Master the Art of Sourcing Alternating Motors for Enhanced

Introduction: Navigating the Global Market for alternating motor

In the rapidly evolving industrial landscape, alternating motors play a pivotal role in powering a wide array of applications across various sectors, from manufacturing to energy generation. These motors are not just components; they are essential for enhancing operational efficiency, reducing energy costs, and driving innovation. For international B2B buyers, especially those based in Africa, South America, the Middle East, and Europe, understanding the nuances of alternating motors is crucial for making informed sourcing decisions.

This comprehensive guide delves deep into the world of alternating motors, providing insights into different types, including induction and synchronous motors, as well as their materials, manufacturing processes, and quality control measures. Additionally, it explores supplier selection criteria, cost considerations, and emerging market trends, equipping buyers with the necessary tools to navigate the global marketplace effectively.

With an emphasis on energy efficiency and sustainability, this guide highlights the importance of selecting the right motor to not only meet operational needs but also comply with global standards and regulations. By leveraging the knowledge presented here, businesses can optimize their procurement strategies, enhance productivity, and achieve a competitive edge in their respective markets. Whether you are sourcing for a new project or seeking to upgrade existing systems, this guide serves as an invaluable resource for making strategic, informed decisions in the complex world of alternating motors.

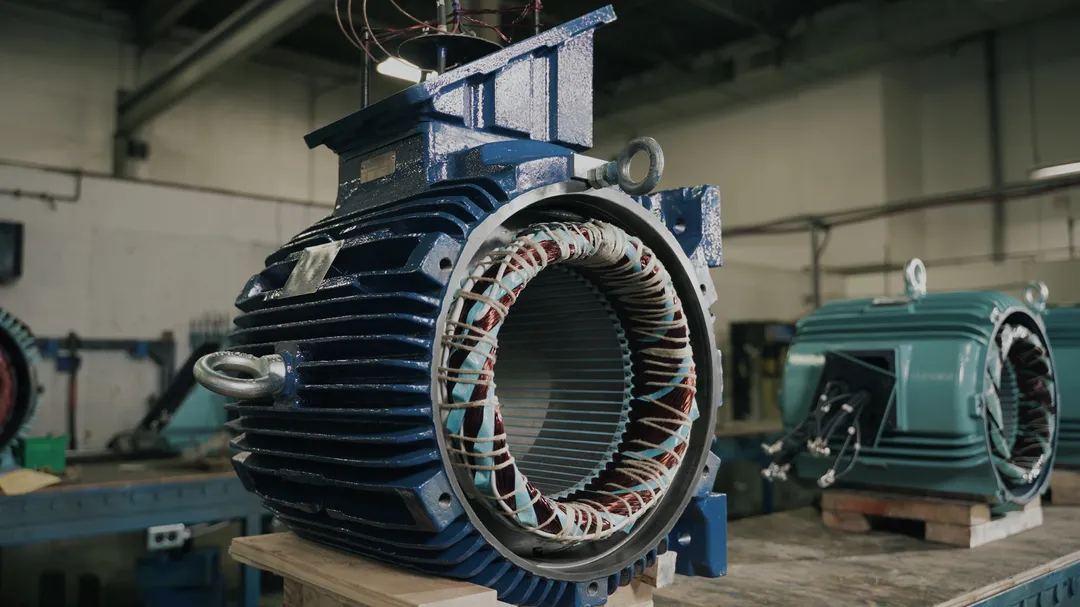

Illustrative Image (Source: Google Search)

Understanding alternating motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Motor | Operates on electromagnetic induction, typically robust | Manufacturing, HVAC systems | Pros: Low cost, minimal maintenance; Cons: Limited speed control, lower starting torque. |

| Synchronous Motor | Rotates at a speed directly proportional to supply frequency | Robotics, precision machinery | Pros: High efficiency, precise speed control; Cons: Complex starting mechanisms, higher initial cost. |

| Permanent Magnet Motor | Utilizes permanent magnets for rotor magnetization | Electric vehicles, industrial drives | Pros: High efficiency, compact size; Cons: Higher material costs, sensitive to temperature. |

| Switched Reluctance Motor | Operates on the principle of reluctance torque | Automotive applications, robotics | Pros: Simple construction, high torque density; Cons: Noise and vibration issues, complex control. |

| Double-Squirrel Cage Motor | Features two rotor windings for improved performance | Heavy machinery, industrial fans | Pros: High starting torque, better speed regulation; Cons: More complex design, higher cost. |

Induction Motor

Induction motors are the backbone of many industrial applications due to their robustness and simplicity. They operate without brushes, which reduces maintenance needs and enhances reliability. Commonly found in manufacturing and HVAC systems, these motors are cost-effective solutions. When purchasing, buyers should evaluate the specific torque and speed requirements of their applications, as induction motors typically have lower starting torque and limited speed control compared to other motor types.

