Master the Essential Types of Latches for Boxes to Enhance

Introduction: Navigating the Global Market for types of latches for boxes

In today’s interconnected global market, sourcing the right types of latches for boxes is crucial for businesses aiming to ensure product security, reliability, and efficiency. Latches serve as essential components in a wide array of industries, from manufacturing to logistics, influencing the durability and functionality of storage solutions. With various designs and materials available, understanding the specifications and performance characteristics of each latch type is vital for making informed purchasing decisions.

This comprehensive guide delves into the diverse types of latches, including toggle, over-center, and recessed latches, alongside an exploration of materials such as stainless steel, plastic, and aluminum. We also address critical factors like manufacturing quality control, sourcing strategies, and supplier selection, offering insights that are particularly relevant to international buyers from Africa, South America, the Middle East, and Europe, including Spain and South Africa.

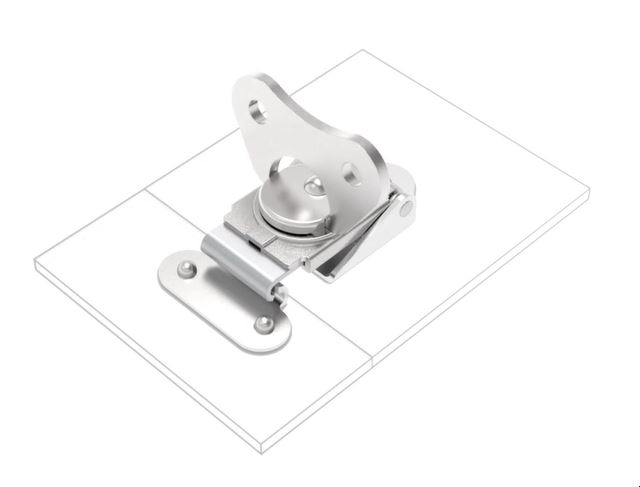

Illustrative Image (Source: Google Search)

Moreover, our analysis includes an overview of market trends and pricing structures, enabling you to navigate potential cost implications effectively. As you explore the FAQs section, you will find answers to common queries that can enhance your sourcing strategies. By leveraging this guide, B2B buyers will be empowered to make educated decisions that align with their operational needs, ensuring they select the most suitable latches for their box applications.

Understanding types of latches for boxes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Over-Center Latches | Locking mechanism that secures the lid when closed. | Cargo containers, industrial boxes | Pros: Strong hold, easy to operate. Cons: May require adjustment over time. |

| Toggle Latches | Lever action for secure closure, available in various sizes. | Equipment enclosures, storage boxes | Pros: Versatile, multiple load capacities. Cons: Can be less secure than other types. |

| Compression Latches | Creates a tight seal by compressing the box lid. | Sensitive equipment, weatherproof boxes | Pros: Excellent sealing, good for outdoor use. Cons: More complex installation. |

| Slam Latches | Automatically locks when the lid is closed. | Toolboxes, mobile storage units | Pros: Quick access, no manual locking needed. Cons: May wear out with frequent use. |

| Drawer Latches | Specifically designed for sliding drawers. | Cabinets, tool chests | Pros: Space-efficient, easy access. Cons: Limited to drawer applications. |

Over-Center Latches

Over-center latches are known for their robust locking mechanism, which ensures that the lid remains securely closed during transport. This type is particularly well-suited for cargo containers and industrial boxes, where security and stability are paramount. When considering an over-center latch, buyers should evaluate the material quality, as durability is essential for heavy-duty applications. While they provide a strong hold, they may require periodic adjustments to maintain optimal performance.

Toggle Latches

Toggle latches utilize a lever action to provide a secure closure, making them a popular choice across various industries. They come in light, medium, and heavy-duty variations, catering to different load requirements. Common applications include equipment enclosures and storage boxes. Buyers should consider the latch’s load capacity and ease of operation, as these factors can significantly affect efficiency. While toggle latches are versatile, they may not offer the same level of security as some other latch types.

Compression Latches

Designed to create a tight seal, compression latches are ideal for applications requiring moisture and dust protection, such as sensitive equipment and weatherproof boxes. The latch compresses the lid against the frame, providing a secure closure that enhances durability. When purchasing compression latches, B2B buyers should assess their sealing capabilities and installation complexity. Although they offer superior sealing, the installation process can be more intricate compared to simpler latch types.

