Master the Different Types of Latches for Optimal B2B

Introduction: Navigating the Global Market for different types of latches

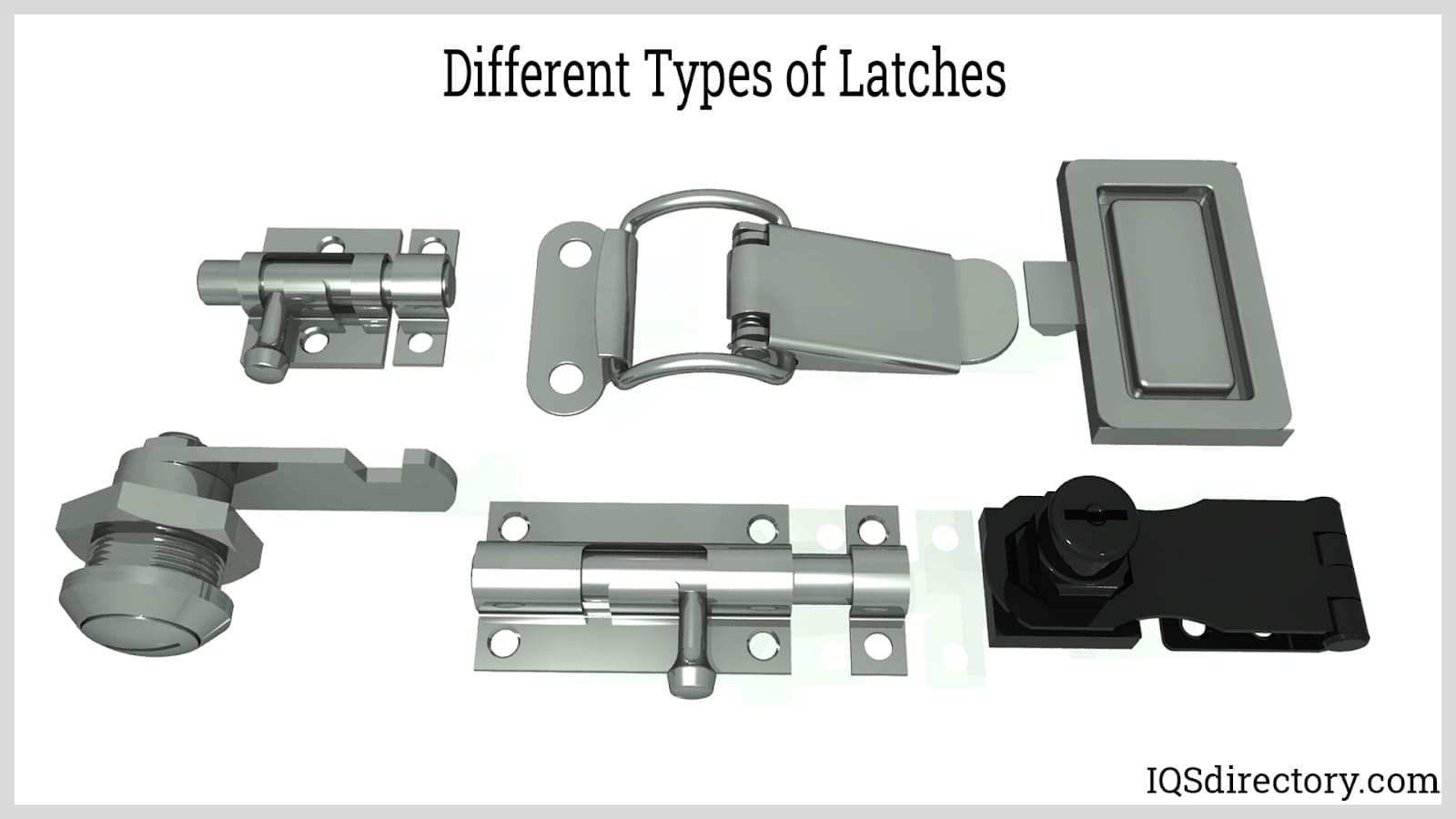

In the dynamic landscape of global trade, the significance of latches as a foundational component in security and access cannot be overstated. These mechanical devices are crucial for ensuring the integrity and functionality of doors, gates, and enclosures across various sectors, from manufacturing to transportation. As B2B buyers, understanding the diverse types of latches available is essential for making informed procurement decisions that align with specific operational needs.

