Master the Art of Sourcing Hydraulic Lifr: Essential

Introduction: Navigating the Global Market for hydraulic lifr

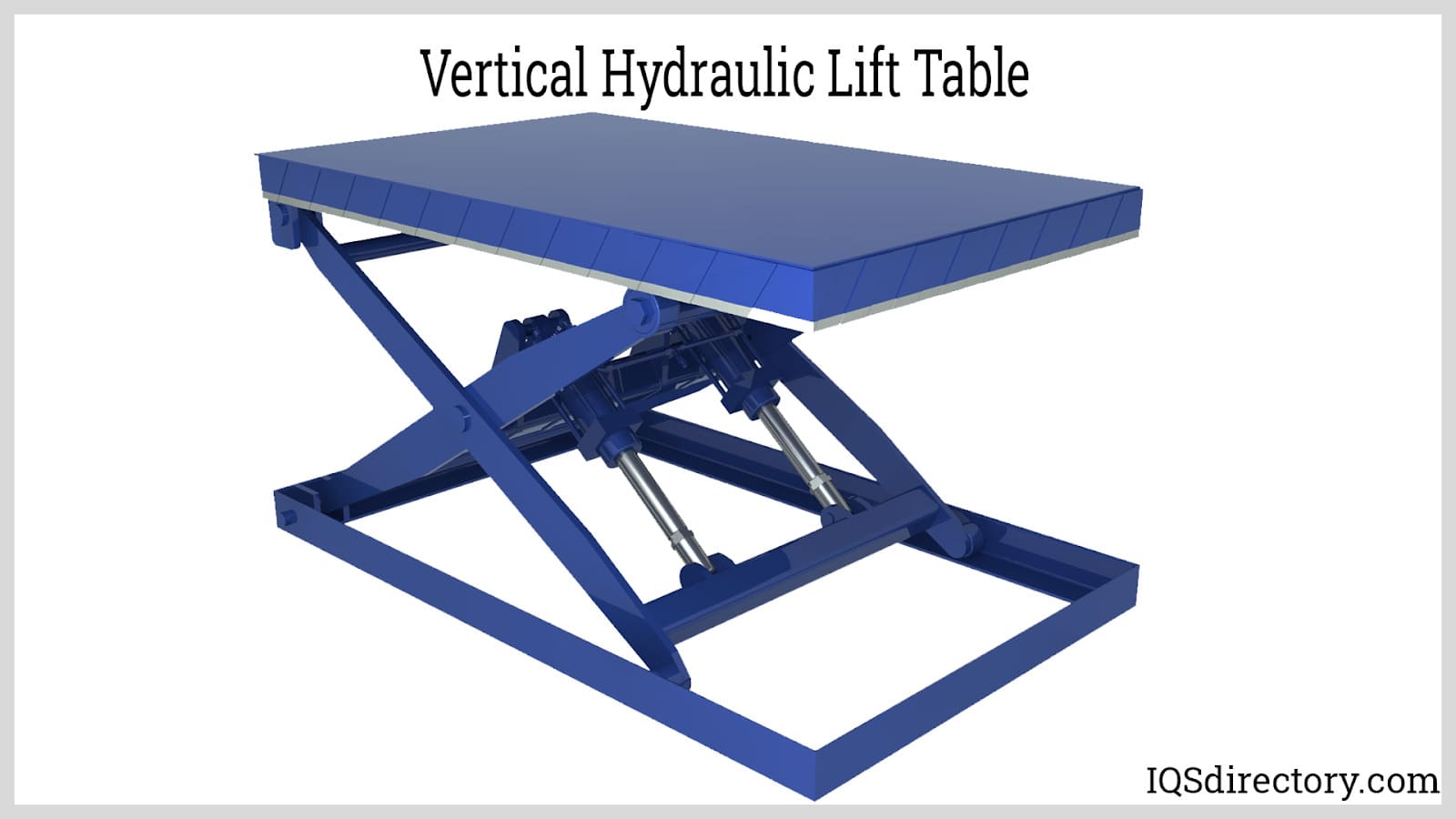

In today’s dynamic global market, understanding the intricacies of hydraulic lift systems is essential for international B2B buyers. Hydraulic lifts are pivotal in various industries, including manufacturing, construction, and logistics, where they facilitate the efficient movement of goods and personnel. The Line Item Fill Rate (LIFR) is a critical metric that helps businesses gauge the efficiency of their supply chain, ensuring that they receive the exact components needed, on time, and in full. This guide is designed to empower buyers by providing a comprehensive overview of hydraulic lifts, from the diverse types and materials available to insights into manufacturing processes, quality control measures, and cost considerations.

Navigating the complexities of sourcing hydraulic lifts can be daunting, especially for buyers from Africa, South America, the Middle East, and Europe. Therefore, this guide outlines key factors such as supplier evaluation, market trends, and FAQs that are crucial for informed decision-making. By leveraging this information, businesses can streamline their procurement processes, optimize their supply chains, and ultimately enhance their operational efficiency.

Whether you’re looking to expand your supplier network or seeking to understand the latest innovations in hydraulic technology, this resource serves as a strategic tool to navigate the global market effectively. With actionable insights at your fingertips, you can make confident sourcing decisions that align with your business objectives.

Understanding hydraulic lifr Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Mechanical Hydraulic Lifters | Uses mechanical components to convert hydraulic pressure into motion. | Automotive, machinery maintenance | Pros: Simplicity, cost-effective. Cons: Limited lifting capacity, mechanical wear. |

| Hydraulic Roller Lifters | Employs rollers to reduce friction and enhance efficiency. | Automotive engines, heavy machinery | Pros: Increased performance, lower wear. Cons: Higher initial cost, complex installation. |

| Hydraulic Flat Tappet Lifters | Flat design for direct contact with the camshaft. | Classic cars, performance engines | Pros: Easy to install, reliable. Cons: Higher friction, potential for wear. |

