Master the Art of Sourcing Agitation Motors for Optimal

Introduction: Navigating the Global Market for agitation motor

Navigating the complexities of the global market for agitation motors is essential for international B2B buyers looking to enhance operational efficiency and product quality. Agitation motors play a critical role in various industries, including chemical processing, food and beverage, and pharmaceuticals, where effective mixing and stirring are vital for achieving optimal results. Understanding the nuances of these motors is not just about selecting a powerful device; it involves recognizing the intricate balance of electrical and mechanical characteristics that influence performance and longevity.

This comprehensive guide serves as a vital resource, addressing key aspects such as types of agitation motors, materials used, and manufacturing and quality control standards. Additionally, it delves into the landscape of suppliers, cost considerations, and market trends that are shaping the industry today. With a dedicated section for frequently asked questions, buyers will find answers to their most pressing queries, empowering them to make informed sourcing decisions.

By leveraging the insights provided, B2B buyers from Africa, South America, the Middle East, and Europe, including regions like Mexico and Germany, can navigate the complexities of motor selection with confidence. This guide is designed to equip you with the knowledge necessary to avoid costly pitfalls, ensuring that your procurement process is efficient and aligned with your operational needs.

Understanding agitation motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Squirrel Cage Induction Motor | Simple design, robust, and cost-effective | Chemical processing, water treatment | Pros: High reliability, low maintenance. Cons: Limited speed control. |

| Permanent Magnet Synchronous Motor | High efficiency, compact size, and precise speed control | Food and beverage, pharmaceuticals | Pros: Excellent energy efficiency, precise control. Cons: Higher initial cost. |

| Wound Rotor Induction Motor | Adjustable speed and torque, complex design | Heavy-duty applications, mining | Pros: Versatile speed control, high starting torque. Cons: More expensive and requires maintenance. |

| Direct Current (DC) Motor | High torque at low speeds, easy speed control | Textile manufacturing, printing | Pros: Simple speed control, high torque. Cons: Requires regular maintenance, less energy efficient. |

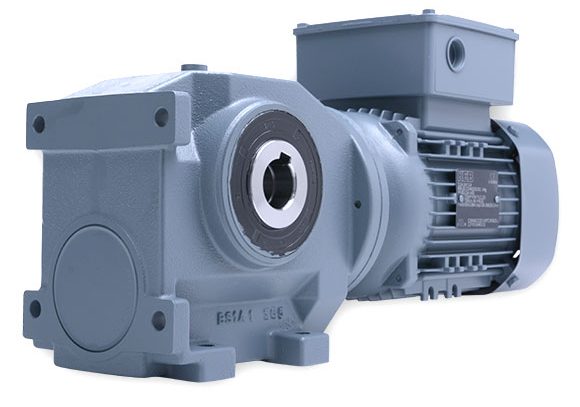

| Gear Motor | Integrated gear system for torque multiplication | Conveyor systems, mixing applications | Pros: High torque output, compact design. Cons: More complex, potential for gear wear. |

Squirrel Cage Induction Motor

Squirrel cage induction motors are widely recognized for their simplicity and robustness. They utilize a rotor that is not connected to any external power source, making them highly reliable and low-maintenance. These motors are particularly suited for applications in chemical processing and water treatment facilities, where durability is essential. When sourcing these motors, buyers should consider their horsepower requirements and the environmental conditions in which the motor will operate, as these factors can significantly impact performance.

Permanent Magnet Synchronous Motor

Permanent magnet synchronous motors are known for their high efficiency and compact design. They provide precise speed control, making them ideal for applications in food and beverage processing, as well as pharmaceuticals. For B2B buyers, the initial cost may be higher compared to other motor types; however, the long-term energy savings and performance reliability can justify the investment. It’s crucial to assess the specific application requirements and operational efficiency goals when selecting this motor type.

Wound Rotor Induction Motor

Wound rotor induction motors are characterized by their ability to adjust speed and torque based on the application needs. This flexibility makes them suitable for heavy-duty applications such as mining and large industrial processes. While they offer high starting torque and versatile speed control, they are typically more expensive and require regular maintenance. Buyers should weigh the operational demands of their application against the motor’s cost and maintenance requirements to make informed decisions.

