Master the Geared Reducer Market: Essential Guide for B2B

Introduction: Navigating the Global Market for geared reducer

Navigating the complexities of the global market for geared reducers is essential for B2B buyers looking to optimize their operational efficiency and machinery performance. Geared reducers play a pivotal role in various industries, converting high-speed, low-torque input into low-speed, high-torque output, crucial for applications ranging from automotive to industrial machinery. As the demand for advanced technology grows—especially with the rise of electric vehicles—understanding the nuances of gear reducer types, materials, and manufacturing quality becomes paramount for informed purchasing decisions.

This guide offers a comprehensive exploration of the geared reducer market, delving into the various types, including worm, planetary, and helical gear reducers, and discussing the latest advancements in materials and manufacturing processes. Buyers will find valuable insights on quality control measures, supplier evaluations, and cost considerations, all tailored to meet the specific needs of international markets, particularly in Africa, South America, the Middle East, and Europe.

By equipping buyers with actionable knowledge, this guide empowers them to make strategic sourcing decisions, ensuring they select the right gear reducer for their applications. Whether you are sourcing components for heavy machinery or optimizing electric vehicle powertrains, understanding the gear reducer landscape will enhance your competitive edge in a rapidly evolving global marketplace.

Understanding geared reducer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Worm Gear Reducer | High torque, right-angle configuration, smooth operation | Conveyors, material handling, lifting equipment | Pros: Compact, quiet operation. Cons: Lower efficiency due to friction losses. |

| Planetary Gear Reducer | Compact design, high torque-to-size ratio | Robotics, heavy machinery, automotive | Pros: High efficiency, excellent load distribution. Cons: More complex and expensive. |

| Helical Gear Reducer | Angled teeth for gradual engagement, quieter operation | Compressors, industrial mixers, conveyors | Pros: Smooth operation, high torque capacity. Cons: More costly and requires precise alignment. |

| Bevel Gear Reducer | Changes direction of force, robust construction | Agricultural equipment, construction machinery | Pros: Durable, good for heavy loads. Cons: Can be bulky and require more space. |

| Cycloidal Gear Reducer | Unique cycloidal motion, high reduction ratios | Robotics, industrial automation, packaging | Pros: High efficiency, compact size. Cons: Limited availability, can be complex to source. |