This guide offers a comprehensive exploration of latch types—including compression, draw, cam, and slide-to-open latches—each tailored for unique applications ranging from industrial machinery to HVAC systems. We will delve into the materials used in latch manufacturing, the quality control processes that ensure durability, and the leading suppliers in the market. Additionally, we will provide insights into cost considerations and market trends, empowering buyers to navigate the complexities of sourcing effectively.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, this guide serves as a vital resource. It equips you with the knowledge needed to assess your options critically, ensuring that you select the right latch solutions that enhance security and operational efficiency. By leveraging this information, businesses can optimize their supply chains, minimize risks, and ultimately drive greater value in their operations.

Understanding different types of latches Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slide-to-open Latches | Linear sliding mechanism, quick access | Machinery enclosures, storage units | Pros: Fast operation, space-saving design. Cons: Limited security compared to locks. |

| Draw Latches | Over-center locking mechanism, strong tension | Cargo containers, HVAC systems | Pros: Excellent vibration resistance. Cons: Can be more complex to install. |

| Compression Latches | Clamping action, seals against dust and moisture | Electrical panels, food processing equipment | Pros: Provides airtight seal, durable. Cons: Higher initial cost due to robust design. |

| Push-to-open Latches | One-touch operation, no visible hardware | Display cabinets, furniture | Pros: Sleek design, easy to use. Cons: May require precise alignment for optimal function. |

| Cam Latches | Rotational locking, simple mechanism | Toolboxes, access panels | Pros: Cost-effective, easy to install. Cons: Less secure than other latch types. |

Slide-to-open Latches

Slide-to-open latches are characterized by their linear sliding mechanism, allowing for rapid engagement and disengagement. These latches excel in environments where quick access is paramount, making them ideal for machinery enclosures and storage units. When purchasing, buyers should consider the latch’s material and durability, especially in demanding industrial settings. While they offer ease of use, it’s important to note that their security features may not match those of traditional locks.

Draw Latches

Draw latches utilize an over-center locking mechanism to create a strong closure by pulling two surfaces tightly together. This makes them particularly effective in applications where vibration and impact resistance are essential, such as securing cargo containers or in HVAC systems. Buyers should evaluate the latch’s size and load-bearing capacity to ensure it meets their specific requirements. While they provide robust security, the installation may require more effort compared to simpler latch types.

Compression Latches

Compression latches apply a clamping force to create a secure seal between surfaces, making them indispensable in environments that require protection against dust, moisture, and electromagnetic interference. Commonly used in electrical panels and food processing equipment, these latches ensure a tight closure. When considering compression latches, buyers should focus on the sealing effectiveness and compliance with industry standards. Although they tend to be more expensive, their durability and functionality justify the investment.

Push-to-open Latches

Push-to-open latches offer a convenient one-touch operation without visible hardware, making them a popular choice for modern display cabinets and furniture. They provide a clean aesthetic while ensuring ease of access. Buyers should assess the installation requirements and alignment precision, as these factors influence the latch’s performance. While they enhance design appeal, their reliance on precise installation can be a downside if not executed correctly.

Cam Latches

Cam latches feature a simple rotational locking mechanism and are widely used in toolboxes and access panels due to their cost-effectiveness and ease of installation. They are suitable for applications where security is not the primary concern. Buyers should consider the latch’s material and resistance to wear, especially in high-use environments. While cam latches are affordable, they may not provide the same level of security as more robust latch types.

