Master the Art of Sourcing AC Motor Parts for Optimal

Introduction: Navigating the Global Market for ac motor parts

In an increasingly interconnected global economy, AC motor parts stand at the forefront of industrial innovation and efficiency. These components are vital for a diverse range of applications, from powering manufacturing equipment to enhancing automation processes. As businesses strive to optimize productivity and reduce operational costs, understanding the intricacies of AC motor parts becomes essential for B2B buyers seeking a competitive edge in their respective markets.

This comprehensive guide delves into the various types of AC motors, their materials, and the manufacturing and quality control processes that underpin their reliability. It also offers insights into selecting the right suppliers, evaluating costs, and understanding the latest market trends. By addressing frequently asked questions, this resource aims to demystify the sourcing process and equip international buyers from Africa, South America, the Middle East, and Europe—particularly in key markets like the UK and Italy—with the knowledge needed to make informed decisions.

With actionable strategies tailored to the unique challenges and opportunities faced by global buyers, this guide empowers companies to enhance their sourcing strategies. By leveraging the information presented, businesses can ensure they select the right AC motor parts that align with their operational goals, ultimately driving long-term success and sustainability in an evolving marketplace.

Understanding ac motor parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Motor | Robust design, operates on electromagnetic induction | Manufacturing, HVAC, pumps | Pros: Low cost, minimal maintenance; Cons: Limited speed control, lower starting torque. |

| Synchronous Motor | Speed synchronized with supply frequency | Robotics, precision machinery | Pros: High efficiency, precise speed control; Cons: Complex starting mechanisms, higher initial cost. |

| Gear Motor | Integrated gearbox for torque multiplication | Conveyors, mixers, agricultural machinery | Pros: Simplified installation; Cons: Potential efficiency loss due to gearing. |

| Servo Motor | High precision with closed-loop control | CNC machinery, automated assembly | Pros: Exceptional accuracy; Cons: Higher cost and complexity. |

| Stepper Motor | Moves in discrete steps for precise positioning | 3D printers, robotics | Pros: Excellent control; Cons: Limited speed and can lose steps under load. |

Induction Motor

Induction motors are the backbone of many industrial applications due to their simple design and durability. They function on the principle of electromagnetic induction, making them suitable for environments that require consistent operation, such as manufacturing and HVAC systems. B2B buyers should consider the motor’s torque and speed requirements, as induction motors typically have lower starting torque and limited speed control. Additionally, evaluate local supply chains for spare parts and maintenance services to ensure operational continuity.

Synchronous Motor

Synchronous motors are engineered for applications that demand precise speed control, operating at a speed directly proportional to the supply frequency. They are ideal for robotics and precision machinery, where efficiency and accuracy are paramount. However, the complexity of their starting mechanisms and higher initial costs may be a barrier for some buyers. When sourcing synchronous motors, assess the long-term energy savings against the initial investment, particularly for operations in energy-sensitive regions.

Gear Motor

Gear motors combine an electric motor with a gearbox, allowing for increased torque output while maintaining a compact design. They are widely used in conveyor systems, mixers, and agricultural machinery, where space is often at a premium. B2B buyers should consider the specific reduction ratios and compatibility with existing equipment. While gear motors simplify installation, potential efficiency losses due to gearing should be evaluated against performance requirements to ensure optimal operation.

Servo Motor

Servo motors provide high precision through closed-loop control systems, making them essential for applications requiring exact positioning, such as CNC machinery and automated assembly lines. These motors are typically more expensive and complex than other types, but they offer significant advantages in terms of accuracy and responsiveness. Buyers should ensure compatibility with their existing control systems and consider the availability of local expertise for installation and maintenance.

Stepper Motor

Stepper motors are designed for applications that require accurate positioning, moving in discrete steps to achieve precise control. They are commonly used in 3D printers and robotics, where exact movements are critical. While stepper motors offer excellent control, they may struggle with speed and can lose steps under heavy loads. B2B buyers should evaluate the specific precision needs of their applications and consider whether the limitations in speed and load capacity align with their operational requirements.