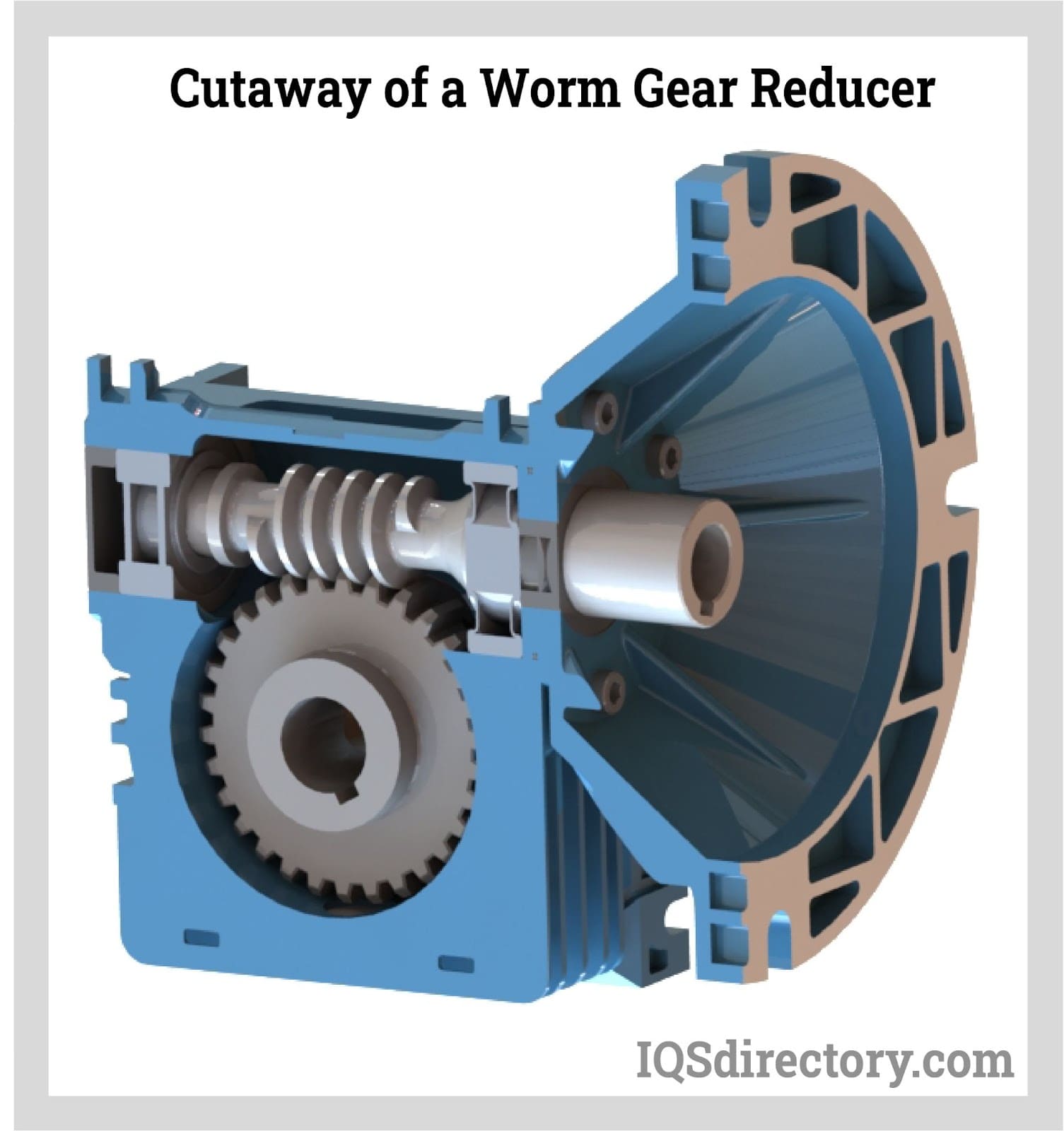

Worm Gear Reducer

Worm gear reducers are characterized by their unique design, which allows for high torque output and right-angle configurations. They are commonly used in applications such as conveyors and material handling systems. When considering a worm gear reducer, B2B buyers should evaluate the specific torque requirements and the potential energy losses due to friction, as these can impact overall efficiency. Despite being less efficient, their compact size and quiet operation make them appealing for various industrial applications.

Planetary Gear Reducer

Planetary gear reducers feature a compact design with multiple gears rotating around a central gear, offering high torque-to-size ratios. This makes them ideal for applications in robotics and heavy machinery where space is limited. Buyers should focus on the gear ratio and load capacity when selecting a planetary reducer, as these factors directly influence performance. While they tend to be more complex and expensive, their high efficiency and durability often justify the investment, especially in high-performance environments.

Illustrative Image (Source: Google Search)