Direct Current (DC) Motor

DC motors are favored for their high torque at low speeds and ease of speed control, making them suitable for applications in textile manufacturing and printing industries. While they provide significant advantages in terms of performance, they do require regular maintenance and are generally less energy efficient than their AC counterparts. Buyers should evaluate their operational needs and consider the maintenance implications when selecting a DC motor for their applications.

Gear Motor

Gear motors integrate a gear system that allows for torque multiplication, making them ideal for conveyor systems and various mixing applications. Their compact design and ability to deliver high torque output are significant advantages. However, the complexity of gear systems can lead to potential wear and necessitate careful consideration of the gear material and design. When purchasing gear motors, it is essential to assess the specific torque and speed requirements of the application to ensure optimal performance.

Key Industrial Applications of agitation motor

| Industry/Sector | Specific Application of agitation motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Mixing ingredients in food production | Ensures uniformity and quality in products | Need for sanitary design, compliance with food safety standards, and energy efficiency. |

| Chemical Processing | Blending chemicals for reactions | Enhances reaction rates and product consistency | Specifications for chemical resistance and temperature control are critical. |

| Pharmaceuticals | Homogenizing active ingredients | Guarantees precise dosing and effective medication | Regulatory compliance, material safety, and precision in mixing are paramount. |

| Wastewater Treatment | Aerating and mixing wastewater | Improves treatment efficiency and reduces costs | Consideration for environmental regulations and energy consumption. |

| Mining and Minerals | Slurry preparation for mineral extraction | Increases extraction efficiency and reduces waste | Durability under harsh conditions and adaptability to various slurry densities are essential. |

Food and Beverage

In the food and beverage industry, agitation motors are pivotal for mixing ingredients during production. They ensure that components are uniformly blended, which is essential for maintaining product quality and consistency. Buyers in this sector should prioritize motors that meet stringent food safety standards, are easy to clean, and offer energy efficiency. Additionally, understanding local regulations on food processing equipment is crucial for international buyers, especially in regions like Africa and South America where standards may vary.

Chemical Processing

In chemical processing, agitation motors facilitate the blending of various chemicals to initiate reactions. This application is vital for achieving desired chemical properties and ensuring product consistency. Buyers must consider motors that can withstand corrosive substances and extreme temperatures. Furthermore, sourcing should focus on suppliers who can provide documentation for material safety and compliance with international standards, particularly in Europe and the Middle East, where regulations are stringent.

Pharmaceuticals

Agitation motors play a critical role in the pharmaceutical industry by homogenizing active ingredients to ensure uniformity in medication. This application is vital for precise dosing and effective drug formulation. International buyers need to focus on sourcing motors that comply with health regulations, such as Good Manufacturing Practices (GMP). Additionally, the materials used in the motor construction must be safe for pharmaceutical applications, requiring thorough vetting of suppliers.

Wastewater Treatment

In wastewater treatment, agitation motors are employed to aerate and mix wastewater, enhancing treatment efficiency. This application helps in breaking down pollutants more effectively, leading to reduced operational costs. Buyers should consider the environmental regulations in their region, ensuring that the motors are energy-efficient and capable of operating under varying conditions. Sourcing from vendors with experience in wastewater applications can provide additional assurance of compliance and reliability.

Mining and Minerals

Agitation motors are utilized in mining for preparing slurries that facilitate mineral extraction. They increase the efficiency of extraction processes by ensuring that the slurry is well-mixed and evenly distributed. Buyers in the mining sector must prioritize motors that are durable and capable of handling harsh environments, including high wear and tear. Additionally, understanding the specific density and viscosity requirements of the slurry is critical for selecting the appropriate motor type.

Related Video: Agitation and Mixing Equipment (Impeller, Vessels, Baffles, etc.) Applied Fluid Dynamics – Clas

Strategic Material Selection Guide for agitation motor

When selecting materials for agitation motors, it is crucial to consider the specific requirements of the application, including environmental conditions, media compatibility, and regulatory standards. Below, we analyze four common materials used in agitation motors, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Aluminum

Key Properties:

Aluminum is lightweight, with excellent thermal conductivity and corrosion resistance. It typically withstands temperatures up to 150°C and pressures around 10 bar, making it suitable for various applications.

