Master the Different Types of Fans for Optimal B2B Sourcing

Introduction: Navigating the Global Market for different types of fans

In today’s rapidly evolving industrial landscape, understanding the diverse types of fans is paramount for B2B buyers seeking to enhance operational efficiency and ensure sustainability. From manufacturing to HVAC systems, the correct fan type can significantly influence air quality, energy consumption, and equipment longevity. As industries across Africa, South America, the Middle East, and Europe increasingly prioritize technological advancements, the demand for specialized fans is more critical than ever.

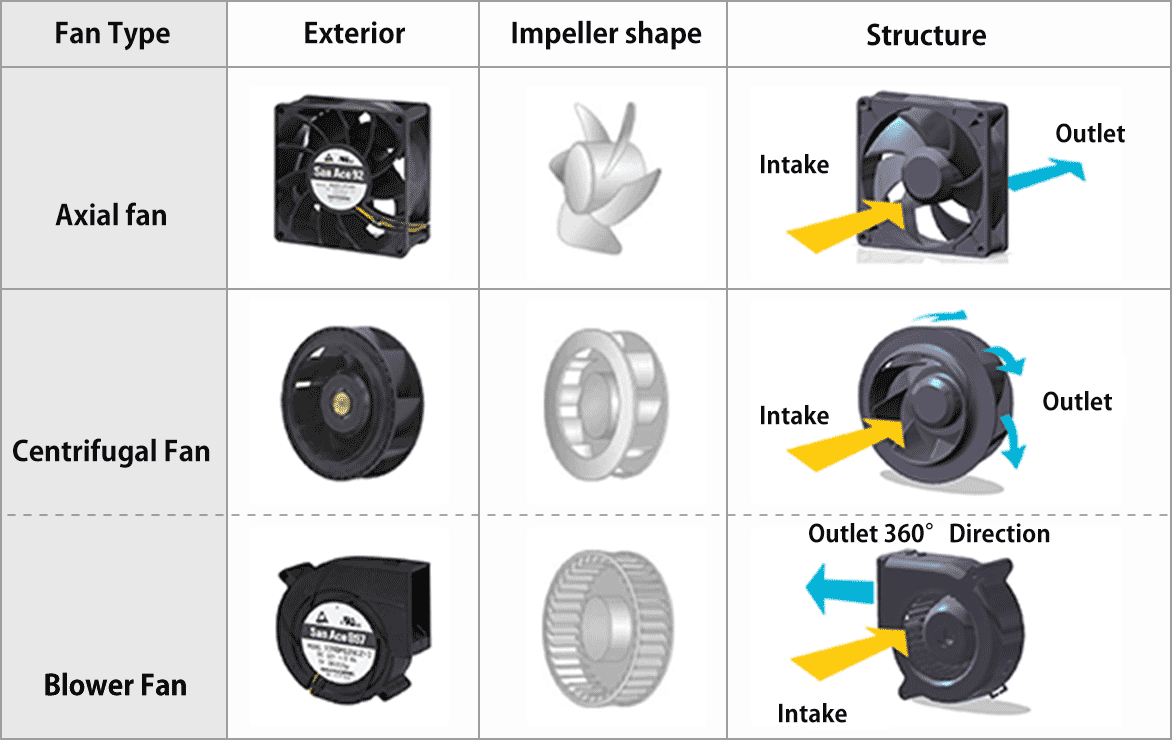

This comprehensive guide delves into the various types of industrial fans, including centrifugal and axial fans, and highlights their specific applications and advantages. We will explore essential factors influencing fan selection, such as airflow, pressure ratings, efficiency, and material durability. Additionally, this guide addresses manufacturing quality control standards, sourcing considerations, and cost implications, empowering buyers to make informed decisions.

