Master the Key Types of Ball Bearings for Optimal B2B

Introduction: Navigating the Global Market for types of ball bearings

In today’s global marketplace, the role of ball bearings is pivotal across various industries, including automotive, manufacturing, and electronics. These small yet essential components facilitate smooth motion and reduce friction, significantly impacting the efficiency and longevity of machinery. For international B2B buyers—especially those from regions like Africa, South America, the Middle East, and Europe—understanding the diverse types of ball bearings available is crucial for optimizing operations and ensuring quality in their supply chains.

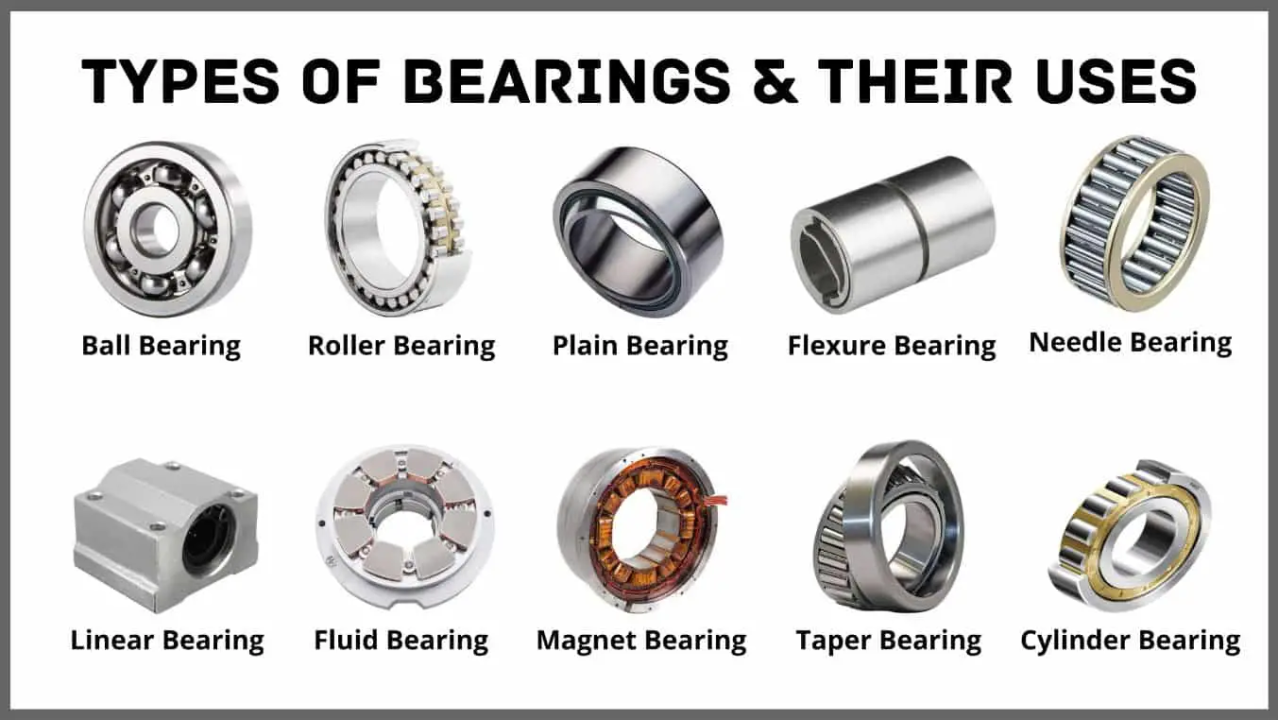

This guide delves into the comprehensive landscape of ball bearings, exploring various types such as deep-groove, angular contact, and thrust bearings, each tailored to meet specific operational demands. Additionally, it examines the materials used, ensuring buyers are informed about durability and performance characteristics. The guide also covers manufacturing and quality control processes, providing insights into supplier standards and certifications that guarantee reliability.

Furthermore, the content addresses cost considerations, helping buyers navigate pricing structures and identify cost-effective solutions without compromising quality. A thorough overview of the market trends and FAQs will empower buyers to make informed decisions, ensuring they select the right bearings for their unique applications. By equipping B2B buyers with this vital knowledge, this guide aims to facilitate strategic sourcing decisions that enhance operational efficiency and foster competitive advantage in an increasingly interconnected world.