Pros & Cons:

Aluminum is durable and cost-effective, offering good performance in many environments. However, it can be less suitable for high-stress applications due to lower tensile strength compared to other metals. Its manufacturing complexity is moderate, as it can be easily machined but may require special coatings for enhanced corrosion resistance.

Impact on Application:

Aluminum is compatible with many media, including water and mild chemicals. However, it may not perform well with strong acids or bases, necessitating careful consideration of the specific media in use.

Considerations for International Buyers:

Buyers should ensure compliance with local standards, such as ASTM or DIN, particularly regarding corrosion resistance and mechanical properties. In regions like Europe, where environmental regulations are stringent, verifying the alloy’s compliance with RoHS directives is essential.

2. Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand temperatures up to 500°C. It also has good pressure ratings, making it suitable for high-pressure applications.

Pros & Cons:

The durability of stainless steel makes it ideal for harsh environments, including those involving corrosive media. However, it is more expensive than aluminum and can be challenging to machine, increasing manufacturing complexity. Its weight can also be a disadvantage in applications where reducing weight is critical.

Impact on Application:

Stainless steel is compatible with a wide range of chemicals, including acids and alkalis, making it versatile for various applications. Its resistance to pitting and crevice corrosion is particularly beneficial in food and pharmaceutical industries.

Considerations for International Buyers:

Buyers should be aware of the specific grades of stainless steel (e.g., 304, 316) that meet their application requirements. Compliance with international standards such as ASTM and JIS is crucial, especially in regulated industries.

3. Cast Iron

Key Properties:

Cast iron offers excellent wear resistance and can handle high temperatures (up to 300°C) and pressures. It has a high density, which contributes to stability in operation.

Pros & Cons:

The primary advantage of cast iron is its durability and ability to absorb vibrations, making it suitable for heavy-duty applications. However, it is prone to corrosion and can be brittle, leading to potential failure under impact or stress. Manufacturing can be complex due to its weight and the need for precise casting techniques.

Impact on Application:

Cast iron is best suited for applications involving non-corrosive media. Its brittleness limits its use in environments where physical impacts are likely.

Considerations for International Buyers:

Buyers need to evaluate local availability and costs, as cast iron can be more expensive to transport due to its weight. Compliance with local standards is also essential, particularly in industries where safety is a concern.

4. Composite Materials

Key Properties:

Composite materials, such as fiberglass-reinforced plastics, are lightweight and offer excellent corrosion resistance. They can withstand temperatures up to 120°C and moderate pressures.

Pros & Cons:

The main advantage of composites is their resistance to chemical attack and low weight, which can reduce overall system costs. However, they may not provide the same mechanical strength as metals, and their manufacturing processes can be more complex and costly.

Impact on Application:

Composites are ideal for applications involving aggressive chemicals, particularly in the chemical processing and wastewater treatment industries.

Considerations for International Buyers:

Buyers should consider the specific certification requirements for composite materials in their region. Understanding local standards and regulations regarding fire safety and environmental impact is critical, especially in Europe and North America.

| Material | Typical Use Case for agitation motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Light-duty mixing applications | Lightweight and cost-effective | Lower tensile strength | Low |

| Stainless Steel | Food and pharmaceutical industries | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Cast Iron | Heavy-duty industrial applications | Durability and vibration absorption | Prone to corrosion and brittleness | Medium |

| Composite Materials | Chemical processing | Corrosion resistance and lightweight | Lower mechanical strength | Medium |

This strategic material selection guide provides a comprehensive overview of the materials used in agitation motors, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for agitation motor

The manufacturing processes and quality assurance measures for agitation motors are critical components for international B2B buyers aiming to ensure long-term performance and reliability. Understanding these elements can significantly impact sourcing decisions, especially in diverse markets such as Africa, South America, the Middle East, and Europe. Below is a comprehensive overview of the typical manufacturing stages, quality control practices, and actionable insights for buyers.

