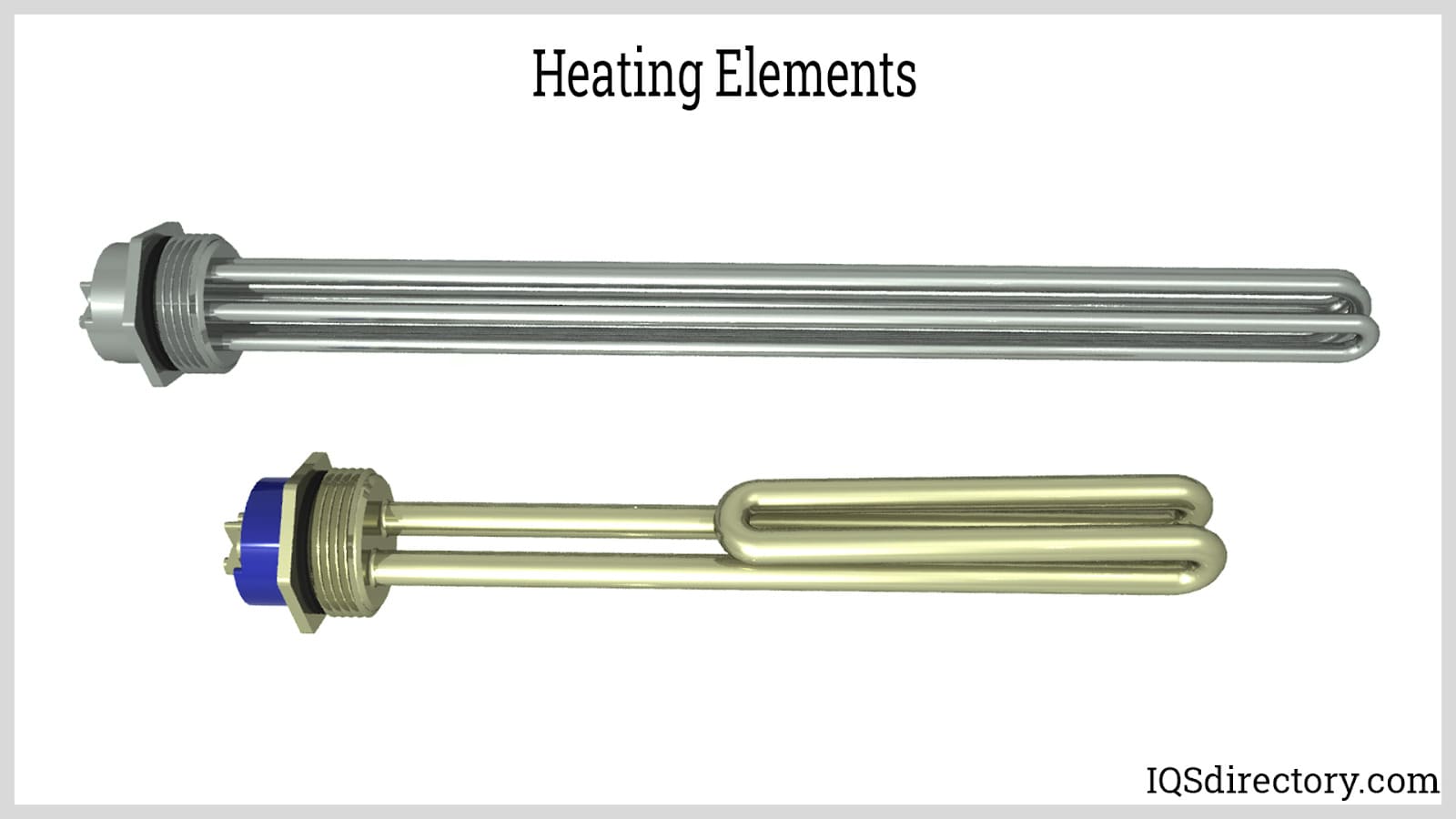

Tubular Heating Elements

Tubular heating elements are versatile and can be customized to fit various applications, including heating liquids and air in industrial ovens. Encased in metal sheaths, they offer good thermal conduction and can be designed for specific heating requirements. Buyers must consider installation complexities and the potential need for custom configurations, which may increase initial costs.

