Master the Essentials of Prong Plug Sourcing for Global

Introduction: Navigating the Global Market for prong plug

In today’s interconnected world, the prong plug serves as a vital link between electrical devices and the power supply, making it an essential component for businesses across various sectors. For international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of prong plugs is crucial for ensuring compatibility, safety, and efficiency in their operations.

This comprehensive guide delves into the diverse types of prong plugs available in the global market, including their materials and manufacturing processes. We will explore quality control measures that are critical for maintaining high standards, alongside insights into reliable suppliers. Additionally, the guide covers pricing strategies and market trends, empowering buyers to make informed sourcing decisions.

By addressing frequently asked questions, we aim to demystify the complexities of prong plug procurement, enabling businesses to streamline their supply chains and enhance operational efficiency. Whether you’re in Spain or South Africa, understanding the prong plug market will not only support compliance with regional standards but also foster innovation and adaptability in your electrical solutions. Equip your business with the knowledge to navigate this essential component, ensuring that your electrical infrastructure is both robust and reliable.

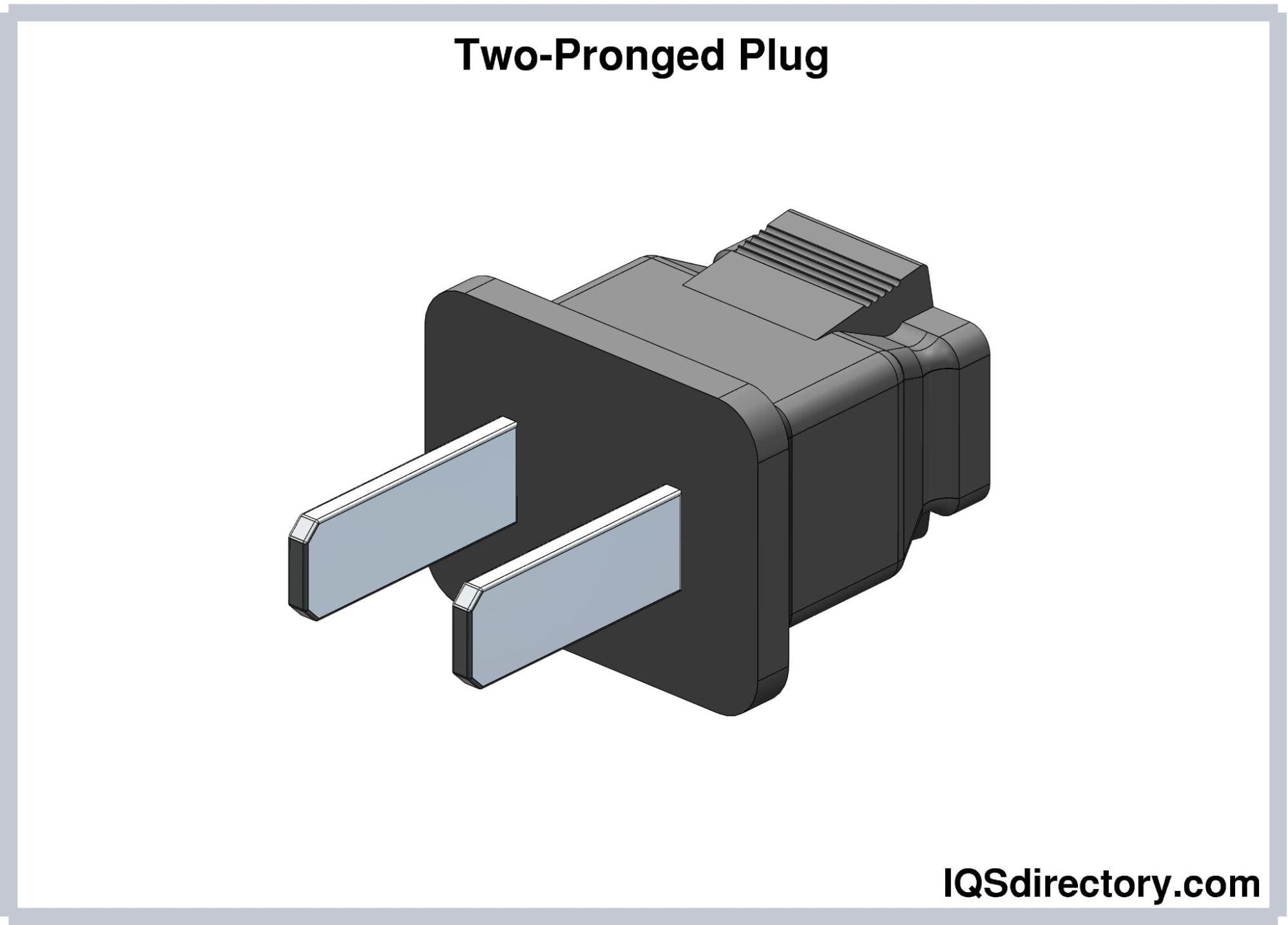

Illustrative Image (Source: Google Search)

Understanding prong plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel prongs | North American electronics | Pros: Widely used, easy to find. Cons: Limited to 120V, not suitable for high-power applications. |

| Type C | Two round prongs | European appliances | Pros: Common in Europe, adaptable. Cons: May require adapters in non-European regions. |

| Type G | Three rectangular prongs (including ground) | UK and Middle Eastern devices | Pros: High safety standards, grounded. Cons: Bulky design can be impractical for compact devices. |

| Type I | Two flat prongs in a V-shape | Australian and Chinese equipment | Pros: Suitable for higher voltages, versatile. Cons: Less common outside of Australia and China. |

| Type N | Two round prongs with ground pin | Brazilian electrical devices | Pros: Modern design, suitable for newer installations. Cons: Limited availability in global markets. |