By understanding the intricacies of fan technology and market dynamics, international B2B buyers can optimize their sourcing strategies and enhance their operational frameworks. Whether you are based in Turkey, Poland, or elsewhere, this guide serves as an invaluable resource to navigate the global market for fans, ensuring you are equipped with the insights needed to drive your business forward. Engage with this guide to unlock actionable strategies that meet your specific ventilation and cooling needs, ultimately fostering a more productive and efficient industrial environment.

Understanding different types of fans Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Centrifugal Fans | High efficiency, handles high static pressures, compact | HVAC systems, dust collection, industrial processes | Pros: Efficient airflow, durable. Cons: Higher initial cost. |

| Axial Fans | Simple design, low-pressure applications, high airflow | Cooling towers, ventilation in buildings | Pros: Cost-effective, easy to install. Cons: Less efficient in high-pressure environments. |

| Blowers | Moves air at high pressure, suitable for long ducts | Industrial drying, pneumatic conveying | Pros: Effective for high resistance systems. Cons: Larger footprint, more complex installation. |

| Enclosure Fans | Designed for thermal management in electronic enclosures | Data centers, telecommunications, medical equipment | Pros: Prevents overheating, compact. Cons: Specific airflow requirements can complicate selection. |

| Tubeaxial Fans | Combines features of axial and centrifugal fans | HVAC, telecommunications, server cooling | Pros: Versatile, efficient in various settings. Cons: Can be more expensive than standard fans. |

Centrifugal Fans

Centrifugal fans are characterized by their ability to handle high static pressures and deliver efficient airflow. They are commonly used in HVAC systems and dust collection applications due to their robust design. When purchasing centrifugal fans, buyers should consider factors such as airflow requirements, energy efficiency, and the fan’s ability to withstand environmental conditions. While these fans may have a higher initial cost, their long-term efficiency can lead to significant cost savings.

Axial Fans

Axial fans are recognized for their simple design and ability to move large volumes of air at low pressures. They are ideal for applications such as cooling towers and building ventilation. B2B buyers should focus on the fan’s airflow rating and installation requirements when making a selection. Although axial fans are typically more cost-effective and easier to install, they may not perform as well in high-pressure situations, which could limit their applicability in certain environments.

Blowers

Blowers are specialized fans designed to move air at high pressures, making them suitable for applications involving long ducts or high resistance systems. Common uses include industrial drying and pneumatic conveying. Buyers should assess the blower’s efficiency, noise levels, and space requirements before purchasing. While blowers can be effective in challenging environments, their larger footprint and more complex installation process may require additional planning and resources.

Enclosure Fans

Enclosure fans are specifically designed for thermal management within electronic enclosures, making them vital for data centers and telecommunications equipment. These fans help prevent overheating by maintaining optimal internal temperatures. When sourcing enclosure fans, buyers should consider airflow ratings, power requirements, and noise levels. Although they are compact and effective, the need for precise airflow specifications can complicate the selection process.

Tubeaxial Fans

Tubeaxial fans combine the features of both axial and centrifugal fans, offering versatility for various applications. They are commonly used in HVAC systems and telecommunications for effective cooling. B2B buyers should evaluate the fan’s airflow capabilities, installation space, and efficiency ratings. While tubeaxial fans can be more expensive than standard axial fans, their adaptability to different operational needs often justifies the investment.

Related Video: PC Fans Types Explained… What is right for your setup?

Key Industrial Applications of different types of fans

| Industry/Sector | Specific Application of different types of fans | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Centrifugal Fans for Dust Collection | Efficient removal of airborne particulates, enhancing air quality and worker safety. | Consider airflow capacity, energy efficiency, and maintenance needs. |

| Food Processing | Axial Fans for Cooling and Ventilation | Maintains optimal temperature for food preservation and safety, preventing spoilage. | Evaluate noise levels, space requirements, and corrosion resistance. |

| Data Centers | Enclosure Fans for Heat Management | Prevents overheating of critical electronic equipment, ensuring operational reliability. | Focus on airflow ratings, thermal load calculations, and installation ease. |

| HVAC Systems | Centrifugal Blowers for Air Distribution | Enhances system efficiency and comfort by optimizing airflow in large spaces. | Assess fan efficiency, duct compatibility, and noise levels. |

| Telecommunications | Tubeaxial Fans for Equipment Cooling | Provides consistent cooling for telecom equipment, reducing downtime and maintenance costs. | Ensure compatibility with specific equipment sizes and airflow requirements. |