Synchronous Motor

Synchronous motors are known for their ability to maintain a constant speed that is synchronized with the supply frequency. This makes them ideal for applications requiring precise speed control, such as robotics and precision machinery. While they offer high efficiency, the complexity of their starting mechanisms and higher initial costs may deter some buyers. For businesses focusing on energy efficiency and precise operations, investing in synchronous motors can yield significant long-term benefits.

Permanent Magnet Motor

Permanent magnet motors utilize permanent magnets for rotor magnetization, resulting in high efficiency and compact designs. They are increasingly used in electric vehicles and various industrial drives. While they offer significant performance advantages, the higher material costs and sensitivity to temperature can be drawbacks. Buyers should consider the application’s requirements for efficiency and size when evaluating permanent magnet motors.

Switched Reluctance Motor

Switched reluctance motors operate based on the principle of reluctance torque, making them a simple and cost-effective option for various applications, including automotive and robotics. Their construction is straightforward, leading to high torque density. However, they can produce noise and vibrations, which may be a concern in sensitive applications. Buyers should weigh the benefits of simplicity and cost against the potential downsides of noise and control complexity.

Double-Squirrel Cage Motor

Double-squirrel cage motors are designed with two rotor windings, enhancing performance in heavy-duty applications such as industrial fans and heavy machinery. They provide high starting torque and better speed regulation compared to standard induction motors. However, their more complex design and higher costs may be a consideration for budget-conscious buyers. When evaluating these motors, businesses should assess their specific operational needs against the benefits of improved performance.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of alternating motor

| Industry/Sector | Specific Application of Alternating Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Improved efficiency and reduced downtime | Supplier reliability, motor durability, and maintenance support |

| HVAC Systems | Air Conditioning Units | Energy efficiency and consistent performance | Energy ratings, compliance with local regulations, and service availability |

| Agriculture | Irrigation Pumps | Enhanced productivity and water management | Sourcing for energy-efficient models and local support for maintenance |

| Mining | Crusher Drives | Increased operational efficiency and reduced costs | Motor power ratings, environmental resistance, and service response time |

| Transportation | Electric Trains | Reduced emissions and operational costs | Supplier certifications, compatibility with existing systems, and warranty terms |

Manufacturing: Conveyor Systems

In the manufacturing sector, alternating motors are extensively used in conveyor systems to facilitate the movement of materials and products. These motors enhance operational efficiency by ensuring smooth and continuous transport, reducing downtime associated with manual handling. Buyers in this sector should prioritize sourcing reliable suppliers who can provide durable motors with adequate torque specifications to meet the demands of their specific applications. Additionally, maintenance support is crucial to minimize disruptions in production.

HVAC Systems: Air Conditioning Units

Alternating motors play a vital role in HVAC systems, particularly in air conditioning units where they drive compressors and fans. The efficiency of these motors directly impacts energy consumption, making it essential for businesses to select models that comply with energy efficiency standards. International buyers, especially from regions with stringent regulations, should consider the energy ratings of motors and ensure that suppliers can provide localized support for installation and maintenance to ensure optimal performance.

Agriculture: Irrigation Pumps

In agriculture, alternating motors are commonly employed in irrigation pumps to facilitate water distribution across fields. These motors significantly enhance productivity by automating irrigation processes, ensuring timely water delivery to crops. Buyers should focus on sourcing energy-efficient models that can operate effectively under varying load conditions. Additionally, considering the local availability of parts and maintenance services is crucial for minimizing downtime during critical growing seasons.

Mining: Crusher Drives

The mining industry utilizes alternating motors in crusher drives to process raw materials efficiently. These motors enable high torque and power output necessary for crushing operations, which are essential for material extraction and processing. Buyers in this sector must consider the power ratings and environmental resistance of motors to withstand harsh operating conditions. Quick response times for service and repairs are also critical to maintaining continuous operations and minimizing production losses.