Type A

Type A plugs feature two flat parallel prongs and are predominantly used in North America. They are suitable for low-voltage applications, making them ideal for consumer electronics and light appliances. When purchasing, B2B buyers should consider the voltage compatibility (typically 120V) and the availability of products that utilize this plug type. While Type A plugs are easy to source, their limited voltage capacity may not meet the needs of higher-power machinery.

Type C

Characterized by two round prongs, Type C plugs are commonly used across Europe and are compatible with many devices. Their versatility makes them suitable for a wide range of appliances, from kitchen equipment to office electronics. Buyers should note that while Type C plugs are adaptable, they may require additional adapters for use in regions that do not support this standard. This adaptability is crucial for businesses operating in multiple countries.

Type G

Type G plugs, which feature three rectangular prongs, are primarily used in the UK and several Middle Eastern countries. This design includes a ground pin, enhancing safety for high-power devices. B2B buyers should prioritize Type G plugs for equipment that requires grounded connections. However, the bulkiness of the design can be a drawback for portable applications, which may affect the usability of devices in tight spaces.

Type I

With two flat prongs arranged in a V-shape, Type I plugs are used in Australia and China. They are suitable for devices operating at higher voltages, making them ideal for industrial applications. B2B buyers should consider the specific voltage requirements of their equipment when selecting Type I plugs. While they offer versatility, their limited presence outside Australia and China may necessitate additional logistical considerations for international operations.

Type N

Type N plugs are distinguished by their two round prongs and a ground pin, primarily used in Brazil. They are designed for modern electrical installations and are increasingly common in newly built facilities. When purchasing, B2B buyers should evaluate whether their equipment is compatible with Type N standards, especially if they are entering the Brazilian market. However, the limited availability of Type N plugs in other regions may pose challenges for international sourcing.