| Hydraulic Lifters with Variable Lift | Adjusts lift height based on engine performance needs. | High-performance engines, racing | Pros: Optimized performance, fuel efficiency. Cons: More complex, higher maintenance. |

| Solid Lifters | No hydraulic mechanism; uses a solid design for durability. | Racing applications, heavy machinery | Pros: High durability, precise performance. Cons: Noisy operation, requires frequent adjustments. |

Mechanical Hydraulic Lifters

Mechanical hydraulic lifters are designed to convert hydraulic pressure into motion using mechanical components. They are widely used in automotive applications and machinery maintenance due to their simplicity and cost-effectiveness. However, buyers should consider that they may have limited lifting capacities and can experience mechanical wear over time, which could lead to increased maintenance costs.

Hydraulic Roller Lifters

Hydraulic roller lifters feature rollers that reduce friction, enhancing efficiency and performance. They are commonly utilized in automotive engines and heavy machinery. The primary advantages include increased performance and reduced wear, making them suitable for high-demand applications. However, they come with a higher initial cost and a more complex installation process, which may be a consideration for budget-conscious buyers.

Hydraulic Flat Tappet Lifters

These lifters have a flat design that allows for direct contact with the camshaft, making them popular in classic cars and performance engines. They are easy to install and generally reliable, making them an attractive option for many buyers. However, they can generate higher friction and potential wear, which necessitates more frequent inspections and possible replacements.

Hydraulic Lifters with Variable Lift

Designed for high-performance engines, hydraulic lifters with variable lift adjust their height based on the engine’s performance needs. This feature optimizes engine performance and fuel efficiency, making them ideal for racing applications. While they provide significant advantages, such as improved performance, they are more complex and may require higher maintenance, which could deter some buyers.

Solid Lifters

Solid lifters utilize a rigid design without hydraulic mechanisms, making them highly durable and precise for applications like racing and heavy machinery. They offer excellent performance and longevity but can be noisier and require frequent adjustments compared to hydraulic options. Buyers interested in solid lifters should be prepared for the maintenance requirements and potential noise issues associated with their operation.