Manufacturing: Centrifugal Fans for Dust Collection

In the manufacturing sector, centrifugal fans are vital for dust collection systems. They efficiently remove airborne particulates, which not only enhances air quality but also improves worker safety and compliance with health regulations. Buyers in this sector should prioritize airflow capacity, energy efficiency, and ease of maintenance when sourcing these fans, especially in regions with stringent environmental standards.

Food Processing: Axial Fans for Cooling and Ventilation

Axial fans are commonly used in the food processing industry for cooling and ventilation purposes. They help maintain optimal temperatures for food preservation, preventing spoilage and ensuring compliance with safety standards. International buyers must consider factors such as noise levels, space constraints, and the fans’ resistance to corrosion, particularly in humid environments prevalent in many African and South American countries.

Data Centers: Enclosure Fans for Heat Management

In data centers, enclosure fans play a critical role in heat management. These fans prevent overheating of sensitive electronic equipment, ensuring operational reliability and minimizing the risk of costly downtime. When sourcing enclosure fans, buyers should focus on airflow ratings, thermal load calculations, and the ease of installation, as these factors significantly impact the efficiency of cooling systems.

HVAC Systems: Centrifugal Blowers for Air Distribution

Centrifugal blowers are essential in HVAC systems for optimal air distribution across large spaces. They enhance system efficiency and comfort, making them ideal for commercial buildings and industrial facilities. Buyers should assess fan efficiency, compatibility with existing ductwork, and noise levels to ensure a seamless integration that meets both performance and regulatory requirements.

Telecommunications: Tubeaxial Fans for Equipment Cooling

Tubeaxial fans are used extensively in the telecommunications sector for cooling equipment. They provide consistent airflow to prevent overheating, thereby reducing maintenance costs and enhancing operational uptime. Buyers must ensure compatibility with specific equipment sizes and airflow requirements, particularly in rapidly developing markets in the Middle East and Europe, where technology infrastructure is critical.

Related Video: Industrial Fans and blowers, major types and applications

Strategic Material Selection Guide for different types of fans

When selecting materials for different types of industrial fans, it is essential to consider their properties, applications, and the specific needs of international B2B buyers. The choice of material can significantly impact fan performance, durability, and overall cost-effectiveness. Below is an analysis of four common materials used in fan manufacturing, focusing on their key properties, advantages, disadvantages, and considerations for buyers from diverse regions.

1. Steel

Key Properties: Steel is renowned for its strength and durability. It typically withstands high temperatures and pressures, making it suitable for heavy-duty applications. Corrosion resistance can be enhanced through galvanization or coatings.

Pros & Cons: Steel fans are highly durable and can handle aggressive environments. However, they tend to be heavier and may require more complex manufacturing processes. The cost of steel can fluctuate based on market conditions, impacting overall project budgets.

Impact on Application: Steel is ideal for environments where mechanical strength is crucial, such as in mining or heavy manufacturing. Its compatibility with various media, including dust and particulates, makes it a versatile choice.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Europe, adherence to environmental regulations regarding emissions and noise is also essential.

2. Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, especially when anodized. It can withstand moderate temperatures and is often used in applications requiring lower weight.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier installation and handling. However, it may not be suitable for high-pressure applications and can be more expensive than steel.

Impact on Application: Aluminum is suitable for applications in HVAC systems and electronics cooling, where weight and corrosion resistance are critical. It is less effective in environments with high mechanical stress.