Understanding types of ball bearings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Deep Groove Ball Bearings | High versatility, capable of handling radial and axial loads | Electric motors, gearboxes, automotive | Pros: Low friction, easy to maintain. Cons: Limited axial load capacity. |

| Angular Contact Ball Bearings | Designed to handle high axial loads at specific angles | Pumps, machine tools, and automotive | Pros: Better axial load handling. Cons: More sensitive to misalignment. |

| Self-Aligning Ball Bearings | Allows for self-alignment, accommodating shaft misalignment | Agricultural machinery, conveyor systems | Pros: Reduces wear due to misalignment. Cons: Generally larger footprint. |

| Thrust Ball Bearings | Specifically designed for axial loads | Vertical shafts, marine applications | Pros: Excellent axial load capacity. Cons: Not suitable for radial loads. |

| Miniature Ball Bearings | Compact size, ideal for limited space applications | Robotics, medical devices, and electronics | Pros: Space-saving design. Cons: Limited load capacity. |

Deep Groove Ball Bearings

Deep groove ball bearings are the most widely used type due to their versatility and ability to handle both radial and axial loads. Their design features deep grooves that facilitate smooth operation at high speeds, making them ideal for applications such as electric motors, gearboxes, and automotive components. For B2B buyers, these bearings offer low friction and ease of maintenance, but they do have limitations in terms of axial load capacity, which must be considered based on specific application requirements.

Angular Contact Ball Bearings

Angular contact ball bearings are engineered to accommodate high axial loads at specific angles, making them ideal for applications where both radial and axial forces are present. Commonly found in pumps, machine tools, and automotive applications, these bearings provide improved performance under load. However, B2B buyers should be aware that they are more sensitive to misalignment and may require precise installation to function optimally.

Self-Aligning Ball Bearings

Self-aligning ball bearings feature a unique design that allows for self-alignment, accommodating shaft misalignment without significant wear. This makes them particularly useful in applications such as agricultural machinery and conveyor systems where alignment issues can occur. For buyers, the primary advantage is reduced wear and extended service life, although these bearings typically require a larger footprint compared to standard designs.

Thrust Ball Bearings

Thrust ball bearings are specifically designed to handle axial loads, making them suitable for applications with vertical shafts, such as marine equipment. Their robust construction allows them to manage substantial axial forces effectively. However, buyers should note that thrust ball bearings are not designed for radial loads, which limits their versatility in certain applications. Understanding the specific load requirements is crucial for selecting the right type.

Miniature Ball Bearings

Miniature ball bearings are compact and designed for applications where space is a premium, such as in robotics, medical devices, and electronics. Their small size allows for intricate designs and lightweight constructions. While they provide significant advantages in terms of space-saving, buyers must consider their limited load capacity, which may restrict their use in high-load scenarios.

Related Video: Different Types of Bearings | types of Ball and Roller bearings | Bearings

Key Industrial Applications of types of ball bearings

| Industry/Sector | Specific Application of types of ball bearings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Wheel hubs and transmission systems | Enhanced durability and performance under heavy loads | Supplier reliability and quality certifications |

| Industrial Machinery | CNC machines and lathes | Increased efficiency and reduced maintenance downtime | Precision specifications and compatibility with existing systems |

| Renewable Energy | Wind turbine rotor assemblies | Improved energy efficiency and reduced operational costs | Material quality and environmental compliance |

| Agriculture | Harvesting equipment and tractors | Higher load capacity and reliability in harsh conditions | Local availability and support for parts replacement |

| Consumer Electronics | Electric motors in appliances | Lower noise levels and extended product lifespan | Cost-effectiveness and supplier lead times |

Automotive Applications

In the automotive sector, types of ball bearings are critical for components like wheel hubs and transmission systems. These bearings support high loads and ensure smooth rotation, which is essential for vehicle performance and safety. For international buyers, especially from regions like South America and Africa, sourcing high-quality bearings that meet specific automotive standards is crucial. Considerations should include supplier reliability, certifications, and the ability to provide after-sales support.