Slam Latches

Slam latches are engineered for quick access, automatically locking when the lid is closed. This feature makes them particularly useful for toolboxes and mobile storage units, where efficiency is crucial. Buyers should consider the latch’s ease of use and durability, especially in high-frequency applications. While slam latches facilitate rapid access, they may be prone to wear if used excessively, which can impact their long-term reliability.

Drawer Latches

Specifically designed for sliding drawers, drawer latches are essential for cabinets and tool chests. They ensure that drawers remain closed during transport while allowing for easy access when needed. B2B buyers should focus on the latch’s space efficiency and ease of installation. Although drawer latches are limited to drawer applications, their user-friendly design and effectiveness in keeping items secure make them a valuable choice for businesses in need of organized storage solutions.

Related Video: How to design 3D printed latches #3dprinting #productdesign

Key Industrial Applications of types of latches for boxes

| Industry/Sector | Specific Application of types of latches for boxes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Secure closure for toolboxes and equipment cases | Enhanced safety and organization of tools | Durability, corrosion resistance, and load capacity |

| Transportation | Locking mechanisms for shipping containers | Protection of goods during transit | Compliance with international shipping standards |

| Construction | Latching systems for storage boxes on-site | Improved security and accessibility of equipment | Weather resistance and ease of use in rugged conditions |

| Automotive | Latches for vehicle storage compartments | Optimized space utilization and security | Lightweight materials and high strength |

| Aerospace | Latching mechanisms for aircraft cargo compartments | Assurance of safety and compliance with regulations | High-performance materials and certification standards |

Manufacturing

In the manufacturing sector, types of latches are crucial for securing toolboxes and equipment cases. These latches not only provide enhanced safety but also help in organizing tools efficiently, minimizing the risk of loss or damage. For international buyers, especially in regions like Africa and South America, sourcing durable latches that resist corrosion and can handle significant load capacity is essential to ensure longevity and reliability in demanding environments.

Transportation

In transportation, latches serve as locking mechanisms for shipping containers, ensuring that goods remain secure during transit. This is particularly vital in international shipping, where compliance with various regulations is necessary to avoid costly delays. Buyers from the Middle East and Europe must consider latches that meet international shipping standards, focusing on materials that can withstand environmental stresses while providing robust security.

Construction

Construction sites often utilize latching systems for storage boxes that hold tools and materials. These latches improve security against theft and allow for easy access to equipment, which is critical in fast-paced environments. Buyers in regions with harsh weather conditions, like South Africa, should prioritize weather-resistant latches that can withstand exposure to the elements while maintaining functionality.

Automotive

In the automotive industry, latches are commonly found in vehicle storage compartments, where they contribute to optimized space utilization and security. As international buyers look for latches, they should focus on lightweight materials that do not compromise strength, ensuring that the latches can endure the rigors of everyday use while enhancing the vehicle’s overall functionality.

Aerospace

Aerospace applications require highly reliable latching mechanisms for aircraft cargo compartments. These latches must assure safety and compliance with stringent regulations, as failures can have severe consequences. Buyers in this sector, particularly in Europe, should seek high-performance latches made from certified materials that meet industry standards, ensuring both safety and operational efficiency.

Related Video: Latches and Flip-Flops 2 – The Gated SR Latch

Strategic Material Selection Guide for types of latches for boxes

When selecting materials for latches used in boxes, international B2B buyers must consider several factors that influence both the performance and suitability of the latch for specific applications. Below is an analysis of four common materials used in latch manufacturing, focusing on their properties, advantages, disadvantages, and implications for buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties: Stainless steel is renowned for its corrosion resistance, making it suitable for environments exposed to moisture and chemicals. It can withstand high temperatures and pressures, ensuring long-term durability.

Pros & Cons: The durability of stainless steel latches is one of its significant advantages, as they can last for years without significant wear. However, they are generally more expensive than other materials and can be heavier, which may not be ideal for lightweight applications.

Impact on Application: Stainless steel latches are particularly effective in applications involving food packaging, pharmaceuticals, and outdoor equipment due to their resistance to rust and staining.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Europe, the preference for stainless steel is high due to stringent safety and hygiene regulations.

Plastic

Key Properties: Plastic latches are lightweight, resistant to corrosion, and can be manufactured in various colors and designs. They generally have lower temperature and pressure ratings compared to metals.