Infrared Heating Elements

Infrared heating elements are designed to emit infrared radiation, providing instant heat for applications such as food processing and drying. They are known for their energy efficiency and rapid heating capabilities. However, buyers should note that while they are efficient for surface heating, their limited penetration depth may not be suitable for all applications.

Flexible Heating Elements

Flexible heating elements are lightweight and adaptable, often made from silicone materials. They are particularly useful in medical devices and automotive applications where space is limited. Their ease of installation is a significant advantage, but buyers should be aware of their limited heat capacity compared to more robust heating options.

Key Industrial Applications of heating element type

| Industry/Sector | Specific Application of heating element type | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Furnaces | Enhanced thermal efficiency and consistent temperature control | Material compatibility, operating temperature range, energy efficiency |

| Food Processing | Ovens and Heat Exchangers | Improved cooking consistency and energy savings | Safety standards, ease of cleaning, and durability |

| Chemical Industry | Process Heating in Reactors | Precise temperature management for chemical reactions | Resistance to corrosive substances, thermal stability, and reliability |

| Textiles | Drying and Curing Equipment | Faster production cycles and reduced energy consumption | Heat distribution uniformity, material compatibility, and safety certifications |

| Laboratories | Heating Elements for Analytical Equipment | Accurate and reliable temperature control for experiments | Calibration standards, energy efficiency, and compatibility with laboratory settings |

Manufacturing: Industrial Furnaces

In the manufacturing sector, heating elements are crucial for industrial furnaces where they ensure high-temperature operations are maintained efficiently. These elements, often made from materials like nichrome or silicon carbide, provide consistent heat distribution, essential for processes such as metal treatment or glass production. Buyers must consider the operating temperature range and material compatibility to prevent premature failure and maintain production efficiency. Energy efficiency is also a priority, as it directly impacts operational costs.

Food Processing: Ovens and Heat Exchangers

Heating elements are extensively used in ovens and heat exchangers within the food processing industry, where they facilitate baking, roasting, and cooking processes. The right heating element ensures uniform cooking, which enhances product quality while reducing energy consumption. Buyers should focus on safety standards to prevent food contamination and consider the ease of cleaning to comply with health regulations. Durability is also essential, as heating elements must withstand frequent use and high temperatures.

Chemical Industry: Process Heating in Reactors

In the chemical industry, heating elements are integral to process heating in reactors, where precise temperature management is critical for successful chemical reactions. Elements made from materials resistant to corrosive substances, such as molybdenum disilicide, are often employed. Buyers need to assess thermal stability and reliability to ensure optimal performance and safety in reactive environments. Additionally, understanding the specific requirements of the chemicals involved can aid in selecting the most suitable heating element.

Textiles: Drying and Curing Equipment

Heating elements are vital in drying and curing equipment used in the textile industry, where they significantly speed up production cycles. By providing consistent and controlled heat, these elements help achieve desired moisture levels and improve fabric quality. Buyers must prioritize heat distribution uniformity and material compatibility to ensure effective operation. Furthermore, safety certifications are crucial, as the equipment often operates in high-temperature environments.

Laboratories: Heating Elements for Analytical Equipment

In laboratories, heating elements are essential for maintaining accurate temperatures in analytical equipment. Whether for experiments or sample preparation, the reliability of these elements directly influences experimental outcomes. Buyers should focus on calibration standards and energy efficiency to ensure consistent performance. Compatibility with various laboratory settings is also important, as different experiments may require specific heating capabilities and safety features.

Related Video: How PTC Heating Element Technology Works

Strategic Material Selection Guide for heating element type

When selecting heating element materials, international B2B buyers must consider various factors to ensure optimal performance and compliance with industry standards. Below, we analyze four common materials used in heating elements, detailing their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Nickel-Chromium Alloys (NiCr)

Key Properties:

Nickel-chromium alloys exhibit high heat resistance and excellent corrosion resistance, making them suitable for high-temperature applications. They can operate effectively at temperatures up to 1,200°C (2,192°F).

Pros & Cons:

The durability of NiCr alloys is a significant advantage, as they can withstand prolonged exposure to high temperatures without degrading. However, they can be more expensive than other materials, which may impact budget considerations. Manufacturing complexities may also arise due to the specific processing techniques required for these alloys.