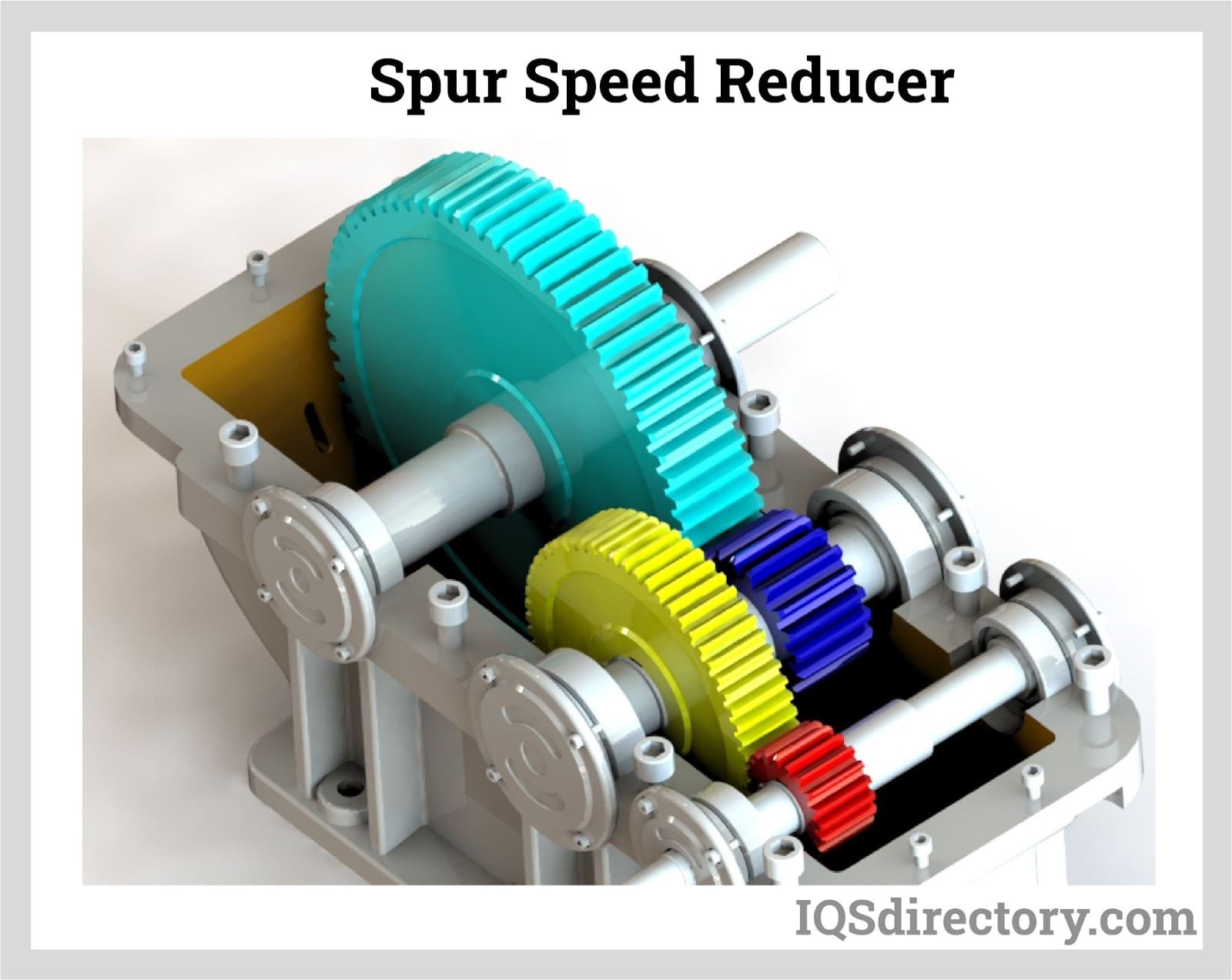

Helical Gear Reducer

Helical gear reducers utilize angled teeth for smoother engagement, resulting in quieter operation compared to other gear types. They are commonly found in compressors and industrial mixers, where high torque and speed are required. B2B buyers should consider the alignment and installation requirements, as precise fitting is crucial for optimal performance. Although they can be more costly, the advantages of reduced noise and enhanced efficiency make them a valuable choice for many industrial applications.

Bevel Gear Reducer

Bevel gear reducers are designed to change the direction of force, making them suitable for applications in agricultural equipment and construction machinery. Their robust construction allows them to handle heavy loads effectively. When purchasing bevel gear reducers, buyers should assess the space available for installation, as these units can be bulkier than other types. While they offer excellent durability, their size and weight may require additional considerations in design and layout.

Cycloidal Gear Reducer

Cycloidal gear reducers operate using a unique cycloidal motion, allowing for high reduction ratios and compact designs. They are increasingly used in robotics and industrial automation due to their efficiency. Buyers should evaluate the specific application needs and the availability of these reducers in their region, as sourcing can be a challenge. Although they offer significant advantages in efficiency and size, the complexity of their design may require specialized knowledge for installation and maintenance.

Related Video: CS 198-126: Lecture 12 – Diffusion Models

Key Industrial Applications of geared reducer

| Industry/Sector | Specific Application of geared reducer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Powertrain systems in electric vehicles | Enhances efficiency, reduces noise, and improves vehicle range | Focus on high-ratio gear reducers that comply with NVH standards |

| Manufacturing | Conveyor systems for material handling | Provides controlled speed and torque for safe operations | Consider durability, efficiency, and compatibility with existing systems |

| Agriculture | Lifting equipment and irrigation systems | Supports heavy loads and ensures smooth operation | Evaluate torque requirements and environmental resistance |

| Robotics | High-precision motion control in robotic arms | Increases accuracy and performance in automation processes | Look for compact designs with high torque-to-size ratios |

| Renewable Energy | Wind turbine gearboxes | Improves energy conversion and operational efficiency | Assess reliability and serviceability in harsh environments |

Automotive Applications

In the automotive sector, geared reducers are pivotal in powertrain systems, particularly for electric vehicles (EVs). These components facilitate the transfer of power from electric motors to the wheels, enhancing overall efficiency and extending vehicle range. As the demand for quieter and more efficient vehicles rises, international B2B buyers must prioritize high-ratio gear reducers that comply with noise, vibration, and harshness (NVH) standards, especially given the regulatory frameworks emerging in regions like the Middle East and Europe.