Pros & Cons: The primary advantage of plastic latches is their low cost and lightweight nature, making them suitable for consumer products and applications where weight is a concern. However, they may not be as durable as metal options and can degrade under UV exposure or extreme temperatures.

Impact on Application: Plastic latches are often used in electronics, toys, and packaging where aesthetics and weight are prioritized over heavy-duty performance.

Considerations for International Buyers: It’s crucial to verify that the plastic materials comply with safety standards, especially in the food and medical sectors. Buyers should also consider the environmental impact of plastic and look for recyclable options.

Zinc-Plated Steel

Key Properties: Zinc-plated steel offers a good balance between strength and corrosion resistance. The zinc coating protects the steel from rust, although it may not be as durable as stainless steel in harsh environments.

Pros & Cons: These latches are typically less expensive than stainless steel while still providing good strength and moderate corrosion resistance. However, they can be prone to corrosion if the zinc layer is scratched or compromised.

Impact on Application: Zinc-plated steel latches are commonly used in automotive and industrial applications where moderate corrosion resistance is acceptable.

Considerations for International Buyers: Buyers should be aware of the specific environmental conditions in their regions, as areas with high humidity or salt exposure may require more robust solutions. Compliance with local standards is also essential.

Aluminum

Key Properties: Aluminum latches are lightweight and resistant to corrosion, making them suitable for various applications. They have a good strength-to-weight ratio but can be less durable than steel options.

Pros & Cons: The lightweight nature of aluminum makes it ideal for applications where weight savings are critical. However, aluminum is softer than steel, which can lead to deformation under heavy loads.

Impact on Application: Aluminum latches are often used in aerospace, automotive, and portable equipment where weight is a significant consideration.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different alloys have varying properties. Compliance with international standards for aerospace and automotive applications is crucial.

Summary Table

| Material | Typical Use Case for types of latches for boxes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food packaging, pharmaceuticals, outdoor equipment | Excellent durability and corrosion resistance | Higher cost and weight | High |

| Plastic | Electronics, toys, consumer packaging | Low cost and lightweight | Less durable, can degrade under UV | Low |

| Zinc-Plated Steel | Automotive, industrial applications | Good strength and moderate corrosion resistance | Prone to corrosion if scratched | Medium |

| Aluminum | Aerospace, automotive, portable equipment | Lightweight and corrosion-resistant | Softer than steel, less durable | Medium |

This strategic material selection guide provides B2B buyers with a comprehensive overview of the materials used for latches in boxes, helping them make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for types of latches for boxes

Manufacturing Processes for Types of Latches for Boxes

Understanding the manufacturing processes involved in producing latches for boxes is crucial for international B2B buyers. This insight not only helps in making informed purchasing decisions but also ensures that the products meet necessary quality standards. The manufacturing process typically involves several stages:

1. Material Preparation

The first step in latch manufacturing is material selection. Common materials include stainless steel, aluminum, and high-grade plastics. Each material has its unique properties, affecting durability, corrosion resistance, and weight.

- Sourcing: Buyers should ensure that suppliers source materials from reputable suppliers, as this impacts the final product’s quality.

- Inspection: Incoming materials are subject to Incoming Quality Control (IQC) to verify compliance with specifications.

2. Forming

Once materials are prepared, they undergo various forming techniques:

- Stamping: This is commonly used for metal latches. Sheets of metal are fed into a stamping machine, where they are cut and shaped.

- Injection Molding: For plastic latches, this technique involves injecting molten plastic into molds. It is efficient for high-volume production.

- Die-Casting: Used for producing complex shapes in metals, this method provides high precision and excellent surface finish.

Each technique has its advantages and limitations, which can influence the latch’s final characteristics.

3. Assembly

After forming, components are assembled. This may involve:

- Mechanical Assembly: Fasteners, springs, and other components are put together using screws, rivets, or clips.

- Welding: In some cases, components are welded to enhance strength and durability.

- Testing During Assembly: In-Process Quality Control (IPQC) is crucial at this stage, where assembly accuracy and functionality are checked.

4. Finishing

Finishing processes enhance the latch’s aesthetic and functional qualities:

- Coating: Latches may be coated with paint, powder, or plating to improve corrosion resistance and appearance.

- Polishing: This is done to achieve a smooth surface finish, especially for stainless steel latches.

- Quality Checks: After finishing, a final round of inspections ensures that the latches meet the required specifications.

Quality Assurance Standards and Practices

Quality assurance is vital in the manufacturing of latches. Buyers must be aware of relevant international standards and industry-specific certifications.