Related Video: AC Motor Components – Parts and Functions

Key Industrial Applications of ac motor parts

| Industry/Sector | Specific Application of ac motor parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhances production efficiency and throughput | Compatibility with existing systems and load capacity |

| HVAC | Air Conditioning Units | Improves energy efficiency and comfort | Energy rating, noise levels, and maintenance support |

| Agriculture | Irrigation Systems | Optimizes water usage and crop yield | Durability in harsh environments and spare parts availability |

| Mining | Material Handling Equipment | Increases operational reliability and safety | Resistance to dust and moisture, and power requirements |

| Transportation | Electric Vehicle Charging Stations | Supports sustainable transport solutions | Compliance with regional electrical standards and scalability |

Manufacturing: Conveyor Systems

In the manufacturing sector, AC motor parts are integral to conveyor systems, which facilitate the movement of goods and materials. These systems enhance production efficiency and throughput by automating the transport process. Buyers must consider the compatibility of motors with existing systems, ensuring they can handle the expected load capacity. Additionally, sourcing durable components that can withstand continuous operation is crucial for minimizing downtime and maintenance costs.

HVAC: Air Conditioning Units

In HVAC applications, AC motors drive air conditioning units, improving energy efficiency and maintaining optimal indoor comfort levels. The right motor parts ensure reliable operation, reducing energy consumption and lowering operational costs. Buyers should evaluate energy ratings, noise levels, and the availability of maintenance support when sourcing these components. Compliance with local regulations regarding energy efficiency is also essential, particularly in European markets.

Agriculture: Irrigation Systems

AC motor parts are vital in agricultural applications, particularly in irrigation systems that optimize water usage and enhance crop yield. These motors power pumps that distribute water efficiently, ensuring consistent irrigation even in challenging climates. For international buyers, especially in Africa and South America, sourcing durable motors that can withstand harsh environmental conditions is essential. Availability of spare parts and local support services should also be a priority to ensure uninterrupted operations.

Mining: Material Handling Equipment

In the mining industry, AC motors are used in material handling equipment, such as conveyor belts and crushers. These motors increase operational reliability and safety by providing consistent power for heavy loads. Buyers should focus on sourcing motors that are resistant to dust and moisture, as these conditions are prevalent in mining environments. Additionally, understanding the specific power requirements for different equipment types is critical for optimal performance.

Transportation: Electric Vehicle Charging Stations

AC motor parts play a significant role in the development of electric vehicle (EV) charging stations, supporting the shift towards sustainable transportation solutions. These motors facilitate the efficient operation of charging units, ensuring quick and reliable service for EV users. When sourcing for this application, compliance with regional electrical standards and scalability to accommodate future growth is vital. Buyers should also consider the integration of smart technologies that enhance user experience and operational efficiency.

Related Video: How Electric Motors Work – 3 phase AC induction motors ac motor

Strategic Material Selection Guide for ac motor parts

When selecting materials for AC motor parts, international B2B buyers must consider several factors that influence performance, durability, and cost-effectiveness. The choice of material not only affects the motor’s efficiency but also its longevity and maintenance requirements. Below is an analysis of four common materials used in AC motor components, focusing on their properties, advantages, disadvantages, and implications for specific applications.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for high-stress applications. It typically has good temperature resistance, withstanding up to 500°C, and can be treated for enhanced corrosion resistance.

Pros & Cons:

Steel is relatively inexpensive and widely available, which makes it a popular choice for many motor components. However, it can be heavy, which may affect the overall weight of the motor. Additionally, untreated steel can corrode in humid or harsh environments, necessitating protective coatings.

Impact on Application:

Steel is compatible with a variety of media, including oils and coolants, making it suitable for industrial applications. However, its susceptibility to rust requires careful consideration in environments with high moisture levels, such as in some regions of Africa and South America.