Manufacturing Applications

In manufacturing, geared reducers are essential in conveyor systems for material handling. They provide controlled speed and torque, which are critical for safe and efficient operations. Buyers should focus on durability and efficiency, ensuring the reducers can withstand heavy loads and continuous use. Additionally, compatibility with existing machinery is crucial, particularly for manufacturers in Africa and South America looking to modernize their operations without extensive overhauls.

Agricultural Applications

The agriculture industry utilizes geared reducers in lifting equipment and irrigation systems. These reducers handle heavy loads and ensure smooth operation, which is vital for the efficiency of farming processes. International buyers must evaluate the torque requirements of their specific applications and consider the environmental conditions—such as humidity and temperature variations—that can affect the performance and longevity of these components.

Robotics Applications

In the robotics sector, geared reducers are used for high-precision motion control in robotic arms. They enhance accuracy and performance, allowing for complex automation processes. B2B buyers should look for compact designs that offer high torque-to-size ratios to maximize space and efficiency. Additionally, sourcing from suppliers with a proven track record in high-precision components is essential for maintaining competitive advantage in this rapidly evolving industry.

Renewable Energy Applications

Geared reducers play a critical role in wind turbine gearboxes, where they improve energy conversion and operational efficiency. As the renewable energy sector expands globally, especially in regions like Europe and South America, buyers need to assess the reliability and serviceability of these components under harsh environmental conditions. Investing in high-quality reducers can significantly enhance the performance and lifespan of wind energy systems, aligning with sustainability goals while ensuring cost-effectiveness.

Related Video: Proper Industrial Gearbox, Gearmotor & Speed Reducer Lubrication | WCHYWT #1

Strategic Material Selection Guide for geared reducer

When selecting materials for geared reducers, international B2B buyers must consider various factors that impact performance, durability, and cost. Below is a detailed analysis of four common materials used in the manufacturing of geared reducers, focusing on their properties, advantages, disadvantages, and specific considerations for buyers in Africa, South America, the Middle East, and Europe.

1. Steel Alloys

Key Properties: Steel alloys are known for their high strength, toughness, and wear resistance. They typically have excellent temperature ratings, making them suitable for high-stress applications. Corrosion resistance can be enhanced through coatings or alloying elements.

Pros & Cons: Steel alloys offer high durability and are relatively easy to machine, which can lower manufacturing complexity. However, they can be more expensive than other materials and may require additional treatments for corrosion resistance, especially in humid or coastal environments.

Impact on Application: Steel alloys are ideal for applications requiring high torque and strength, such as heavy machinery and automotive systems. They can handle various media, including oils and lubricants, without significant degradation.

Considerations for International Buyers: Compliance with standards such as ASTM or DIN is crucial for ensuring quality. Buyers should also consider local availability and sourcing challenges, particularly in regions with limited access to high-grade steel.

2. Aluminum Alloys

Key Properties: Aluminum alloys are lightweight, with good corrosion resistance and moderate strength. They typically have lower temperature ratings compared to steel but can perform well in non-extreme conditions.

Pros & Cons: The primary advantage of aluminum is its low weight, which can improve the efficiency of applications where weight is a critical factor. However, aluminum is less durable than steel and may not be suitable for high-torque applications. Additionally, it can be more expensive than traditional steel options.

Impact on Application: Aluminum is often used in applications where weight savings are critical, such as in aerospace and automotive sectors. Its corrosion resistance makes it suitable for environments exposed to moisture.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards like JIS or EN. In regions like Europe, the preference for lightweight materials is increasing, making aluminum a popular choice.

3. Cast Iron

Key Properties: Cast iron is characterized by its excellent wear resistance and good damping properties. It has a high compressive strength and can operate well under high pressure and temperature conditions.

Pros & Cons: The durability of cast iron makes it suitable for heavy-duty applications. However, it is brittle, which can lead to failure under shock loads. Additionally, cast iron can be heavier than steel or aluminum, which may limit its use in weight-sensitive applications.

Impact on Application: Cast iron is commonly used in industrial machinery and equipment where vibration damping and stability are essential. It is compatible with various lubricants and media.

Considerations for International Buyers: Compliance with manufacturing standards is essential, especially in regions with stringent regulations. Buyers should also consider the availability of cast iron in their local markets, as it may vary significantly.

4. Composite Materials

Key Properties: Composite materials, often made from a combination of polymers and fibers, offer unique properties such as low weight, high corrosion resistance, and good thermal stability.