International Standards

- ISO 9001: This standard ensures that manufacturers maintain a quality management system that meets customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: For latches used in the oil and gas industry, API standards ensure the products can withstand harsh environments.

Quality Control Checkpoints

- Incoming Quality Control (IQC): Verifies the quality of materials before production begins.

- In-Process Quality Control (IPQC): Monitors production processes to catch defects early.

- Final Quality Control (FQC): Conducts final inspections before shipment, ensuring that products meet all specifications.

Common Testing Methods

- Mechanical Testing: Includes tensile strength, fatigue, and impact tests to ensure durability.

- Corrosion Testing: Essential for metal latches to verify resistance to environmental factors.

- Functional Testing: Ensures that latches operate as intended under normal and extreme conditions.

Verifying Supplier Quality Control

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is paramount.

Key Strategies for Verification

- Supplier Audits: Regular audits provide insights into a supplier’s manufacturing and quality assurance processes. Ensure that auditors are trained and impartial.

- Requesting Quality Reports: Suppliers should provide detailed reports on their quality control measures, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s capabilities and product quality.

Navigating QC Nuances in International Trade

International buyers must navigate various nuances when it comes to quality control:

- Cultural Differences: Quality standards and practices can vary significantly across regions. Understanding these differences is vital for effective communication with suppliers.

- Regulatory Compliance: Buyers must ensure that products meet the regulatory requirements of their local markets, which can involve additional testing and certifications.

- Risk Management: Establishing a clear risk management strategy can mitigate potential quality issues. This includes having contingency plans for supply chain disruptions or product recalls.

By understanding the manufacturing processes and quality assurance practices related to latches for boxes, B2B buyers can make more informed decisions, ensuring that they procure high-quality products that meet their specific needs.

Related Video: Amazing Manufacturing Process of Corrugated Carton Boxes with Paper Roll

Comprehensive Cost and Pricing Analysis for types of latches for boxes Sourcing

The cost structure and pricing of latches for boxes are influenced by several key components and factors that international B2B buyers must consider when sourcing these products. Understanding these elements can lead to better negotiation outcomes and more informed purchasing decisions.

Cost Components

-

Materials: The choice of materials (e.g., stainless steel, aluminum, plastic) significantly impacts the cost. High-quality materials often come with a higher price tag but can enhance durability and performance.

-

Labor: Labor costs vary by region and are influenced by the complexity of the latch design. Custom or complex latches may require skilled labor, thereby increasing costs.

-

Manufacturing Overhead: This includes the costs associated with running the manufacturing facility, such as utilities, rent, and administrative expenses. These costs are generally fixed and may be distributed across all products manufactured.

Illustrative Image (Source: Google Search)

-

Tooling: Initial tooling costs can be significant, especially for custom latches. Buyers should inquire about whether these costs are included in the quoted price or are charged separately.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety but adds to the overall cost. Certifications (e.g., ISO, CE) can also influence pricing, as they may require additional testing and documentation.

-

Logistics: Transportation costs can vary widely based on the origin of the product, shipping method, and destination. Consideration of Incoterms is essential, as they dictate who bears the cost and risk during shipping.

-

Margin: Supplier margins can vary, affecting the final price. Bulk orders often lead to lower per-unit costs due to economies of scale.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) can impact pricing; larger orders typically benefit from discounted rates. Buyers should evaluate their needs against potential savings from bulk purchasing.

-

Specifications/Customization: Custom latches tailored to specific applications can increase costs. It’s important to balance the need for customization with budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Quality/Certifications: Higher-quality latches with industry certifications often come at a premium. Buyers should assess whether the additional cost aligns with their operational requirements.

Buyer Tips

-

Negotiation: Engage in negotiations to secure better pricing, especially for larger orders. Leverage competitive quotes from multiple suppliers to strengthen your position.

-

Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also installation, maintenance, and replacement costs over time.

-

Pricing Nuances: Be aware of potential fluctuations in pricing due to changes in material costs or exchange rates, particularly for international transactions. This is especially relevant for buyers in Africa and South America, where currency volatility can impact costs.

-

Regional Considerations: European buyers, for instance, might prioritize certifications and compliance with EU regulations, which can affect pricing. In contrast, buyers from the Middle East may focus on durability and resistance to extreme temperatures.