Related Video: 5 Types of Common Industrial Latches

Key Industrial Applications of different types of latches

| Industry/Sector | Specific Application of different types of latches | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of compression latches in machinery enclosures | Enhanced safety and reduced downtime due to secure closures | Durability, resistance to vibrations, and compliance with safety standards |

| Transportation | Draw latches for securing cargo containers and trailer doors | Increased cargo security and reduced risk of loss or damage | Load capacity, corrosion resistance, and ease of operation |

| HVAC Systems | Compression latches for access panels to HVAC units | Improved energy efficiency and reduced maintenance costs | Seal integrity, thermal resistance, and compatibility with existing systems |

| Food Processing | Pull latches for securing equipment in food production lines | Enhanced hygiene and safety, preventing contamination | Sanitary design, ease of cleaning, and resistance to harsh chemicals |

| Electrical Enclosures | Slide-to-open latches for quick access to electrical components | Reduced maintenance time and improved operational efficiency | Quick access design, compatibility with various panel sizes, and reliability |

Detailed Applications

Manufacturing: In manufacturing settings, compression latches are critical for securing machinery enclosures. These latches prevent accidental openings, which can lead to workplace injuries or equipment damage. Buyers should prioritize latches that offer high durability and resistance to vibrations, especially in high-impact environments. Moreover, ensuring compliance with local safety standards is essential for international buyers, particularly in regions like Africa and South America, where regulations may vary.

Transportation: Draw latches are widely used in the transportation sector, particularly for securing cargo containers and trailer doors. Their design provides a strong closure that withstands the rigors of transit, significantly reducing the risk of cargo loss or damage. For B2B buyers in the Middle East and Europe, sourcing latches that are corrosion-resistant is vital due to varying climate conditions, ensuring long-term reliability and performance.

HVAC Systems: In HVAC applications, compression latches are essential for access panels, ensuring airtight seals that improve energy efficiency. This is crucial for reducing operational costs in commercial buildings. Buyers must consider the seal integrity and thermal resistance of latches to maintain optimal system performance. In regions with extreme weather, such as parts of Africa and Europe, the ability to withstand temperature fluctuations is a key factor.

Food Processing: Pull latches play a significant role in the food processing industry by securing equipment and ensuring hygiene. They help prevent contamination, which is critical for compliance with health regulations. Buyers should look for latches with a sanitary design that allows for easy cleaning and maintenance, especially in South American countries where food safety standards are stringent.

Electrical Enclosures: Slide-to-open latches are particularly useful for electrical enclosures, allowing quick access to components for maintenance and inspections. This design minimizes downtime and enhances operational efficiency, which is vital for businesses in fast-paced environments. Buyers should ensure compatibility with various panel sizes and prioritize reliability to reduce the risk of equipment failure, especially in the Middle East where industrial operations are rapidly expanding.

Related Video: Different Types of Hinges – Choosing the Right Hinge for Your Application

Strategic Material Selection Guide for different types of latches

When selecting latches for various applications, the choice of material is critical as it directly influences performance, durability, and cost. Here, we will analyze four common materials used in latch manufacturing, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating up to 800°F (427°C) and can endure significant mechanical stress.

Pros & Cons:

The durability of stainless steel makes it ideal for heavy-duty applications, particularly in harsh environments. However, it can be more expensive than other materials, and its manufacturing process may involve complex machining, increasing production costs.

Impact on Application:

Stainless steel latches are particularly suitable for outdoor applications, marine environments, and food processing industries due to their resistance to rust and contamination.

Considerations for Buyers:

International buyers should ensure compliance with standards such as ASTM A240 for stainless steel grades. In regions like Europe and the Middle East, certifications related to food safety and corrosion resistance may be required.

Zinc Alloy

Key Properties:

Zinc alloy is lightweight and offers good corrosion resistance, although not as robust as stainless steel. It can withstand temperatures up to about 250°F (121°C) and is often used in less demanding environments.

