Master the Best Burn Barrel Design for Efficient Waste

Introduction: Navigating the Global Market for best burn barrel design

In today’s increasingly regulated and environmentally-conscious landscape, the design and application of burn barrels have evolved into a crucial component of waste management strategies worldwide. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the best burn barrel designs is not just about choosing a product; it’s about making informed decisions that align with both operational efficiency and regulatory compliance.

The significance of optimal burn barrel design cannot be overstated. A well-engineered burn barrel minimizes emissions, maximizes combustion efficiency, and ensures safety during operation—factors that are vital for businesses looking to enhance their sustainability practices. This guide offers a comprehensive exploration of burn barrel designs, covering various types such as traditional and smokeless models, materials used in their construction, and best manufacturing practices, including quality control measures.

Moreover, it will delve into supplier options, cost considerations, and market trends, providing actionable insights for effective sourcing. Frequently asked questions will also be addressed to equip buyers with the knowledge needed to navigate the complexities of burn barrel procurement. By leveraging this guide, B2B buyers can confidently select burn barrels that not only meet their waste disposal needs but also contribute to their broader environmental goals and regulatory compliance efforts.

Understanding best burn barrel design Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Burn Barrel | 55-gallon metal drum, basic design | Waste disposal in rural areas | Pros: Cost-effective, easy to source; Cons: Limited emission control, potential regulatory issues. |

| Smokeless Burn Barrel | Secondary air supply, reduced smoke emissions | Eco-friendly waste management | Pros: Lower environmental impact, reduced smoke; Cons: Higher initial cost, requires more complex setup. |

| Yard Waste Incinerator | Designed for yard debris, often includes a cover | Landscaping and agricultural waste disposal | Pros: Safe for burning yard waste, minimizes fire risks; Cons: May require permits, limited to specific materials. |

| Portable Burn Barrel | Lightweight, often collapsible or easy to transport | Remote site waste management | Pros: Versatile, easy to transport; Cons: Smaller capacity, may not handle larger waste volumes effectively. |

| Multi-Chamber Burn Barrel | Multiple chambers for varied waste types | Industrial waste disposal | Pros: Efficient for diverse waste streams; Cons: More complex design, higher maintenance needs. |

Traditional Burn Barrel

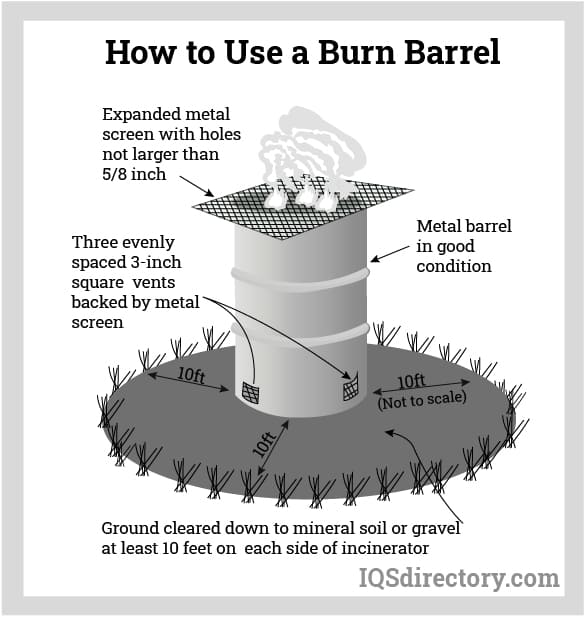

The traditional burn barrel, typically a repurposed 55-gallon drum, is widely recognized for its simplicity and cost-effectiveness. It is primarily used in rural settings for the incineration of combustible waste. While it offers a straightforward solution for waste disposal, buyers must be aware of potential regulatory issues regarding emissions and local burning ordinances. This type is suitable for businesses with minimal waste management budgets but may not comply with stricter environmental standards.

Smokeless Burn Barrel

The smokeless burn barrel features a secondary air supply system that enhances combustion efficiency and significantly reduces smoke emissions. This design is particularly appealing to businesses focused on sustainability and environmental compliance. Although the initial investment may be higher, the long-term benefits include improved air quality and adherence to increasingly stringent regulations. Buyers should consider local emissions laws and the potential for reduced liability when opting for this design.