Disclaimer

Prices for latches can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain multiple quotes before making purchasing decisions to ensure they are getting the best value for their investment.

Spotlight on Potential types of latches for boxes Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of latches for boxes’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of latches for boxes

When selecting latches for boxes, international B2B buyers must understand key technical properties and industry terminology that can significantly impact their purchasing decisions. This knowledge helps ensure that the selected latches meet operational requirements and comply with regional standards.

Key Technical Properties

-

Material Grade

– Definition: The type and quality of materials used in the latch construction, such as stainless steel, aluminum, or plastic.

– Importance: Material grade affects durability, resistance to corrosion, and overall strength. For instance, stainless steel latches are ideal for outdoor applications in humid environments, while plastic latches may be suitable for lightweight, indoor use. -

Load Capacity

– Definition: The maximum weight a latch can securely hold without failure.

– Importance: Understanding load capacity is crucial for ensuring that the latch can withstand the intended application. Buyers must match the latch’s load capacity with the weight of the box’s contents to prevent malfunction or damage. -

Tolerance

– Definition: The allowable variation in dimensions of the latch components, typically expressed in millimeters or inches.

– Importance: Tolerance affects the fit and function of the latch. Accurate tolerances ensure that latches operate smoothly and securely, which is particularly important in high-precision applications. -

Finish Type

– Definition: The surface treatment applied to the latch, such as powder coating, anodizing, or plating.

– Importance: The finish type can enhance aesthetics and protect against wear and corrosion. Buyers should consider the environment in which the latch will be used to select an appropriate finish that prolongs the latch’s lifespan. -

Locking Mechanism

– Definition: The method by which the latch secures the box, which may include toggle, spring-loaded, or key-lock mechanisms.

– Importance: The locking mechanism influences security and ease of use. For applications requiring higher security, a latch with a key-lock mechanism is preferable, while a toggle latch may suffice for general use.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships helps buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell in a single order.

– Significance: Knowing the MOQ is vital for budget planning and inventory management, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specific products.

– Significance: Submitting an RFQ allows buyers to compare pricing and terms from different suppliers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Significance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risk management in cross-border transactions. -

Lead Time

– Definition: The time it takes from placing an order to receiving the goods.

– Significance: Recognizing lead time is essential for planning inventory and ensuring timely project completion, especially in industries with strict deadlines.

By equipping themselves with knowledge of these technical properties and trade terms, international B2B buyers can make informed decisions that align with their operational needs and market dynamics. Understanding these aspects not only enhances product selection but also fosters better supplier relationships and negotiation outcomes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of latches for boxes Sector

Market Overview & Key Trends

The global market for latches used in box applications is witnessing robust growth driven by various factors including increased demand for secure packaging solutions, advancements in manufacturing technologies, and the expansion of e-commerce. As businesses focus on enhancing product security and user experience, latches are becoming essential components in a wide range of industries, from automotive to electronics.

Key trends impacting international B2B buyers include the rise of smart latching systems that integrate IoT technology for enhanced security features. This trend is particularly relevant for buyers in Africa and South America, where supply chain security is paramount. Additionally, the shift toward lightweight and durable materials, such as aluminum and high-strength polymers, is gaining traction. These materials not only improve the functionality of latches but also reduce shipping costs and environmental impact.

Moreover, B2B buyers should be aware of regional market dynamics. In Europe, stringent regulations regarding product safety and quality are influencing sourcing decisions. Conversely, in the Middle East, the focus on construction and infrastructure development is driving demand for heavy-duty latching solutions. Understanding these regional nuances can significantly enhance sourcing strategies and supplier relationships.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical consideration for B2B buyers in the latch market. The environmental impact of manufacturing processes, particularly regarding resource consumption and waste generation, necessitates a shift towards sustainable practices. Buyers are increasingly prioritizing suppliers who implement eco-friendly manufacturing processes and use recyclable materials in their products.

Ethical sourcing is also gaining importance. Buyers should seek out suppliers who demonstrate transparency in their supply chains and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical standards.

Furthermore, the adoption of “green” materials—such as biodegradable plastics and sustainably sourced metals—can not only reduce environmental impact but also appeal to environmentally conscious consumers. By integrating sustainability and ethical considerations into sourcing strategies, buyers can enhance their brand reputation and meet regulatory requirements while contributing to a more sustainable future.