Pros & Cons:

Zinc alloy is cost-effective and easier to manufacture, making it suitable for mass production. However, it may not be as durable in high-stress applications and can corrode over time if not properly coated.

Impact on Application:

Zinc alloy latches are commonly used in residential and light commercial applications where cost is a major concern. They are ideal for indoor use but may require protective coatings for outdoor applications.

Considerations for Buyers:

Buyers in Africa and South America should check for compliance with local standards, such as ASTM B69 for zinc coatings. Awareness of environmental regulations regarding zinc usage is also crucial.

Plastic (Polymer)

Key Properties:

Plastic latches are lightweight, resistant to corrosion, and can operate in a wide range of temperatures, typically from -40°F to 200°F (-40°C to 93°C). They also offer good electrical insulation properties.

Pros & Cons:

The primary advantage of plastic latches is their low cost and versatility in design. However, they may not withstand heavy loads or extreme temperatures as effectively as metal latches, limiting their use in high-stress applications.

Impact on Application:

Plastic latches are suitable for applications in electronics, automotive interiors, and consumer products where weight savings and corrosion resistance are important.

Considerations for Buyers:

Buyers should ensure that the selected plastic meets relevant standards such as UL 94 for flammability. In Europe, compliance with REACH regulations regarding chemical safety is also essential.

Aluminum

Key Properties:

Aluminum is lightweight, has good corrosion resistance, and can handle temperatures up to 400°F (204°C). It is also known for its strength-to-weight ratio, making it a popular choice for various applications.

Pros & Cons:

Aluminum latches are durable and easy to manufacture, making them a good choice for both industrial and commercial applications. However, they can be more expensive than plastic and may require additional coatings to enhance corrosion resistance.

Impact on Application:

Aluminum latches are often used in aerospace, automotive, and outdoor applications where weight and strength are critical factors.

Considerations for Buyers:

International buyers must consider compliance with standards like ASTM B221 for aluminum extrusions. In regions like the Middle East, understanding local environmental conditions that may affect aluminum performance is crucial.

Summary Table

| Material | Typical Use Case for different types of latches | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty outdoor applications, food processing | Excellent corrosion resistance | Higher cost, complex machining | High |

| Zinc Alloy | Residential and light commercial applications | Cost-effective, easy to manufacture | Less durable, potential corrosion | Low |

| Plastic (Polymer) | Electronics, automotive interiors | Lightweight, versatile | Limited load capacity | Low |

| Aluminum | Aerospace, automotive, outdoor applications | Good strength-to-weight ratio | Higher cost, may need coatings | Medium |

This strategic material selection guide provides international B2B buyers with essential insights to make informed decisions when sourcing latches, ensuring that they meet both functional requirements and compliance standards in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for different types of latches

Manufacturing Processes for Different Types of Latches

The production of latches involves several key stages that ensure high-quality, durable products suitable for various applications. Understanding these processes is essential for B2B buyers aiming to source latches that meet their specific requirements.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: Latches are typically manufactured from metals such as stainless steel, zinc alloy, or plastic. The choice of material impacts durability, resistance to corrosion, and overall functionality.

– Material Processing: Raw materials are often subjected to treatments such as annealing or hardening to enhance their mechanical properties before fabrication. -

Forming

– Techniques: Common forming methods include stamping, forging, and casting. Stamping is favored for high-volume production as it allows for precise shapes and reduces material waste. Forging is used for heavy-duty latches requiring superior strength.

– Machining: After initial forming, latches may undergo machining processes like milling and drilling to achieve the desired dimensions and features.

-

Assembly

– Component Integration: Various components of the latch, such as the housing, bolt, and spring, are assembled. This may be done manually or with automated systems to ensure consistency.