Yard Waste Incinerator

Yard waste incinerators are specifically designed to handle organic materials such as leaves, branches, and grass clippings. They often come with features like a cover to contain embers and minimize fire hazards. This type is particularly relevant for landscaping companies and agricultural businesses that generate significant organic waste. However, users must be cautious about local regulations regarding burning yard waste, as permits may be required. The benefits include safer disposal practices and reduced wildfire risks.

Portable Burn Barrel

Portable burn barrels are lightweight and designed for ease of transport, making them ideal for remote job sites or temporary waste disposal needs. This type is particularly useful for construction companies or outdoor events that generate waste away from traditional disposal facilities. While they offer versatility, buyers should consider their smaller capacity, which may necessitate more frequent emptying and monitoring. The trade-off between portability and capacity is crucial for businesses with variable waste generation.

Multi-Chamber Burn Barrel

Multi-chamber burn barrels are engineered to handle different types of waste simultaneously, providing efficient incineration for diverse materials. This design is particularly beneficial for industrial applications, where various waste streams need to be managed. While they offer efficiency and versatility, buyers must be prepared for a more complex design that may require additional maintenance and monitoring. Understanding the specific waste types and volumes generated by their operations is essential for businesses considering this option.

Related Video: Stop Doing Basic – Build a BETTER Burn Barrel

Key Industrial Applications of best burn barrel design

| Industry/Sector | Specific Application of best burn barrel design | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Yard Waste Management | Efficient disposal of agricultural waste, reducing landfill use and promoting sustainability. | Compliance with local environmental regulations; materials that ensure durability and safety. |

| Waste Management | Incineration of Non-Recyclable Waste | Reduces waste volume and minimizes pollution, while adhering to waste management protocols. | Sourcing barrels that meet safety standards and local regulations for waste disposal. |

| Construction & Demolition | Disposal of Construction Debris | Streamlined disposal process for construction sites, enhancing efficiency and compliance with waste management laws. | Durability of materials; ease of transport; compliance with construction site regulations. |

| Forestry | Controlled Burning of Wood Waste | Reduces fire hazards and promotes sustainable forest management by efficiently managing biomass. | Fire safety features; ability to handle various types of wood waste; local burn permits. |

| Environmental Services | Ash Management and Disposal | Safe disposal of ash from burning operations, promoting environmental compliance and reducing contamination risks. | Compliance with environmental regulations; sourcing barrels designed for ash containment. |

Agriculture

In the agricultural sector, the best burn barrel design is utilized for yard waste management, particularly in regions where traditional waste disposal services are limited. Farmers can efficiently incinerate organic waste, such as tree trimmings and crop residues, reducing landfill dependency and promoting sustainable practices. International buyers, especially from Africa and South America, must consider local regulations regarding burning practices and ensure that the burn barrels are constructed from durable materials resistant to corrosion and extreme temperatures.

Waste Management

Within the waste management industry, burn barrels serve as a practical solution for incinerating non-recyclable waste. This application is crucial in areas lacking advanced waste processing facilities. The efficient disposal of waste not only minimizes environmental pollution but also aligns with increasing global regulatory pressures for sustainable waste management. B2B buyers should prioritize sourcing barrels that comply with local waste disposal regulations and safety standards to mitigate legal risks.

Illustrative Image (Source: Google Search)

Construction & Demolition

In construction and demolition, burn barrels are essential for the disposal of debris that cannot be recycled. By using burn barrels, construction companies can streamline their waste disposal processes, reducing delays and ensuring compliance with local waste management laws. Buyers in this sector should focus on sourcing robust and transportable burn barrels that are capable of withstanding the rigors of construction sites while meeting safety and regulatory requirements.

Forestry

The forestry industry benefits from the best burn barrel design by utilizing it for controlled burning of wood waste. This method helps manage biomass effectively, mitigating fire hazards and promoting sustainable forest management practices. Buyers, particularly from the Middle East and Europe, should ensure that their burn barrels are equipped with features that enhance fire safety and comply with local forestry regulations regarding controlled burns.

Environmental Services

Environmental services utilize burn barrels for the safe management and disposal of ash produced from incineration processes. This application is critical for preventing soil and water contamination, thus promoting environmental health. International B2B buyers must ensure that the burn barrels are designed specifically for ash containment and comply with environmental regulations to avoid potential liabilities.