Pros & Cons: Composites can be engineered for specific applications, providing tailored solutions. However, they can be more expensive to manufacture and may require specialized processing techniques.

Impact on Application: Composites are ideal for applications where weight and corrosion resistance are paramount, such as in marine or chemical processing environments. They may not be suitable for high-torque applications.

Considerations for International Buyers: Buyers should be aware of the specific certifications required for composites, especially in regulated industries. The availability of composite materials may vary by region, affecting sourcing strategies.

Summary Table

| Material | Typical Use Case for geared reducer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel Alloys | Heavy machinery, automotive systems | High durability and strength | Higher cost and corrosion treatment | High |

| Aluminum Alloys | Aerospace, automotive applications | Lightweight and corrosion-resistant | Less durable under high torque | Medium |

| Cast Iron | Industrial machinery, vibration damping | Excellent wear resistance | Brittle under shock loads | Medium |

| Composite Materials | Marine, chemical processing applications | Tailored solutions and low weight | Higher manufacturing costs | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for geared reducer

The manufacturing processes and quality assurance protocols for geared reducers are critical to ensuring that these components meet the rigorous demands of various industries, including automotive, industrial machinery, and robotics. This section provides an in-depth look at the typical stages of manufacturing and the essential quality control measures that international B2B buyers should consider when sourcing geared reducers.

Manufacturing Processes

1. Material Preparation

The manufacturing of geared reducers begins with the careful selection and preparation of materials. Common materials include high-strength steels, aluminum alloys, and various polymers, depending on the specific application and performance requirements.

-

Material Testing: Before proceeding, materials undergo testing for mechanical properties, including tensile strength, hardness, and fatigue resistance. This ensures that only materials that meet the required specifications are used in production.

-

Machining Preparation: The raw materials are cut to the desired dimensions and shapes. This may involve processes such as sawing, shearing, or plasma cutting, depending on the material type and thickness.

2. Forming

The forming stage involves shaping the prepared materials into the components of the geared reducer.

-

CNC Machining: Computer Numerical Control (CNC) machining is widely used to achieve high precision in manufacturing gears and housings. This technology allows for intricate designs and tight tolerances, which are critical for the performance of the gear reducer.

-

Forging and Casting: For larger components, forging or casting processes may be utilized. Forging enhances the strength and durability of the material, while casting allows for complex shapes to be formed efficiently.

3. Assembly

Once the individual components are produced, they are assembled into a complete geared reducer.

-

Sub-Assembly: Components such as gears, shafts, and housings are often assembled into sub-units before final assembly. This staged approach helps in managing quality at each level.

-

Alignment and Fitting: Precision alignment is crucial during assembly to ensure that the gears mesh correctly. Misalignment can lead to increased wear, noise, and decreased efficiency.

4. Finishing

The final stage involves applying finishing processes to enhance the performance and aesthetics of the geared reducers.

-

Surface Treatment: Common treatments include hardening, coating (e.g., anodizing, painting), and grinding to reduce friction and wear. These processes also protect against corrosion, particularly important in harsh environments.

-

Final Inspection: Before packaging, the finished products undergo a thorough inspection to check for defects and ensure compliance with specifications.

Quality Assurance

Quality assurance is a vital aspect of the geared reducer manufacturing process, ensuring that products are reliable and meet international standards.

Relevant International Standards

-

ISO 9001: This globally recognized quality management standard ensures that manufacturers maintain consistent quality in their processes. Compliance with ISO 9001 indicates a commitment to quality and customer satisfaction.

-

CE Marking: In Europe, CE marking is mandatory for many products, demonstrating compliance with safety and environmental protection standards.

-

API Standards: For geared reducers used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is crucial. These standards ensure that products can withstand the demanding conditions of this sector.

Quality Control Checkpoints

Quality control in geared reducer manufacturing typically includes several key checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers should provide certification and test reports for materials, ensuring they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, operators conduct regular inspections and tests. This may include monitoring machining tolerances, measuring component dimensions, and checking alignment during assembly.

-

Final Quality Control (FQC): Before dispatch, each finished geared reducer undergoes a comprehensive inspection. This includes functional tests, such as load testing and noise level measurement, to verify performance against specifications.

Common Testing Methods

- Torque Testing: Verifying that the geared reducer can handle specified torque levels without failure.

- Vibration Analysis: Identifying potential issues related to misalignment or imbalance that could affect performance.

- Noise Testing: Ensuring that the noise levels produced by the reducer comply with industry standards, particularly important for applications in the automotive and consumer sectors.