Considerations for Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN for steel grades. In markets like Europe and the Middle East, where quality standards are stringent, selecting high-grade steel can prevent future maintenance issues.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can operate effectively at temperatures up to 200°C and is often anodized for additional protection against corrosion.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can reduce the overall mass of the motor, enhancing efficiency. However, it is generally more expensive than steel and may not be as strong under high-stress conditions.

Impact on Application:

Aluminum is particularly effective in applications requiring lightweight components, such as in aerospace and automotive sectors. Its corrosion resistance makes it suitable for environments with exposure to moisture, which is beneficial in humid regions.

Considerations for Buyers:

Buyers in Europe and the Middle East should ensure that aluminum parts meet specific industry standards, such as EN or JIS. The initial higher cost may be offset by lower maintenance needs and longer lifespan, making it a worthwhile investment.

3. Copper

Key Properties:

Copper is an excellent conductor of electricity, with high thermal conductivity and resistance to corrosion. It can withstand high temperatures, typically up to 300°C, making it ideal for electrical components.

Pros & Cons:

Copper’s superior conductivity enhances the efficiency of AC motors, leading to lower energy consumption. However, it is more expensive than both steel and aluminum, which can impact overall motor costs. Additionally, copper is heavier, which may not be ideal for all applications.

Impact on Application:

Copper is essential in windings and electrical connections within AC motors, ensuring optimal performance. Its compatibility with various electrical media makes it a preferred choice for high-performance applications.

Considerations for Buyers:

International buyers should be aware of the fluctuating prices of copper and consider sourcing from regions with stable supply chains. Compliance with electrical standards is crucial, especially in European markets where regulations are strict.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They typically operate effectively at temperatures up to 100°C and can be engineered for specific applications.

Pros & Cons:

The primary advantage of plastic composites is their versatility and low weight, which can reduce the overall size of the motor. However, they may not offer the same level of strength or heat resistance as metals, limiting their use in high-stress applications.

Impact on Application:

These materials are often used in non-load-bearing components, such as housings and insulators, where weight and corrosion resistance are critical. They are particularly beneficial in environments where moisture is a concern.

Considerations for Buyers:

B2B buyers should ensure that the selected composites meet local compliance standards and are suitable for the intended application. In markets like South America and Africa, where environmental conditions can vary, selecting the right composite can enhance performance and durability.

Summary Table

| Material | Typical Use Case for ac motor parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, shafts | High strength, durability | Heavy, corrosion potential | Low |

| Aluminum | Housings, rotors | Lightweight, corrosion-resistant | Higher cost, lower strength | Medium |

| Copper | Electrical windings, connectors | Excellent conductivity | Expensive, heavier | High |

| Plastic Composites | Non-load-bearing components, housings | Lightweight, corrosion-resistant | Limited strength, heat resistance | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for ac motor parts