Transportation: Electric Trains

In the transportation sector, alternating motors are pivotal in electric trains, providing the necessary propulsion while minimizing emissions compared to traditional diesel engines. These motors contribute to significant operational cost savings and are increasingly favored in sustainable transport initiatives. Buyers should ensure that the motors they source are compatible with existing systems and come from certified suppliers who can provide warranties and support, thus ensuring long-term reliability and performance.

Related Video: How alternating current motors work?

Strategic Material Selection Guide for alternating motor

When selecting materials for alternating motors, international B2B buyers must consider various factors that affect performance, durability, and cost. Below is an analysis of four common materials used in the construction of alternating motors, along with their properties, advantages, disadvantages, and specific considerations for buyers from diverse regions.

1. Copper

Key Properties: Copper is known for its excellent electrical conductivity, thermal conductivity, and resistance to corrosion. It typically operates effectively within a temperature range of -200°C to 300°C.

Pros & Cons: The primary advantage of copper is its high conductivity, which enhances motor efficiency and performance. However, copper is relatively expensive compared to alternatives like aluminum, and its manufacturing process can be complex, requiring careful handling to avoid oxidation.

Impact on Application: Copper’s superior conductivity makes it ideal for windings in motors, where efficient energy transfer is crucial. However, its weight can be a consideration in applications where weight reduction is a priority.

Considerations for International Buyers: Buyers must ensure compliance with international standards like ASTM B170 for copper wire. In regions like Europe and the Middle East, where energy efficiency is emphasized, copper’s performance advantages align well with regulatory requirements.

2. Aluminum

Key Properties: Aluminum offers good electrical conductivity, is lightweight, and has excellent corrosion resistance. It typically operates effectively at temperatures up to 150°C.

Pros & Cons: The lightweight nature of aluminum is a significant advantage, making it suitable for applications where weight is a critical factor. However, its conductivity is lower than that of copper, which may impact efficiency. Additionally, aluminum can be more susceptible to mechanical wear and tear compared to copper.

Impact on Application: Aluminum is often used in motor housings and frames, where weight savings can lead to more efficient designs. Its corrosion resistance is beneficial in humid or corrosive environments.

Considerations for International Buyers: Buyers should be aware of standards such as ASTM B221 for aluminum extrusions. In regions like Africa and South America, where cost sensitivity is higher, aluminum’s lower price point can be appealing, but buyers must balance this with performance needs.

3. Steel

Key Properties: Steel is known for its strength, durability, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 600°C, depending on the alloy.

Pros & Cons: The primary advantage of steel is its mechanical strength, making it suitable for heavy-duty applications. However, steel is heavier than other materials, which can be a disadvantage in applications requiring lightweight components. Additionally, it may require coatings to prevent corrosion.

Impact on Application: Steel is commonly used in motor frames and shafts, where strength and durability are paramount. Its ability to handle high torque loads makes it ideal for industrial applications.

Considerations for International Buyers: Compliance with standards such as DIN 17100 is essential for steel components. In Europe, buyers may also need to consider environmental regulations regarding the use of certain steel grades.

4. Insulation Materials (e.g., PVC, Epoxy)

Key Properties: Insulation materials like PVC and epoxy are crucial for electrical insulation, withstanding temperatures typically up to 200°C. They also provide resistance to moisture and chemicals.

Pros & Cons: These materials are relatively low-cost and easy to manufacture, providing effective insulation for motor windings. However, they may degrade over time under extreme conditions, affecting motor longevity.

Impact on Application: Proper insulation is vital for preventing electrical shorts and enhancing motor safety. The choice of insulation material can significantly influence the motor’s operational lifespan and efficiency.

Considerations for International Buyers: Buyers should ensure that insulation materials meet standards such as UL 94 for flammability. In regions with strict electrical safety regulations, such as the EU, compliance with relevant directives is crucial.

Summary Table

| Material | Typical Use Case for alternating motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings | High electrical conductivity | High cost, complex manufacturing | High |

| Aluminum | Motor housings and frames | Lightweight, good corrosion resistance | Lower conductivity than copper | Medium |

| Steel | Frames and shafts | High strength and durability | Heavier, may require corrosion coatings | Medium |

| Insulation Materials | Electrical insulation for windings | Effective insulation, low cost | Potential degradation under extremes | Low |

This guide provides a comprehensive overview of material selection for alternating motors, emphasizing the need for international B2B buyers to align their choices with performance requirements, regulatory standards, and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for alternating motor

In the competitive landscape of international B2B sourcing, understanding the manufacturing processes and quality assurance measures for alternating motors is crucial for buyers. This section provides a detailed overview of the typical manufacturing stages and the quality control practices that ensure product reliability and performance.