Industrial Machinery

Deep groove and angular contact ball bearings are widely used in CNC machines and lathes. Their ability to handle radial and axial loads ensures precision in machining operations, thus enhancing efficiency. For B2B buyers in Europe and the Middle East, it’s vital to evaluate the compatibility of bearings with existing machinery and the precision specifications required for optimal performance. Suppliers should also demonstrate a strong track record in quality control to minimize downtime.

Renewable Energy

In renewable energy applications, such as wind turbines, ball bearings play a vital role in rotor assemblies. They help improve energy efficiency by reducing friction and wear, leading to lower operational costs. Buyers from Africa and Europe should prioritize sourcing bearings that comply with environmental standards and are constructed from materials that can withstand harsh weather conditions. Supplier certifications and material quality are essential factors to consider.

Agricultural Equipment

Ball bearings are essential in agricultural machinery, particularly in harvesting equipment and tractors. They provide the necessary load capacity and reliability needed to operate effectively in rugged environments. For buyers in South America and the Middle East, understanding the local availability of specific bearing types and the support offered for parts replacement is critical. Selecting suppliers with a robust distribution network can mitigate delays during peak agricultural seasons.

Consumer Electronics

In consumer electronics, ball bearings are used in electric motors for appliances. They contribute to lower noise levels and enhance the overall lifespan of products. For B2B buyers in Europe, sourcing cost-effective bearings that do not compromise on quality is essential, particularly in a competitive market. Buyers should also consider supplier lead times to ensure timely production and delivery of their products.

Related Video: Applications of Bearings 1 [Common Types]

Strategic Material Selection Guide for types of ball bearings

When selecting materials for ball bearings, it’s essential to consider the specific application requirements, environmental conditions, and performance expectations. Here, we analyze four common materials used in the manufacturing of ball bearings, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

1. Stainless Steel

Key Properties:

Stainless steel, particularly AISI 440C, is known for its excellent corrosion resistance and high strength. It can withstand temperatures up to 300°C and has a good resistance to wear.

Pros & Cons:

Stainless steel bearings are durable and can operate in harsh environments, making them suitable for applications in food processing, pharmaceuticals, and marine environments. However, they are generally more expensive than carbon steel bearings and can be more challenging to manufacture due to their hardness.

Impact on Application:

Stainless steel is compatible with a wide range of media, including water and various chemicals, making it ideal for applications that require hygiene and corrosion resistance.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A276 for stainless steel products. In regions like Europe, adherence to EU regulations regarding materials in food contact is crucial.

2. Carbon Steel

Key Properties:

Carbon steel, often used for its cost-effectiveness, has good strength and hardness but lacks corrosion resistance unless treated. It typically operates effectively at temperatures up to 150°C.

Pros & Cons:

These bearings are less expensive than stainless steel and can be produced with relative ease. However, their susceptibility to rust and wear limits their use in corrosive environments, necessitating protective coatings or lubrication.

Impact on Application:

Carbon steel bearings are suitable for dry environments or applications where exposure to moisture is minimal. They are commonly used in automotive and industrial machinery.

Considerations for International Buyers:

Buyers should be aware of the need for protective measures in humid climates, particularly in regions like Africa and South America, where moisture can lead to rapid degradation.

3. Ceramic

Key Properties:

Ceramic materials, such as silicon nitride, exhibit exceptional hardness, low density, and excellent thermal resistance, capable of withstanding temperatures exceeding 1000°C.

Pros & Cons:

Ceramic ball bearings offer low friction and high wear resistance, making them suitable for high-speed applications. However, they are brittle and can be more expensive than metal alternatives, which may deter some buyers.

Impact on Application:

These bearings are ideal for applications in high-temperature environments, such as aerospace and certain industrial processes. They are also non-magnetic, making them suitable for sensitive electronic equipment.

Considerations for International Buyers:

Buyers should evaluate the specific application requirements and ensure that ceramic bearings meet the necessary performance standards. In Europe, compliance with RoHS directives may be relevant.

4. Polymer

Key Properties:

Polymer bearings, often made from materials like PTFE or PEEK, are lightweight and resistant to corrosion and chemicals. They can operate effectively at temperatures up to 250°C.

Pros & Cons:

These bearings are non-corrosive and can be self-lubricating, reducing maintenance needs. However, they typically have lower load capacities compared to metal bearings, limiting their use in heavy-duty applications.