Related Video: Lecture 1 Two compartment models

Key Industrial Applications of hydraulic lifr

| Industry/Sector | Specific Application of hydraulic lifr | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and positioning heavy materials | Increases efficiency and reduces labor costs | Reliability and compliance with safety standards |

| Manufacturing | Automation of assembly lines | Enhances productivity and precision | Supplier reliability and maintenance support |

| Mining | Operation of excavators and drilling rigs | Improves operational efficiency | Durability in harsh environments and supply chain reliability |

| Agriculture | Control of planting and harvesting equipment | Optimizes yield and reduces operational time | Compatibility with existing machinery and service availability |

| Energy & Utilities | Hydraulic systems in power plants | Increases energy efficiency and reduces downtime | Compliance with international regulations and performance metrics |

Construction

In the construction sector, hydraulic lifr is essential for lifting and positioning heavy materials like steel beams and concrete blocks. The use of hydraulic systems in cranes and lifts allows for precise control, which enhances safety and efficiency on job sites. International buyers should focus on sourcing equipment that meets stringent safety standards and can withstand the rigors of construction environments. Reliability is crucial, as delays can lead to increased costs and project overruns.

Manufacturing

In manufacturing, hydraulic lifr is utilized in automated assembly lines, allowing for the seamless movement of components and products. This application increases productivity by minimizing manual handling and enhancing precision in operations. B2B buyers should prioritize suppliers who offer robust hydraulic solutions with strong maintenance support, ensuring minimal downtime and consistent production flow. Understanding the specific requirements of the assembly process is vital for effective sourcing.

Mining

The mining industry heavily relies on hydraulic lifr for the operation of excavators, drilling rigs, and other heavy machinery. Hydraulic systems provide the necessary power to operate these machines efficiently, improving overall operational efficiency. Buyers in this sector must consider the durability and reliability of hydraulic components, especially in harsh environments. Sourcing from suppliers with a proven track record in mining applications can significantly reduce maintenance costs and downtime.

Agriculture

In agriculture, hydraulic lifr is used to control planting and harvesting equipment, such as tractors and combines. This technology optimizes yield by allowing for precise control of machinery, thereby reducing operational time and improving the quality of work. International buyers should ensure that the hydraulic systems are compatible with their existing machinery and that suppliers provide adequate service support. Understanding the seasonal demands of agriculture is also important for effective procurement.

Energy & Utilities

Hydraulic lifr plays a crucial role in energy and utility sectors, particularly in power plants where it is used to operate various hydraulic systems. These systems enhance energy efficiency and reduce operational downtime, which is critical for maintaining energy production. Buyers should focus on suppliers that comply with international regulations and performance metrics, ensuring that the hydraulic systems are both efficient and reliable. Investing in high-quality hydraulic solutions can lead to long-term cost savings and improved operational performance.

Related Video: Directional Control Valves (Hydraulic & Pneumatic): Types, Mechanism, Actuating Method, Applications

Strategic Material Selection Guide for hydraulic lifr

When selecting materials for hydraulic lifr systems, it is crucial to consider various factors that influence performance, durability, and cost. Below, we analyze four common materials used in hydraulic lifr applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Steel

Key Properties: Steel is known for its high tensile strength and excellent pressure ratings, making it suitable for high-pressure hydraulic applications. It typically withstands temperatures up to 250°C, depending on the alloy.

Pros & Cons: Steel’s durability and strength are significant advantages, ensuring longevity in demanding environments. However, it is susceptible to corrosion, which can limit its use in certain applications without protective coatings. The manufacturing complexity can also increase costs, especially for custom parts.

Impact on Application: Steel is compatible with a wide range of hydraulic fluids, including oil-based and water-based fluids, but may require additional treatments for compatibility with corrosive media.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A36 or DIN 17100. In regions like Europe and the Middle East, corrosion-resistant coatings may be necessary due to environmental conditions.