Manufacturing Processes for Alternating Motors

The manufacturing of alternating motors involves several critical stages, each requiring specific techniques and materials. Below is a breakdown of the main stages of the manufacturing process:

1. Material Preparation

The first step in manufacturing alternating motors is the preparation of raw materials. Common materials used include:

– Copper: Essential for windings due to its excellent conductivity.

– Steel and Aluminum: Used for the motor frame and rotor, chosen for their strength and lightweight properties.

– Insulation Materials: These are critical for electrical safety and performance.

The selection of high-quality materials is vital, as it directly impacts the motor’s efficiency and lifespan. B2B buyers should inquire about the sourcing and quality of these materials from suppliers.

2. Forming

This stage involves shaping the prepared materials into components. Key techniques include:

– Stamping: Used to create the stator and rotor laminations, which reduce energy losses.

– Winding: Copper wire is wound around the stator to form the electromagnetic coils. This can be done using automated machines for precision.

– Casting: Some components, like the motor housing, may be created through casting processes to achieve complex shapes.

Precision in forming ensures that all components fit correctly, which is crucial for the motor’s performance.

3. Assembly

Once components are formed, they are assembled into the final motor structure. This involves:

– Mounting the Stator and Rotor: Components are aligned and secured within the motor housing.

– Electrical Connections: Ensuring that all electrical connections are properly made and insulated.

– Quality Checks: During assembly, initial quality checks (IPQC) should occur to catch any defects early.

A well-structured assembly line enhances efficiency and reduces the likelihood of errors.

4. Finishing

The finishing stage includes several processes that enhance the motor’s durability and performance:

– Surface Treatment: Processes like painting or powder coating protect against corrosion.

– Balancing: The rotor is balanced to minimize vibrations during operation.

– Final Testing: Each motor undergoes final quality control tests before packaging.

Finishing processes not only improve aesthetics but also extend the operational life of the motor.

Quality Assurance Measures

Quality assurance is a critical aspect of manufacturing alternating motors, ensuring that products meet international standards and customer expectations.

International Standards

B2B buyers should be aware of the relevant international standards that manufacturers must adhere to:

– ISO 9001: Focuses on quality management systems and continuous improvement.

– IEC Standards: International Electrotechnical Commission standards ensure safety and performance in electrical devices.

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

These certifications are essential for ensuring that the motors meet global quality benchmarks.

Quality Control Checkpoints

Effective quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing checks during production to identify and rectify issues immediately.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all specifications.

These checkpoints help maintain high-quality standards throughout the manufacturing cycle.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of alternating motors:

– Electrical Testing: Measures resistance, insulation, and current draw.

– Mechanical Testing: Assesses physical integrity and performance under load.

– Vibration Analysis: Detects imbalances and potential issues in motor operation.

B2B buyers should request detailed reports on these tests from suppliers to ensure compliance with quality standards.

Verifying Supplier Quality Control

To ensure that suppliers adhere to quality control standards, buyers can implement several verification strategies:

- Supplier Audits: Conducting on-site audits of manufacturing facilities helps buyers assess the quality management processes in place.

- Requesting Quality Reports: Suppliers should provide documentation of quality tests and certifications, offering transparency regarding their practices.

- Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the manufacturing process and quality assurance measures.

These steps are particularly important for international buyers, as they mitigate risks associated with sourcing from different regions.

Quality Control Considerations for International Buyers

For buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Consider the following:

- Regulatory Compliance: Ensure that the supplier’s products comply with local regulations in the buyer’s region, which may differ from those in the supplier’s country.

- Cultural Differences: Be aware of potential cultural differences in business practices and quality expectations.

- Supply Chain Transparency: Demand transparency throughout the supply chain to ensure that all components meet quality standards.

By focusing on these areas, international B2B buyers can enhance their sourcing strategy for alternating motors, ensuring that they receive high-quality products that meet their operational needs.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for alternating motor Sourcing

Navigating the cost structure and pricing landscape for alternating motors is essential for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. A clear understanding of the various cost components, pricing influencers, and strategic buyer tips can significantly impact sourcing decisions and overall profitability.