Related Video: How to Understand Two-Prong Outlets | Ask This Old House

Key Industrial Applications of prong plug

| Industry/Sector | Specific Application of prong plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering machinery and equipment | Ensures operational efficiency and safety | Compliance with local electrical standards and voltage requirements |

| Construction | Temporary power supply for tools and equipment | Facilitates project completion and productivity | Durability and weather resistance, especially in outdoor conditions |

| Hospitality | Charging stations for guest devices | Enhances guest experience and satisfaction | Compatibility with various device types and universal design |

| Telecommunications | Providing power to networking equipment | Supports uninterrupted communication services | Reliability and safety certifications for critical infrastructure |

| Transportation | Powering electric vehicles and public transport systems | Promotes sustainable energy use and efficiency | Adherence to international safety standards and charging protocols |

Manufacturing

In the manufacturing sector, prong plugs are essential for powering various machinery and equipment. They ensure that devices operate efficiently and safely, minimizing downtime and enhancing productivity. Buyers in this sector should prioritize compliance with local electrical standards, as well as the voltage requirements specific to their machinery. Ensuring that prong plugs can handle the necessary load without overheating is crucial for operational safety.

Construction

In construction, prong plugs are commonly used for providing temporary power to tools and equipment on-site. This application is vital for maintaining workflow and ensuring timely project completion. Buyers should consider the durability of the plugs, as they must withstand harsh outdoor conditions, including exposure to moisture and dust. Weather-resistant designs that comply with safety regulations are important factors for sourcing.

Hospitality

The hospitality industry benefits from prong plugs by offering charging stations for guest devices, such as smartphones and laptops. This convenience enhances the guest experience, leading to higher satisfaction rates and repeat business. For international buyers, ensuring compatibility with various device types and adherence to universal design standards will be critical. Additionally, plugs should meet safety certifications to prevent any risk of electrical hazards in guest areas.

Telecommunications

In telecommunications, prong plugs provide power to networking equipment, which is vital for maintaining uninterrupted communication services. The reliability of these plugs directly impacts the efficiency of data transmission and connectivity. Buyers must ensure that the prong plugs are certified for safety, particularly when integrated into critical infrastructure. Sourcing plugs that can handle high power loads while remaining safe is essential for this sector.

Transportation

The transportation industry increasingly relies on prong plugs to power electric vehicles (EVs) and public transport systems. This application supports the shift towards sustainable energy use and enhances operational efficiency. Buyers should focus on sourcing plugs that adhere to international safety standards and charging protocols to ensure compatibility with various EV models. Additionally, the ability to withstand different environmental conditions is crucial for long-term reliability.

Related Video: How to Change a Dryer Plug: 4 Prong Plug to a 3 Prong Plug

Strategic Material Selection Guide for prong plug

When selecting materials for prong plugs, international B2B buyers must consider various factors that affect performance, compliance, and overall suitability for their applications. Below is an analysis of four common materials used in prong plugs, focusing on their properties, advantages, disadvantages, and considerations for buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

1. Polyvinyl Chloride (PVC)

Key Properties:

PVC is known for its excellent electrical insulation properties and resistance to moisture. It can withstand temperatures up to 70°C and has good mechanical strength.

Pros & Cons:

– Pros: PVC is cost-effective and easy to mold, making it suitable for high-volume production. It is also resistant to chemicals and moisture, which enhances durability.

– Cons: Its temperature rating limits its use in high-heat applications. Additionally, PVC can become brittle over time, particularly in colder climates.

Impact on Application:

PVC is compatible with a wide range of electrical devices, making it a popular choice for consumer electronics. However, it may not perform well in environments with extreme temperatures or exposure to certain chemicals.

Considerations for Buyers:

Buyers should ensure that PVC prong plugs comply with relevant standards, such as ASTM D1784 for materials. In regions like Europe, adherence to RoHS directives regarding hazardous substances is crucial.

2. Thermoplastic Elastomer (TPE)

Key Properties:

TPE combines the properties of rubber and plastic, offering flexibility and resilience. It can handle temperatures from -40°C to 100°C, making it versatile for various applications.

Pros & Cons:

– Pros: TPE is highly durable, resistant to UV light, and maintains its properties across a wide temperature range. Its flexibility allows for easy handling and installation.

– Cons: TPE can be more expensive than PVC, and its manufacturing process may be more complex, potentially leading to higher production costs.