Aluminum

Key Properties: Aluminum is lightweight and offers good corrosion resistance, making it suitable for applications where weight savings are critical. It can handle pressures up to 200 bar and temperatures ranging from -40°C to 120°C.

Pros & Cons: The primary advantage of aluminum is its low weight, which reduces overall system weight and improves efficiency. However, it has lower tensile strength compared to steel, which can limit its use in high-pressure applications. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum is compatible with many hydraulic fluids but may not be suitable for high-temperature applications or aggressive chemical environments.

Considerations for International Buyers: Compliance with standards such as JIS H 4000 for aluminum alloys is essential. Buyers in South America and Africa should consider local availability and the potential for higher costs due to importation.

Composite Materials

Key Properties: Composites, such as carbon fiber reinforced polymers, offer excellent strength-to-weight ratios and corrosion resistance. They can handle pressures up to 300 bar and temperatures between -50°C and 150°C.

Pros & Cons: The lightweight nature of composites allows for innovative designs and reduced weight. However, they can be expensive to manufacture and may require specialized skills for repairs.

Impact on Application: Composites are ideal for applications requiring high strength and low weight, but their compatibility with specific hydraulic fluids should be verified to prevent degradation.

Considerations for International Buyers: Buyers should be aware of the limited availability of composite materials in certain regions. Compliance with ASTM D3039 for testing composite materials is also critical.

Brass

Key Properties: Brass is known for its good corrosion resistance and machinability. It typically handles pressures up to 150 bar and temperatures up to 200°C.

Pros & Cons: Brass is durable and offers excellent resistance to corrosion, making it suitable for various environments. However, it is heavier than aluminum and can be more expensive than steel.

Impact on Application: Brass is compatible with many hydraulic fluids but may not be suitable for high-pressure applications compared to steel or composites.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B16 for brass alloys. In Europe, the use of leaded brass may be restricted due to environmental regulations.

Summary Table

| Material | Typical Use Case for hydraulic lifr | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-pressure hydraulic systems | High tensile strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications | Low weight | Lower tensile strength | High |

| Composite | Advanced lightweight designs | Excellent strength-to-weight ratio | Expensive and specialized repairs | High |

| Brass | General hydraulic fittings | Good corrosion resistance | Heavier than aluminum | Medium |

This guide provides a comprehensive overview of materials used in hydraulic lifr systems, empowering international B2B buyers to make informed decisions based on performance requirements, costs, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic lifr

Manufacturing Processes for Hydraulic Lifters

The manufacturing of hydraulic lifters involves a series of meticulously planned stages that ensure high-quality outputs capable of meeting rigorous operational demands. Understanding these processes is crucial for B2B buyers, particularly those sourcing from diverse regions like Africa, South America, the Middle East, and Europe. Here, we will explore the key stages of manufacturing hydraulic lifters, along with the techniques employed at each stage.

Material Preparation

The first stage in the manufacturing process is material preparation. Hydraulic lifters are typically made from high-strength steel or aluminum alloys, which are selected based on their mechanical properties and resistance to wear.

- Material Selection: Choosing the right material is critical. Buyers should look for suppliers that utilize alloys with proven performance in hydraulic applications.

- Cutting and Shaping: The raw materials are cut into specific dimensions using methods such as laser cutting or water jet cutting. Precision in this phase is essential to minimize waste and ensure compatibility during the assembly phase.

Forming

Once the materials are prepared, the next step is forming. This stage shapes the components into their final form.

- Forging: This is a common technique used for producing hydraulic lifters, where heated metal is shaped under pressure. Forged components exhibit superior strength and durability.

- Machining: After forming, machining processes like turning, milling, and grinding are employed to achieve precise dimensions and surface finishes. Advanced CNC (Computer Numerical Control) machines are often used to enhance accuracy and repeatability.

Assembly

The assembly process involves putting together the various components of the hydraulic lifter.

- Sub-Assembly: Components such as plungers, springs, and check valves are first assembled into sub-units before being combined into the final product.