Considerations for International Buyers: Buyers should check for compliance with international standards and consider the availability of aluminum in their region. In South America and Africa, sourcing aluminum may be more challenging due to local supply constraints.

3. Plastic (Polymer)

Key Properties: Various plastics, such as polycarbonate and polypropylene, offer excellent corrosion resistance and lightweight characteristics. They can operate effectively in a wide temperature range, depending on the specific polymer used.

Pros & Cons: Plastic fans are generally less expensive and easier to manufacture. However, they may not be as durable as metal options and can be susceptible to UV degradation if not treated.

Impact on Application: Ideal for applications involving corrosive environments, such as chemical processing or food production, plastic fans can handle moisture and chemical exposure well.

Considerations for International Buyers: Buyers must ensure that the selected plastic complies with food safety standards (if applicable) and has certifications for chemical resistance. In regions with high UV exposure, selecting UV-stabilized plastics is crucial.

4. Stainless Steel

Key Properties: Stainless steel combines the strength of steel with enhanced corrosion resistance, making it suitable for harsh environments. It can withstand high temperatures and is often used in food-grade applications.

Pros & Cons: The durability and resistance to corrosion are significant advantages, particularly in industries such as food processing and pharmaceuticals. However, stainless steel is typically more expensive and heavier than other materials.

Impact on Application: Stainless steel fans are ideal for environments where hygiene and corrosion resistance are paramount, such as in the food and beverage industry.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ISO for food safety. In regions like the Middle East, where humidity can be high, ensuring the right grade of stainless steel is essential to prevent rusting.

| Material | Typical Use Case for different types of fans | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High durability and strength | Heavier and more complex to manufacture | Medium |

| Aluminum | HVAC and electronics cooling | Lightweight and corrosion resistant | Not suitable for high-pressure use | High |

| Plastic (Polymer) | Chemical processing and food production | Cost-effective and lightweight | Less durable than metal options | Low |

| Stainless Steel | Food processing and pharmaceutical industries | Excellent corrosion resistance | Higher cost and weight | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of fans

Manufacturing Processes for Different Types of Fans

When sourcing industrial fans, understanding the manufacturing processes is crucial for B2B buyers. The quality of the fan significantly impacts its performance, durability, and overall value. Below is a detailed overview of the main stages of manufacturing and assembly, highlighting key techniques utilized in the production of different types of fans.

Main Stages of Manufacturing

-

Material Preparation

– The manufacturing process begins with the selection of high-quality raw materials. Common materials include metals such as steel and aluminum, as well as high-grade plastics for specific fan components.

– Material properties must be assessed, including strength, corrosion resistance, and thermal stability, particularly for fans designed for harsh environments.

– Suppliers should provide Material Safety Data Sheets (MSDS) to confirm compliance with international safety standards. -

Forming

– Various techniques are employed to shape the materials into fan components. This includes:- Stamping: Used for creating the fan blades and casing from sheet metal.

- Extrusion: Ideal for producing fan housings, ensuring uniform cross-sections.

- Injection Molding: Utilized for plastic components, allowing for complex shapes and lightweight designs.

- Precision in this stage is vital, as it affects the aerodynamic performance of the fan.

-

Assembly

– The assembly process incorporates all manufactured components, including motors, blades, casings, and control systems.

– Automated assembly lines are often used to enhance efficiency and reduce human error. However, skilled technicians may perform critical assembly tasks to ensure precision.

– Components are aligned and fastened using screws, bolts, or welding techniques, depending on the fan design and intended application. -

Finishing

– Finishing processes include surface treatments to enhance durability and aesthetic appeal. Techniques such as powder coating or anodizing are commonly employed to protect against corrosion and wear.

– Quality checks are integrated into this stage to ensure that the finishing process meets specified standards.

Quality Assurance in Fan Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process for industrial fans. It ensures that products meet established standards and performance criteria. Here’s an overview of relevant international standards and typical QA checkpoints.