Impact on Application:

TPE is ideal for applications requiring flexibility and durability, such as in outdoor electrical devices. Its resistance to environmental factors makes it suitable for regions with harsh climates.

Considerations for Buyers:

International buyers should verify that TPE materials meet local compliance standards. For example, in South America, conformity with INMETRO regulations may be necessary.

3. Nylon

Key Properties:

Nylon is a strong, lightweight synthetic polymer with excellent abrasion resistance and a high melting point (around 220°C). It also provides good electrical insulation.

Pros & Cons:

– Pros: Its strength and heat resistance make nylon suitable for high-performance applications. It is also resistant to many chemicals, enhancing its longevity.

– Cons: Nylon can absorb moisture, which may affect its electrical properties over time. Additionally, it may be more costly than other materials like PVC.

Impact on Application:

Nylon is often used in industrial applications where mechanical strength and heat resistance are critical. It is compatible with a variety of electrical devices but may not be ideal for humid environments.

Considerations for Buyers:

Buyers in Europe should ensure compliance with EN 60670-1 standards for electrical accessories. In Africa, understanding local material sourcing and availability is essential for consistent supply.

4. Metal (Brass or Copper)

Key Properties:

Metal prong plugs, typically made from brass or copper, offer excellent conductivity and durability. They can withstand high temperatures and are resistant to corrosion.

Pros & Cons:

– Pros: Metals provide superior electrical performance and are highly durable, making them suitable for heavy-duty applications. They are also recyclable, which can appeal to environmentally conscious buyers.

– Cons: Metal plugs can be more expensive and may require additional coatings to prevent corrosion. They are also heavier than plastic alternatives, which can be a drawback for portable devices.

Impact on Application:

Metal prong plugs are ideal for industrial applications requiring high conductivity and durability. However, they may not be suitable for environments where moisture is prevalent unless properly treated.

Considerations for Buyers:

Buyers should ensure that metal plugs comply with international standards such as IEC 60884-1. In the Middle East, understanding local regulations regarding electrical safety is crucial.

Summary Table

| Material | Typical Use Case for prong plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride | Consumer electronics | Cost-effective and durable | Limited temperature range | Low |

| Thermoplastic Elastomer | Outdoor electrical devices | Flexible and UV resistant | Higher cost and complexity | Medium |

| Nylon | Industrial applications | High strength and heat resistance | Moisture absorption | Medium |

| Metal (Brass/Copper) | Heavy-duty electrical applications | Superior conductivity and durability | Higher cost and weight | High |

This material selection guide provides actionable insights for B2B buyers to make informed decisions when sourcing prong plugs, ensuring compliance with regional standards and suitability for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for prong plug

Manufacturing Processes for Prong Plugs

The production of prong plugs involves several critical stages, each designed to ensure the final product meets safety, functionality, and durability standards. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first stage in the manufacturing process is material preparation. High-quality materials are essential for prong plugs, typically including:

- Conductive Metals: Copper or aluminum is used for the prongs due to their excellent conductivity.

- Insulating Materials: Thermoplastics like polyvinyl chloride (PVC) or thermoplastic elastomers (TPE) are commonly used for the casing, providing insulation and protection.

- Mechanical Components: Springs, screws, and other fasteners may also be required depending on the plug design.

During this stage, raw materials are sourced from certified suppliers to ensure compliance with international standards. Buyers should inquire about the material certifications to verify the quality and safety of the components.

2. Forming

Once materials are prepared, the next step is forming the components. This involves several key techniques:

- Stamping: This is often used to create the prongs from metal sheets, ensuring uniformity and precise dimensions.

- Molding: The insulating casing is produced through injection molding or compression molding, allowing for complex shapes and designs.

- Machining: Any additional features, such as grooves or notches, are added through machining processes.

Each technique requires specialized machinery and skilled operators to maintain the integrity of the components. Buyers should evaluate the manufacturer’s capabilities and machinery to ensure they can produce high-quality products consistently.