Cost Components

-

Materials: The primary cost driver in motor manufacturing, materials such as copper, steel, and specialized electronic components account for a significant portion of the total expense. Premium materials like stainless steel or high-grade magnets can elevate costs, while opting for standard materials may result in savings.

-

Labor: Labor costs vary by region, influenced by local wage rates and the availability of skilled workers. High labor costs in developed countries can lead to increased prices, whereas countries with lower wages may offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and general administrative expenses. Efficient manufacturing processes and technological advancements can help reduce overhead, which can be beneficial for pricing strategies.

-

Tooling: The initial investment in tooling is crucial for motor production, particularly for custom designs. Buyers should consider these costs in their total investment, especially if they require unique specifications.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with industry standards. While this adds to manufacturing costs, it can lead to long-term savings by reducing defects and returns.

-

Logistics: Shipping and transportation costs can fluctuate based on distance, mode of transport, and fuel prices. For international buyers, understanding Incoterms is vital to determining who bears these costs and risks.

-

Margin: Suppliers typically apply a margin on top of the manufacturing costs, which can vary widely. Factors such as brand reputation, market demand, and exclusivity of the product can influence margin levels.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to better pricing. Buyers should assess their needs and negotiate accordingly to achieve favorable terms.

-

Specifications/Customization: Custom motors tailored to specific applications typically cost more. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Materials and Quality Certifications: Motors that meet higher quality standards or certifications (like ISO or IEC) may command a premium. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: Established suppliers may offer better reliability and service, potentially justifying higher prices. However, newer suppliers might provide competitive pricing to gain market share.

-

Incoterms: Understanding the implications of different Incoterms can help buyers manage costs effectively. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who is responsible for shipping and insurance, impacting overall expenses.

Buyer Tips

-

Negotiation: Always be prepared to negotiate prices and terms. Leverage market research to support your position and explore multiple suppliers to enhance your bargaining power.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the upfront price. Consider long-term savings from energy-efficient motors and lower maintenance costs.

-

Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes, which can affect the final cost. Consider these factors in your budgeting.

-

Supplier Relationships: Build strong relationships with suppliers to improve communication and potentially secure better pricing and terms over time.

Disclaimer

The indicative prices for electric motors can range widely based on the factors mentioned. Small to medium-sized motors may fall between USD 100 and USD 500, while industrial-grade motors can exceed several thousand dollars. Always request detailed quotes and clarify pricing components to ensure transparency in your sourcing decisions.

Spotlight on Potential alternating motor Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘alternating motor’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for alternating motor

Key Technical Properties of Alternating Motors

Understanding the essential technical properties of alternating motors is crucial for international B2B buyers. Here are some critical specifications that influence purchasing decisions:

-

Material Grade

– Definition: The quality of materials used in motor construction, including steel, copper, and insulation materials.

– Importance: Higher-grade materials enhance durability and efficiency, leading to lower maintenance costs and longer operational lifespans. Buyers should consider the material grade based on their operational environment and required longevity. -

Power Rating

– Definition: The maximum power output that the motor can handle, typically expressed in horsepower (HP) or kilowatts (kW).

– Importance: Selecting a motor with the correct power rating is essential for ensuring adequate performance in specific applications. Underpowered motors may fail prematurely, while overpowered units can lead to unnecessary energy costs. -

Efficiency Class

– Definition: A classification that indicates the energy efficiency of the motor, often categorized as IE1, IE2, IE3, or IE4.

– Importance: Higher efficiency motors reduce energy consumption, aligning with global sustainability goals and lowering operational costs. For buyers, investing in efficient motors can lead to significant long-term savings and compliance with environmental regulations. -

Torque

– Definition: The rotational force produced by the motor, usually measured in Newton-meters (Nm).

– Importance: Understanding the torque requirements for specific applications is vital. Motors with insufficient torque can lead to performance issues, while those with excessive torque may result in mechanical failures. -

Voltage Rating

– Definition: The electrical voltage required for the motor to operate effectively, commonly 230V or 400V for industrial applications.

– Importance: Ensuring that the motor’s voltage rating matches the available power supply is critical. Mismatches can lead to inefficiencies or equipment damage, impacting production schedules. -

Tolerance

– Definition: The allowable deviation from specified dimensions or performance metrics.