Relevant International Standards

- ISO 9001: This standard outlines the criteria for a quality management system. It emphasizes customer satisfaction and continuous improvement, making it essential for manufacturers of industrial fans.

- CE Certification: Required for products sold in the European Economic Area, ensuring they meet safety, health, and environmental protection standards.

- API Standards: Particularly relevant for fans used in the oil and gas industry, these standards ensure that products are safe and reliable under operational conditions.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– This initial checkpoint assesses the quality of raw materials and components received from suppliers. Inspections ensure that materials conform to specifications before they enter the production process. -

In-Process Quality Control (IPQC)

– Conducted at various stages of manufacturing, IPQC involves monitoring production processes to detect defects early. This may include visual inspections and measurements to confirm tolerances are maintained. -

Final Quality Control (FQC)

– The FQC phase occurs after assembly and finishing, where the final product undergoes comprehensive testing. This includes performance testing, noise level assessments, and safety checks.

Common Testing Methods

- Performance Testing: Evaluates airflow, pressure, and energy consumption to ensure the fan operates within specified parameters.

- Noise Testing: Measures the decibel levels produced by the fan, crucial for applications in noise-sensitive environments.

- Durability Testing: Subjecting fans to extreme conditions to assess their resistance to wear, corrosion, and temperature variations.

Verifying Supplier Quality Control

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential. Here are some actionable steps:

- Conduct Supplier Audits: Regular audits can help assess the manufacturing processes and QA practices of suppliers. This provides insight into their commitment to quality and compliance with standards.

- Request Quality Reports: Suppliers should provide detailed quality assurance reports, including results from IQC, IPQC, and FQC. This documentation serves as proof of the adherence to quality standards.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can ensure unbiased evaluations of the manufacturing processes and the final products.

- Understand Certification Nuances: Different regions may have specific certification requirements. For instance, CE marking is essential for the European market, while other certifications may be required in Africa or South America. Familiarizing yourself with these nuances can prevent compliance issues.

Conclusion

Understanding the manufacturing processes and quality assurance mechanisms in the production of industrial fans is vital for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, along with adhering to international standards and implementing robust QA practices, buyers can ensure they source reliable and efficient products. Engaging in thorough supplier verification processes further strengthens procurement strategies, ultimately leading to better operational outcomes.

Related Video: Top 10 Fantastic Mass Production Factory Process Videos.

Comprehensive Cost and Pricing Analysis for different types of fans Sourcing

When sourcing different types of fans for industrial applications, understanding the cost structure and pricing dynamics is crucial for B2B buyers. This analysis will break down the key cost components, price influencers, and provide actionable tips to enhance cost-efficiency while navigating international markets.

Cost Components

-

Materials: The choice of materials significantly affects the overall cost. Fans made from high-quality metals and corrosion-resistant materials typically incur higher upfront costs but can lead to savings in longevity and maintenance. For instance, stainless steel fans are more expensive than plastic but offer superior durability, especially in harsh environments.

-

Labor: Labor costs vary by region, impacting the final price of the fan. Countries with higher labor costs may see an increase in manufacturing expenses. Conversely, sourcing from regions with lower labor costs, such as parts of Asia or Eastern Europe, can offer significant savings.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and indirect labor. Efficient manufacturing processes can reduce these overheads, impacting the final pricing structure.

-

Tooling: Custom tooling for specialized fan designs can be a significant upfront cost. Buyers should consider whether they need standard models or custom solutions, as the latter may require substantial initial investment.

-

Quality Control (QC): Robust QC processes ensure product reliability and performance, which can add to costs. However, investing in quality control can reduce long-term costs by minimizing returns and replacements.

-

Logistics: Transportation and shipping costs can vary widely based on the origin of the product and destination. Buyers should be aware of the total logistics costs, including freight, customs duties, and insurance, especially when importing from different continents.

Illustrative Image (Source: Google Search)

- Margin: Supplier margins vary based on market positioning and competition. Understanding the market landscape can help buyers negotiate better prices.