Impact on Application:

NiCr alloys are ideal for electric heating elements used in industrial furnaces and heat treatment processes. They are compatible with various media, including air and inert gases, but may not perform well in highly reactive environments.

Considerations for Buyers:

Buyers should ensure compliance with relevant standards such as ASTM and DIN when sourcing NiCr heating elements. Understanding local regulations regarding material safety and environmental impact is crucial for buyers in regions like South Africa and Brazil.

Silicon Carbide (SiC)

Key Properties:

Silicon carbide is known for its exceptional high-temperature resistance, capable of withstanding temperatures up to 2,700°C (4,892°F). It also offers excellent thermal shock resistance and oxidation resistance.

Pros & Cons:

The primary advantage of SiC is its ability to function in extreme conditions, making it suitable for demanding applications like kilns and industrial furnaces. However, the high cost of SiC can be a limiting factor for some buyers, and its brittle nature may pose challenges during handling and installation.

Impact on Application:

SiC is particularly effective in oxidizing atmospheres, ensuring longevity and reliability in operations that involve high thermal stress. Buyers must consider the specific operational environment to maximize the benefits of SiC heating elements.

Considerations for Buyers:

International buyers should be aware of the availability of SiC in their regions and the associated import regulations. Compliance with international standards is essential, especially in Europe, where stringent regulations govern material use.

Molybdenum Disilicide (MoSi₂)

Key Properties:

Molybdenum disilicide can withstand temperatures up to 1,700°C (3,092°F) and forms a protective oxide layer that enhances its durability in high-temperature applications.

Pros & Cons:

MoSi₂ elements are highly durable and resistant to oxidation, making them suitable for prolonged use in harsh environments. However, they can be relatively costly and may require specialized manufacturing techniques, which could complicate sourcing.

Impact on Application:

These heating elements are commonly used in glass manufacturing and ceramic kilns, where high temperatures and oxidation resistance are critical. Compatibility with specific media is essential, as MoSi₂ performs best in controlled atmospheres.

Considerations for Buyers:

Buyers should evaluate the total cost of ownership, including installation and maintenance, when considering MoSi₂ heating elements. Understanding the supply chain and sourcing options in regions like the Middle East can help mitigate costs.

Kanthal (FeCrAl Alloys)

Key Properties:

Kanthal alloys, primarily composed of iron, chromium, and aluminum, can operate effectively at temperatures up to 1,300°C (2,372°F) and offer excellent oxidation resistance.

Pros & Cons:

The key advantage of Kanthal is its balance of performance and cost, making it a popular choice for many applications. However, it may not perform as well as NiCr in extremely high-temperature environments, which could limit its use in specialized applications.

Impact on Application:

Kanthal is widely used in heating elements for industrial furnaces and heat treatment processes, providing reliable performance in various media, including air and inert gases.

Considerations for Buyers:

Buyers should ensure that Kanthal products meet local and international standards, particularly in Europe, where compliance is strictly enforced. Understanding the specific requirements of their applications will help buyers make informed decisions.

Summary Table

| Material | Typical Use Case for heating element type | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nickel-Chromium Alloys (NiCr) | Industrial furnaces, heat treatment processes | High heat and corrosion resistance | Higher cost, manufacturing complexity | High |

| Silicon Carbide (SiC) | Kilns, industrial furnaces | Exceptional high-temperature resistance | Brittle nature, high cost | High |

| Molybdenum Disilicide (MoSi₂) | Glass manufacturing, ceramic kilns | Durable, oxidation resistant | Costly, specialized manufacturing | High |

| Kanthal (FeCrAl Alloys) | Industrial furnaces, heat treatment processes | Good balance of performance and cost | Limited high-temperature performance | Medium |

This guide provides a strategic overview for B2B buyers to make informed decisions regarding the selection of heating element materials, considering both performance and compliance factors relevant to their specific regions.

In-depth Look: Manufacturing Processes and Quality Assurance for heating element type

The manufacturing processes and quality assurance protocols for heating elements are critical for ensuring reliability and efficiency in various industrial applications. B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be well-versed in these processes to make informed procurement decisions. This section explores the typical stages of manufacturing heating elements, relevant quality control measures, and how buyers can verify supplier compliance with international standards.