Related Video: BURN BARREL GRATE HARDWARE KIT

Strategic Material Selection Guide for best burn barrel design

When selecting materials for burn barrel design, international B2B buyers must consider various factors, including the material’s properties, performance, and compliance with regional standards. Below, we analyze four common materials used in burn barrel construction: steel, stainless steel, aluminum, and fiberglass. Each material has unique characteristics that influence its suitability for different applications.

Steel

Key Properties: Steel is known for its high strength and ability to withstand high temperatures, making it an excellent choice for burn barrels. It typically has a temperature rating of up to 1,200°F (649°C) and can handle significant pressure.

Pros & Cons: Steel is durable and cost-effective, often available at a lower price point than alternatives. However, it is prone to corrosion, especially when exposed to moisture and chemicals, which can reduce its lifespan. Manufacturing complexity is moderate, as it can be easily welded and shaped.

Impact on Application: Steel burn barrels are suitable for general waste incineration, including yard waste and untreated wood. However, users must ensure proper maintenance to prevent rusting and degradation over time.

Considerations for International Buyers: Compliance with local regulations is crucial, particularly in Europe, where environmental standards are stringent. Buyers should look for products that meet ASTM or DIN standards to ensure quality and safety.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance and can withstand high temperatures, with a rating similar to that of carbon steel. It is also resistant to staining and rust.

Pros & Cons: The primary advantage of stainless steel is its longevity and low maintenance requirements. However, it is significantly more expensive than carbon steel, which may impact budget-conscious buyers. Manufacturing complexity is higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel burn barrels are ideal for applications requiring frequent use and exposure to harsh conditions, such as in coastal areas where saltwater corrosion is a concern.

Considerations for International Buyers: Buyers in regions like the Middle East and Africa should ensure that the stainless steel used complies with international standards, such as JIS or ASTM, to guarantee performance and durability.

Aluminum

Key Properties: Aluminum is lightweight and has good thermal conductivity, with a melting point around 1,220°F (660°C). It is also resistant to corrosion, although not as robust as stainless steel.

Pros & Cons: The lightweight nature of aluminum makes it easy to transport and handle. However, it is less durable than steel and can be more expensive than carbon steel options. Manufacturing processes for aluminum can be complex, requiring specialized techniques.

Impact on Application: Aluminum burn barrels are suitable for lighter applications, such as burning paper waste or small amounts of yard debris. They may not be ideal for heavy-duty use due to their lower structural integrity.

Considerations for International Buyers: Buyers should verify that aluminum products meet local regulations regarding waste disposal and emissions, especially in Europe, where compliance with environmental standards is critical.

Fiberglass

Key Properties: Fiberglass is a composite material known for its lightweight and high resistance to corrosion and chemical damage. It can withstand temperatures up to 300°F (149°C), making it less suitable for high-heat applications.

Pros & Cons: The primary advantage of fiberglass is its resistance to corrosion and low maintenance needs. However, it is not as durable under high temperatures and can be more expensive than metal options. Manufacturing complexity is moderate, as it requires careful molding and curing processes.

Impact on Application: Fiberglass burn barrels are best suited for applications involving low-heat waste, such as paper or organic materials. They are not recommended for burning high-temperature materials.

Considerations for International Buyers: Compliance with safety standards is essential, particularly in regions with strict environmental regulations. Buyers should ensure that fiberglass products meet relevant ASTM standards.

Summary Table

| Material | Typical Use Case for best burn barrel design | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General waste incineration | Cost-effective and durable | Prone to corrosion | Low |

| Stainless Steel | Frequent use in harsh conditions | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Burning paper waste and light yard debris | Lightweight and easy to handle | Less durable | Medium |

| Fiberglass | Low-heat waste burning | Corrosion resistant | Not suitable for high heat | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in burn barrel design, facilitating informed purchasing decisions tailored to their specific regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for best burn barrel design

Manufacturing a high-quality burn barrel involves several critical stages, each designed to ensure that the final product meets safety, efficiency, and environmental standards. Understanding these processes is essential for international B2B buyers seeking reliable suppliers, especially in regions like Africa, South America, the Middle East, and Europe.

