Master the Art of Sourcing Polyurethane Rollers for Optimal

Introduction: Navigating the Global Market for polyurethane rollers

In today’s competitive industrial landscape, the choice of rollers can significantly influence operational efficiency and product quality. Polyurethane rollers have gained recognition as a premier solution across various sectors, thanks to their superior durability, abrasion resistance, and load-bearing capabilities. These versatile components are essential in applications ranging from automotive assembly lines to packaging and logistics, where reliability and performance are paramount.

This guide serves as a comprehensive resource for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. It delves into the intricacies of polyurethane rollers, covering critical aspects such as types, materials, manufacturing and quality control processes, supplier insights, cost considerations, and market trends. By equipping buyers with this knowledge, the guide empowers them to make informed sourcing decisions that enhance their operations and drive cost-efficiency.

Understanding the global market for polyurethane rollers is crucial for businesses looking to optimize their supply chains and maintain a competitive edge. With tailored insights into regional suppliers and innovative solutions, this guide ensures that buyers can navigate the complexities of sourcing these essential components effectively. Whether you are in Kenya, Turkey, or beyond, this resource is designed to facilitate strategic partnerships and elevate your procurement strategy to new heights.

Understanding polyurethane rollers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Drive Rollers | Designed for propulsion, high load capacity, and durability | Conveyor systems, automotive assembly lines | Pros: Efficient power transfer, high durability. Cons: May require more initial investment. |

| Idler Rollers | Supportive, low-friction design, often lighter | Material handling, packaging, and logistics | Pros: Cost-effective, easy to install. Cons: Limited load capacity compared to drive rollers. |

| Concave Rollers | Curved design for better material handling | Glass handling, delicate material transport | Pros: Improved grip and stability. Cons: Customization may increase lead time. |

| Hubbed Rollers | Integrated hub for easy attachment and replacement | Printing, paper manufacturing | Pros: Simplified maintenance, versatile. Cons: More expensive due to design complexity. |

| V-Groove Rollers | V-shaped profile for guiding materials | Cable and wire handling, conveyor systems | Pros: Enhanced tracking, stability. Cons: Limited to specific applications. |

Drive Rollers

Drive rollers are engineered for propulsion and are characterized by their high load capacity and durability. These rollers are essential in applications where consistent power transfer is crucial, such as conveyor systems and automotive assembly lines. When purchasing drive rollers, buyers should consider the specific load requirements and the operating environment, as these factors can influence the roller’s performance and lifespan. While they may require a higher initial investment, their efficiency and longevity can result in lower total cost of ownership.

Idler Rollers

Idler rollers serve a supportive role, designed to reduce friction and assist in the movement of materials. Typically lighter than drive rollers, they are commonly used in material handling, packaging, and logistics applications. Buyers should evaluate the load capacity and ease of installation when selecting idler rollers. While they offer a cost-effective solution, their load-bearing capabilities may be limited compared to drive rollers, making it essential to match them with appropriate applications.

Concave Rollers

Concave rollers feature a curved design that enhances material handling, particularly for delicate items like glass. Their shape provides improved grip and stability, making them ideal for applications requiring careful handling. Buyers considering concave rollers should focus on customization options, as tailored solutions can optimize performance. However, the need for specific designs may lead to longer lead times, which should be factored into project timelines.

Hubbed Rollers

Hubbed rollers come with an integrated hub, allowing for easy attachment and replacement. This design is particularly advantageous in industries like printing and paper manufacturing, where rapid maintenance is critical. When purchasing hubbed rollers, buyers should assess the versatility of the design and the potential for simplified maintenance. Although these rollers may be more expensive due to their complexity, the benefits of reduced downtime can offset the initial costs.