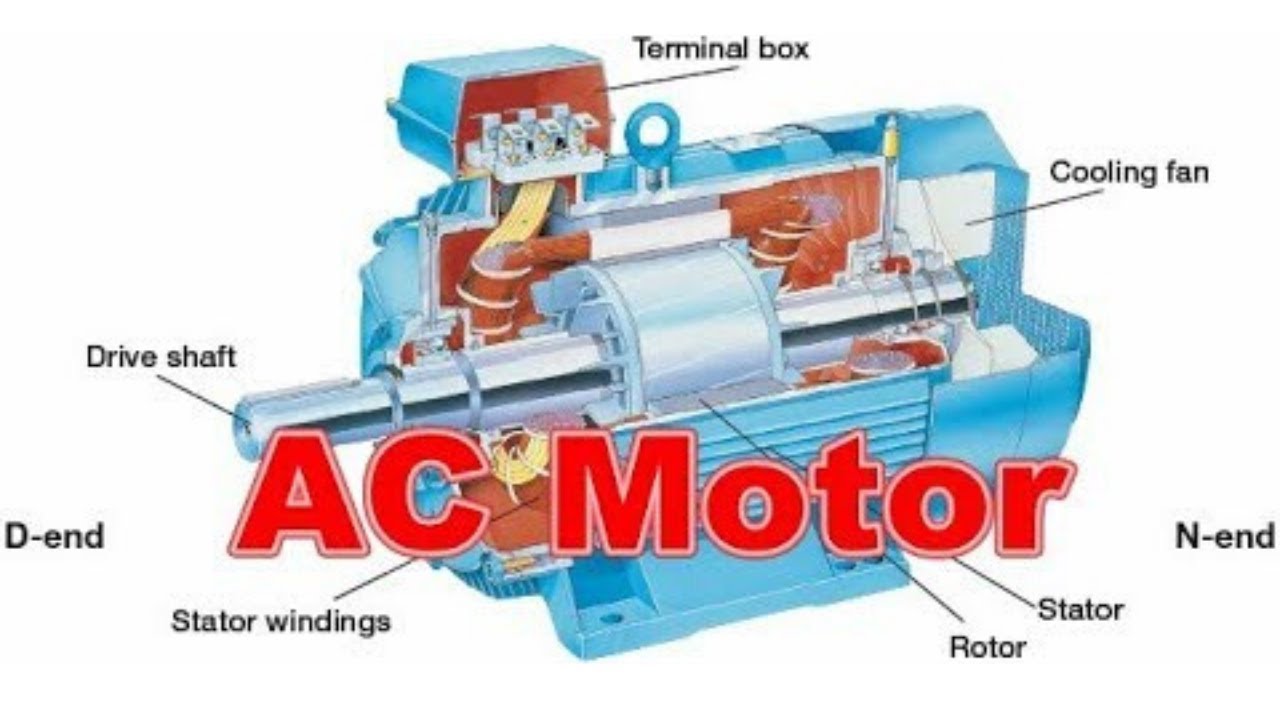

Manufacturing Processes for AC Motor Parts

The manufacturing of AC motor parts is a multi-stage process that ensures high-quality components are produced consistently. Understanding these stages is crucial for B2B buyers looking to source reliable motor parts from international suppliers. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

1. Material Preparation

The foundation of any high-quality AC motor part is the selection of appropriate raw materials. Common materials used include:

- Copper and Aluminum: For windings due to their excellent conductivity.

- Steel Alloys: For the motor frame and rotor, providing strength and durability.

- Insulation Materials: Such as varnishes and resins to protect windings from electrical shorts and environmental factors.

Before manufacturing begins, materials undergo inspection to ensure they meet industry standards. This step often involves assessing the chemical composition and physical properties of the materials to prevent defects in the final product.

2. Forming

The forming process involves shaping raw materials into specific components. Key techniques include:

- Casting: Used for creating complex shapes such as motor housings and rotor cores. This method involves pouring molten metal into molds and allowing it to solidify.

- Machining: Essential for precision components like shafts and bearings. Techniques such as turning, milling, and grinding are employed to achieve tight tolerances.

- Stamping: Utilized for producing thin metal parts like laminations. This process involves pressing sheets of metal into desired shapes using dies.

B2B buyers should ensure that suppliers utilize modern forming techniques, as these often lead to greater efficiency and reduced production costs.

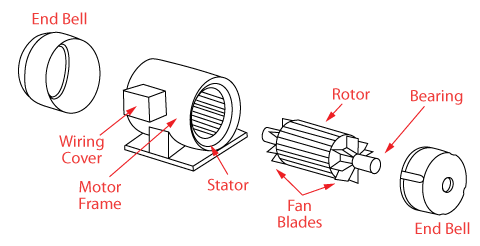

3. Assembly

The assembly stage combines the various formed components into a complete motor. This process typically involves:

- Winding: Copper or aluminum wire is wound around the stator to create electromagnetic fields. The winding process is critical, as improper winding can lead to inefficiencies or failures.

- Integration: Components such as bearings, end bells, and rotors are assembled using precise alignment techniques to ensure optimal performance.

- Electrical Connections: Ensuring all electrical connections are secure and insulated to prevent shorts.