Manufacturing Process

Material Preparation

The journey of a burn barrel begins with material selection. Typically, manufacturers use steel or aluminum, chosen for their durability and resistance to high temperatures. The most common form is a 55-gallon drum, which must be free of contaminants, rust, and other imperfections.

- Sourcing: Suppliers should ensure that materials come from reputable sources that adhere to international standards.

- Inspection: Incoming materials undergo rigorous Incoming Quality Control (IQC) checks to verify compliance with specifications.

Forming

Once the materials are ready, the forming process begins, which includes cutting, welding, and shaping the barrels.

- Cutting: The drums are cut to the required dimensions, ensuring that they will fit the designed specifications for combustion efficiency and safety.

- Welding: Advanced welding techniques are employed to join components. Techniques like MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding are common for their strength and precision.

- Assembly: Various components, such as air inlets for improved combustion, are assembled. This stage may also involve the installation of safety features like spark guards.

Finishing

The finishing stage is crucial for the longevity and effectiveness of the burn barrel.

- Coating: A heat-resistant coating is applied to protect against corrosion and wear. Common coatings include powder coating or high-temperature paint, which also enhances aesthetics.

- Final Assembly: Any additional components, such as handles or lids, are added.

Quality Assurance

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each burn barrel meets safety and performance standards.

International Standards

B2B buyers should be aware of international quality standards that govern manufacturing processes:

- ISO 9001: This standard ensures that organizations have effective quality management systems in place. Suppliers should be able to provide documentation of their ISO certification.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. Suppliers targeting European markets should ensure their products bear this mark.

Industry-Specific Standards

In addition to general standards, specific regulations may apply to burn barrels, such as:

- API (American Petroleum Institute): For barrels used in certain industrial applications, compliance with API standards may be necessary.

- Local regulations: Countries may have their own guidelines regarding burn barrel use, especially concerning emissions and safety.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspects raw materials upon arrival.

- In-Process Quality Control (IPQC): Monitors production processes, ensuring adherence to standards during manufacturing.

- Final Quality Control (FQC): A comprehensive inspection before shipment, where each burn barrel is checked for defects and functionality.

Common Testing Methods

To ensure compliance with quality standards, manufacturers employ various testing methods:

- Pressure Testing: Confirms the structural integrity of the barrel.

- Emissions Testing: Ensures that the burn barrel operates within acceptable pollution limits.

- Durability Testing: Simulates long-term use to assess wear and tear.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is essential:

- Audits: Conduct regular audits to evaluate compliance with quality standards and manufacturing processes. This can be done through either self-audits or third-party audits.

- Documentation: Request detailed reports on quality control procedures, including IQC, IPQC, and FQC findings.

- Third-Party Inspections: Engage third-party inspection agencies to validate manufacturing processes and product quality before shipment.

Quality Control and Certification Nuances for International Buyers

Navigating the quality control landscape can be challenging for buyers from diverse regions:

- Cultural Differences: Be aware that quality expectations may vary by region. Ensure that your supplier understands the specific requirements of your target market.

- Language Barriers: Clear communication is crucial. Suppliers should provide documentation in the buyer’s preferred language to avoid misunderstandings.

- Regulatory Compliance: Different regions may have varying regulations regarding burn barrels. Ensure that your supplier is well-versed in these requirements and can provide necessary documentation.

Conclusion

Understanding the manufacturing processes and quality assurance standards for burn barrels is essential for international B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with rigorous quality control checks and international compliance, buyers can ensure they are procuring safe, efficient, and environmentally responsible products. Engaging suppliers that uphold these standards will not only meet regulatory requirements but also enhance your business’s reputation in the marketplace.

Related Video: Amazing factories and processes| Manufacturing method and top 5 processes| Mass production process

Comprehensive Cost and Pricing Analysis for best burn barrel design Sourcing

Cost Structure and Pricing Analysis for Burn Barrel Design Sourcing

Understanding the cost structure and pricing nuances in sourcing burn barrels is essential for international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe. The pricing of burn barrels is influenced by various components that can significantly impact overall expenditure.

Cost Components

-

Materials: The primary material used for burn barrels is typically metal, such as steel or aluminum. The cost of raw materials can fluctuate based on global market conditions. Buyers should consider sourcing from regions with lower material costs to enhance profitability.