3. Assembly

The assembly process brings together all the formed components. This stage may include:

- Joining Components: Soldering or crimping the prongs to the internal wiring and ensuring secure connections.

- Quality Checks: Implementing in-process quality control (IPQC) to detect any defects before moving on to the next stage.

Efficient assembly lines that utilize automation can significantly reduce production time while enhancing quality. Buyers should assess the manufacturer’s assembly processes and workforce training to ensure optimal efficiency and quality.

4. Finishing

Finishing touches are crucial for the aesthetic and functional qualities of prong plugs. Key activities include:

- Surface Treatment: Applying coatings or plating to enhance corrosion resistance and durability.

- Final Inspection: Conducting a thorough inspection of the finished product to ensure it meets all specifications.

Finishing processes not only affect the appearance but also the longevity of the prong plugs. Buyers should ask about the types of finishes used and their impact on the product’s performance in various environments.

Quality Assurance Protocols

Quality assurance (QA) is a vital aspect of manufacturing prong plugs. It ensures that products meet international safety and performance standards, which is particularly important for B2B buyers operating in diverse markets.

International Standards

Manufacturers often comply with several international standards, including:

- ISO 9001: Focuses on quality management systems, ensuring consistent quality and customer satisfaction.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with safety, health, and environmental protection standards.

- API Standards: Important for plugs used in industrial applications, ensuring they meet specific performance criteria.

Buyers should verify that manufacturers hold these certifications, as they reflect a commitment to quality and safety.

Quality Control Checkpoints

Quality control is implemented at various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Monitoring production processes to detect defects in real-time.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before they are shipped.

Each checkpoint plays a critical role in maintaining product quality. B2B buyers should inquire about the specific QC methods employed by suppliers and request access to QC reports.

Common Testing Methods

To ensure the reliability and safety of prong plugs, various testing methods are utilized, including:

- Electrical Testing: Measures insulation resistance, dielectric strength, and current leakage.

- Mechanical Testing: Assesses durability, pull strength, and resistance to wear and tear.

- Environmental Testing: Evaluates performance under extreme temperatures, humidity, and other environmental conditions.

These tests provide essential data on product performance and safety. Buyers can request test reports or certifications to validate the results.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of potential suppliers is crucial. Here are actionable steps to ensure compliance:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes, quality control systems, and compliance with international standards.

- Quality Reports: Request detailed QC reports that outline inspection results, testing methods, and any corrective actions taken.

- Third-Party Inspections: Engage independent inspection agencies to evaluate the manufacturing processes and product quality.

By implementing these strategies, buyers can mitigate risks associated with quality issues and ensure they source from reliable manufacturers.

Navigating Certification Nuances

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, must navigate various certification requirements. Here are some key considerations:

- Regional Compliance: Understand the specific regulations and standards applicable in your region. For example, the CE marking is essential for products sold in Europe, while UL certification may be required in North America.

- Documentation: Ensure that suppliers can provide all necessary documentation for certifications, as this will facilitate smoother customs clearance and market entry.

- Cultural Sensitivity: Be aware of cultural differences in quality perceptions and standards, which can impact supplier relationships and negotiations.

By staying informed and proactive, international B2B buyers can successfully navigate the complexities of sourcing prong plugs while ensuring quality and compliance with industry standards.

Related Video: Amazing scenes。Top 6 Most Popular Factory Manufacturing Videos in China

Comprehensive Cost and Pricing Analysis for prong plug Sourcing

When sourcing prong plugs, understanding the comprehensive cost structure is crucial for international B2B buyers. This section will break down the various cost components, analyze price influencers, and offer actionable tips for effective negotiation and cost management.

Cost Components

-

Materials: The primary cost driver for prong plugs is the raw materials used in production. Common materials include thermoplastics for the housing, copper or aluminum for the prongs, and rubber for insulation. The choice of material significantly impacts both cost and product quality.