Manufacturing Processes

The manufacturing of heating elements generally involves several key stages: material preparation, forming, assembly, and finishing. Each stage is vital in ensuring that the final product meets the desired specifications and quality standards.

Material Preparation

- Selection of Materials: The initial step involves selecting appropriate resistive and insulating materials based on the intended application. Common materials include nickel-chromium alloys for high temperatures and magnesium oxide for insulation.

- Material Treatment: The raw materials undergo treatments such as annealing or surface cleaning to enhance their properties, ensuring they are free from contaminants that could affect performance.

Forming

- Wire Drawing: For resistance wire elements, the metallic alloy is drawn into thin wires. This process requires precision to maintain consistent diameter and resistivity.

- Molding: For ceramic or composite heating elements, the materials are shaped using molding techniques, which may involve pressing or extrusion methods to achieve the desired form.

Assembly

- Winding and Coiling: In some heating elements, the resistive wire is wound or coiled around a core or inside a sheath to optimize heat distribution.

- Encapsulation: The assembly process may also include encapsulating the heating elements in protective materials to enhance durability and safety.

Finishing

- Insulation Application: Insulation materials are applied to prevent heat loss and ensure safety. This step is critical in high-temperature applications where thermal efficiency is paramount.

- Surface Treatment: Final surface treatments, such as coating or polishing, are applied to improve corrosion resistance and enhance the overall aesthetic of the heating element.

Quality Assurance

Quality assurance is essential in the manufacturing of heating elements to ensure they meet international standards and customer specifications. The following measures are typically employed:

International Standards

- ISO 9001 Certification: This standard outlines a framework for a quality management system, ensuring consistent quality in manufacturing processes. Buyers should prioritize suppliers with this certification as it indicates a commitment to quality.

- CE Marking: For products sold in Europe, CE marking demonstrates compliance with health, safety, and environmental protection standards. This is particularly important for buyers in European markets.

Industry-Specific Standards

- API Standards: In industries such as oil and gas, compliance with API standards ensures that heating elements are suitable for high-stress environments.

- UL and CSA Standards: For electrical heating elements, compliance with Underwriters Laboratories (UL) and Canadian Standards Association (CSA) standards ensures safety and reliability.

Quality Control Checkpoints

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of incoming raw materials. Suppliers should conduct thorough inspections to ensure materials meet specified criteria before production begins.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is crucial. Techniques such as statistical process control (SPC) can be used to track performance and identify any deviations from standards.

- Final Quality Control (FQC): Before shipment, a final inspection ensures that the finished heating elements meet all specifications. This may include dimensional checks, visual inspections, and functional tests.

Common Testing Methods

To ensure the quality and performance of heating elements, several testing methods are employed:

- Electrical Resistance Testing: This test measures the resistivity of the heating element to ensure it meets specified electrical characteristics.

- Thermal Performance Testing: Heating elements are subjected to operational conditions to evaluate their thermal efficiency and heat distribution capabilities.

- Durability Testing: Elements are tested under extreme conditions to assess their longevity and performance under stress, simulating real-world applications.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify the quality control processes of potential suppliers:

- Audits: Conducting on-site audits of suppliers can provide insight into their manufacturing processes and quality assurance protocols. Buyers should look for evidence of adherence to international standards and best practices.

- Quality Assurance Reports: Requesting detailed QA reports can help buyers understand the supplier’s quality control measures, including testing results and inspection frequencies.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s compliance with industry standards and quality benchmarks.

Illustrative Image (Source: Google Search)

Quality Control Nuances for International Buyers

When sourcing heating elements internationally, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances:

- Regulatory Differences: Different regions may have varying regulatory requirements. Understanding local standards and certifications is crucial to ensuring compliance and product acceptance.

- Cultural and Logistical Considerations: Buyers should consider cultural differences in business practices and communication. Additionally, logistical challenges, such as shipping and customs clearance, can affect supply chain reliability.

- Supplier Reliability: Building long-term relationships with trusted suppliers can mitigate risks associated with quality and delivery. Buyers should seek out suppliers with a proven track record in their respective markets.