-

Labor: Labor costs vary widely based on the geographical location of the manufacturer. In regions with higher wage standards, such as parts of Europe, labor costs can constitute a significant portion of the total price. Therefore, understanding local labor market conditions is crucial.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses. Effective management of these costs can lead to competitive pricing. Manufacturers in regions with lower operational costs can offer more attractive pricing structures.

-

Tooling: The initial investment in tooling for burn barrel production can be substantial. Custom designs may require specialized tooling, which can increase costs. Buyers should inquire about tooling costs if customization is needed.

-

Quality Control (QC): Implementing stringent QC processes is essential to ensure product safety and compliance with regulations. While this adds to the cost, it is crucial for maintaining quality and avoiding costly recalls.

-

Logistics: Shipping costs, including freight and insurance, can significantly impact the final price, especially for international buyers. Understanding Incoterms is vital to clarify responsibilities and costs associated with shipping.

-

Margin: Supplier margins can vary based on their market position and competition. It is essential to compare multiple suppliers to ensure competitive pricing.

Price Influencers

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Negotiating minimum order quantities (MOQs) can lead to significant savings.

-

Specifications/Customization: Custom designs or specific features can increase the price. Buyers should assess if these customizations are necessary or if standard models suffice.

-

Quality/Certifications: Barrels that comply with specific environmental or safety certifications may cost more. However, investing in certified products can reduce liability risks.

-

Supplier Factors: Established suppliers with a reputation for reliability may charge higher prices. However, their proven track record can justify the cost.

-

Incoterms: Understanding the implications of Incoterms can help buyers manage costs better. Terms like FOB (Free on Board) can shift shipping responsibilities and costs.

Buyer Tips

-

Negotiation: Always negotiate pricing, especially when dealing with large orders. Suppliers may have flexibility in their pricing structure.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and disposal costs. A lower initial price may result in higher long-term costs.

-

Pricing Nuances: Be aware of currency fluctuations and their impact on pricing, particularly when sourcing from international suppliers. Locking in prices through contracts can mitigate this risk.

-

Research Local Regulations: Different regions may have varying regulations regarding burn barrels. Understanding these can help avoid potential fines and additional costs.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide a clearer picture of the market and help in negotiating better terms.

Disclaimer

Prices for burn barrels can vary widely based on the aforementioned factors and market conditions. It is advisable to conduct thorough research and engage in discussions with multiple suppliers to obtain indicative pricing that reflects your specific needs.

Spotlight on Potential best burn barrel design Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘best burn barrel design’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for best burn barrel design

When evaluating burn barrel designs, several technical properties and industry terms are essential for B2B buyers, especially those sourcing from diverse markets like Africa, South America, the Middle East, and Europe. Understanding these specifications and terminologies can significantly enhance decision-making processes and ensure compliance with safety and environmental regulations.

Key Technical Properties

-

Material Grade

– The material used in burn barrels, typically steel or aluminum, must meet specific grades to ensure durability and resistance to corrosion and high temperatures. For instance, carbon steel (often with a minimum tensile strength of 400 MPa) is favored for its strength and longevity. Buyers should prioritize material grades that align with local environmental regulations and usage conditions to avoid premature failure. -

Wall Thickness

– The thickness of the barrel walls is crucial for maintaining structural integrity under high heat. Standard wall thickness ranges from 1.2 mm to 2.5 mm. A thicker wall offers better heat retention and reduces the risk of warping, which is vital for consistent burning performance. B2B buyers must evaluate local conditions and intended usage when selecting wall thickness. -

Airflow Design

– Effective airflow is essential for efficient combustion. Burn barrels should include features like preheated secondary air inlets to enhance combustion efficiency and reduce smoke emissions. Understanding airflow design can help buyers select barrels that not only comply with regulations but also minimize environmental impact. -

Capacity

– Burn barrels typically come in various capacities, with the 55-gallon drum being the most common. Buyers should consider the volume of waste to be incinerated regularly and select a barrel size that optimally meets their operational needs without requiring excessive monitoring or frequent emptying. -

Compliance with Safety Standards

– Depending on the region, burn barrels must adhere to specific safety and environmental standards (e.g., ISO, EPA regulations). Buyers should ensure that the designs they consider meet local legislation to avoid fines and enhance community safety. -