Manufacturing Processes

1. Material Preparation

The first stage in the manufacturing of agitation motors involves the careful selection and preparation of raw materials. Common materials include:

- Electrical Steel: Used for laminating the motor cores to enhance efficiency and reduce energy losses.

- Copper: Essential for winding the motor coils due to its excellent conductivity.

- Aluminum: Often used in rotor construction for its lightweight properties.

- Insulating Materials: Required to prevent electrical shorts and ensure safety.

Prior to manufacturing, these materials undergo rigorous testing to verify their properties, such as tensile strength, conductivity, and thermal resistance.

2. Forming

This stage involves shaping the prepared materials into components that will constitute the agitation motor. Key techniques include:

- Stamping: Electrical steel sheets are stamped to form the stator and rotor laminations.

- Winding: Copper wires are wound around the stator to create the electromagnetic field. The winding can be done using automated machines for precision.

- Casting: Components such as the rotor may be cast in aluminum to achieve desired shapes and weight specifications.

Precision in forming is vital, as even minor deviations can lead to inefficiencies or failures in motor operation.

3. Assembly

In this stage, the various components are assembled into a complete agitation motor. This typically involves:

- Mounting the Stator and Rotor: Ensuring proper alignment to facilitate smooth operation.

- Electrical Connections: Making secure connections for power supply and control systems.

- Enclosure Assembly: Installing protective casings to safeguard internal components from environmental factors.

Assembly lines often utilize jigs and fixtures to maintain consistency and reduce assembly time.

4. Finishing

The final stage focuses on enhancing the motor’s durability and performance. Techniques include:

- Surface Treatment: Applying coatings to resist corrosion, especially for motors used in harsh environments.

- Balancing: Ensuring that rotating parts are well-balanced to prevent vibrations that can lead to mechanical failure.

- Testing: Conducting functional tests to verify operational specifications before shipment.

Quality Assurance

International Standards

For B2B buyers, understanding the relevant quality standards is crucial. Key certifications include:

- ISO 9001: This standard ensures that manufacturers adhere to a quality management system that consistently provides products meeting customer and regulatory requirements.

- CE Marking: Indicates compliance with European safety and health regulations, essential for buyers in the European market.

- API Standards: Relevant for motors used in the oil and gas sector, ensuring reliability under extreme conditions.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints including:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing stages to detect and correct issues early.

- Final Quality Control (FQC): Comprehensive testing of the finished product to confirm compliance with performance and safety standards.

Common Testing Methods

B2B buyers should be aware of various testing methods employed, including:

- Electrical Testing: Verifying voltage, current, and insulation resistance to ensure safe operation.

- Thermal Imaging: Assessing the motor’s thermal performance under load.

- Vibration Analysis: Identifying potential mechanical issues that could lead to failure.

Verifying Supplier Quality Control

For international buyers, verifying the quality assurance processes of potential suppliers is essential. Here are actionable steps:

- Conduct Audits: Regular audits of suppliers can help assess their compliance with established quality standards and manufacturing practices.

- Request QC Reports: Ask for detailed quality control documentation, including test results and inspection reports, to validate the reliability of the motors.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the manufacturing process and final products, especially for large orders.

Quality Control Nuances for International Buyers

When sourcing from different regions, particularly Africa, South America, the Middle East, and Europe, buyers should consider the following:

- Cultural Differences: Understand that manufacturing standards and practices may vary significantly across regions. Engage suppliers in discussions to align expectations.

- Regulatory Compliance: Ensure that the products meet local regulations and standards in the buyer’s market. This is particularly important for buyers in Europe, where compliance with CE marking is mandatory.

- Supply Chain Transparency: Establish clear communication channels with suppliers to facilitate transparency in the sourcing process. This helps in promptly addressing any potential quality issues that may arise.

By comprehensively understanding the manufacturing processes and quality assurance practices for agitation motors, international B2B buyers can make informed decisions that ensure the reliability and efficiency of their operations.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for agitation motor Sourcing

Understanding the cost structure and pricing dynamics of agitation motors is crucial for international B2B buyers. This analysis will break down the cost components, price influencers, and provide actionable tips for effective sourcing.