During assembly, quality control checkpoints are crucial. These may include automated systems that check alignment and torque specifications, ensuring that every assembled motor meets operational standards.

4. Finishing

The finishing stage enhances the durability and performance of AC motor parts. Key processes include:

- Coating: Application of protective coatings to prevent corrosion and wear. This is particularly important for motors used in harsh environments, common in industries across Africa and South America.

- Testing: Each motor undergoes rigorous testing to ensure it meets performance specifications. This includes electrical testing, thermal testing, and mechanical stress testing.

B2B buyers should request detailed reports on the finishing processes used by suppliers, as these can significantly impact the longevity and reliability of the motor parts.

Quality Assurance in AC Motor Manufacturing

Quality assurance (QA) is paramount in the manufacturing of AC motor parts. Buyers must be aware of the standards and practices that ensure product reliability and compliance with international regulations.

Relevant International Standards

Several international standards guide the manufacturing and quality assurance of AC motors, including:

- ISO 9001: This standard outlines the requirements for a quality management system (QMS), ensuring that suppliers maintain consistent quality in their processes.

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

- API Standards: Relevant for motors used in the oil and gas industry, ensuring that products meet specific performance and safety requirements.

Quality Control Checkpoints

Quality control (QC) involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet performance and safety standards before shipment.

Common Testing Methods

B2B buyers should be familiar with common testing methods used in the quality assurance of AC motor parts, including:

- Electrical Testing: Assessing voltage, current, and insulation resistance to ensure proper functionality.

- Thermal Imaging: Identifying hotspots that may indicate potential failures.

- Vibration Testing: Evaluating the mechanical integrity of the motor during operation.

Verifying Supplier Quality Control

To ensure that suppliers adhere to high-quality standards, buyers should consider the following strategies:

- Audits: Conduct regular audits of suppliers’ facilities to verify compliance with quality standards and practices.

- Quality Reports: Request detailed quality reports that outline testing results and any corrective actions taken.

- Third-Party Inspections: Engage independent third-party organizations to perform quality inspections and certifications, providing an unbiased assessment of supplier capabilities.

QC and Certification Nuances for International Buyers

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of QC and certification is vital. Factors to consider include:

- Regional Regulations: Be aware of specific regulations in your region that may affect product compliance, such as environmental standards or import tariffs.

- Cultural Differences: Recognize that manufacturing practices and quality expectations may vary across cultures. Building strong relationships with suppliers can enhance communication and ensure alignment on quality expectations.

By navigating the manufacturing processes and quality assurance practices effectively, international B2B buyers can make informed sourcing decisions, ensuring they procure high-quality AC motor parts that meet their operational needs.

Related Video: How to Make Electric MOTOR in Factory | Amazing Electrical Motors Manufacturing Process

Comprehensive Cost and Pricing Analysis for ac motor parts Sourcing

When sourcing AC motor parts, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers. The costs associated with AC motor parts can be broken down into several key components:

Cost Components

-

Materials: The choice of materials significantly impacts the cost of AC motor parts. Common materials include steel, copper, and specialized alloys. Prices can fluctuate based on global market trends and availability, so buyers should stay informed about raw material costs.

-

Labor: Labor costs vary by region and influence the overall pricing of motor parts. Countries with higher labor costs may offer more skilled labor, which can enhance the quality of production. Buyers should consider the balance between labor costs and expected quality when sourcing.

-

Manufacturing Overhead: This includes all costs associated with the production environment, such as utilities, factory maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: Tooling costs encompass the expenses related to the creation of molds and fixtures necessary for production. For custom parts, these costs can be substantial. Buyers should inquire about tooling fees upfront, especially for low-volume orders.

-

Quality Control (QC): Implementing stringent quality control processes is crucial for ensuring the reliability of AC motor parts. While these processes can add to the cost, they can also prevent costly failures and returns, making them a worthwhile investment.

-

Logistics: Shipping costs, including freight, insurance, and handling, can vary significantly based on the destination and shipping method. Incoterms can also affect the final pricing, so buyers should clarify responsibility for logistics costs with suppliers.