Impact on Application:

Polymer bearings are suitable for applications in the food and beverage industry, as well as in medical devices, where corrosion resistance and hygiene are paramount.

Considerations for International Buyers:

Buyers should check for compliance with food safety regulations in their respective regions, such as FDA regulations in the U.S. or EU food contact materials regulations in Europe.

| Material | Typical Use Case for types of ball bearings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals, marine applications | Excellent corrosion resistance | More expensive, harder to manufacture | High |

| Carbon Steel | Automotive, industrial machinery | Cost-effective, easy to produce | Susceptible to rust, requires protection | Low |

| Ceramic | Aerospace, high-speed applications | High wear resistance, low friction | Brittle, higher cost | High |

| Polymer | Food and beverage industry, medical devices | Corrosion-resistant, self-lubricating | Lower load capacity | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for types of ball bearings

Ball bearings are essential components in various industrial applications, and understanding their manufacturing processes and quality assurance protocols is crucial for B2B buyers. This section delves into the key stages of manufacturing ball bearings and the quality control measures that ensure they meet international standards.

Manufacturing Processes for Ball Bearings

The manufacturing process of ball bearings is intricate, involving several key stages that ensure precision and quality. Here’s a breakdown of the main steps:

1. Material Preparation

The first stage involves selecting the appropriate materials, typically high-carbon chrome steel or stainless steel. The choice depends on the bearing’s application and desired properties, such as corrosion resistance and strength. After selecting the raw materials, they undergo a series of processes:

- Heat Treatment: The steel is heat-treated to improve hardness and durability. This process enhances the material’s mechanical properties, allowing it to withstand high loads and friction.

- Surface Treatment: Depending on the application, additional treatments like nitriding or coating may be applied to enhance wear resistance.

2. Forming

In this stage, the raw materials are shaped into the components of the ball bearing:

- Forging: The material is often forged to create the inner and outer races, which provides better grain structure and mechanical properties.

- Machining: Precision machining is used to achieve the exact dimensions and surface finishes required for the races and balls. This may include processes like turning, milling, and grinding.

3. Assembly

After forming, the individual components are assembled:

- Ball Insertion: Balls are placed between the inner and outer races. This can be done manually or using automated machines for higher efficiency.

- Caging: A cage is often used to hold the balls in place and ensure even spacing, reducing friction and wear.

4. Finishing

The final stage involves several finishing processes to ensure optimal performance:

- Surface Finishing: Processes such as polishing and grinding are employed to achieve a smooth surface finish. This reduces friction and enhances the bearing’s operational lifespan.

- Lubrication: Bearings are lubricated to minimize wear and improve efficiency. The choice of lubricant can significantly affect performance and durability.

Quality Assurance in Ball Bearings

Quality assurance is paramount in the manufacturing of ball bearings. International standards, such as ISO 9001, provide frameworks for ensuring consistent quality across production processes. Here are some critical aspects of quality control:

Relevant International Standards

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Common in Europe, this certification indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For bearings used in the oil and gas industry, adherence to American Petroleum Institute (API) standards is essential.

QC Checkpoints

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival. Ensuring materials meet specifications is critical to avoid defects in finished products.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify issues in real time. This may include dimensional checks and surface roughness measurements.

- Final Quality Control (FQC): After assembly, the finished bearings undergo rigorous testing to ensure they meet design specifications and performance standards.

Common Testing Methods

Various testing methods are employed to assess the quality and performance of ball bearings:

- Dimensional Inspection: Using precision measuring tools to ensure that components meet specified tolerances.

- Load Testing: Evaluating how bearings perform under different load conditions, ensuring they can withstand operational stresses.

- Fatigue Testing: Simulating long-term use to identify potential failure points and ensure durability.

Verifying Supplier Quality Control

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are some strategies:

- Supplier Audits: Conducting on-site audits of suppliers can provide insights into their manufacturing processes and quality management systems. This helps ensure compliance with international standards.

- Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can help assess a supplier’s reliability.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control processes and product quality.

Quality Control Nuances for International Buyers

B2B buyers should be aware of the nuances in quality control when sourcing ball bearings internationally:

- Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding local practices can help buyers navigate potential challenges.

- Regulatory Compliance: International buyers must ensure that suppliers comply with both local and international regulations, which may vary significantly between regions.