- Joining Techniques: Techniques like welding, soldering, or the use of adhesives are employed to ensure robust connections between parts. The choice of technique may depend on the specific design requirements and material types.

Finishing

Finishing processes are essential for enhancing the durability and aesthetics of hydraulic lifters.

- Surface Treatment: Common treatments include anodizing, coating, or plating to improve corrosion resistance and reduce friction.

- Inspection: After finishing, components undergo rigorous inspections to ensure they meet the required specifications. This is often the stage where visual and dimensional checks are performed.

Quality Assurance in Hydraulic Lifter Manufacturing

Quality assurance (QA) is a critical aspect of hydraulic lifter manufacturing. It ensures that products meet established standards and specifications, which is especially important for international buyers who must navigate varying regulations across regions.

International Standards

B2B buyers should be aware of the relevant international and industry-specific standards that govern hydraulic lifter manufacturing.

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable across various industries. Suppliers certified under ISO 9001 are more likely to have established processes for quality control.

- CE Marking: In Europe, products must meet specific health, safety, and environmental protection standards to obtain CE marking, indicating compliance with EU legislation.

- API Standards: The American Petroleum Institute (API) provides specifications for hydraulic components used in the oil and gas industry, ensuring safety and reliability.

Quality Control Checkpoints

Quality control (QC) checkpoints are integral throughout the manufacturing process. B2B buyers should ensure that their suppliers implement the following checkpoints:

- Incoming Quality Control (IQC): Materials and components are inspected upon receipt to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to verify that processes are within acceptable limits and to identify any deviations early.

- Final Quality Control (FQC): The finished hydraulic lifters undergo final inspections to ensure they meet all specifications and standards before shipping.

Common Testing Methods

Several testing methods are employed to validate the quality and performance of hydraulic lifters:

- Hydraulic Testing: Components are subjected to high-pressure testing to ensure they can withstand operational conditions without failure.

- Dimensional Inspection: Utilizing tools such as calipers and micrometers, manufacturers check the dimensions of components against specifications to ensure accuracy.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or magnetic particle inspection can be used to detect internal flaws without damaging the components.

Verifying Supplier Quality Control

B2B buyers must adopt thorough verification processes to ensure that suppliers adhere to quality standards.

- Audits: Conducting regular audits of suppliers’ facilities can provide insights into their manufacturing and quality control processes. This includes reviewing documentation and observing operations firsthand.

- Quality Reports: Requesting detailed quality reports and certifications can help buyers assess a supplier’s commitment to quality. This documentation should include results from various tests performed on the products.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality assurance practices and products. This is particularly beneficial for international transactions where trust may be a concern.

Quality Control and Certification Nuances for International Buyers

International B2B buyers should be cognizant of various nuances that can impact quality control and certification processes:

- Regulatory Compliance: Different regions have varying regulatory requirements. Buyers from Africa, South America, the Middle East, and Europe must ensure their suppliers comply with local laws and international regulations.

- Cultural and Operational Differences: Understanding the cultural context and operational practices of suppliers in different regions can help buyers navigate potential challenges in quality assurance.

- Language Barriers: Clear communication regarding quality expectations is vital. Buyers should ensure that all documentation is available in languages understood by both parties to avoid misinterpretations.

By comprehensively understanding the manufacturing processes and quality assurance measures related to hydraulic lifters, B2B buyers can make informed decisions when sourcing from international suppliers. This knowledge not only enhances procurement strategies but also fosters strong supplier relationships built on trust and quality.

Related Video: The Most Sophisticated Manufacturing Process In The World Inside The Fab | Intel

Comprehensive Cost and Pricing Analysis for hydraulic lifr Sourcing

Understanding Cost Components for Hydraulic Lift Sourcing

When sourcing hydraulic lifts, it is crucial to grasp the various cost components that contribute to the overall price. These include:

-

Materials: The primary materials used in hydraulic lifts typically include steel, aluminum, and hydraulic fluid. The quality and source of these materials can significantly impact the pricing.