Brief Evolution/History

The evolution of latches for boxes can be traced back to ancient civilizations, where simple mechanisms were used for securing containers. Over time, advancements in metallurgy and manufacturing processes led to the development of more sophisticated latching systems, catering to various industrial needs. The introduction of spring-loaded and toggle latches in the 20th century revolutionized the industry, providing enhanced security and ease of use.

In recent years, the focus has shifted toward integrating technology with traditional latching systems, leading to the emergence of smart latches that offer features like remote locking and monitoring. This evolution reflects the changing demands of consumers and businesses alike, positioning latches as not just functional components, but as integral parts of modern security solutions.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of latches for boxes

-

What should I consider when vetting suppliers for latches?

When vetting suppliers, focus on their industry experience, product quality, and customer reviews. Verify certifications relevant to your region, such as ISO or specific industry standards. Request samples to assess the quality and functionality of their latches. Additionally, investigate their production capacity and reliability in meeting deadlines. Establish communication to gauge their responsiveness and customer service, which can be crucial for long-term partnerships. -

Can I customize latches to fit my specific requirements?

Many suppliers offer customization options for latches, including dimensions, materials, and finishes. When discussing customization, provide detailed specifications and any design files if available. Ensure that the supplier has the capability to meet your customization needs, and ask about any additional costs or lead times associated with custom orders. This proactive approach can help you achieve a product that perfectly fits your application. -

What are the typical minimum order quantities (MOQs) and lead times?

Minimum order quantities vary significantly between suppliers, often depending on the type of latch and customization requirements. Standard MOQs may range from 50 to several hundred units. Lead times can vary based on production schedules and whether the order is customized. It’s essential to discuss these details upfront to align with your project timelines and inventory management strategies. -

What payment terms should I expect when sourcing latches internationally?

Payment terms can vary widely among suppliers. Common practices include upfront payments, partial payments, or payment upon delivery. For international transactions, consider secure payment methods such as letters of credit or escrow services to minimize risks. Ensure you have a clear agreement on payment terms before finalizing the contract, and be aware of any currency exchange implications. -

How can I ensure quality assurance and certification compliance?

Request documentation regarding quality assurance processes and certifications from your supplier. Many reputable manufacturers follow strict QA protocols and can provide certificates for their products. Consider conducting third-party inspections or audits, especially for larger orders, to verify compliance with your quality standards. This step is crucial to mitigate risks associated with defective products. -

What logistics considerations should I keep in mind when sourcing latches?

When planning logistics, evaluate shipping options, costs, and delivery times to your location. Discuss incoterms with your supplier to clarify responsibilities for shipping, insurance, and customs clearance. Understanding the implications of international shipping, such as potential delays at customs, can help you manage your supply chain more effectively. Collaborating with a reliable freight forwarder can also streamline the logistics process. -

How should I handle disputes with suppliers?

Establish clear terms in your contracts regarding dispute resolution mechanisms, such as mediation or arbitration. Maintain open communication with your supplier to address issues promptly. Document all correspondence and agreements, as this can be valuable in resolving disputes. If a significant issue arises, consider involving a third-party mediator to facilitate a resolution while preserving the business relationship. -

What are the best practices for maintaining supplier relationships?

Building strong supplier relationships involves regular communication and feedback. Schedule periodic reviews to discuss performance, quality, and any areas for improvement. Show appreciation for their efforts, especially during challenging times, to foster loyalty. Consider collaborating on product development or marketing initiatives to strengthen the partnership and create mutual benefits, which can lead to better service and pricing in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of latches for boxes

In today’s dynamic global marketplace, strategic sourcing of latches for boxes is crucial for maximizing operational efficiency and ensuring product integrity. By understanding the diverse types of latches—ranging from over-centre latches to toggle and catch latches—buyers can select the most appropriate solutions tailored to their specific needs. It is essential to consider factors such as load capacity, environmental conditions, and ease of use when making sourcing decisions.

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, leveraging relationships with reputable manufacturers can lead to significant cost savings and improved product quality. Establishing direct connections with suppliers, like Protex, can facilitate quicker turnaround times and access to the latest innovations in latch technology.

As we look towards the future, the demand for reliable and efficient latching solutions will only increase. Buyers are encouraged to stay informed about emerging trends and advancements in latch design and functionality. By prioritizing strategic sourcing, businesses can not only enhance their supply chain resilience but also ensure that they remain competitive in a rapidly evolving market. Embrace this opportunity to refine your sourcing strategy and connect with trusted suppliers today.