Cost Components

The overall cost of agitation motors can be categorized into several key components:

-

Materials: The choice of materials significantly impacts the cost. High-grade materials for windings, housing, and components enhance durability but also elevate costs. Common materials include copper for windings and steel for housing, with prices fluctuating based on market conditions.

-

Labor: Labor costs can vary based on geographical location and the complexity of the motor. Skilled labor in regions like Europe may command higher wages compared to emerging markets. This difference can influence the overall pricing.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can reduce overhead costs, thus lowering the price of the final product.

-

Tooling: Custom or specialized tooling is often necessary for production. This upfront investment can be significant but is amortized over the production run, making bulk orders more cost-effective.

-

Quality Control (QC): Robust QC measures ensure the reliability and performance of agitation motors. Implementing stringent QC protocols may increase costs initially but can lead to long-term savings by reducing failure rates.

-

Logistics: Shipping and handling costs can vary widely depending on the origin and destination of the motors. Factors such as transportation mode, distance, and freight terms (Incoterms) play a crucial role in determining these expenses.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can fluctuate based on market demand, competition, and the supplier’s pricing strategy.

Price Influencers

Several factors can influence the pricing of agitation motors:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to discounts. Suppliers are more willing to negotiate on price for bulk orders, which can significantly reduce the unit cost.

-

Specifications/Customization: Custom motors tailored to specific applications may incur higher costs due to additional engineering and production complexity. Buyers should weigh the benefits of customization against the increased price.

-

Materials: The choice of materials affects both cost and performance. Higher-quality materials can result in longer-lasting motors but at a premium price.

-

Quality/Certifications: Motors that meet international quality standards or possess certifications (e.g., ISO, CE) may command higher prices. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Established suppliers with a proven track record may charge higher prices due to perceived reliability. Conversely, newer suppliers may offer competitive pricing to gain market entry.

-

Incoterms: The choice of Incoterms can significantly affect total costs. Terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) define responsibilities and costs associated with shipping, which can impact the overall pricing strategy.

Buyer Tips

To optimize the sourcing process and achieve cost efficiency, buyers should consider the following strategies:

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing terms. Establishing a strong relationship with suppliers can lead to favorable conditions.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider factors such as energy efficiency, maintenance costs, and lifespan, as these can influence long-term expenses.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, costs in Europe may be higher than in Africa or South America due to labor and regulatory factors. Understanding these nuances can help in making informed decisions.

-

Supplier Research: Conduct thorough due diligence on suppliers. Assess their financial stability, production capabilities, and reputation within the industry to ensure a reliable partnership.

Disclaimer

Prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements of the agitation motors. Always seek updated quotes and conduct market research before finalizing any procurement decisions.

Spotlight on Potential agitation motor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘agitation motor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for agitation motor

When sourcing agitation motors, understanding the technical specifications and trade terminology is crucial for making informed decisions. This section outlines the essential properties and common jargon that B2B buyers should be familiar with.

Key Technical Properties of Agitation Motors

-

Horsepower (HP)

– Definition: This measures the motor’s output power. For agitation motors, it indicates the ability to move fluids or materials effectively.

– Importance: Selecting the right horsepower is essential for ensuring that the motor can handle the required load without overworking or underperforming, which can lead to operational inefficiencies. -

Speed (RPM)

– Definition: Revolutions per minute (RPM) indicates how fast the motor shaft turns. This affects the mixing efficiency and shear rates in agitation applications.

– Importance: The correct RPM is critical for achieving optimal mixing conditions. Different applications may require varying speeds to maintain product quality. -

Frame Size

– Definition: This refers to the physical dimensions of the motor, including mounting specifications.

– Importance: Proper frame size ensures compatibility with existing equipment and installation spaces, reducing the risk of operational disruptions. -

Voltage Rating

– Definition: The voltage rating specifies the electrical input required for the motor to function correctly.

– Importance: Understanding voltage requirements is vital for ensuring the motor operates efficiently within the electrical infrastructure of your facility, especially in regions with varying electrical standards. -

Enclosure Type

– Definition: The enclosure type indicates the environmental protection level of the motor (e.g., open, closed, or explosion-proof).