In conclusion, understanding the manufacturing processes and quality assurance measures for heating elements is essential for B2B buyers. By prioritizing suppliers who adhere to international standards and demonstrating robust quality control practices, buyers can ensure that they procure reliable and efficient heating solutions for their industrial applications.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for heating element type Sourcing

The cost structure and pricing for sourcing heating elements are multifaceted, involving various components that impact the final price. Understanding these components and the factors influencing pricing is critical for international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe.

Cost Components

- Materials: The choice of materials significantly affects the cost of heating elements. High-quality resistive materials like nickel-chromium alloys or silicon carbide generally come at a premium. Conversely, more economical options, such as iron or copper, may be suitable for less demanding applications.

- Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer more competitive pricing but may also impact quality. It’s essential to evaluate the balance between cost and craftsmanship.

- Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Manufacturers with efficient processes can often offer better pricing due to lower overhead.

- Tooling: The initial investment in tooling and molds can be substantial, especially for custom heating elements. This cost is often amortized over the production run, impacting unit pricing based on order volume.

- Quality Control (QC): Rigorous QC processes ensure product reliability and compliance with industry standards. However, enhanced QC measures can increase costs. Buyers should assess whether the added expense correlates with their quality requirements.

- Logistics: Transportation and logistics costs are crucial, especially for international shipping. Factors such as distance, shipping mode, and customs duties can significantly influence the overall cost.

- Margin: Suppliers will include their profit margin in the pricing structure. This margin can vary based on supplier reputation, market demand, and competition.

Price Influencers

Several factors can influence the pricing of heating elements, including:

- Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating MOQs that align with their needs to optimize pricing.

- Specifications/Customization: Custom heating elements tailored to specific applications typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

- Materials: The choice of material not only affects the base price but also the operational longevity and efficiency of the heating elements. High-performance materials may justify their cost through lower total ownership expenses.

- Quality/Certifications: Products that meet international standards or possess specific certifications may come at a premium. However, the assurance of quality can mitigate risks associated with failures and downtime.

- Supplier Factors: The supplier’s reputation, reliability, and location can impact pricing. Established suppliers might charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

- Incoterms: Understanding shipping terms and responsibilities can affect overall costs. Buyers should clarify who bears the risk and costs associated with shipping, customs clearance, and insurance.

Buyer Tips

- Negotiation: Engage suppliers in discussions about pricing, particularly for larger orders. Leverage your position as a buyer to negotiate better terms, especially regarding volume discounts.

- Cost Efficiency: Focus on the Total Cost of Ownership (TCO), which includes initial costs, operational costs, and maintenance expenses. This perspective can lead to better long-term investment decisions.

- Pricing Nuances for International Buyers: Be aware of currency fluctuations and international trade tariffs that can impact prices. Ensure to factor in these variables when budgeting for purchases.

Disclaimer

Prices for heating elements can vary significantly based on the aforementioned factors. It is advisable to request detailed quotations from multiple suppliers to gain a clearer understanding of the pricing landscape in your specific market context.

Spotlight on Potential heating element type Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘heating element type’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for heating element type

In the competitive landscape of international B2B transactions, particularly in industries reliant on heating elements, understanding essential technical properties and industry terminology is crucial for making informed purchasing decisions. Here are key specifications and terminology to consider when sourcing heating elements.

Critical Technical Properties

- Material Grade

– The material grade indicates the quality and performance characteristics of the heating element. Common grades include nickel-chromium alloys for high-temperature applications and silicon carbide for extreme conditions. Understanding the material grade helps buyers ensure compatibility with their operational environments, reducing risks of premature failure. - Tolerance

– Tolerance refers to the allowable deviation from specified dimensions or performance metrics. In heating elements, this could affect resistance values and thermal output. A tight tolerance ensures consistent performance and reliability, which is essential for maintaining product quality in manufacturing processes. - Operating Temperature Range

– Each heating element is designed to operate within specific temperature limits. Knowing the operating temperature range is vital for selecting a suitable element to prevent overheating or underperformance. Exceeding these limits can lead to equipment failure and increased operational costs. - Power Rating

– The power rating, measured in watts, indicates the amount of energy the heating element consumes and its efficiency. This specification is crucial for calculating energy costs and ensuring that the element meets the thermal demands of the application. Buyers should evaluate their energy requirements to optimize operational efficiency. - Insulation Type

– The type of insulation used in a heating element affects its thermal efficiency and safety. Common insulation materials include magnesium oxide and various ceramics. Selecting the appropriate insulation type helps minimize heat loss and ensures safe operation, particularly in high-temperature environments. - Lifespan

– Lifespan is a key performance indicator for heating elements, influenced by materials, operating conditions, and maintenance practices. A longer lifespan translates to reduced replacement costs and downtime, making it a critical consideration for B2B buyers focused on efficiency and cost-effectiveness.