-

Margin: Supplier margins vary based on market conditions and competition. Understanding the typical margins in the region of sourcing can help buyers negotiate better prices.

Price Influencers

Several factors can influence the pricing of AC motor parts:

-

Volume/MOQ: Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should consider their projected usage to negotiate minimum order quantities (MOQ) effectively.

-

Specifications/Customization: Customized parts or specific technical specifications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials impacts both performance and cost. Higher-grade materials may offer better durability but come at a premium.

-

Quality/Certifications: Products with recognized quality certifications (e.g., ISO, CE) may command higher prices. However, such certifications can offer peace of mind regarding performance and safety.

-

Supplier Factors: The supplier’s reputation, manufacturing capabilities, and geographical location can affect pricing. Established suppliers may have higher prices but offer better reliability and support.

-

Incoterms: These terms define the responsibilities of buyers and sellers regarding shipping and logistics. Understanding Incoterms can help buyers avoid unexpected costs and ensure smooth transactions.

Buyer Tips

To optimize sourcing strategies, international B2B buyers should consider the following tips:

-

Negotiation: Be prepared to negotiate terms and prices. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the purchase price. Consider maintenance, energy consumption, and lifespan when assessing overall value.

-

Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing variations due to tariffs, local regulations, and market demand.

-

Stay Informed: Regularly monitor market trends and material prices to make informed purchasing decisions.

-

Build Relationships: Establishing long-term relationships with reliable suppliers can lead to better pricing and service over time.

Disclaimer

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier negotiations, and specific requirements. Buyers should conduct thorough market research and seek multiple quotes to ensure competitive pricing.

Spotlight on Potential ac motor parts Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘ac motor parts’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for ac motor parts

Understanding the technical specifications and trade terminology associated with AC motor parts is crucial for international B2B buyers. This knowledge not only facilitates informed purchasing decisions but also enhances negotiation power, ultimately leading to optimized procurement processes.

Key Technical Properties of AC Motor Parts

-

Material Grade

– Definition: Refers to the specific composition and quality of materials used in manufacturing motor parts, such as steel, aluminum, or specialty alloys.

– B2B Importance: The material grade affects the durability, efficiency, and performance of the motor. For instance, high-grade materials can withstand higher temperatures and loads, reducing the risk of failure in demanding applications. -

Tolerance

– Definition: This specification indicates the allowable variation in the dimensions of a part, ensuring that components fit and function together correctly.

– B2B Importance: Precision in manufacturing is critical for performance and longevity. Tight tolerances can minimize wear and tear, enhance efficiency, and reduce operational downtime, which is particularly important in sectors like automotive and manufacturing. -

Power Rating

– Definition: Measured in kilowatts (kW) or horsepower (HP), this indicates the motor’s capacity to perform work.

– B2B Importance: Understanding the power rating helps buyers select motors that meet the operational demands of their equipment. Choosing a motor with insufficient power can lead to underperformance, while over-specifying can increase costs unnecessarily. -

Efficiency Class

– Definition: This classification reflects how effectively a motor converts electrical energy into mechanical energy, often denoted by energy efficiency ratings (e.g., IE1, IE2, IE3).

– B2B Importance: Higher efficiency classes typically result in lower energy costs and reduced environmental impact. International buyers, particularly from regions with strict energy regulations, should prioritize efficient motors to comply with local standards and achieve cost savings. -

Insulation Class

– Definition: Indicates the temperature range a motor can operate without overheating, categorized into classes (e.g., Class A, B, F, H).

– B2B Importance: Selecting the appropriate insulation class is vital for ensuring reliable operation in varying environmental conditions. This is especially relevant in sectors like agriculture and mining, where motors face extreme conditions.

Common Trade Terminology

- OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers ensure they are sourcing high-quality components that meet industry standards.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Awareness of MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQ to align with their operational needs without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing information for specific products or services.

– Importance: An effective RFQ process allows buyers to compare offers from multiple suppliers, facilitating better pricing and terms. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international sales terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs.