V-Groove Rollers

V-groove rollers are designed with a V-shaped profile that enhances the tracking of materials, making them ideal for applications involving cable and wire handling. Their unique design provides stability and precision in conveyor systems. Buyers should consider the specific application needs when selecting V-groove rollers, as their functionality is often limited to certain tasks. While they offer enhanced tracking capabilities, their application range may restrict their use in more generalized settings.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of polyurethane rollers

| Industry/Sector | Specific Application of Polyurethane Rollers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Assembly line conveyors | Enhanced durability and resistance to oils and greases, reducing downtime. | Look for suppliers with expertise in high-temperature applications. |

| Aerospace | Material handling for sensitive components | High load-bearing capacity ensures safety and precision in operations. | Ensure compliance with industry standards and certifications. |

| Packaging & Logistics | Conveyor systems for sorting and transporting goods | Minimizes wear and tear, leading to lower maintenance costs. | Consider suppliers who offer customization for specific load requirements. |

| Printing & Paper | Printing press rollers | Consistent surface finish ensures high-quality output and reduces defects. | Source from manufacturers with experience in precision molding. |

| Wood & Glass Processing | Rollers for handling delicate materials | Excellent grip and shock absorption prevent material damage. | Evaluate the flexibility of the supplier to provide custom compounds. |

In the automotive industry, polyurethane rollers are commonly used in assembly line conveyors where they are exposed to oils, greases, and high temperatures. Their superior durability ensures that they can withstand the harsh conditions of manufacturing without significant wear, thereby minimizing downtime and maintenance costs. International buyers should prioritize suppliers who specialize in high-temperature applications and can provide evidence of performance under similar conditions.

Within the aerospace sector, polyurethane rollers play a critical role in handling sensitive components during manufacturing and assembly processes. These rollers offer high load-bearing capacity, which is essential for ensuring safety and precision in operations. Buyers should verify that potential suppliers comply with strict industry standards and certifications to maintain safety and quality.

In packaging and logistics, polyurethane rollers are integral to conveyor systems that sort and transport goods. Their abrasion resistance means they can endure long hours of operation with minimal wear, significantly reducing maintenance costs. B2B buyers should consider suppliers that offer customizable rollers tailored to specific load requirements, ensuring optimal performance in their operations.

The printing and paper industry relies on polyurethane rollers to maintain consistent surface finishes during the printing process. This consistency is vital for producing high-quality outputs and minimizing defects. Buyers should seek manufacturers with expertise in precision molding to guarantee that the rollers meet stringent quality standards and operational requirements.

In wood and glass processing, polyurethane rollers are utilized for handling delicate materials. Their excellent grip and ability to absorb shocks prevent damage to sensitive surfaces, making them ideal for these applications. Buyers should assess the flexibility of suppliers in providing custom compounds that suit their specific needs, ensuring optimal performance in demanding environments.

Related Video: How it’s Made. Polyurethane. INSIDE FACTORIES

Strategic Material Selection Guide for polyurethane rollers

When selecting materials for polyurethane rollers, it is essential to consider various options that can enhance performance, durability, and application suitability. Below, we analyze four common materials used in the production of polyurethane rollers, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

1. Polyether Polyurethane

Key Properties: Polyether polyurethane is known for its excellent flexibility and resistance to hydrolysis, making it suitable for humid environments. It typically operates effectively in temperature ranges from -40°C to 80°C.

Pros & Cons: This material exhibits good abrasion resistance and is less expensive compared to other polyurethanes. However, it has lower resistance to chemicals and oils, which can limit its use in certain industrial applications.

Impact on Application: Polyether polyurethane is ideal for applications involving moisture exposure, such as in food processing or packaging industries. However, its chemical sensitivity must be considered when dealing with aggressive substances.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local food safety standards, while European buyers may prioritize certifications such as FDA or EU regulations.

2. Polyester Polyurethane

Key Properties: Polyester polyurethane provides superior chemical resistance and can withstand higher temperatures, typically rated from -30°C to 100°C.

Pros & Cons: Its durability and resilience to oils and solvents make it a preferred choice in automotive and industrial applications. However, it is generally more expensive and can be more challenging to process due to its higher viscosity.

Impact on Application: This material is well-suited for environments with exposure to harsh chemicals, such as manufacturing plants or chemical processing facilities. Its high tensile strength also supports heavy loads effectively.