– Precision Fitting: It is critical that parts fit together seamlessly to ensure functionality. Tolerances must be strictly adhered to during assembly. -

Finishing

– Surface Treatments: Finishing processes include plating (e.g., nickel or chrome), powder coating, or anodizing, which enhance aesthetics and protect against environmental factors.

– Quality Checks: Each latch undergoes final inspections to ensure it meets the specifications and visual standards.

Quality Assurance in Latch Manufacturing

Quality assurance is vital in ensuring that latches function correctly and meet safety standards. Different international and industry-specific standards guide these practices.

International Standards

- ISO 9001: This standard focuses on quality management systems and is applicable across industries. Manufacturers pursuing ISO 9001 certification demonstrate their commitment to quality and continuous improvement.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards. It is essential for latches used in consumer and industrial applications.

Industry-Specific Standards

- API Standards: The American Petroleum Institute (API) provides guidelines for latches used in oil and gas applications, emphasizing safety and reliability under extreme conditions.

- UL Certification: Underwriters Laboratories (UL) certification is important for latches used in electrical enclosures, ensuring they meet safety requirements.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Materials are inspected upon arrival to verify compliance with specifications.

– Documentation and certificates of conformity are reviewed. -

In-Process Quality Control (IPQC)

– Continuous monitoring during the manufacturing process ensures adherence to defined tolerances.

– Random sampling of products during production helps identify defects early. -

Final Quality Control (FQC)

– Completed latches undergo rigorous testing, including functional tests, dimensional checks, and surface inspections.

– Testing for environmental resilience (e.g., corrosion resistance, impact testing) is conducted based on the intended application.

Common Testing Methods

- Functional Testing: Ensures the latch operates smoothly and meets design specifications.

- Durability Testing: Involves repeated use scenarios to assess longevity and reliability.

- Environmental Testing: Simulates conditions such as humidity, temperature variations, and exposure to chemicals.

Verifying Supplier Quality Control

B2B buyers should conduct thorough due diligence to verify a supplier’s quality control processes:

- Supplier Audits: Regular audits can help assess compliance with international standards and internal quality procedures. Buyers should inquire about the frequency and scope of these audits.

- Quality Reports: Request detailed quality assurance reports that outline testing methods, results, and corrective actions taken on non-conformities.

- Third-Party Inspections: Engage third-party inspection agencies to conduct independent assessments of the manufacturing process and final products. This is particularly valuable for buyers in regions like Africa and South America, where local standards may vary.

Quality Control Considerations for International Buyers

- Cultural Differences: Understanding the manufacturing culture in different regions (e.g., Europe vs. the Middle East) can influence communication and expectations regarding quality.

- Regulatory Compliance: Ensure that the supplier complies with both local and international regulations, particularly when exporting products.

- Logistics and Supply Chain: Consider the implications of logistics on quality, such as transportation methods that may affect product integrity during shipment.

By comprehensively understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing latches. Emphasizing quality at every stage of the supply chain ensures that the selected products meet the necessary standards for safety and reliability in their respective applications.

Related Video: What is Production? Types of Production, Factors of Production

Comprehensive Cost and Pricing Analysis for different types of latches Sourcing

In sourcing latches for international B2B transactions, understanding the comprehensive cost structure and pricing dynamics is crucial for optimizing procurement strategies. The cost of latches comprises several components, each influencing the final price.

Cost Components

-

Materials: The choice of materials significantly impacts costs. Common materials include stainless steel, plastic, and aluminum. Premium materials like brass or specialized composites may increase costs due to their superior durability and resistance.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs, such as parts of Africa and South America, may offer more competitive pricing. However, skilled labor for complex latches may command higher wages.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and facility maintenance. Efficient manufacturing processes can lower overhead costs, which is a key factor in competitive pricing.

-

Tooling: Custom tooling for specific latch designs can incur significant upfront costs. Buyers should factor this into the total cost, especially when ordering customized latches.