– Importance: Tolerances affect the interchangeability of parts and overall motor performance. Tight tolerances may be necessary for high-precision applications, influencing both cost and manufacturing complexity.

Common Trade Terminology in the Alternating Motor Industry

Navigating the technical landscape of alternating motors involves familiarity with key industry terms. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces components or equipment that may be marketed by another manufacturer.

– Importance: Buyers often engage with OEMs for quality assurance and compatibility in motor applications. Understanding OEM relationships can facilitate better sourcing decisions. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess whether a supplier’s offerings align with their project needs, especially for bulk purchases or new product development. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products or services.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, ensuring they receive the best value for their procurement. -

Incoterms (International Commercial Terms)

– Definition: A set of standardized terms defining the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms is essential for understanding shipping costs, insurance, and risk during transportation. Proper use of these terms can prevent costly misunderstandings. -

VFD (Variable Frequency Drive)

– Definition: An electronic device that controls the speed and torque of an AC motor by varying the frequency and voltage of the power supplied.

– Importance: VFDs enhance the efficiency and performance of motors, especially in applications requiring variable speeds. Buyers should consider VFD compatibility to optimize motor operations. -

NEMA (National Electrical Manufacturers Association) Standards

– Definition: A set of standards for electrical equipment, including motors, in the United States.

– Importance: Compliance with NEMA standards ensures that motors meet specific performance and safety criteria, essential for regulatory compliance and operational reliability.

By understanding these technical properties and industry terminology, international B2B buyers can make informed decisions that optimize their operations and align with their strategic objectives.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the alternating motor Sector

Global drivers in the alternating motor sector are significantly shaped by technological advancements, sustainability mandates, and changing consumer preferences. The push towards Industry 4.0 is fostering an increasing demand for smart motors equipped with IoT capabilities, enabling better monitoring and efficiency. Furthermore, the rise of electric vehicles (EVs) and automation in manufacturing processes has spurred growth in the motor market, particularly for brushless DC motors. Buyers should note that regions like Africa and South America are witnessing rapid industrialization, leading to a burgeoning demand for reliable motor solutions that enhance productivity and reduce operational costs.

Emerging trends include a shift towards energy-efficient motors, driven by regulations such as the EU Ecodesign Directive, which mandates energy consumption reduction. B2B buyers should prioritize suppliers who offer IE4 and IE3 rated motors, as these provide significant energy savings over their less efficient counterparts. Additionally, the adoption of Variable Frequency Drives (VFDs) is becoming commonplace, allowing for improved motor control and energy efficiency. For buyers in the Middle East and Europe, engaging with suppliers that integrate these technologies can lead to substantial long-term cost reductions and enhanced operational performance.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

The environmental impact of alternating motors is a critical consideration for B2B buyers. The manufacturing of electric motors typically involves materials such as copper, steel, and rare earth elements, which can have significant ecological footprints. To mitigate these impacts, companies must prioritize ethical sourcing practices, ensuring that raw materials are obtained from suppliers who adhere to sustainable mining and production methods.

The importance of ‘green’ certifications cannot be overstated. Buyers should look for suppliers who offer products certified by recognized bodies, such as the Global Environmental Management Initiative (GEMI) or those meeting ISO 14001 standards. These certifications indicate a commitment to minimizing environmental impact throughout the product lifecycle. Additionally, utilizing recyclable materials in the manufacturing of alternating motors not only reduces waste but also supports a circular economy. By choosing suppliers who prioritize sustainability, businesses can enhance their brand reputation and align with consumer demand for environmentally responsible products.

Brief Evolution/History

The evolution of alternating motors dates back to the late 19th century with the advent of alternating current (AC) systems. Initially, AC motors were limited by the technology of the time, but advancements in electromagnetic design and materials in the mid-20th century significantly enhanced their efficiency and applications. The introduction of synchronous and induction motors allowed for widespread adoption in various sectors, including manufacturing and HVAC. Over the past few decades, innovations such as brushless DC motors and smart technologies have revolutionized the sector, enabling higher efficiency and integration with modern automation systems. Understanding this historical context is vital for B2B buyers, as it highlights the continuous improvement and the future potential of alternating motor technologies.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of alternating motor

-

How can I effectively vet suppliers for alternating motors?