Mobility Features

– Features like wheels or handles can significantly enhance the usability of burn barrels, especially in rural or semi-urban settings where waste management may require relocation of the unit. Buyers should assess their operational environment and choose designs that facilitate ease of use.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. B2B buyers should understand OEM specifications to ensure compatibility with existing waste management systems. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers to manage inventory effectively and negotiate better pricing and terms. -

RFQ (Request for Quotation)

– An RFQ is a document used to solicit price quotes from suppliers. B2B buyers should prepare detailed RFQs that specify technical requirements, quantities, and delivery timelines to receive accurate and competitive bids. -

Incoterms (International Commercial Terms)

– These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk allocation, and delivery responsibilities, which is essential for smooth cross-border transactions. -

Lead Time

– This term refers to the time it takes from placing an order to receiving the product. Understanding lead times helps buyers plan their inventory and production schedules effectively. -

Certification

– Certifications (e.g., ISO 9001) indicate that a product meets specific quality standards. Buyers should seek suppliers with relevant certifications to ensure that the burn barrels they purchase are reliable and safe for use.

By understanding these technical properties and terminologies, international B2B buyers can make informed decisions when sourcing burn barrels, ensuring compliance with regulations and optimizing operational efficiency.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the best burn barrel design Sector

In the burn barrel design sector, the market is influenced by a variety of global drivers, particularly the growing need for efficient waste management solutions. Increasing environmental regulations are prompting businesses to adopt safer alternatives to open burning, with burn barrels emerging as a viable option. Notably, regions such as Africa and South America are experiencing rapid urbanization, leading to heightened waste generation and the necessity for innovative waste disposal methods.

Key Trends in B2B Sourcing

-

Technological Advancements: The integration of advanced materials and design technologies is shaping the evolution of burn barrels. Smokeless designs, which utilize preheated secondary air supplies, are gaining traction among environmentally conscious buyers. This trend not only reduces emissions but also enhances combustion efficiency.

-

Regulatory Compliance: As governments worldwide tighten regulations surrounding waste disposal, burn barrel designs are increasingly required to meet specific safety and environmental standards. Buyers need to stay informed about local regulations to ensure compliance.

-

Customization: International B2B buyers are now seeking custom solutions tailored to their specific waste management needs. Manufacturers offering modular designs that can be adapted for different types of waste (e.g., yard waste, industrial refuse) are likely to see increased demand.

-

Supply Chain Transparency: There is a growing emphasis on transparency within supply chains, particularly regarding sourcing materials. Buyers are more inclined to partner with suppliers who can demonstrate ethical practices and sustainability in their production processes.

Sustainability & Ethical Sourcing in B2B

The environmental impact of burn barrels is a critical consideration for international buyers. As waste disposal methods evolve, the importance of selecting designs that minimize emissions and adhere to eco-friendly practices cannot be overstated. Ethical sourcing practices are becoming a priority, with buyers seeking materials that are not only durable but also sustainably produced.

Illustrative Image (Source: Google Search)

Green Certifications: Many manufacturers are now obtaining green certifications for their products, which can enhance their appeal in the market. Certifications such as ISO 14001 (Environmental Management) and other eco-labels signify a commitment to sustainable practices and can serve as a differentiator in a competitive landscape.

Material Selection: Buyers should prioritize burn barrels constructed from recycled materials or those that have a reduced carbon footprint. For instance, utilizing repurposed steel drums not only lowers environmental impact but also aligns with the global shift towards circular economy principles.

Brief Evolution/History

Burn barrels have evolved significantly from their traditional use as simple incinerators for waste disposal. Initially crafted from repurposed metal drums, modern burn barrels now incorporate innovative designs aimed at improving safety and efficiency. The shift towards smokeless models reflects an increased awareness of air quality issues and the need for environmentally responsible waste management solutions. This evolution underscores the growing role of technology and sustainability in the burn barrel design sector, making it crucial for B2B buyers to stay informed and adapt to these changes.

Related Video: The Ultimate DIY Burn Barrel Guide

Frequently Asked Questions (FAQs) for B2B Buyers of best burn barrel design

-

What should I consider when vetting suppliers for burn barrels?

When vetting suppliers, prioritize their industry experience, production capacity, and adherence to international quality standards. Verify their certifications, such as ISO or local environmental compliance. Request references from other international buyers, and assess their responsiveness to inquiries. Additionally, evaluate their ability to provide customization options to meet specific regional regulations or customer needs. Conducting a factory visit can also help in assessing their manufacturing processes and quality control measures. -

Can I customize the burn barrel design to meet specific needs?