– Importance: Selecting the appropriate enclosure helps protect the motor from dust, moisture, and other hazardous conditions, which is especially important in industrial settings. -

Insulation Class

– Definition: This specifies the temperature rating of the motor’s insulation materials.

– Importance: Knowing the insulation class helps in determining the motor’s longevity and reliability under varying thermal conditions, which is critical in high-temperature applications.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that manufactures products that are then marketed by another company.

– Relevance: Understanding the distinction between OEM parts and generic alternatives can influence the quality and reliability of the motors you procure. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Relevance: Knowing the MOQ helps buyers manage inventory levels and negotiate better terms, especially when planning for bulk purchases. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers asking for a price quote for a specific quantity of goods or services.

– Relevance: Utilizing RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring competitive pricing and better decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in shipping contracts.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, facilitating smoother international transactions. -

Lead Time

– Definition: The time it takes from placing an order until the goods are delivered.

– Relevance: Understanding lead times is essential for planning production schedules and avoiding delays in operations. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the performance and longevity of the motor.

– Relevance: Knowledge of warranty terms can provide peace of mind and financial protection against potential defects or failures.

By grasping these technical specifications and trade terms, B2B buyers can make more informed decisions, ensuring they select the right agitation motors for their specific needs while navigating the complexities of international sourcing effectively.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the agitation motor Sector

Market Overview & Key Trends

The agitation motor sector is experiencing significant growth driven by several global factors. Key among these is the increasing demand for automation and efficiency across various industries, including chemical processing, food and beverage, and pharmaceuticals. As industries seek to improve operational efficiencies, the need for reliable and high-performance agitation motors has surged. Furthermore, the rise of Industry 4.0 technologies, such as IoT and smart manufacturing, is influencing sourcing trends, pushing buyers to seek motors that not only meet traditional performance metrics but also integrate seamlessly with advanced digital systems.

In terms of sourcing trends, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are moving towards more data-driven decision-making processes. This includes leveraging predictive analytics to forecast motor performance and lifespan, thus reducing downtime and maintenance costs. Additionally, there is a noticeable shift towards vendor consolidation; buyers prefer to establish long-term relationships with fewer suppliers who can provide comprehensive solutions, including installation, maintenance, and support services.

Market dynamics are also influenced by regional considerations. For instance, buyers in Europe are increasingly focused on energy efficiency and regulatory compliance, while those in Africa and South America may prioritize cost-effectiveness and adaptability to local conditions. Understanding these regional nuances is crucial for buyers to make informed sourcing decisions that align with their specific operational needs.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a vital consideration in the sourcing of agitation motors. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, pushing companies to adopt greener practices. For B2B buyers, this translates into a demand for motors that are not only energy-efficient but also produced using sustainable materials and methods.

Ethical sourcing is equally important; buyers are increasingly aware of the social implications of their procurement decisions. This includes ensuring that suppliers adhere to fair labor practices and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are critical indicators of a supplier’s commitment to sustainability and ethical practices.

Incorporating ‘green’ certifications into the sourcing process not only helps mitigate environmental impact but also enhances brand reputation. B2B buyers should seek suppliers who can provide transparency in their supply chains, showcasing their commitment to sustainable practices. This not only aligns with global sustainability goals but also meets the growing consumer demand for ethically sourced products.

Brief Evolution/History

The agitation motor sector has evolved significantly over the past few decades, driven by advancements in technology and changing market demands. Initially, motors were primarily mechanical devices with limited functionality. However, the introduction of electronic controls and variable frequency drives (VFDs) has transformed agitation motors into sophisticated systems capable of precise control over speed and torque.

This evolution has been particularly beneficial for industries requiring consistent mixing and stirring processes, such as chemicals and food production. As industries have become more automated, the integration of agitation motors with smart technology has allowed for real-time monitoring and optimization of processes, further enhancing efficiency and reliability. Understanding this historical context is essential for B2B buyers aiming to select motors that meet contemporary operational challenges and future-proof their investments.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of agitation motor

-

What key factors should I consider when vetting suppliers for agitation motors?