Verifying Supplier Quality Control

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability.

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality management systems, and adherence to international standards.

-

Documentation and Reporting: Requesting detailed reports on quality control processes, including inspection records and compliance certifications, can help assess a supplier’s commitment to quality.

-

Third-Party Inspection: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. This is particularly important when dealing with suppliers from regions where standards may vary.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for geared reducers is essential for international B2B buyers seeking reliable components. By focusing on material preparation, forming, assembly, and finishing, alongside rigorous quality control measures, buyers can ensure they source high-quality geared reducers that meet their operational needs. Engaging in thorough supplier verification processes further enhances confidence in product quality, making it a vital strategy for successful procurement in today’s global market.

Related Video: Amazing Garment Manufacturing Process from Fabric to Finished Product Inside the Factory

Comprehensive Cost and Pricing Analysis for geared reducer Sourcing

The cost structure and pricing of geared reducers are influenced by multiple components and factors, which can significantly affect international sourcing strategies, especially for buyers in Africa, South America, the Middle East, and Europe. Understanding these elements is critical for making informed purchasing decisions.

Cost Components

-

Materials: The primary materials used in geared reducers include steel, aluminum, and specialized alloys. Material costs can fluctuate based on market demand and availability, impacting the overall price of the reducer. High-quality materials may enhance durability and efficiency but can also increase the initial cost.

-

Labor: Labor costs vary significantly by region. In countries with higher wage standards, such as those in Europe, labor can constitute a larger portion of the total cost compared to regions with lower labor costs. Skilled labor is essential for the precision manufacturing of gear reducers, influencing the overall pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers in the form of lower prices.

-

Tooling: Tooling expenses are incurred for the specialized equipment needed to produce different types of gear reducers. Custom tooling can be costly, especially for unique designs or specifications, and these costs are typically reflected in the pricing.

-

Quality Control (QC): Ensuring the quality and reliability of geared reducers requires robust quality control measures. The expenses related to testing and certification processes can add to the overall cost, but they are essential for ensuring product performance and compliance with industry standards.

-

Logistics: Transportation and shipping costs can vary widely based on the distance between the supplier and the buyer, as well as the chosen Incoterms. This includes freight charges, customs duties, and insurance, which can significantly impact the total landed cost.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market position, competition, and the perceived value of their product.

Price Influencers

-

Volume/MOQ: Larger orders often benefit from economies of scale, leading to lower per-unit costs. Minimum order quantities (MOQs) can also impact pricing; negotiating lower MOQs can be advantageous for smaller companies.

-

Specifications/Customization: Customized gear reducers tailored to specific applications typically cost more than standard models. Buyers should clearly outline their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Higher-quality materials and compliance with industry certifications (ISO, CE, etc.) can raise costs but may provide better performance and longevity, thus affecting the Total Cost of Ownership (TCO).

-

Supplier Factors: Established suppliers with a reputation for quality may charge more but can offer reliability and better support. Newer or less reputable suppliers may offer lower prices, but the risk of quality issues should be considered.

-

Incoterms: The choice of Incoterms affects the distribution of costs and responsibilities between buyers and sellers. Understanding these terms is crucial for calculating total costs, including shipping and insurance.

Buyer Tips

-

Negotiation: Engaging suppliers in negotiations can yield better pricing. Buyers should be prepared to discuss volume discounts and explore options for shared savings.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership, not just the initial purchase price. Consider factors such as energy efficiency, maintenance costs, and potential downtime when selecting gear reducers.

-

International Pricing Nuances: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and local regulations that may impact pricing. Building relationships with local suppliers can also provide insights into market trends and pricing strategies.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including their production capabilities, quality records, and customer feedback. This information can help mitigate risks associated with international sourcing.

Disclaimer

Prices for geared reducers can vary significantly based on numerous factors, including market conditions, supplier negotiations, and specific application requirements. The information provided here is indicative and should be validated with suppliers for accurate quotations.