– Importance: Familiarity with Incoterms helps buyers manage risks and costs associated with international shipping, ensuring clarity in transactions. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Understanding lead times is essential for planning production schedules and inventory levels, particularly in industries with tight deadlines. -

Certification Standards

– Definition: Industry-specific standards that components must meet to ensure safety, quality, and performance (e.g., ISO, CE).

– Importance: Compliance with certification standards is crucial for international trade, affecting product acceptance in various markets and ensuring safety regulations are met.

Equipping yourself with knowledge of these specifications and terms will empower international buyers to make informed decisions, negotiate effectively, and ultimately optimize their sourcing strategies in the global market for AC motor parts.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the ac motor parts Sector

Market Overview & Key Trends

The global AC motor parts market is witnessing transformative changes driven by technological advancements, sustainability initiatives, and evolving consumer demands. Key factors propelling market growth include the increasing adoption of automation across various industries, such as manufacturing, HVAC, and automotive sectors, particularly in emerging markets in Africa and South America. Additionally, the rise of smart technologies and IoT applications is enhancing the functionality of AC motors, allowing for improved energy efficiency and reduced operational costs.

B2B buyers are increasingly focusing on sourcing trends that emphasize quality and reliability. The growing importance of supply chain transparency is leading buyers to seek suppliers who demonstrate compliance with international quality standards and can provide detailed certifications. Furthermore, buyers should consider the implications of raw material volatility and invest in strategic partnerships to mitigate risks associated with fluctuating prices. This is particularly pertinent for regions like the Middle East and Europe, where energy costs are critical to operational budgets.

Emerging technologies such as 3D printing and additive manufacturing are also reshaping the landscape, enabling rapid prototyping and customized solutions in AC motor parts. As these technologies become more accessible, buyers can leverage them to meet specific operational needs without significant lead time. Understanding these dynamics will empower international B2B buyers to make informed decisions that align with their strategic sourcing objectives.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal consideration for international B2B buyers in the AC motor parts sector. The environmental impact of manufacturing processes and materials used in motor components is under increasing scrutiny. As a result, companies are prioritizing ethical sourcing to minimize their carbon footprint and enhance their corporate social responsibility profiles. This shift is particularly important for buyers in Europe, where regulatory frameworks around sustainability are becoming more stringent.

Ethical supply chains that prioritize transparency and fair labor practices are not just a moral imperative; they also resonate with consumers and stakeholders who increasingly favor companies with a commitment to sustainability. Buyers should seek suppliers that adhere to recognized green certifications, such as ISO 14001 for environmental management systems or other industry-specific sustainability standards.

Moreover, opting for eco-friendly materials and components—such as those made from recycled metals or sustainably sourced raw materials—can significantly reduce the environmental impact of AC motor parts. Integrating sustainability into the sourcing strategy not only enhances brand reputation but also aligns with global trends towards circular economies.

Brief Evolution/History

The evolution of AC motors can be traced back to the late 19th century, when Nikola Tesla developed the induction motor, revolutionizing the field of electrical engineering. This innovation laid the groundwork for widespread industrial applications, transforming manufacturing processes and enabling greater efficiency. Over the decades, advancements in materials and technology have led to the development of diverse motor types, including synchronous and brushless DC motors, each catering to specific operational needs.

Today, the focus has shifted towards enhancing energy efficiency and integrating smart technologies, allowing AC motors to adapt to the demands of modern industries. This historical context is essential for B2B buyers, as it highlights the ongoing innovations and the importance of selecting motor parts that not only meet current operational standards but also align with future sustainability goals.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of ac motor parts

-

What should I consider when vetting suppliers for AC motor parts?

When vetting suppliers, prioritize their industry experience, reputation, and compliance with international standards. Request references from previous clients and evaluate their production capabilities through site visits or virtual tours. Ensure they have a robust quality assurance process and certifications such as ISO 9001. Additionally, check their financial stability to mitigate risks associated with supply chain disruptions. A supplier with a strong track record in your specific region can also provide valuable insights into local market conditions. -

Can I customize AC motor parts to fit my specific requirements?