- Supply Chain Transparency: Establishing clear communication channels with suppliers regarding their quality control processes can foster trust and ensure product quality.

Conclusion

Understanding the manufacturing processes and quality assurance practices for ball bearings is crucial for international B2B buyers. By familiarizing themselves with these processes, buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs. Engaging with suppliers who adhere to recognized standards and demonstrate robust quality control practices will ultimately lead to improved performance and reliability in their applications.

Related Video: how ball bearings are made | bearing manufacturing process | bearing assembly

Comprehensive Cost and Pricing Analysis for types of ball bearings Sourcing

Cost Structure for Ball Bearings

When sourcing ball bearings, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of materials used significantly impacts the cost. Common materials include steel, ceramic, and plastic. High-performance materials, like stainless steel or hybrid ceramics, can increase costs but may offer better durability and performance.

-

Labor: Labor costs vary by region and production complexity. Automated manufacturing can reduce labor costs, but highly specialized or custom bearings may require skilled labor, increasing expenses.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: Tooling costs are associated with the design and production of molds and fixtures necessary for manufacturing specific bearing types. Custom tooling can be a significant upfront investment but may reduce per-unit costs in large production runs.

-

Quality Control (QC): Ensuring product quality involves inspection and testing processes, which contribute to overall costs. High-quality certifications (like ISO) may require additional investments in QC processes but can enhance product reliability.

Illustrative Image (Source: Google Search)

-

Logistics: Shipping and handling costs can fluctuate based on distance, shipping methods, and urgency. International shipments may incur additional customs duties and tariffs, impacting overall pricing.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s market position, competition, and the unique value they offer.

Price Influencers

Several factors can influence the pricing of ball bearings:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts. Buyers should negotiate for better pricing based on volume commitments.

-

Specifications/Customization: Custom bearings tailored to specific applications typically cost more due to the additional engineering and production requirements.

-

Materials: High-grade or specialized materials can significantly elevate costs. Understanding the trade-offs between cost and performance is crucial.

-

Quality/Certifications: Bearings that meet stringent quality standards (like ISO certifications) may command higher prices but can lead to lower failure rates and longer service life.

-

Supplier Factors: The reputation, location, and reliability of suppliers can affect pricing. Engaging with well-established suppliers may yield better quality but at a premium.

-

Incoterms: The chosen Incoterms (International Commercial Terms) influence shipping costs and responsibilities. Buyers must factor these into their total cost calculations to avoid unexpected expenses.

Buyer Tips

To optimize sourcing strategies for ball bearings, consider the following actionable tips:

-

Negotiate: Always negotiate prices, especially if committing to large orders. Suppliers may have flexibility that can lead to significant savings.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) instead of just the initial purchase price. Consider factors like maintenance, performance, and longevity when assessing value.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import duties, and local taxes that can affect overall costs. Establishing long-term relationships with suppliers can help mitigate some of these risks.

-

Research Market Trends: Stay informed about market conditions, material availability, and technological advancements. This knowledge can provide leverage during negotiations and help anticipate price changes.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers can reduce shipping costs and lead times, contributing to overall savings.

Disclaimer

Prices for ball bearings can vary widely based on specifications, market conditions, and supplier negotiations. It is advisable to obtain multiple quotes and conduct thorough due diligence before finalizing any purchases.

Spotlight on Potential types of ball bearings Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of ball bearings’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of ball bearings

Key Technical Properties of Ball Bearings

Understanding the essential technical properties of ball bearings is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications that should be considered:

-

Material Grade

The material used for ball bearings significantly affects their performance and durability. Common materials include stainless steel, chrome steel, and ceramic. Stainless steel offers corrosion resistance, making it suitable for applications in humid environments, while chrome steel provides high load capacity and durability. Ceramic bearings are lighter and have lower friction but may be more expensive. Selecting the appropriate material can enhance the lifespan of machinery and reduce maintenance costs. -

Tolerance

Tolerance refers to the allowable variation in dimensions. It is essential for ensuring a proper fit between the bearing and the shaft. High precision tolerances (such as ABEC ratings) lead to improved performance and efficiency. For example, ABEC 1 is standard, while ABEC 7 and higher provide greater precision, suitable for high-speed applications. Understanding tolerance levels helps buyers assess compatibility with their machinery and ensures optimal performance. -