Considerations for International Buyers: Buyers in the Middle East, where chemical exposure is common, should prioritize polyester polyurethane for its robustness. Compliance with ASTM or DIN standards can enhance marketability in Europe.

3. Thermoplastic Polyurethane (TPU)

Key Properties: TPU combines the elasticity of rubber with the durability of plastic, functioning effectively in a temperature range of -40°C to 90°C. It is also known for its excellent abrasion resistance and tear strength.

Pros & Cons: TPUs are versatile and can be processed using various methods, including injection molding and extrusion. However, they can be more costly than traditional polyurethanes and may require specific processing equipment.

Impact on Application: TPUs are ideal for applications requiring flexibility and resilience, such as in conveyor systems and automotive components. Their ability to handle dynamic loads makes them suitable for high-performance environments.

Considerations for International Buyers: Buyers from Europe might seek TPUs that comply with RoHS directives, while those in South America may focus on cost-effectiveness and availability of local suppliers.

4. High-Performance Urethanes

Key Properties: These specialized polyurethanes are engineered for extreme conditions, with temperature ratings often exceeding 100°C and enhanced chemical resistance.

Pros & Cons: High-performance urethanes offer unparalleled durability and longevity, making them suitable for the most demanding applications. However, they come at a significantly higher cost and may have longer lead times for production.

Impact on Application: Ideal for aerospace and heavy machinery, these materials can withstand extreme pressures and temperatures, ensuring reliable performance in critical applications.

Considerations for International Buyers: Buyers in regions with stringent quality requirements, like Europe, should ensure these materials meet relevant industry standards. In contrast, buyers in Africa and the Middle East may need to assess the cost-benefit ratio for their specific applications.

Summary Table

| Material | Typical Use Case for polyurethane rollers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyether Polyurethane | Food processing, packaging | Excellent flexibility and moisture resistance | Lower chemical resistance | Medium |

| Polyester Polyurethane | Automotive, industrial applications | Superior chemical resistance | Higher cost and processing complexity | High |

| Thermoplastic Polyurethane | Conveyor systems, automotive components | Versatile processing options | Higher cost and specific equipment needed | High |

| High-Performance Urethanes | Aerospace, heavy machinery | Unparalleled durability and longevity | Significantly higher cost | High |

This strategic material selection guide provides international B2B buyers with actionable insights into the various types of polyurethane rollers available, enabling informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane rollers

Manufacturing Processes for Polyurethane Rollers

The manufacturing of polyurethane rollers involves several distinct stages that ensure high-quality performance and longevity. Each stage plays a critical role in determining the final product’s characteristics, such as durability, load-bearing capacity, and resistance to wear and tear. Below is a detailed overview of the main stages of the manufacturing process.

1. Material Preparation

The first step in the manufacturing process involves selecting the appropriate polyurethane compound based on the desired properties of the roller. Polyurethane can be tailored to achieve specific hardness, flexibility, and abrasion resistance. Key tasks in this stage include:

- Material Selection: Choosing the right formulation, which may include additives to enhance properties like UV resistance or anti-static features.

- Mixing: The selected compounds are precisely measured and mixed to create a homogeneous material. This process often involves advanced machinery to ensure consistency.