Yes, many suppliers offer customization options for AC motor parts, including size, design, and material specifications. When discussing customization, clearly outline your requirements and ensure the supplier understands your application needs. Request prototypes or samples to evaluate the fit and performance before committing to a large order. Keep in mind that customization may affect lead times and costs, so negotiate these aspects early in the procurement process to avoid delays. -

What are the typical minimum order quantities (MOQs) and lead times for AC motor parts?

Minimum order quantities can vary widely depending on the supplier and the type of motor parts you need. Generally, MOQs range from a few dozen to several hundred units. Lead times also depend on factors like the supplier’s location, production capacity, and whether customization is required. For international buyers, consider potential delays due to customs and logistics. It’s essential to discuss these details upfront to align your procurement timeline with your operational needs. -

What payment methods are commonly accepted when sourcing AC motor parts internationally?

International suppliers typically accept various payment methods, including wire transfers, letters of credit, and online payment platforms. Wire transfers are common for direct transactions, while letters of credit can provide security for larger orders. Always clarify payment terms before finalizing the deal, including deposits and balance payments. Consider using escrow services for added security, especially when dealing with new suppliers, to ensure that funds are released only upon satisfactory delivery. -

How can I ensure quality assurance and certifications for AC motor parts?

To ensure quality assurance, request documentation of the supplier’s certifications, such as ISO standards, and inquire about their quality control processes. Many suppliers conduct regular inspections and testing of their products. You may also consider third-party quality audits or inspections before shipping. If applicable, check if the parts comply with regional standards, such as CE marking in Europe or UL certification in the US, to ensure they meet local regulatory requirements. -

What logistics considerations should I keep in mind when importing AC motor parts?

Logistics are crucial when importing AC motor parts. Evaluate shipping options, including air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations in your destination country, including tariffs and import duties. Work with a logistics partner experienced in international shipping to navigate these complexities. Additionally, ensure you have a plan for handling potential delays or damages during transport, including insurance coverage. -

How should I handle disputes with suppliers regarding AC motor parts?

To handle disputes effectively, establish clear terms in your contract, including delivery schedules, quality expectations, and payment terms. In case of a dispute, communicate promptly and professionally with the supplier to resolve issues amicably. If necessary, escalate the matter to a higher management level within the supplier’s organization. Consider mediation or arbitration as alternative dispute resolution methods if direct negotiations fail. Always document all communications and agreements to support your position. -

What are the best practices for maintaining a long-term relationship with AC motor parts suppliers?

Building a long-term relationship with suppliers requires open communication, trust, and mutual respect. Regularly provide feedback on product performance and quality to foster collaboration. Engage in joint planning sessions to align on future needs and innovations. Timely payments and honoring contract terms also demonstrate reliability. Lastly, consider establishing a partnership framework that includes performance reviews, which can help in addressing issues proactively and ensuring both parties benefit from the relationship.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for ac motor parts

In conclusion, strategic sourcing of AC motor parts is essential for businesses aiming to optimize performance and reduce operational costs. International B2B buyers must prioritize a thorough understanding of motor types, their applications, and the implications of material selection. This knowledge equips buyers to navigate complex supply chains, manage costs effectively, and ensure compliance with regional standards.

Key takeaways include the importance of evaluating supplier capabilities, considering long-term partnerships for reliability, and leveraging market insights to negotiate favorable terms. By focusing on quality, efficiency, and sustainability, companies can enhance their competitive advantage in a dynamic global market.

As you look toward the future, remember that the landscape of motor sourcing is continually evolving with technological advancements and shifting market demands. Embrace innovation and seek suppliers who can offer not only products but also valuable insights and support. Take the next step in your sourcing journey by engaging with trusted partners and exploring opportunities that align with your operational goals, particularly in the growing markets of Africa, South America, the Middle East, and Europe. Your strategic sourcing decisions today will shape your success tomorrow.