-

Quality Control (QC): Stringent QC measures ensure product reliability and compliance with international standards. While this may add to costs, it is essential for avoiding defects and ensuring customer satisfaction.

-

Logistics: Shipping and handling costs can vary widely depending on the origin and destination. International buyers should consider freight costs, insurance, and any tariffs or duties applicable in their region.

-

Margin: Supplier margins can differ based on market conditions, competition, and perceived value. Understanding the supplier’s pricing strategy is essential for effective negotiation.

Price Influencers

Several factors can influence the pricing of latches:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically yield lower per-unit prices. Negotiating favorable terms based on anticipated volume can lead to significant savings.

-

Specifications/Customization: Custom latches tailored to specific applications may attract higher prices due to the additional design and manufacturing complexities involved.

-

Quality/Certifications: Products that meet higher quality standards or possess certifications (e.g., ISO, CE) may come at a premium but often justify the cost through enhanced performance and reliability.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the terms of trade (e.g., FOB, CIF) is vital, as they dictate responsibility for shipping, insurance, and tariffs, directly affecting overall costs.

Buyer Tips

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-effectiveness:

-

Negotiate Terms: Engage suppliers in negotiations regarding pricing, payment terms, and delivery schedules. Establishing a long-term relationship may yield better deals.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also the lifetime costs associated with maintenance, durability, and potential failures. Choosing higher-quality latches may reduce long-term costs.

-

Leverage Local Insights: Buyers should utilize local market knowledge to understand pricing dynamics and supply chain nuances specific to their regions. This can help identify better sourcing opportunities.

-

Stay Informed on Pricing Trends: Monitor global market trends and commodity prices, as these can influence material costs and overall pricing strategies.

Disclaimer

Prices for latches can vary widely based on the factors mentioned above. The figures discussed are indicative and should be verified with suppliers for accurate and up-to-date pricing information.

Spotlight on Potential different types of latches Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘different types of latches’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for different types of latches

Key Technical Properties of Different Types of Latches

Understanding the technical specifications of latches is crucial for international B2B buyers, as these properties directly impact the functionality, durability, and overall performance of the latch in various applications. Here are some essential specifications to consider:

-

Material Grade

– Definition: The quality of material used in manufacturing latches, often specified in terms of steel grade (e.g., stainless steel, carbon steel) or plastic type (e.g., polyamide, polycarbonate).

– Importance: Material grade affects corrosion resistance, strength, and durability. For instance, stainless steel latches are ideal for outdoor applications in humid environments, while plastic latches may be suitable for lightweight applications. -

Load Capacity

– Definition: The maximum weight or force a latch can securely hold without failure.

– Importance: Load capacity is critical in industrial applications where latches may be subjected to significant stress. Buyers must ensure that the latch can withstand the operational demands of their specific use case, such as securing heavy machinery or cargo. -

Tolerance

– Definition: The permissible limit of variation in a physical dimension of the latch, often expressed in millimeters or inches.

– Importance: Proper tolerance is vital for ensuring a snug fit between the latch and the mounting surface, preventing wear and ensuring reliable operation. Inaccurate tolerances can lead to malfunction or premature failure. -

Operating Temperature Range

– Definition: The range of temperatures within which a latch can operate effectively without degradation.

– Importance: This property is particularly significant in industries like automotive and aerospace, where components may be exposed to extreme temperatures. Selecting latches with suitable operating temperature ranges ensures reliability and performance in varying environmental conditions. -

Finish Type

– Definition: The surface treatment applied to a latch, which may include coatings, plating, or anodizing.

– Importance: The finish type affects the latch’s resistance to corrosion, wear, and aesthetics. For example, powder-coated latches provide an additional layer of protection against environmental factors, making them suitable for outdoor use. -

Actuation Mechanism

– Definition: The method by which a latch is engaged or disengaged, such as manual, electronic, or pneumatic.

– Importance: Understanding the actuation mechanism is essential for determining compatibility with existing systems. For instance, electronic latches may be integrated into smart access control systems, while manual latches may be preferred for simplicity and reliability.