When vetting suppliers, prioritize their industry reputation, experience, and certifications. Check for ISO certifications, which indicate quality management standards. Additionally, evaluate their customer service responsiveness and after-sales support. Request references from previous clients, particularly those in your region or industry, to assess reliability. Don’t hesitate to conduct site visits if feasible, as this can provide insight into their manufacturing capabilities and operational practices. -

Can agitation motors be customized to fit specific applications?

Yes, many suppliers offer customization options for agitation motors. This can include adjustments to speed, torque, and mounting configurations to suit particular mixing processes. When discussing customization, be clear about your application requirements and any constraints, such as space limitations or environmental conditions. Engaging early in the design process can ensure that the final product meets your operational needs without significant delays.

-

What are the typical minimum order quantities (MOQs) and lead times for agitation motors?

MOQs can vary significantly based on the supplier and the specific motor configuration. Generally, custom orders may require higher MOQs, often starting from 5 to 10 units, while standard models might have lower MOQs. Lead times typically range from 4 to 12 weeks, depending on customization and supplier location. It’s crucial to discuss these factors upfront to align your procurement timeline with your operational requirements. -

What payment terms should I expect when sourcing agitation motors internationally?

Payment terms can vary by supplier and region but typically include options such as upfront deposits (20-50%) and balance payment upon shipment or delivery. Some suppliers might offer letters of credit for larger transactions, providing additional security. Always clarify payment methods accepted (e.g., bank transfers, credit cards) and be aware of any additional fees that might arise from currency conversion or international transactions. -

How can I ensure quality assurance and certification compliance for my agitation motors?

To ensure quality assurance, request detailed specifications and test reports from your supplier. Look for motors that meet international standards such as CE marking in Europe or UL certification in North America. Ask about the supplier’s quality control processes, including testing protocols and inspection procedures. Establishing a clear agreement on quality expectations before production starts can help mitigate potential issues later on. -

What logistics considerations should I keep in mind when sourcing agitation motors?

Logistics play a critical role in international sourcing. Consider the shipping methods available (air freight vs. sea freight), as this can significantly impact delivery time and cost. Be aware of import regulations and potential tariffs in your country, which could affect overall expenses. Collaborating with a reliable freight forwarder can streamline the shipping process and ensure compliance with all necessary documentation.

Illustrative Image (Source: Google Search)

-

How can I handle disputes with suppliers effectively?

To manage disputes effectively, establish clear communication channels and maintain thorough documentation of all agreements and correspondence. If issues arise, address them promptly through direct discussions with the supplier. If resolution proves difficult, consider mediation or arbitration as a next step, as these methods can be less adversarial than litigation. Ensure that any dispute resolution mechanisms are outlined in your contract to provide a clear path forward. -

What should I do if the agitation motor does not meet performance expectations upon delivery?

Upon receiving the motor, conduct thorough testing to verify performance against agreed specifications. If discrepancies are found, document the issues clearly and reach out to the supplier immediately. Most reputable suppliers will have a warranty or return policy in place to address such situations. Be prepared to provide evidence of the performance issues, and engage in discussions for possible replacements or repairs under warranty terms.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for agitation motor

In navigating the complexities of sourcing agitation motors, international B2B buyers must prioritize strategic decision-making to ensure optimal outcomes. Key takeaways from this guide emphasize the importance of understanding both electrical and mechanical specifications, alongside the operational context of each motor. Utilizing a structured sourcing process—starting with a clear assessment of needs and thorough data collection—can significantly mitigate risks associated with poor procurement decisions.

Value of Strategic Sourcing

Investing time in strategic sourcing not only enhances the reliability and efficiency of operations but also fosters long-term supplier relationships that can provide ongoing support and innovation. Buyers are encouraged to leverage vendor expertise, utilize historical data, and assess installation requirements comprehensively to avoid common pitfalls.

Looking Ahead

As markets evolve and demand for efficient mixing solutions grows, the need for adaptable and high-quality agitation motors becomes increasingly critical. B2B buyers in Africa, South America, the Middle East, and Europe should proactively engage with suppliers, seeking tailored solutions that align with their specific operational challenges. By embracing these practices, businesses can position themselves for success in an increasingly competitive landscape.