Vetting suppliers for alternating motors involves assessing their manufacturing capabilities, quality control processes, and industry reputation. Start by checking certifications such as ISO 9001 or specific motor-related standards. Engage in direct communication to gauge their responsiveness and willingness to provide technical details. Request references from past clients, especially those in similar industries or regions. Additionally, consider visiting their facilities if feasible, or use third-party inspection services to ensure compliance with your standards. -

Can alternating motors be customized to meet specific requirements?

Yes, many manufacturers offer customization options for alternating motors to meet specific application needs. Customizations can include adjustments in power ratings, dimensions, mounting configurations, and even specific materials for harsh environments. When seeking custom solutions, clearly articulate your requirements and expected performance metrics. Ensure the supplier has a track record of successful custom projects, and discuss lead times and potential cost implications upfront. -

What are the typical minimum order quantities (MOQ) and lead times for alternating motors?

Minimum order quantities for alternating motors can vary significantly based on the supplier and the type of motor. Generally, MOQs can range from a single unit for standard models to several dozen for custom orders. Lead times typically range from 4 to 12 weeks, depending on the complexity of the order and the supplier’s production schedule. Always confirm these details before placing an order and inquire about expedited options if urgent delivery is necessary. -

What quality assurance measures should I expect from suppliers?

Quality assurance measures vary by supplier but should include comprehensive testing protocols before shipment. Expect documentation of quality checks such as performance testing, thermal imaging, and vibration analysis. Additionally, inquire about compliance with international standards like IEC or NEMA. Suppliers should also provide certifications for raw materials used in manufacturing. A robust QA process not only ensures product reliability but also reduces the likelihood of disputes post-purchase. -

What payment options are typically available when sourcing alternating motors?

Payment options for alternating motors often include bank transfers, letters of credit, and payment platforms like PayPal. The choice of payment method may depend on the supplier’s policies and the transaction amount. For larger orders, letters of credit can provide security for both parties. Ensure that payment terms are clearly defined in the contract, including any advance payments, installment plans, or conditions for releasing payments upon delivery or inspection. -

How can I ensure smooth logistics and shipping for my order?

To ensure smooth logistics, collaborate closely with your supplier to establish clear shipping terms. Discuss preferred shipping methods, incoterms (like FOB or CIF), and estimated delivery times. Prepare for customs clearance by ensuring all necessary documentation, such as invoices and certificates of origin, is accurate and complete. Additionally, consider engaging a freight forwarder who specializes in international shipments to navigate potential challenges and streamline the logistics process. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, the first step is to communicate directly with the supplier to address the issue amicably. Document all correspondence and agreements to provide a clear record of the situation. If informal resolution fails, refer to the contract for dispute resolution clauses, which may include mediation or arbitration. Engaging legal counsel familiar with international trade laws can also be beneficial. Always aim for a resolution that maintains the business relationship while protecting your interests. -

Are there specific certifications I should look for in alternating motors?

Yes, when sourcing alternating motors, look for certifications that demonstrate compliance with international standards. Relevant certifications include ISO 9001 for quality management, CE marking for European markets, and UL certification for safety standards. Additionally, energy efficiency certifications such as IE3 or IE4 can indicate superior performance and compliance with environmental regulations. These certifications not only assure quality but can also enhance your company’s sustainability profile in the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for alternating motor

In conclusion, strategic sourcing of alternating motors is essential for international B2B buyers aiming to enhance operational efficiency and sustainability. As the demand for energy-efficient solutions grows, understanding the various types of motors—such as induction, synchronous, and brushless DC—enables businesses to align their procurement strategies with their specific applications and goals. Key takeaways for buyers include the importance of evaluating supplier capabilities, focusing on quality materials, and considering the total cost of ownership rather than just initial pricing.

Moreover, the current market landscape underscores the significance of energy-efficient motors, particularly in light of regulatory pressures and sustainability initiatives across regions like Africa, South America, the Middle East, and Europe. As you navigate this evolving market, prioritize partnerships with reputable suppliers who demonstrate transparency and reliability in their offerings.

Looking ahead, the landscape for alternating motors will continue to shift with advancements in technology and increased focus on sustainability. Embrace these changes by leveraging strategic sourcing practices to not only meet today’s demands but also position your business for future growth. Take action now—explore your options, engage with suppliers, and invest in the right motor solutions that will drive your success in the competitive global marketplace.