-

Labor: Labor costs encompass the wages for skilled workers involved in assembly, maintenance, and quality assurance. Labor costs can vary by region; for instance, labor is generally more expensive in Europe than in Africa or South America.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help reduce overhead, which can be a key negotiation point.

-

Tooling: The cost of tools and equipment required for production can be substantial, especially if custom tooling is needed for specific designs.

-

Quality Control (QC): Rigorous QC processes are essential for ensuring product reliability and safety. The costs associated with these processes can vary based on the standards required, such as ISO certifications.

-

Logistics: Transportation and warehousing costs also play a critical role in the total cost. These expenses can fluctuate based on geographic location and shipping methods.

-

Margin: Suppliers typically apply a margin to cover their costs and generate profit. Understanding typical margins in your region can help in negotiations.

Key Price Influencers

Several factors influence the pricing of hydraulic lifts:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to discounts due to economies of scale. Buyers should negotiate MOQ to maximize savings.

-

Specifications and Customization: Custom features can significantly increase costs. Be clear about your requirements to avoid unexpected expenses.

-

Materials: The choice of materials directly affects pricing. Opting for higher-quality materials may increase initial costs but can lead to lower maintenance expenses over time.

-

Quality and Certifications: Products that meet international standards or possess relevant certifications often come at a premium but can enhance reliability and marketability.

-

Supplier Factors: The supplier’s reputation, experience, and service level can impact pricing. Established suppliers may charge more but often provide better support and quality assurance.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is crucial, as they dictate who bears the costs and risks at various stages of the supply chain.

Buyer Tips for Cost-Efficiency

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Use your understanding of cost components and price influencers to negotiate better terms. Don’t hesitate to ask for discounts on bulk orders or longer contract durations.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs, including maintenance, operational efficiency, and potential downtime.

-

Research and Benchmark: Conduct market research to benchmark prices and services across different suppliers. This information can strengthen your negotiation position.

-

Understand Pricing Nuances: Be aware of regional pricing dynamics. For instance, suppliers in Europe may have higher prices due to stricter regulations compared to those in emerging markets.

-

Evaluate Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Look for suppliers who are willing to invest in your long-term success.

Disclaimer

Prices and cost structures can vary widely based on numerous factors, including market fluctuations, regional economic conditions, and specific buyer-supplier negotiations. Always consult multiple sources and conduct thorough due diligence before making purchasing decisions.

Spotlight on Potential hydraulic lifr Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘hydraulic lifr’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for hydraulic lifr

Critical Technical Properties of Hydraulic Lifr

When procuring hydraulic lifr, understanding its technical properties is crucial for ensuring performance and compatibility with existing systems. Here are some essential specifications:

-

Material Grade

The material grade of hydraulic lifr significantly affects its durability and performance. Common materials include carbon steel, stainless steel, and specialized alloys. Choosing the right material is vital for resistance to corrosion and wear, especially in harsh environments typical in industries such as construction and manufacturing. -

Tolerance Levels

Tolerance refers to the allowable deviation in dimensions during manufacturing. Tight tolerances are essential for components that operate under high pressure or require precise fitment. Understanding tolerance levels helps buyers ensure that the hydraulic lifr will integrate seamlessly with other machinery, thereby reducing the risk of operational failure. -

Pressure Rating

The pressure rating indicates the maximum pressure the hydraulic lifr can withstand during operation. This specification is critical for safety and efficiency, as exceeding the pressure rating can lead to catastrophic failures. Buyers must assess the operational environment to select a hydraulic lifr with an appropriate pressure rating.

-

Operating Temperature Range

Hydraulic lifr must function effectively within specific temperature ranges. This property is crucial for applications in extreme conditions, whether hot or cold. Knowing the operating temperature range helps buyers avoid premature wear or failure due to thermal stress. -

Flow Rate

The flow rate is the volume of hydraulic fluid that can pass through the lifr within a given time. This specification is essential for determining the efficiency and speed of hydraulic operations. Buyers should match the flow rate with their system requirements to optimize performance. -

Surface Finish

The surface finish affects the hydraulic lifr’s ability to resist wear and reduce friction. A smoother surface finish can enhance performance and longevity, particularly in dynamic applications. Buyers should consider the surface finish when evaluating overall quality and performance.