Common Trade Terms

- OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is essential for buyers seeking components that will fit seamlessly into existing systems. - MOQ (Minimum Order Quantity)

– MOQ denotes the minimum number of units a supplier requires for an order. Recognizing MOQ helps buyers assess their purchasing strategy and negotiate better terms, especially in international trade where shipping costs can be significant. - RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting a quote for specific products or services. It is an essential step in the procurement process, enabling buyers to compare prices and terms from different suppliers efficiently. - Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps in understanding shipping, insurance, and delivery responsibilities. - Lead Time

– Lead time is the period between placing an order and receiving the product. Knowing the lead time is crucial for planning and inventory management, especially in industries where timely delivery is critical to operational success. - Certification Standards

– Certification standards, such as ISO or CE, indicate compliance with specific safety and quality regulations. Buyers should verify these certifications to ensure the heating elements meet the necessary industry standards, which can affect marketability and regulatory compliance.

Understanding these technical properties and trade terminology will empower international B2B buyers to make informed decisions, optimize procurement processes, and ensure the successful integration of heating elements into their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the heating element type Sector

Market Overview & Key Trends

The heating element sector is currently experiencing significant transformations driven by technological advancements and shifting market demands. One of the key global drivers is the increasing focus on energy efficiency and sustainability, prompting buyers to seek high-performance heating solutions that minimize energy consumption. This is particularly relevant for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where energy costs are a major concern.

Emerging trends include the rise of smart heating elements that integrate IoT technology, enabling remote monitoring and control. This trend is particularly appealing to industries such as manufacturing and food processing, where precision heating can lead to substantial cost savings and improved product quality. Additionally, the demand for customized heating solutions is growing, as businesses look to optimize processes across various applications, from industrial ovens to laboratory equipment.

In terms of market dynamics, buyers should be aware of regional variations in supply chains and sourcing practices. For instance, manufacturers in Europe may prioritize high-quality, locally-sourced materials due to stringent regulatory standards, while buyers in Africa or South America might focus on cost-effectiveness and availability. Understanding these nuances can aid international buyers in making informed purchasing decisions that align with their operational needs and budget constraints.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of sourcing in the heating element industry. The environmental impact of production processes and the lifecycle of heating elements are under increasing scrutiny. International buyers must consider the carbon footprint associated with the materials used, as well as the energy consumption during operation.

Ethical sourcing is critical, particularly in light of the increasing demand for transparency in supply chains. Buyers should seek suppliers who demonstrate commitment to sustainable practices, such as using recyclable materials or adhering to ‘green’ certifications. Materials like silicon carbide and molybdenum disilicide are gaining popularity due to their durability and resistance to high temperatures, thus reducing the need for frequent replacements and minimizing waste.

Moreover, certifications such as ISO 14001 for environmental management and compliance with RoHS (Restriction of Hazardous Substances) regulations can serve as indicators of a supplier’s commitment to sustainability. By prioritizing ethical sourcing and sustainability, B2B buyers not only meet regulatory requirements but also enhance their brand reputation and appeal to environmentally-conscious consumers.

Brief Evolution/History

The evolution of heating elements dates back to the late 19th century, with the introduction of resistive wire elements made from materials like nickel-chromium alloys. Over the decades, advancements in material science have led to the development of more efficient and durable heating elements, such as ceramic and Silicon carbide components, designed for high-temperature applications.

This historical progression reflects a broader trend towards specialization and customization in the heating element market. As industries have advanced, the need for tailored heating solutions has become more pronounced, driving innovation and expanding the range of materials and technologies available to B2B buyers today. Understanding this evolution can help buyers appreciate the diverse options at their disposal, enabling more strategic sourcing decisions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of heating element type

- How do I vet suppliers for heating elements?