-

Labor: Labor costs vary by region and can be a significant portion of total manufacturing costs. In countries with lower labor costs, such as some African and South American nations, sourcing may be more cost-effective. However, it’s essential to consider the skill level of the workforce, as this affects the quality of the final product.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which can be a negotiating point for buyers.

-

Tooling: Initial setup costs for molds and tools can be substantial, especially for custom designs. This cost is amortized over the production run, making larger orders more cost-effective per unit.

-

Quality Control (QC): Implementing strict QC measures ensures product reliability but adds to costs. Buyers should consider suppliers that offer certifications (e.g., ISO) that guarantee quality standards, as these may influence the final price.

-

Logistics: Shipping costs can vary greatly depending on the distance, mode of transport, and Incoterms. Understanding these logistics costs is essential to determining the total landed cost of prong plugs.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market position, reputation, and the competitive landscape.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders usually result in lower per-unit costs due to economies of scale.

-

Specifications/Customization: Custom designs or unique specifications can increase costs. Buyers should assess whether customization is necessary or if standard options suffice.

-

Materials and Quality: Higher-quality materials and certifications will increase costs but may provide long-term benefits in terms of durability and safety.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Engaging with established suppliers may provide better quality assurance but at a higher cost.

-

Incoterms: The choice of Incoterms can affect logistics costs and responsibilities. For instance, choosing DDP (Delivered Duty Paid) may result in higher upfront costs but simplifies the purchasing process.

Buyer Tips

-

Negotiation: Engage suppliers in discussions about pricing, especially for large orders. Leverage your position as a potential repeat customer to negotiate better terms.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not only the purchase price but also costs related to maintenance, durability, and potential failures.

-

Pricing Nuances: For international buyers, fluctuations in currency exchange rates can affect pricing. It’s advisable to lock in prices when favorable exchange rates are available.

-

Regional Considerations: Buyers in Africa, South America, the Middle East, and Europe should be aware of regional supply chain challenges that could impact delivery times and costs. Establishing relationships with local distributors may mitigate some of these risks.

In summary, understanding the multifaceted cost structure and price influencers in the prong plug market empowers international B2B buyers to make informed sourcing decisions. It is essential to consider not only the upfront costs but also the long-term implications of quality, reliability, and supplier relationships.

Spotlight on Potential prong plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘prong plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for prong plug

Key Technical Properties of Prong Plugs

Understanding the essential technical specifications of prong plugs is crucial for B2B buyers, particularly when sourcing from diverse markets such as Africa, South America, the Middle East, and Europe. Here are some critical specifications to consider:

-

Material Grade: Prong plugs are typically manufactured from materials like thermoplastic, polycarbonate, or nylon for the casing, and copper or brass for the prongs. The choice of material affects durability, conductivity, and resistance to heat. Importance: Selecting the right material grade can ensure longevity and safety, which are paramount for industrial applications.

-

Voltage Rating: This specification indicates the maximum voltage the plug can handle safely, commonly found in ranges such as 110V, 220V, or 240V. Importance: Buyers must match the voltage rating with their equipment requirements to prevent electrical failures or hazards.

-

Current Rating (Amperage): Prong plugs are rated for specific current loads, typically between 5A to 15A. Importance: Understanding current ratings is essential for ensuring that the plug can handle the electrical load without overheating, which is particularly critical in high-demand industrial environments.

-

Tolerance: This refers to the allowable variation in dimensions and performance of the plug. For example, prong thickness or spacing may have tolerances of ±0.1 mm. Importance: Proper tolerances ensure compatibility with sockets and connectors, reducing the risk of faulty connections or electrical issues.

-

Safety Certifications: Look for plugs that have undergone testing and certification by recognized safety standards organizations, such as UL, CE, or IEC. Importance: These certifications guarantee that the plugs meet specific safety and performance criteria, which can significantly mitigate risks in electrical applications.

Common Trade Terminology

Familiarity with industry terminology can streamline communications and negotiations for international B2B buyers. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Importance: Understanding OEM relationships can help buyers identify reliable suppliers who provide quality components tailored to specific needs.