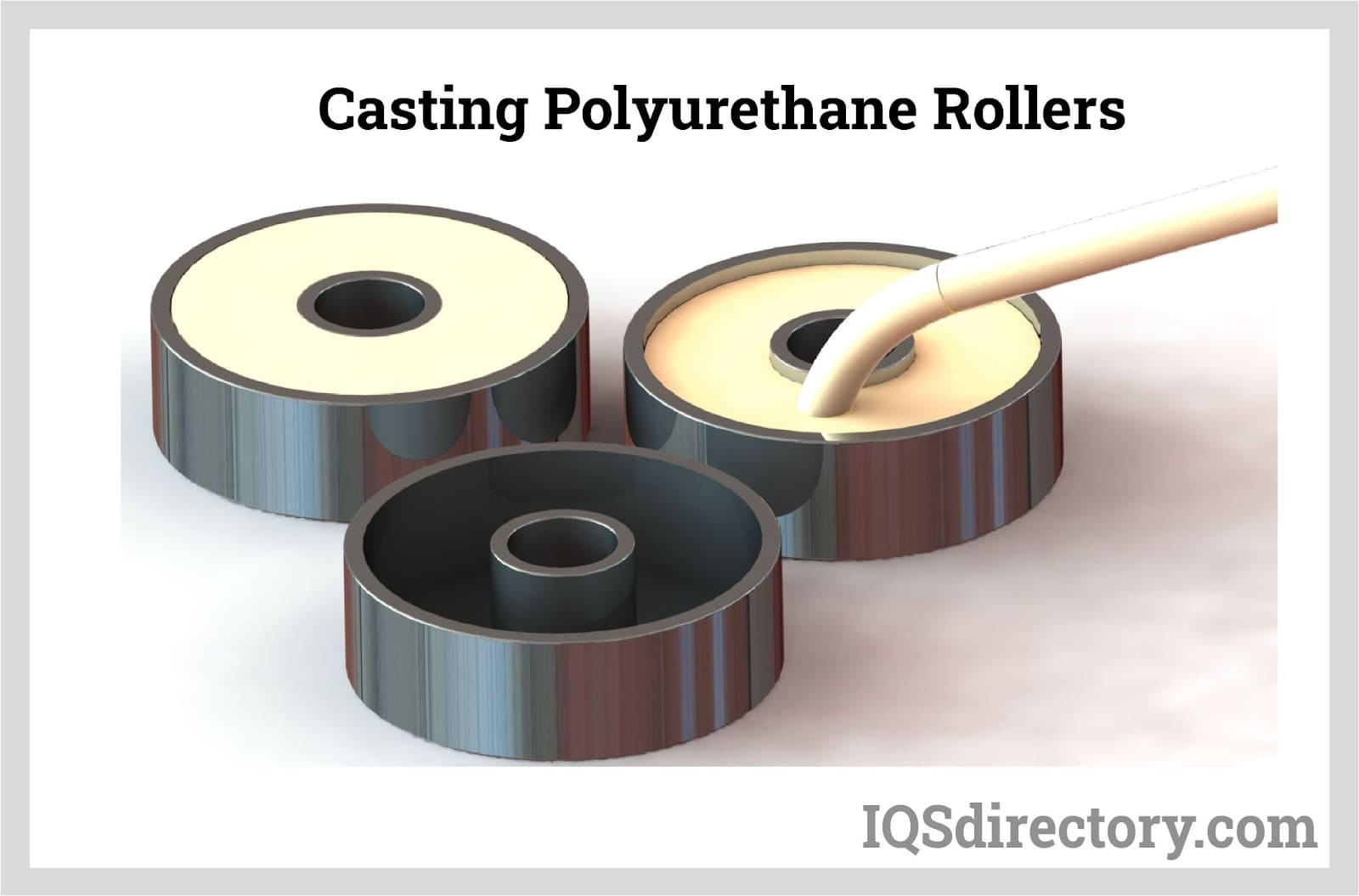

2. Forming

Once the material is prepared, the next step is forming the rollers. This can be achieved through several techniques, including:

- Casting: Liquid polyurethane is poured into molds that shape the rollers. This method allows for intricate designs and custom specifications.

- Extrusion: Polyurethane is forced through a die to create continuous lengths of rollers, which can then be cut to the desired size.

- Machining: For rollers that require specific dimensions or surface finishes, machining processes like CNC milling or turning may be employed.

Each of these techniques can be tailored to meet the specific requirements of different applications, ensuring that the rollers can withstand the operational demands they will face.

3. Assembly

In some cases, polyurethane rollers are assembled with other components, such as metal cores. This hybrid approach enhances the strength and load-bearing capabilities of the rollers. Key activities during this stage include:

- Bonding: The polyurethane is often bonded to metal cores using adhesives or by molding the polyurethane directly onto the core. This creates a robust composite roller.

- Alignment and Fitting: Ensuring that all components are properly aligned and fitted together is crucial for optimal performance.