Common Trade Terminology in the Latch Industry

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms that buyers should understand:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Knowing the OEM can help buyers assess the quality and reliability of the latches they are purchasing, as established OEMs often adhere to strict manufacturing standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for budget planning and inventory management. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory costs. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price quotes from suppliers for specific products or services.

– Relevance: An RFQ is a critical step in the procurement process, enabling buyers to compare offers and ensure they are getting competitive pricing for latches. -

Incoterms (International Commercial Terms)

– Definition: A set of internationally recognized rules that define the responsibilities of buyers and sellers for the delivery of goods.

– Relevance: Understanding Incoterms is essential for international transactions, as they clarify who is responsible for shipping, insurance, and tariffs, helping buyers manage risks and costs effectively.

Illustrative Image (Source: Google Search)

-

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Relevance: Knowing the lead time is critical for project planning. Buyers should consider lead times when ordering latches to ensure timely project completion. -

Certification

– Definition: A formal verification that a product meets specific standards or regulations.

– Relevance: Certifications can indicate compliance with safety, quality, and environmental standards. Buyers should prioritize latches that carry relevant certifications to ensure reliability and legal compliance in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing latches for their operations, ultimately enhancing their productivity and securing their investments.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the different types of latches Sector

Market Overview & Key Trends

The global latch market is experiencing significant growth, driven by the increasing demand for security solutions across various industries. Key trends influencing this sector include technological advancements in latch design, the integration of smart technology, and the rising focus on efficiency and ease of use. International B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are increasingly sourcing latches that not only provide robust security but also enhance operational efficiency.

Emerging technologies, such as electronic latches and smart access control systems, are reshaping the market landscape. Buyers are seeking latches that can integrate with IoT devices, enabling remote access and monitoring. This trend is especially relevant in urban centers across Brazil and Mexico, where smart city initiatives are driving demand for advanced security solutions.

Market dynamics are also influenced by the rising importance of customization and flexibility in latch applications. Industries such as manufacturing, transportation, and construction require latches that can adapt to specific needs, prompting suppliers to offer tailored solutions. Additionally, the emphasis on sustainability and ethical sourcing is reshaping procurement strategies, as businesses prioritize suppliers who demonstrate a commitment to environmental responsibility and ethical labor practices.

Sustainability & Ethical Sourcing in B2B

In today’s market, sustainability has become a critical factor for B2B buyers sourcing latches. The environmental impact of manufacturing processes and materials used in latch production cannot be overlooked. Buyers are increasingly seeking suppliers who employ eco-friendly practices, such as using recycled materials and minimizing waste during production.

Illustrative Image (Source: Google Search)

Ethical sourcing is equally important, as companies strive to ensure that their supply chains are free from labor exploitation and comply with international labor standards. Certifications like ISO 14001 for environmental management and Fair Trade certification are becoming essential for suppliers looking to establish credibility in the market.

Buyers should also consider the lifecycle of latch products. Opting for latches made from durable, recyclable materials can significantly reduce environmental impact. Additionally, choosing suppliers committed to sustainable practices can enhance brand reputation and appeal to environmentally-conscious consumers.

Brief Evolution/History

The evolution of latch mechanisms can be traced back to ancient civilizations, where simple wooden latches were used to secure doors and gates. As societies progressed, so did the complexity of latch designs, incorporating metals and advanced mechanisms for improved security and functionality.

In the industrial era, the demand for more robust and reliable latches surged, leading to the development of specialized types such as compression and draw latches, tailored for specific applications. Today, with the advent of smart technology, latches are evolving once again, integrating electronic components to meet the needs of modern security challenges. This historical context highlights the continuous innovation in latch technology, providing valuable insights for B2B buyers seeking reliable and advanced solutions.

Related Video: Chapter 9: International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of different types of latches

-

What should I consider when vetting suppliers for latches?