-

MOQ (Minimum Order Quantity): This is the smallest number of units that a supplier is willing to sell. Importance: Knowing the MOQ can help buyers manage their inventory and cash flow effectively, especially when dealing with manufacturers in different regions.

-

RFQ (Request for Quotation): A document sent to suppliers requesting pricing and terms for specified products. Importance: An RFQ helps streamline the procurement process, allowing buyers to compare offers efficiently and make informed purchasing decisions.

-

Incoterms: Short for International Commercial Terms, these are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Importance: Understanding Incoterms helps buyers clarify shipping costs, risks, and responsibilities, ensuring smoother cross-border transactions.

-

Lead Time: This refers to the time taken from placing an order to its delivery. Importance: Knowing the lead time is critical for planning and inventory management, particularly in international trade where delays can occur due to customs or logistical challenges.

-

Certification Mark: A symbol or designation indicating that a product meets specific standards set by a certifying body. Importance: Certification marks can enhance product credibility and provide assurance to buyers regarding safety and quality.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing prong plugs and ensure that their procurement processes are efficient and effective.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the prong plug Sector

Market Overview & Key Trends

The prong plug sector is witnessing significant growth driven by the increasing demand for connectivity solutions across various industries. Globally, the surge in electronic devices, from consumer electronics to industrial machinery, is propelling the market. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate this landscape, several key trends emerge.

Smart Plug Technology: The advent of smart technology is reshaping the prong plug market. Smart plugs that integrate with IoT systems are gaining traction, offering enhanced functionality such as remote control and energy monitoring. B2B buyers should consider suppliers that provide innovative products that align with technological advancements.

Standardization and Compliance: As regulations tighten, compliance with international standards (like IEC and UL certifications) is crucial. Buyers must prioritize manufacturers who adhere to these standards, ensuring safety and reliability in their sourcing decisions. This is particularly relevant in European markets where stringent regulations govern electrical products.

Sourcing Trends: There’s a notable shift towards regional sourcing as companies seek to minimize lead times and logistics costs. For buyers in Africa and South America, establishing partnerships with local manufacturers can enhance supply chain resilience and foster economic growth within their regions.

Sustainability Focus: Increasing awareness of environmental issues has led to a demand for eco-friendly plugs made from sustainable materials. Buyers should look for suppliers committed to sustainable practices and products that reduce environmental impact.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a non-negotiable aspect of the prong plug sector. The environmental impact of manufacturing practices and the materials used is under scrutiny, with consumers and businesses alike favoring eco-friendly options. B2B buyers must evaluate their supply chains for sustainability, focusing on ethical sourcing practices.

Importance of Ethical Supply Chains: Ethical sourcing ensures that products are produced in a manner that respects human rights and environmental standards. Buyers should seek suppliers who are transparent about their supply chains and who uphold ethical labor practices. This not only mitigates risks associated with unethical practices but also enhances brand reputation.

Green Certifications and Materials: Certifications such as Energy Star, RoHS, and WEEE are increasingly important in the procurement process. These certifications demonstrate a commitment to sustainability and can be a deciding factor for buyers. Additionally, sourcing plugs made from recycled or biodegradable materials can significantly reduce the carbon footprint associated with production and disposal.

Brief Evolution/History

The prong plug, a fundamental component of electrical connectivity, has evolved from simple designs to more complex, multifunctional units. Initially, plugs were designed for basic electrical connections; however, with the proliferation of electronic devices, the need for safety and versatility has led to significant innovations.

In the late 20th century, the introduction of standardized plug types (e.g., Type C, Type G) facilitated international compatibility. Today, the integration of smart technology and sustainable materials reflects the ongoing evolution of the prong plug sector. This historical context underscores the importance of innovation in meeting the demands of modern consumers and businesses alike.

In summary, B2B buyers in the prong plug market must stay informed about market dynamics, prioritize sustainable sourcing, and embrace the ongoing technological evolution to remain competitive.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of prong plug

-

What criteria should I use to vet suppliers for prong plugs?