4. Finishing

The final stage of manufacturing involves finishing processes that enhance the roller’s performance and appearance. This may include:

- Surface Treatment: Techniques such as grinding or polishing are used to achieve specific surface finishes required for particular applications.

- Coating: Additional protective coatings may be applied to enhance chemical resistance or reduce friction.

- Quality Inspection: Before final packaging, rollers undergo rigorous inspections to ensure they meet quality standards.

Quality Assurance in Manufacturing

Quality assurance is a vital component of the manufacturing process for polyurethane rollers. It ensures that products meet international and industry-specific standards, thereby guaranteeing performance and reliability. Here’s how quality assurance is typically structured:

Relevant International Standards

International standards play a crucial role in guiding manufacturers toward best practices. Some key standards include:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that manufacturers adhere to consistent processes that lead to high-quality products.

- CE Marking: Particularly important for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For applications in the oil and gas industry, adhering to American Petroleum Institute standards is essential.

Quality Control Checkpoints

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify any deviations from quality standards.

- Final Quality Control (FQC): A thorough inspection of finished products to verify compliance with specifications before shipping.

Common Testing Methods

To ensure that polyurethane rollers meet performance requirements, various testing methods are employed:

- Tensile and Compression Testing: Determines the strength and load-bearing capacity of the rollers.

- Abrasion Resistance Testing: Assesses how well the rollers can withstand wear over time.

- Chemical Resistance Testing: Evaluates the rollers’ ability to resist degradation from exposure to chemicals.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is essential. Here are actionable steps buyers can take:

- Conduct Audits: Regular on-site audits of manufacturing facilities can help buyers assess the quality control processes in place.

- Request Quality Reports: Suppliers should provide documentation of their quality control measures and testing results. This includes certifications and compliance with international standards.

- Engage Third-Party Inspectors: Utilizing independent inspection services can provide unbiased evaluations of product quality before shipment.

Quality Control Considerations for International Buyers

When sourcing polyurethane rollers, international buyers should be aware of specific nuances in quality control:

- Cultural and Regulatory Differences: Understanding local regulations and cultural practices can impact quality expectations and compliance.

- Supply Chain Transparency: Buyers should seek suppliers who are transparent about their sourcing, manufacturing, and QC processes, as this builds trust and reliability in the partnership.

- Long-term Relationships: Establishing long-term relationships with manufacturers can lead to better customization and quality assurance as the supplier becomes familiar with specific needs.

By understanding the manufacturing processes and quality assurance practices for polyurethane rollers, international B2B buyers can make informed decisions that enhance their operational efficiencies and product reliability.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for polyurethane rollers Sourcing

The sourcing of polyurethane rollers involves a complex cost structure influenced by various components and market dynamics. Understanding these can empower international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Cost Components

-

Materials: The primary cost driver in the production of polyurethane rollers is the raw material itself. Polyurethane compounds vary widely in price based on the formulation, hardness, and specific properties required (e.g., abrasion resistance, chemical stability). Buyers should assess the material specifications to align with their operational needs.

-

Labor: Labor costs encompass the wages of skilled workers involved in the manufacturing process, including those engaged in custom molding and assembly. Regions with lower labor costs may offer competitive pricing, but buyers should also consider the expertise and experience of the workforce.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can reduce overhead, influencing the overall pricing of the product.

-

Tooling: Custom tooling for specific roller designs can be a significant upfront investment. Buyers should factor in these costs, particularly when ordering specialized or large-volume rollers.

-

Quality Control (QC): Ensuring the quality of polyurethane rollers is crucial, especially for high-stakes industries like aerospace and automotive. Comprehensive QC processes may add to the overall cost but are essential for minimizing defects and ensuring performance.

-

Logistics: Shipping and handling costs can vary greatly based on the origin of the rollers, destination, and chosen Incoterms. Buyers should be aware of potential tariffs and import duties that could affect the final cost.

-

Margin: Suppliers typically apply a margin based on their operational costs, market demand, and competitive positioning. Understanding the typical margins in the industry can aid buyers in evaluating supplier pricing.