When vetting suppliers for latches, prioritize their reputation and experience in the industry. Request references and case studies to understand their previous work and customer satisfaction levels. Evaluate their production capabilities, including technology and workforce, to ensure they can meet your needs. Additionally, check for certifications such as ISO standards, which indicate adherence to quality management systems. Conducting an on-site visit can further help assess their operations and quality control processes. -

Can I customize latches to fit specific requirements?

Yes, many manufacturers offer customization options for latches to cater to specific applications or design requirements. When considering customization, clearly communicate your specifications, including dimensions, materials, and functionalities. It’s also beneficial to inquire about the design process and whether the supplier has the capability for prototyping. Keep in mind that customized latches may have longer lead times and potentially higher costs compared to standard products. -

What are typical minimum order quantities (MOQ) and lead times?

Minimum order quantities (MOQ) for latches can vary significantly based on the supplier and the type of latch. Generally, standard products may have lower MOQs, while customized latches could require larger orders. Lead times also depend on the complexity of the order, ranging from a few weeks for standard items to several months for custom designs. Always confirm these details during initial discussions to plan your inventory and production schedules effectively. -

What payment terms should I expect when sourcing latches internationally?

Payment terms in international trade can differ by supplier and region. Common practices include upfront deposits (often 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer credit terms based on your business relationship and creditworthiness. Ensure you understand the payment methods accepted, such as wire transfers, letters of credit, or online payment platforms. It is wise to negotiate terms that protect your interests while fostering a positive relationship with the supplier. -

How can I ensure quality assurance and certifications for latches?

To ensure quality assurance, request information about the supplier’s quality management practices and any certifications they hold. ISO 9001 certification is a strong indicator of a supplier’s commitment to quality. Additionally, inquire about their testing processes, including material inspections and performance testing. Request samples before placing a large order to evaluate the product quality firsthand. Establishing clear quality standards in your contract can also help mitigate risks. -

What logistics considerations should I be aware of when importing latches?

Logistics plays a crucial role in the timely delivery of latches. Consider factors such as shipping methods (air vs. sea), customs regulations, and import duties specific to your country. Collaborate with a reliable freight forwarder to navigate these complexities. It’s also essential to plan for potential delays due to customs inspections or other unforeseen circumstances. Ensure that the supplier provides all necessary documentation for smooth customs clearance. -

How can I handle disputes with suppliers regarding latch orders?

To minimize disputes, establish clear terms in your purchase agreement, including product specifications, delivery schedules, and payment terms. In the event of a dispute, maintain open communication with the supplier to resolve issues amicably. Document all correspondence and agreements to provide a clear record of the situation. If necessary, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. -

What are some common challenges faced when sourcing latches internationally?

Common challenges include language barriers, differing regulations, and varying quality standards across regions. Cultural differences can also impact negotiation styles and communication. To mitigate these issues, engage a local representative or consultant familiar with the market and its practices. Conduct thorough research on the supplier’s background and the region’s trade regulations. Building strong relationships with suppliers can also enhance collaboration and lead to better outcomes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for different types of latches

In conclusion, understanding the diverse types of latches—such as compression, draw, and slide-to-open latches—can significantly enhance security and operational efficiency in various applications. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, strategic sourcing of latch systems is essential for ensuring durability, ease of access, and robust performance.

By prioritizing quality and compatibility with specific operational environments, buyers can mitigate risks associated with equipment failure and enhance overall productivity. Moreover, engaging with suppliers who offer a comprehensive portfolio tailored to industry-specific needs can lead to long-term partnerships and cost savings.

As global markets evolve, the demand for innovative latch solutions will continue to grow. Buyers are encouraged to stay informed about emerging technologies and trends in latch mechanisms to make educated purchasing decisions. Take the next step in optimizing your security and access solutions by exploring the latest offerings in latch technology tailored to your industry’s needs.