When vetting suppliers, prioritize their industry experience, certifications, and compliance with international standards such as ISO or IEC. Request references from previous clients and review their production capabilities. It’s also beneficial to check their financial stability through credit reports and to evaluate their customer service responsiveness. Consider conducting a factory audit or visiting their facility if possible, especially for large orders, to ensure they meet your quality and operational standards. -

Can I customize prong plugs to suit specific market needs?

Yes, many manufacturers offer customization options for prong plugs. You can specify design elements like color, size, and material, as well as technical specifications such as voltage ratings and plug types. Ensure you communicate your requirements clearly and confirm that the supplier has the capability to meet these specifications. Additionally, be prepared for possible minimum order quantities (MOQs) that may apply to customized products. -

What are typical minimum order quantities (MOQs) and lead times for prong plugs?

MOQs for prong plugs can vary significantly based on the supplier and product specifications. Generally, MOQs range from 500 to 5,000 units. Lead times depend on the complexity of the order and current production schedules, typically ranging from 4 to 12 weeks. Discuss these factors early in negotiations to align expectations and avoid delays in your supply chain. -

What payment terms are commonly accepted when sourcing prong plugs?

Payment terms may vary by supplier and region, but standard practices include partial upfront payments (30-50%) with the balance due upon shipment or delivery. Some suppliers may offer net payment terms (e.g., Net 30 or Net 60) based on your creditworthiness and history with them. Always ensure that payment methods are secure, and consider using escrow services for larger transactions to mitigate risks. -

How can I ensure quality assurance for prong plugs?

To ensure quality assurance, request samples before placing large orders. Implement a quality control plan that includes inspections at different production stages. Verify that the supplier holds relevant quality certifications (e.g., CE, UL) and is willing to provide test reports. Additionally, consider third-party inspections to evaluate product quality and compliance with international standards before shipment.

Illustrative Image (Source: Google Search)

-

What certifications should I look for when sourcing prong plugs?

Key certifications to look for include CE marking for European markets, UL certification for North America, and SANS for South African products. These certifications indicate compliance with safety and quality standards. Confirm that your supplier can provide documentation of these certifications for your records, as they may be necessary for customs clearance and legal compliance in your target market. -

What logistics considerations should I be aware of when importing prong plugs?

Logistics can be complex; ensure you understand shipping methods, costs, and potential customs duties. Choose a reliable freight forwarder experienced in handling electrical products. Familiarize yourself with local import regulations in your country to avoid delays or fines. Additionally, consider the terms of Incoterms (e.g., FOB, CIF) to clarify responsibilities for shipping and insurance. -

How should I handle disputes with suppliers?

To handle disputes effectively, establish clear communication channels and documentation practices from the outset. Include dispute resolution clauses in your contracts, specifying whether arbitration or mediation will be used. If a dispute arises, try to resolve it amicably through direct negotiation first. If necessary, escalate the matter according to the agreed-upon procedures in your contract, and consider involving legal counsel if the situation does not improve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for prong plug

In the evolving landscape of global trade, strategic sourcing for prong plugs presents a multitude of opportunities for international B2B buyers. Key takeaways include the importance of aligning with reliable suppliers who prioritize innovation and sustainability. Understanding regional compliance standards is critical, especially for buyers in diverse markets like Africa, South America, the Middle East, and Europe. By leveraging technology and establishing robust partnerships, businesses can enhance their supply chains, reduce costs, and improve product quality.

The value of strategic sourcing cannot be overstated. It allows companies to not only secure better pricing but also gain access to the latest technologies and materials that can differentiate their offerings in competitive markets. As consumer demand for more efficient and versatile prong plugs continues to rise, staying ahead of industry trends will be essential.

Looking ahead, B2B buyers are encouraged to actively seek out partnerships that foster innovation and adaptability. By investing in strategic sourcing practices today, businesses will be better equipped to meet future challenges and capitalize on emerging opportunities. Embrace this pivotal moment to enhance your supply chain and drive growth in your respective markets.