Yes, many suppliers offer customization options for burn barrels, including size, material, and features such as air vents or ash collection systems. Discuss your requirements upfront to ensure the supplier can accommodate your needs. Specify any regulatory compliance necessary for your region, such as emissions standards, and request samples or prototypes before placing a bulk order. This step is crucial to ensure that the final product aligns with your operational requirements and local regulations. -

What are the typical minimum order quantities (MOQ) and lead times?

Minimum order quantities can vary widely by supplier and design complexity. Generally, you might encounter MOQs ranging from 50 to 500 units. Lead times depend on factors such as customization, production schedules, and shipping arrangements. For international orders, plan for additional time for customs clearance. Always discuss these details during negotiations to avoid any surprises and ensure timely delivery aligned with your project timelines. -

What payment methods are common for international transactions?

Common payment methods for international transactions include wire transfers, letters of credit, and escrow services. Wire transfers are widely accepted but ensure that you use a secure method to protect your funds. Letters of credit provide additional security, ensuring payment is only released upon fulfilling contractual obligations. Always clarify payment terms, including deposits and balances, and ensure that the payment method chosen aligns with your company’s financial policies and risk management strategies. -

How can I ensure quality assurance and certifications for burn barrels?

To ensure quality, request documentation of certifications relevant to your region, such as CE marking in Europe or ISO standards. Ask about the supplier’s quality control processes and whether they conduct regular inspections during production. Consider conducting third-party quality audits to verify compliance with safety and performance standards. Establish clear quality expectations in your contract, including penalties for non-compliance, to protect your investment. -

What logistics considerations should I be aware of when importing burn barrels?

Logistics play a critical role in international trade. Assess shipping options, including freight forwarders that specialize in heavy industrial goods. Understand the incoterms (International Commercial Terms) to clarify responsibilities for shipping, insurance, and customs duties. Also, consider the potential for delays in customs clearance and plan accordingly. Collaborate with your supplier to ensure all necessary documentation, such as invoices and packing lists, is accurate to avoid complications during transit. -

How should I handle disputes with suppliers?

Disputes can arise from various issues, including quality concerns, delays, or misunderstandings. The best approach is to establish clear communication channels and terms in your contract, including dispute resolution mechanisms such as arbitration or mediation. Keep detailed records of all transactions and communications. If a dispute arises, address it promptly and professionally, seeking to resolve it amicably before escalating to legal channels. Understanding the legal frameworks in both countries can also aid in navigating disputes effectively. -

What are the environmental regulations I should consider when sourcing burn barrels?

Environmental regulations vary significantly by region, especially regarding emissions and waste management. Research local laws in your target markets, particularly if you are operating in Europe, where regulations are stringent. Ensure that the burn barrels comply with local emissions standards and that the supplier can provide relevant documentation. Engaging with local environmental agencies or consultants can provide insights into compliance requirements, helping to avoid potential legal issues and enhance your brand’s sustainability profile.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for best burn barrel design

In conclusion, effective strategic sourcing of burn barrel designs plays a pivotal role in enhancing waste management practices across diverse international markets. Buyers in Africa, South America, the Middle East, and Europe must prioritize safety, efficiency, and regulatory compliance when selecting burn barrels. As demonstrated, advanced designs, such as those featuring preheated secondary air supplies and enhanced emission control, are not only environmentally friendly but also optimize waste incineration processes.

Key takeaways for B2B buyers include:

– Invest in quality: Choose burn barrels that meet local safety standards and environmental regulations to ensure compliance and operational efficiency.

– Understand local regulations: Familiarize yourself with specific burn ordinances in your region to avoid potential legal issues.

– Focus on innovation: Look for suppliers offering modern designs that enhance combustion efficiency while minimizing harmful emissions.

As the global landscape shifts towards more sustainable practices, the demand for effective waste management solutions will continue to rise. Now is the time for international buyers to engage with reputable manufacturers and suppliers to secure the best burn barrel designs, ensuring a sustainable future for their operations. By making informed sourcing decisions, businesses can contribute positively to environmental stewardship while optimizing their waste management strategies.