Spotlight on Potential geared reducer Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘geared reducer’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for geared reducer

Key Technical Properties of Gear Reducers

Understanding the essential technical properties of gear reducers is crucial for B2B buyers to make informed decisions. Below are some critical specifications that buyers should consider:

-

Material Grade

The choice of materials used in gear reducers affects durability, performance, and cost. Common materials include steel, aluminum, and composite materials. Steel is preferred for its strength and resistance to wear, while aluminum offers a lightweight alternative, ideal for applications where weight is a concern. Selecting the right material ensures optimal performance and longevity. -

Gear Ratio

The gear ratio defines the relationship between the input and output speeds of the reducer. A higher gear ratio results in lower output speed but higher torque, making it suitable for heavy-load applications. Buyers should match the gear ratio to their specific operational requirements to achieve desired performance levels. -

Torque Capacity

Torque capacity indicates the maximum load a gear reducer can handle without failure. This specification is vital for applications involving heavy machinery or continuous operation. It is essential for B2B buyers to assess their load requirements carefully to select a gear reducer that can withstand operational demands. -

Efficiency Rating

Efficiency refers to how effectively a gear reducer transmits power from the input to the output shaft. Higher efficiency ratings lead to reduced energy losses, which can significantly lower operating costs over time. Buyers should prioritize gear reducers with high efficiency ratings to enhance overall system performance and sustainability. -

Tolerance

Tolerance specifies the permissible limit of variation in a dimension or measurement. High tolerance levels ensure precise fitting and operation, which are critical in applications requiring accuracy. Buyers should consider the tolerance levels that suit their machinery to avoid operational inefficiencies and ensure seamless integration.

Common Trade Terminology

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms related to gear reducers:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that manufactures products that are sold under another brand name. In the context of gear reducers, buyers often source from OEMs to ensure compatibility with their machinery and to meet specific performance standards. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers, as it can impact inventory management and cash flow. Negotiating MOQs can lead to more favorable purchasing terms, especially for smaller enterprises. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products or services. B2B buyers use RFQs to compare offers from multiple suppliers, ensuring they secure the best deal for their gear reducer needs. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for B2B buyers to understand shipping costs, risks, and delivery responsibilities, aiding in smoother transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. Understanding lead times is essential for planning and maintaining production schedules. Buyers should inquire about lead times when sourcing gear reducers to align with their operational timelines.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the gear reducer market more effectively, ensuring they make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the geared reducer Sector

Market Overview & Key Trends

The geared reducer market is experiencing notable growth driven by the increasing demand for efficiency in power transmission across various industries, including automotive, manufacturing, and renewable energy. The global automotive gear reducer market is projected to reach USD 11.3 billion by 2024, with a compound annual growth rate (CAGR) of 4.2% anticipated through 2034. This growth is largely attributed to the rise in electric vehicles (EVs), which require high-ratio gear reducers for optimal powertrain performance. As EV adoption surges—accounting for 15% of total passenger cars in 2023—international B2B buyers must focus on sourcing high-quality gear reducers that enhance efficiency and reduce noise, aligning with emerging regulatory standards on noise emissions.

Emerging trends include the integration of advanced technologies such as dual-clutch and continuously variable transmissions (CVT), which necessitate more complex gear reducers. Manufacturers are increasingly prioritizing lightweight materials like carbon and aluminum to improve torque and fuel economy, which can lead to more compact and efficient designs. Moreover, the demand for gear reducers in automated vehicles is rising, as these systems require precision components to support complex functionalities like adaptive cruise control and automated parking. For international buyers, understanding these trends will be crucial in selecting suppliers who can provide innovative, high-performance solutions.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a cornerstone of the geared reducer sector, as environmental impact and ethical sourcing practices gain importance among consumers and regulators alike. B2B buyers must consider the lifecycle of gear reducers, from materials sourcing to manufacturing processes, to mitigate environmental harm. The use of recycled materials and sustainable manufacturing practices can significantly reduce the carbon footprint associated with gear reducer production.

Furthermore, ethical supply chains are essential for fostering trust and transparency in business relationships. Suppliers that adhere to sustainability standards and possess certifications such as ISO 14001 (Environmental Management) demonstrate a commitment to reducing environmental impact. Additionally, the integration of ‘green’ materials—such as biodegradable lubricants and energy-efficient manufacturing processes—can further enhance the appeal of gear reducers to environmentally-conscious buyers. As the global market shifts towards sustainability, buyers should prioritize suppliers that align with these values to ensure compliance with regulations and meet consumer expectations.

Brief Evolution/History

The evolution of geared reducers can be traced back to the industrial revolution when the need for efficient power transmission became paramount. Initially, simple mechanical designs dominated the market, but advancements in materials science and engineering have led to the development of more complex and efficient systems. The introduction of planetary gear systems, for instance, revolutionized the industry by allowing for compact designs with high torque-to-size ratios. Today, the focus is on integrating smart technologies and sustainable practices, reflecting a significant shift in both consumer demand and regulatory requirements. This historical context underscores the importance of continuous innovation in the geared reducer sector, providing B2B buyers with a roadmap for sourcing future-ready solutions.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of geared reducer

-

What should I consider when vetting suppliers for geared reducers?