Price Influencers

-

Volume/MOQ: Bulk orders often lead to reduced per-unit costs. Buyers should negotiate minimum order quantities (MOQs) to achieve better pricing.

-

Specifications/Customization: Custom rollers designed for specific applications may incur higher costs. Providing detailed specifications upfront can help suppliers offer accurate quotes.

-

Materials: The choice of polyurethane compound directly impacts pricing. High-performance materials may come at a premium, but they can result in long-term savings through enhanced durability.

-

Quality/Certifications: Suppliers offering recognized quality certifications (e.g., ISO) may charge more, but these certifications can provide peace of mind regarding product reliability.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers with a track record of quality may command higher prices, justified by their service level and product consistency.

-

Incoterms: Understanding Incoterms is vital for international transactions. They define the responsibilities of buyers and sellers in terms of shipping costs, insurance, and risk, which can significantly affect the total landed cost.

Buyer Tips

-

Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing. Building a relationship with suppliers can lead to more favorable terms over time.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just the upfront price. Consider factors such as maintenance costs and lifespan to determine the best value.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa and South America should be particularly mindful of currency fluctuations, shipping times, and potential delays due to customs, all of which can impact pricing and delivery schedules.

Disclaimer

Prices for polyurethane rollers can vary widely based on the aforementioned factors. It is essential for buyers to obtain quotes from multiple suppliers and conduct thorough market research to ensure competitive pricing.

Spotlight on Potential polyurethane rollers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘polyurethane rollers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for polyurethane rollers

When considering the procurement of polyurethane rollers, understanding their technical properties and industry terminology is essential for making informed purchasing decisions. This section outlines the critical specifications and common trade terms that international B2B buyers should be familiar with.

Key Technical Properties of Polyurethane Rollers

-

Material Grade

– Definition: Refers to the specific formulation of polyurethane used in roller manufacturing, which influences durability, flexibility, and resistance to wear.

– B2B Importance: Selecting the right material grade ensures that the roller will perform optimally under the specific conditions of its intended application, thereby reducing maintenance costs and downtime. -

Hardness (Shore A Scale)

– Definition: A measure of the firmness of the polyurethane, typically expressed in Shore A durometer. Softer formulations (30-60 Shore A) provide better grip and cushioning, while harder formulations (60-90 Shore A) are suited for heavy-duty applications.

– B2B Importance: Understanding hardness is crucial for selecting rollers that will provide the appropriate balance of traction and load-bearing capacity, essential for efficiency in material handling and production processes.

Illustrative Image (Source: Google Search)

-

Tensile Strength

– Definition: The maximum amount of tensile (pulling) stress that the polyurethane can withstand before failure, usually measured in pounds per square inch (PSI).

– B2B Importance: High tensile strength is vital for rollers used in heavy-duty applications, as it ensures they maintain their shape and performance under significant loads, thus preventing costly breakdowns. -

Abrasion Resistance

– Definition: The ability of the roller material to resist wear due to friction or contact with abrasive materials.

– B2B Importance: Rollers with superior abrasion resistance will last longer in harsh environments, leading to lower replacement costs and increased operational efficiency. -

Chemical Resistance

– Definition: The capacity of polyurethane to withstand exposure to various chemicals without degrading.

– B2B Importance: In industries where rollers may come into contact with oils, solvents, or other harsh substances, chemical resistance is critical to maintaining performance and longevity. -

Temperature Resistance

– Definition: The ability of polyurethane to maintain its properties at elevated or reduced temperatures.

– B2B Importance: Knowing the temperature range in which the rollers can operate effectively helps in selecting the right product for environments with fluctuating temperatures, thus ensuring reliability.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is vital for buyers looking for compatible parts and ensuring quality standards in roller replacement or integration. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers assess the feasibility of purchasing in bulk and evaluating cost-effectiveness, especially for small to medium-sized enterprises. -

RFQ (Request for Quotation)

– Definition: A formal process where buyers request price quotes from suppliers for specific quantities of products or services.