Price Influencers

-

Volume/MOQ: Pricing often benefits from economies of scale. Larger orders typically lead to lower per-unit costs. Buyers should assess their needs and consider bulk purchasing if feasible.

-

Specifications/Customization: Customized fans tailored to specific applications usually come at a premium. Clearly defining requirements can help in negotiating better prices for custom solutions.

-

Materials: As mentioned, the choice of materials plays a critical role in pricing. High-performance materials may increase costs but can enhance the fan’s lifespan and efficiency.

-

Quality/Certifications: Fans that meet international quality standards or certifications (such as ISO or CE) may carry higher price tags. However, these certifications often translate to improved reliability and performance.

-

Supplier Factors: Supplier reputation, reliability, and service can influence pricing. Established suppliers may charge more due to their track record, while emerging suppliers might offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They dictate the responsibilities of buyers and sellers regarding shipping, risk, and costs. Different terms can significantly affect total costs.

Buyer Tips

-

Negotiation: Always negotiate prices, especially for large orders. Leverage competing quotes to gain better terms and pricing.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), not just the purchase price. Consider maintenance, operational efficiency, and lifespan in your calculations.

-

Pricing Nuances: International buyers should be aware of currency fluctuations and local market conditions that may affect pricing. Engaging local experts can provide insights into regional pricing trends.

-

Evaluate Suppliers: Assess potential suppliers based on their ability to meet quality standards, delivery timelines, and after-sales support. A reliable supplier can mitigate risks associated with sourcing.

Disclaimer

Prices for industrial fans can vary widely based on the factors mentioned above. The insights provided here are indicative and should be validated through direct inquiries with manufacturers and suppliers for accurate quotes tailored to specific requirements.

Spotlight on Potential different types of fans Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘different types of fans’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for different types of fans

When selecting industrial fans for various applications, understanding the essential technical properties and trade terminology is crucial for B2B buyers. This knowledge enables informed purchasing decisions and enhances operational efficiency. Below are key specifications and industry terms that every buyer should be familiar with.

Critical Specifications

-

Airflow Rate

– Definition: Measured in cubic meters per second (CMS) or cubic feet per minute (CFM), this indicates the volume of air a fan can move within a specified timeframe.

– Importance: Adequate airflow is vital for effective ventilation, cooling, and dust control in industrial settings. Buyers must calculate the airflow needs based on the specific environment and application to avoid under or over-specifying. -

Static Pressure

– Definition: The resistance a fan must overcome to move air through a system, typically measured in inches of water gauge (inWG) or Pascals (Pa).

– Importance: Understanding static pressure helps buyers select fans that can operate effectively in ducted systems or environments with obstructions. Choosing a fan that can handle the expected static pressure ensures optimal performance and energy efficiency. -

Fan Efficiency

– Definition: This is the ratio of the fan’s output power to the input power, often expressed as a percentage.

– Importance: Higher efficiency means lower operating costs and reduced energy consumption, which is increasingly important for sustainability and cost management. Buyers should look for fans that provide a good balance between upfront cost and long-term savings. -

Noise Level

– Definition: Measured in decibels (dB), this indicates the sound produced by the fan during operation.

– Importance: Noise can be a critical factor in environments where quiet operation is necessary, such as hospitals or office buildings. Buyers must consider noise levels to ensure compliance with workplace regulations and to maintain a comfortable environment. -

Material Grade

– Definition: The type and quality of materials used in fan construction, such as steel, aluminum, or composite materials.

– Importance: Material selection impacts durability, resistance to corrosion, and overall lifespan of the fan. Buyers should assess the operating environment to ensure that the materials used are suitable for conditions like humidity or exposure to chemicals. -

Size and Dimensions

– Definition: Refers to the physical dimensions of the fan, including diameter and housing size.