Common Trade Terminology in Hydraulic Lifr Procurement

Familiarity with industry-specific terms is critical for effective communication and negotiation in the procurement process. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM helps buyers identify reliable suppliers who adhere to industry standards and quality benchmarks. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is essential for budgeting and inventory management, particularly for international buyers who may need to account for shipping and storage costs. -

RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing and availability of specific products. Issuing an RFQ allows buyers to compare offers and negotiate terms effectively, ensuring they secure the best possible deal. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risk transfer, and delivery obligations, which are crucial for smooth transactions. -

Lead Time

Lead time is the period from placing an order to receiving the product. Understanding lead times is vital for project planning, as delays can impact project timelines and costs. -

Certification Standards

Certification standards, such as ISO or ANSI, indicate that a product meets specific quality and safety criteria. Buyers should prioritize suppliers who provide certified products to ensure compliance with industry regulations and standards.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, enhancing procurement efficiency and operational effectiveness in their respective markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the hydraulic lifr Sector

Market Overview & Key Trends

The hydraulic lift sector is experiencing significant transformations driven by several global factors. Increasing urbanization, particularly in developing regions such as Africa and South America, has heightened demand for efficient vertical transportation solutions. Additionally, advancements in technology are reshaping the procurement landscape. The integration of IoT (Internet of Things) into hydraulic systems is not only enhancing operational efficiency but also providing real-time data analytics, which allows for better decision-making in sourcing and maintenance.

Illustrative Image (Source: Google Search)

Emerging trends in the B2B space include a shift towards digital procurement platforms that streamline the sourcing process. These platforms enable buyers to access a broader range of suppliers, compare prices, and evaluate product specifications more effectively. Furthermore, the rise of automation in manufacturing processes is contributing to lower production costs, making hydraulic lifts more accessible to businesses across diverse sectors.

International B2B buyers should also be aware of regional market dynamics. For instance, European markets are increasingly leaning towards energy-efficient models due to stringent regulations and consumer demand for sustainability. Conversely, markets in the Middle East and Africa may focus on cost-effectiveness and durability, given the varying economic conditions and infrastructure needs. Engaging with local suppliers can provide valuable insights into these dynamics, ensuring that procurement strategies are tailored to specific market conditions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a central focus in the hydraulic lift sector as businesses recognize the environmental impact of their operations. Buyers are increasingly prioritizing suppliers that adhere to sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials. The importance of ethical supply chains cannot be overstated; transparency in sourcing ensures compliance with regulations and builds trust with stakeholders.

Incorporating ‘green’ certifications into procurement processes is a growing trend. Certifications like ISO 14001 for environmental management systems signal a commitment to sustainability and can enhance a company’s reputation in the market. Additionally, sourcing materials that are recyclable or produced using renewable energy can significantly reduce the environmental impact of hydraulic lifts.

Buyers should also consider the lifecycle of hydraulic lift products. Selecting suppliers that offer durable solutions with a longer lifespan not only reduces waste but also lowers overall costs. Engaging in sustainability initiatives, such as participating in local community projects or supporting responsible sourcing practices, can further strengthen a company’s brand and appeal to environmentally conscious consumers.

Brief Evolution/History

The hydraulic lift sector has evolved significantly since its inception in the late 19th century. Originally developed to facilitate the movement of heavy goods in industrial settings, hydraulic lifts have transformed into sophisticated systems used in various applications, including residential buildings, commercial spaces, and public infrastructure.