– Importance: Issuing an RFQ allows buyers to compare prices, terms, and conditions from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of sellers and buyers in international transactions, particularly regarding shipping and delivery.

– Importance: Familiarity with Incoterms ensures that buyers understand their obligations and risks during the shipping process, which is crucial for budget management and delivery timelines. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Importance: Understanding lead times is essential for planning inventory and production schedules, particularly in industries where downtime can be costly. -

Custom Molding

– Definition: The process of creating rollers tailored to specific application requirements through precision molding techniques.

– Importance: Custom molding capabilities allow buyers to obtain rollers that meet unique specifications, enhancing performance and ensuring compatibility with existing equipment.

By grasping these essential technical properties and trade terms, international B2B buyers can navigate the complexities of sourcing polyurethane rollers effectively, ensuring they select products that enhance their operational efficiency and reliability.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the polyurethane rollers Sector

Market Overview & Key Trends

The polyurethane rollers market is experiencing significant growth driven by the increasing demand for high-performance materials across diverse industries such as automotive, packaging, and manufacturing. Key factors influencing this market include the need for durability, the ability to withstand extreme conditions, and the rising focus on efficiency in production processes. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for making informed purchasing decisions.

Emerging technologies such as custom molding and advanced manufacturing techniques are reshaping the sourcing landscape. Buyers can now leverage CNC machining and 3D printing to obtain tailored solutions that meet specific application requirements. This trend allows for the production of rollers with varying hardness levels, enhancing performance in applications ranging from heavy-duty industrial uses to sensitive material handling.

Moreover, the market is witnessing an increase in collaborative supply chain models, where manufacturers work closely with clients to design and produce rollers that are optimized for their operational needs. This trend not only improves product performance but also reduces lead times and costs, making it a valuable strategy for B2B buyers looking to streamline their operations.

Buyers should also stay attuned to regional market dynamics. In Africa and South America, the growth of manufacturing sectors presents opportunities for suppliers of polyurethane rollers to expand their reach, while buyers in Europe and the Middle East may benefit from more established supply chains and technological advancements.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal concern for businesses worldwide, and the polyurethane rollers sector is no exception. The environmental impact of manufacturing processes and materials used in production is increasingly under scrutiny. B2B buyers are now prioritizing suppliers who demonstrate commitment to sustainable practices, including the use of eco-friendly materials and processes.

Ethical sourcing is essential in this context. Buyers should seek manufacturers who adhere to stringent environmental regulations and possess certifications such as ISO 14001, which indicates a robust environmental management system. Furthermore, the use of bio-based polyurethanes is gaining traction, providing an alternative that reduces reliance on petroleum-based products and minimizes carbon footprints.

Illustrative Image (Source: Google Search)

In addition to sourcing sustainable materials, companies are encouraged to consider the entire lifecycle of polyurethane rollers, from production to disposal. Engaging with suppliers who offer recycling programs for end-of-life products can significantly reduce environmental impact. Buyers should also explore partnerships with manufacturers that invest in renewable energy sources during production, contributing to a more sustainable supply chain.

Brief Evolution/History

The development of polyurethane rollers can be traced back to the advancements in polymer chemistry during the mid-20th century. Initially used in niche applications, the versatility of polyurethane quickly caught the attention of various industries. By the 1980s, the unique properties of polyurethane, including its superior abrasion resistance and load-bearing capabilities, led to its widespread adoption in manufacturing and material handling.

Over the decades, innovations in polyurethane formulations and processing techniques have further enhanced the performance characteristics of rollers. Today, the ability to customize hardness and surface properties has made polyurethane rollers an essential component in modern industrial applications. As industries continue to evolve, the demand for high-performance, sustainable solutions in the polyurethane rollers market will likely grow, shaping the future of sourcing strategies for international B2B buyers.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane rollers

-

How do I vet a polyurethane roller supplier?