– Importance: The size must fit the installation space while still meeting performance requirements. Buyers should ensure that the chosen fan can be installed without hindrance and can effectively circulate air in the intended area.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications ensures compatibility and quality assurance in industrial applications. -

MOQ (Minimum Order Quantity)

– The smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to negotiate pricing and manage inventory efficiently. -

RFQ (Request for Quotation)

– A document sent to suppliers to invite them to provide a quote for specific products or services. An RFQ helps buyers compare prices and terms effectively. -

Incoterms (International Commercial Terms)

– A set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations. -

Static Pressure

– While previously defined in specifications, in trade terminology, it emphasizes the importance of understanding how resistance impacts fan selection and system design. -

Lead Time

– The time taken from placing an order to its delivery. Understanding lead times is essential for planning and ensuring that projects stay on schedule.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing industrial fans, ultimately leading to better operational outcomes and cost savings.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the different types of fans Sector

Global drivers in the industrial fan market are evolving rapidly, influenced by technological advancements, energy efficiency mandates, and increasing demand for air quality management across various sectors. The market is characterized by a shift towards automation and IoT integration, enabling real-time monitoring and control of ventilation systems. This trend is particularly relevant for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, where infrastructure development is pivotal. In addition, the growing awareness of climate change is driving industries to adopt more energy-efficient solutions, thus increasing the demand for high-performance industrial fans that minimize energy consumption while maximizing airflow.

Emerging sourcing trends include a preference for suppliers that offer customizable solutions tailored to specific industry needs. For instance, buyers are increasingly looking for axial and centrifugal fans that are designed to meet unique operational requirements, such as specific airflow rates and pressure conditions. The ability to source from local manufacturers is also gaining traction, particularly in Europe and parts of Africa, as it reduces lead times and transportation costs. Furthermore, the trend towards digitalization in procurement processes, including the use of e-procurement platforms, is streamlining the sourcing of industrial fans, making it easier for buyers to compare products and prices.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of purchasing decisions in the industrial fan sector. The environmental impact of manufacturing processes and product life cycles is under scrutiny, prompting buyers to seek out manufacturers that prioritize eco-friendly practices. This includes sourcing materials that are recyclable or biodegradable and implementing energy-efficient production methods.

Ethical supply chains are also gaining importance, particularly in regions where labor practices can be inconsistent. Buyers are encouraged to engage with suppliers who can demonstrate compliance with international labor standards and provide transparency in their supply chain operations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are increasingly sought after, as they signal a commitment to sustainable and ethical practices. Additionally, the use of ‘green’ materials in fan manufacturing—such as low-impact plastics and sustainable metals—can enhance a company’s brand reputation and appeal to environmentally conscious consumers.

Brief Evolution/History

The industrial fan sector has undergone significant transformation since its inception in the early 20th century. Originally designed for basic ventilation, fans have evolved into sophisticated systems capable of handling complex airflow requirements across diverse applications. The introduction of energy-efficient designs in the late 20th century marked a pivotal moment, driven by rising energy costs and environmental concerns. Today, advancements in materials science and digital technology have further enhanced fan performance, leading to innovations such as smart fans that integrate with building management systems. This evolution reflects a broader trend towards efficiency and sustainability in industrial processes, making it essential for B2B buyers to stay informed about the latest developments and technologies in the fan market.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of different types of fans

-

What factors should I consider when vetting suppliers for industrial fans?

When vetting suppliers, consider their reputation, experience, and expertise in manufacturing the specific type of fan you need. Look for certifications such as ISO 9001 for quality management and ensure they have a proven track record in international trade. Request references or case studies from previous clients, especially those in your industry or region. Evaluate their production capacity, lead times, and after-sales support. Lastly, inquire about their compliance with local regulations and standards relevant to your market. -

Can I customize the fans to meet specific requirements?