When vetting suppliers for geared reducers, prioritize their industry experience, reputation, and technical expertise. Request references and case studies to assess their performance history. Additionally, confirm their manufacturing capabilities, quality control processes, and compliance with international standards. Assess their responsiveness and customer service, as these factors can significantly impact your partnership. Lastly, consider their location and the potential for logistical challenges, especially when sourcing from regions like Africa or South America. -

Can geared reducers be customized to fit specific applications?

Yes, many manufacturers offer customization options for geared reducers to meet specific application requirements. This includes adjustments in gear ratios, sizes, and materials based on your operational needs. When discussing customization, provide detailed specifications and performance expectations to the supplier. It’s advisable to engage in a collaborative design process to ensure the final product aligns with your operational goals, particularly in industries like automotive or heavy machinery. -

What are typical minimum order quantities (MOQ) and lead times for geared reducers?

Minimum order quantities for geared reducers can vary widely depending on the supplier and the type of product. Generally, MOQs range from 10 to 100 units, especially for customized products. Lead times can also vary, typically ranging from 4 to 12 weeks, influenced by factors such as manufacturing capacity and the complexity of the customization. Always discuss these details upfront to avoid production delays and ensure your supply chain remains uninterrupted.

Illustrative Image (Source: Google Search)

-

How can I ensure quality assurance and certifications for my purchased geared reducers?

To ensure quality assurance, request documentation of the supplier’s quality control processes and certifications, such as ISO 9001. Ask for test reports, performance data, and any relevant certifications that demonstrate compliance with international standards. You may also consider conducting factory audits or third-party inspections to verify quality before shipment. Establishing a clear agreement on quality expectations in your contract can help mitigate risks associated with product performance. -

What logistics considerations should I keep in mind when importing geared reducers?

When importing geared reducers, consider shipping methods, customs regulations, and potential tariffs. Work closely with your logistics provider to determine the best shipping options that balance cost and delivery time. Ensure that all documentation, including bills of lading and customs declarations, is accurate and complete to avoid delays. Additionally, factor in the supplier’s location and the potential for logistical challenges, especially when sourcing from remote areas. -

How should I handle disputes with suppliers over geared reducers?

To manage disputes with suppliers effectively, establish clear communication channels and document all agreements. In case of a dispute, first attempt to resolve the issue amicably through discussion. If necessary, refer to the terms outlined in your contract, including any arbitration or mediation clauses. Consider involving legal counsel if the situation escalates, particularly when dealing with international suppliers, as different jurisdictions may have varying laws and regulations. -

What payment options are typically available for international B2B transactions?

Common payment options for international B2B transactions include wire transfers, letters of credit, and payment platforms like PayPal or Escrow services. Each option has its pros and cons; for example, letters of credit offer security for both parties but can be complex and costly. Discuss payment terms early in negotiations, including any deposits required before production. Understand the currency exchange rates and any additional fees that may apply to ensure a smooth transaction process. -

What are the advantages of sourcing geared reducers from different regions like Africa or South America?

Sourcing geared reducers from Africa or South America can offer several advantages, including competitive pricing and access to local markets. These regions may have emerging manufacturers that provide innovative solutions tailored to specific needs. Additionally, establishing relationships with local suppliers can enhance supply chain resilience and reduce lead times. However, be mindful of potential challenges, such as varying quality standards and logistical constraints, and ensure thorough vetting of suppliers before making commitments.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for geared reducer

As the global demand for geared reducers continues to rise, particularly in the context of electric vehicles and advanced machinery, international B2B buyers must prioritize strategic sourcing to enhance operational efficiency and competitiveness. Key considerations include understanding the specific torque and speed requirements of your applications, evaluating the latest technologies in gear reducer designs, and selecting suppliers that offer high-quality components tailored to your needs.

Investing in advanced gear reducers not only optimizes performance but also aligns with global trends toward sustainability and energy efficiency. Buyers should focus on suppliers that provide innovative solutions, such as lightweight materials and high-precision components, which are essential for modern applications.

Looking ahead, the gear reducer market is poised for significant growth, driven by advancements in automotive and industrial technologies. B2B buyers from Africa, South America, the Middle East, and Europe should take proactive steps to engage with reputable manufacturers and distributors, ensuring they remain at the forefront of industry developments. By leveraging strategic sourcing, businesses can enhance their operational capabilities and contribute to a more sustainable future.