To effectively vet a polyurethane roller supplier, start by evaluating their industry experience and expertise. Look for suppliers who have a proven track record in manufacturing and supplying polyurethane products specific to your industry. Request references or case studies from previous clients, especially those in your region. Additionally, assess their quality assurance processes and certifications, such as ISO 9001. Consider visiting their facility, if possible, to inspect their production capabilities and working conditions. -

Can I customize polyurethane rollers to meet my specific needs?

Yes, many manufacturers offer customization options for polyurethane rollers. Customization can include variations in hardness, size, and specific formulations tailored to your application. When discussing customization, provide detailed specifications and requirements, including load capacity, environmental conditions, and any unique performance characteristics needed. Engaging with the supplier early in the design process can ensure the final product meets your operational demands. -

What are the typical minimum order quantities (MOQs) and lead times for polyurethane rollers?

Minimum order quantities for polyurethane rollers can vary significantly based on the manufacturer and the complexity of the customization. Generally, MOQs can range from a few pieces to several hundred. Lead times can also vary, often falling between 2 to 8 weeks depending on the supplier’s production capacity and your order specifications. Always clarify these details upfront to ensure they align with your project timelines and budget constraints. -

What payment terms should I expect when purchasing polyurethane rollers?

Payment terms for polyurethane rollers often depend on the supplier’s policies and the size of your order. Common arrangements include a deposit upon order confirmation (usually 30-50%) with the balance due before shipment. Some suppliers may offer credit terms for established businesses. It’s advisable to negotiate favorable terms that suit your cash flow while ensuring both parties feel secure in the transaction. -

What quality assurance measures should I look for?

When sourcing polyurethane rollers, inquire about the supplier’s quality assurance measures. Look for certifications such as ISO 9001, which indicate adherence to international quality standards. Suppliers should provide documentation of testing procedures for material properties like tensile strength, abrasion resistance, and chemical compatibility. Ask for samples or test reports to assess the quality before committing to larger orders. -

How does logistics work when importing polyurethane rollers?

Logistics for importing polyurethane rollers involves several key steps. First, clarify shipping options with your supplier, including freight costs and delivery timelines. Ensure that you understand customs regulations in your country to avoid delays. It may be beneficial to work with a freight forwarder who can manage shipping and customs clearance. Be proactive in discussing packaging methods to ensure the rollers arrive undamaged. -

What should I do if there are disputes or issues with the order?

In the event of a dispute or issue with your order, first refer to the contract or purchase agreement for resolution procedures. Open communication with your supplier is crucial; address concerns promptly and professionally. If necessary, consider mediation or arbitration as outlined in your agreement. Establishing a clear understanding of return policies and warranties at the outset can also mitigate potential disputes. -

Are there specific certifications I need to be aware of when sourcing polyurethane rollers?

Yes, various certifications may be relevant depending on your industry and region. Look for suppliers that hold certifications related to material safety, such as REACH or RoHS, especially if your operations are in the EU. Additionally, certifications related to manufacturing quality (e.g., ISO 9001) are important. Ensure that the rollers meet any industry-specific standards that apply to your application, such as FDA approval for food processing or automotive standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for polyurethane rollers

Strategic sourcing of polyurethane rollers is essential for international B2B buyers looking to enhance operational efficiency and reduce costs. The key benefits of polyurethane, such as its superior abrasion resistance, high load-bearing capacity, and customization options, make it a critical material in various sectors including automotive, aerospace, and logistics. By partnering with experienced manufacturers who offer tailored solutions, businesses can optimize their roller performance and longevity, minimizing downtime and maintenance expenses.

As buyers from Africa, South America, the Middle East, and Europe navigate the complexities of sourcing, it is crucial to prioritize suppliers who understand regional market demands and can provide high-quality, durable products. Emphasizing collaboration with manufacturers not only ensures the selection of the right material composition but also aligns with specific operational needs.

Looking ahead, the market for polyurethane rollers is expected to grow as industries increasingly recognize the advantages of this versatile material. Now is the time for B2B buyers to leverage strategic sourcing, ensuring they remain competitive and equipped to meet future challenges. Invest in reliable, high-performance polyurethane rollers today to secure a sustainable and efficient operational framework for tomorrow.