Yes, many manufacturers offer customization options for industrial fans to cater to specific operational needs. This can include modifications in size, airflow capacity, materials, and design features. When discussing customization, be clear about your requirements and ask the supplier about their capabilities and limitations. Ensure you receive technical drawings or prototypes for approval prior to final production. This can significantly enhance performance and efficiency tailored to your application. -

What are the typical minimum order quantities (MOQ) and lead times for industrial fans?

Minimum order quantities can vary significantly based on the supplier and the type of fan. Generally, MOQs range from 10 to 100 units for standard models, while custom designs may require higher quantities. Lead times often depend on the complexity of the order; standard products might be available within 4-6 weeks, while customized fans could take 8-12 weeks or longer. Always discuss these factors upfront to align with your procurement timelines and avoid delays. -

What payment terms should I expect when sourcing industrial fans internationally?

Payment terms can vary widely among suppliers, but common practices include a deposit (often 30-50%) upfront, with the balance due before shipment or upon delivery. Some suppliers may offer letters of credit or escrow services for added security. Be cautious about payment methods and choose options that provide adequate protection against fraud. It’s essential to clarify payment terms in the purchase agreement to avoid misunderstandings later in the transaction. -

How can I ensure quality assurance and certification compliance for the fans I purchase?

To ensure quality assurance, request documentation of certifications that demonstrate compliance with relevant industry standards, such as CE, UL, or ISO certifications. Conduct audits of the manufacturing facility if possible, or inquire if the supplier can provide third-party inspection services. Additionally, consider requesting a sample before committing to a large order to verify that the product meets your specifications. Establishing a clear quality assurance process in your contract can help mitigate risks. -

What are the logistics considerations for importing industrial fans?

Logistics is a critical aspect of importing industrial fans. Assess shipping options, including air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations and tariffs applicable in your country to avoid unexpected costs. Ensure that your supplier provides proper documentation, such as bills of lading and commercial invoices. Additionally, consider warehousing solutions if you’re ordering in bulk, as this can help streamline distribution once the fans arrive. -

How should disputes over quality or delivery issues be managed with suppliers?

Disputes should be addressed promptly and professionally. Establish clear terms regarding quality expectations, delivery timelines, and recourse in the event of disputes in your contract. Maintain open communication with the supplier, documenting all correspondence. If issues arise, discuss them directly and seek a resolution, which may include replacements, refunds, or adjustments. Consider including arbitration clauses in your contracts to facilitate smoother dispute resolution processes without escalating to legal action. -

What are the common risks associated with sourcing industrial fans internationally, and how can I mitigate them?

Common risks include fluctuating exchange rates, shipping delays, and quality inconsistencies. To mitigate these risks, conduct thorough market research and supplier evaluations before committing to an order. Use fixed exchange rate contracts when possible to avoid financial losses from currency fluctuations. Establish clear communication channels with your supplier and consider using logistics partners experienced in international shipping. Additionally, diversifying your supplier base can reduce dependency on a single source and enhance supply chain resilience.

Illustrative Image (Source: Google Search)

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different types of fans

In navigating the complex landscape of industrial fans, international B2B buyers must prioritize strategic sourcing to ensure optimal performance and cost-effectiveness. The variety of fans—ranging from centrifugal to axial—each offers unique advantages that cater to different industrial applications. Understanding key factors such as airflow, pressure, and energy efficiency is crucial for making informed purchasing decisions that align with operational needs.

Moreover, as industries evolve, the demand for fans capable of withstanding harsh environments and providing reliable ventilation will only increase. Buyers from Africa, South America, the Middle East, and Europe should leverage local and global suppliers who can meet these needs while offering competitive pricing and timely delivery.

In conclusion, prioritizing strategic sourcing not only enhances operational efficiency but also fosters long-term partnerships with manufacturers. As the market continues to innovate, now is the time to invest in high-quality fan solutions that can adapt to future challenges. Engage with reputable suppliers today to explore the best options for your specific applications and ensure your operations remain at the forefront of industry advancements.