The introduction of hydraulic fluid technology allowed for more efficient and reliable operations, paving the way for innovations such as automatic elevators and lifts. Over the decades, technological advancements, including the integration of electronic control systems and safety mechanisms, have enhanced the performance and safety of hydraulic lifts, making them indispensable in modern infrastructure. As the industry continues to innovate, understanding this evolution helps buyers appreciate the advancements that drive current market dynamics and sourcing strategies.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic lifr

-

What criteria should I use to vet suppliers of hydraulic lifr?

When vetting suppliers, consider their experience in the industry, client testimonials, and financial stability. Check for certifications such as ISO 9001, which indicate quality management standards. Additionally, assess their production capacity and ability to meet your specific requirements. It’s also beneficial to visit their facilities, if possible, or conduct a virtual audit to ensure they adhere to safety and quality standards. -

Can hydraulic lifr be customized to meet specific needs?

Yes, many suppliers offer customization options for hydraulic lifr to accommodate unique specifications. When discussing customization, clearly outline your requirements, including dimensions, pressure ratings, and material preferences. Engage in a dialogue with the supplier about their capabilities and any potential limitations. Make sure to document all specifications to avoid misunderstandings during production. -

What are typical minimum order quantities (MOQ) and lead times for hydraulic lifr?

Minimum order quantities can vary significantly among suppliers, often ranging from 50 to 500 units. Lead times also depend on the complexity of the order and the supplier’s production schedule, typically ranging from 4 to 12 weeks. Always clarify these details upfront to plan your procurement effectively and avoid disruptions in your supply chain. -

What payment terms are commonly offered for international purchases?

Payment terms can vary, but common practices include a deposit upfront (often 30-50%) with the balance due upon delivery or after shipment. Some suppliers may offer letters of credit or payment upon receipt of goods. It’s essential to negotiate terms that align with your cash flow needs while ensuring the supplier’s confidence in the transaction.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certification compliance?

Request copies of quality assurance certifications and inspection reports from the supplier. Implement a quality control process, such as receiving inspections upon arrival, to verify compliance with specifications. Consider establishing a third-party inspection agency to conduct quality audits before shipment, especially for large orders or critical applications. -

What logistics considerations should I keep in mind when sourcing hydraulic lifr?

When planning logistics, factor in shipping methods, customs regulations, and potential tariffs that could affect costs. Determine the best shipping route and method (air vs. sea) based on urgency and budget. Collaborate with logistics providers who have experience in handling hydraulic components to ensure safe and timely delivery. -

What steps should I take if a dispute arises with a supplier?

If a dispute occurs, start by documenting all communications and agreements. Reach out to the supplier to address the issue directly, aiming for a resolution through negotiation. If an agreement cannot be reached, consider mediation or arbitration as outlined in your contract. Always maintain a professional tone to preserve the relationship for future business opportunities. -

How can I stay updated on industry trends and supplier performance?

Regularly engage with industry publications, attend trade shows, and participate in relevant webinars to stay informed about market trends and innovations in hydraulic lifr. Utilize supplier performance metrics, such as on-time delivery rates and quality defect rates, to evaluate their reliability. Continuous monitoring can help you make informed decisions about ongoing and future supplier partnerships.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for hydraulic lifr

Strategic sourcing in the hydraulic lifr sector is pivotal for international B2B buyers aiming to optimize procurement processes and enhance operational efficiency. By focusing on key metrics such as Line Item Fill Rate (LIFR), companies can improve inventory management, reduce costs, and foster stronger supplier relationships. Additionally, leveraging technology for supplier management and analytics ensures that procurement decisions are data-driven, leading to improved responsiveness to market demands.

In today’s interconnected global economy, particularly for buyers in Africa, South America, the Middle East, and Europe, understanding regional market dynamics and supplier capabilities is essential. Strategic sourcing not only mitigates risks associated with supply chain disruptions but also opens avenues for innovation and sustainable practices.

As we look to the future, organizations should prioritize collaboration with suppliers, invest in digital procurement solutions, and continuously evaluate their sourcing strategies. Embrace these practices to position your business for success in an evolving landscape. Take the next step—assess your current sourcing strategies and consider how adopting a more strategic approach can drive growth and profitability in your operations.