When vetting suppliers, focus on their industry reputation, certifications, and experience in manufacturing heating elements. Check for compliance with international standards such as ISO or IEC to ensure quality and safety. Request references or case studies from similar industries to gauge their reliability. It’s also beneficial to evaluate their production capabilities and technology, as well as their responsiveness to inquiries. Engage in direct communication to clarify any doubts and assess their customer service approach, which is critical for ongoing support. - Can heating elements be customized for my specific needs?

Yes, many suppliers offer customization options for heating elements to meet specific operational requirements. This may include variations in size, shape, material, and power output. When discussing customization, provide detailed specifications regarding temperature ranges, application environments, and mounting configurations. Ensure the supplier has experience with custom orders and can provide prototypes for testing before full-scale production. A collaborative approach can yield the best results in achieving tailored heating solutions. - What are the typical minimum order quantities (MOQs) and lead times?

MOQs for heating elements can vary significantly based on the supplier, material, and customization requirements. Generally, you might expect MOQs to range from 50 to 500 units for standard products, while custom elements may have higher MOQs. Lead times can also differ, typically ranging from 4 to 12 weeks depending on production schedules and complexity. Always confirm these details with your supplier early in negotiations to align expectations and avoid production delays. - What payment terms should I expect when sourcing heating elements?

Payment terms can vary widely among suppliers, but common practices include 30% upfront payment with the balance due upon delivery or net 30 days post-invoice. Some suppliers might offer discounts for early payments or bulk orders. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. Always discuss and agree upon payment terms before finalizing contracts to ensure clarity and prevent disputes. - What quality assurance (QA) measures should suppliers provide?

Quality assurance is critical in the heating element industry due to safety and performance concerns. Suppliers should provide certifications that comply with international standards, such as ISO 9001 for quality management systems. Inquire about their QA processes, including material inspections, in-process testing, and final product evaluations. Request documentation of these processes, such as test reports or certificates of conformity, to ensure that the heating elements meet the required specifications and performance standards. - How should I handle logistics and shipping for international orders?

When managing logistics for international orders of heating elements, collaborate closely with your supplier to determine the best shipping methods and carriers based on cost and delivery timelines. Understand the customs regulations and import duties applicable in your region to avoid unexpected charges. Establish clear communication regarding shipping schedules and tracking procedures. Consider using freight forwarders to streamline the process, especially if you are unfamiliar with international shipping protocols.

Illustrative Image (Source: Google Search)

- What steps can I take to resolve disputes with suppliers?

To resolve disputes with suppliers, maintain open lines of communication to address issues as they arise. Document all agreements and communications to provide a clear record of expectations. If disputes escalate, consider mediation or arbitration as a first step before pursuing legal action. Having a well-defined contract that includes clauses for conflict resolution can help mitigate risks. Familiarize yourself with local laws and regulations regarding trade disputes to ensure you are prepared for potential challenges. - What certifications should I look for in heating elements?

When sourcing heating elements, look for certifications that demonstrate compliance with safety and performance standards. Common certifications include UL (Underwriters Laboratories), CE (Conformité Européenne), and RoHS (Restriction of Hazardous Substances). These certifications indicate that the products have been tested for quality and safety. Additionally, inquire if the supplier adheres to industry-specific standards relevant to your application, such as API or ASME, to ensure reliability and compatibility with your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for heating element type

As international B2B buyers navigate the complexities of sourcing heating elements, the importance of strategic sourcing cannot be overstated. By understanding the various materials and types of heating elements available—such as resistive wire elements, ceramic heating elements, and their specific applications—buyers can enhance operational efficiency, ensure safety, and optimize energy consumption.

Key takeaways include the necessity of matching heating elements to specific operational requirements, considering factors like temperature ranges, material compatibility, and energy efficiency. Buyers should prioritize elements that not only meet their immediate needs but also promise durability and long-term performance, thereby reducing the risk of costly downtime.

Looking ahead, the demand for high-quality heating elements will continue to rise, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By investing in strategic sourcing practices now, companies can position themselves competitively in a dynamic global market. Engage with reliable suppliers, leverage technological advancements, and prioritize sustainability to ensure that your heating solutions are not only effective but also future-proof. Make informed choices today to secure a competitive edge in your industry.