Load Rating

Load rating indicates the maximum load a bearing can withstand without failure. This rating is crucial for applications involving heavy machinery or high-stress environments. Bearings come with dynamic and static load ratings, with dynamic ratings applicable during operation and static ratings for stationary loads. Selecting a bearing with an adequate load rating prevents premature failure and ensures reliability. -

Speed Rating

Speed rating specifies the maximum operational speed at which a bearing can function effectively. This is particularly important in high-speed applications, where excessive speeds can lead to overheating and failure. Buyers should consider the speed requirements of their applications to choose bearings that can handle the intended operational speeds without compromising performance. -

Seal Type

The type of seal affects the bearing’s ability to resist contamination and retain lubrication. Common seal types include rubber seals and metal shields. Rubber seals provide superior protection against dirt and moisture, while metal shields offer lower friction but less sealing capability. Understanding the sealing requirements based on the operational environment is essential to prolonging bearing life.

Common Trade Terminology in Ball Bearing Procurement

Familiarity with industry-specific terminology can streamline communication and negotiation for B2B buyers. Here are some essential terms:

- OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. When purchasing ball bearings, knowing whether the supplier is an OEM can assure quality and compatibility with existing machinery.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for budgeting and inventory management, especially for smaller businesses that may not require large quantities of bearings. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products. When looking for ball bearings, submitting an RFQ can help buyers gather competitive pricing and terms from various suppliers, enabling informed decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms (such as FOB – Free on Board, CIF – Cost, Insurance, and Freight) helps buyers understand shipping responsibilities, costs, and risks associated with international shipping. -

P/N (Part Number)

A part number is a unique identifier assigned to each bearing type by manufacturers. Using P/N ensures precise identification and ordering of the correct bearings, which is essential to avoid costly errors in procurement.

Understanding these technical properties and trade terminologies will empower B2B buyers to make more informed decisions when sourcing ball bearings, ultimately leading to improved operational efficiency and reduced costs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of ball bearings Sector

Market Overview & Key Trends

The global ball bearings market is witnessing dynamic changes driven by technological advancements, increased industrialization, and a shift towards automation. Key drivers include the growing demand for high-performance machinery in sectors such as automotive, aerospace, and manufacturing. Emerging economies in Africa and South America are experiencing a surge in infrastructure projects, leading to heightened demand for various types of ball bearings, particularly deep-groove and tapered roller bearings, which are known for their versatility and efficiency in load handling.

B2B technology trends are transforming sourcing practices. The rise of Industry 4.0 has prompted manufacturers to adopt smart bearings equipped with sensors, enabling predictive maintenance and real-time monitoring. This innovation not only enhances operational efficiency but also minimizes downtime, making it critical for international buyers to consider suppliers that incorporate these technologies. Additionally, digital platforms for sourcing are becoming increasingly popular, allowing buyers from diverse regions, including Italy and Argentina, to access a wider range of products and suppliers seamlessly.

As market dynamics evolve, buyers should prioritize partnerships with manufacturers that demonstrate agility and responsiveness to changing market conditions. This is particularly important in regions facing economic fluctuations, where reliable supply chains and flexibility can significantly impact business success.

Sustainability & Ethical Sourcing in B2B

In the context of ball bearings, sustainability is becoming a crucial factor for B2B buyers. The manufacturing process of bearings can have significant environmental impacts, including energy consumption and waste generation. As a result, there is an increasing emphasis on sourcing materials that are produced sustainably and ethically. International buyers are encouraged to seek suppliers who utilize eco-friendly manufacturing practices, such as reduced emissions and responsible waste management.

Ethical supply chains are essential for fostering trust and transparency. Buyers should inquire about the sourcing of raw materials, ensuring that they are obtained from suppliers who comply with international labor standards and environmental regulations. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a manufacturer’s commitment to sustainability.

Moreover, the adoption of “green” materials in the production of ball bearings is gaining traction. This includes the use of recycled metals and bio-based lubricants, which not only reduce the environmental footprint but also enhance the product’s lifecycle. By prioritizing suppliers with robust sustainability practices, international buyers can contribute to a more responsible supply chain while meeting the growing demand for eco-friendly products.

Brief Evolution/History

The history of ball bearings dates back to ancient civilizations, with the first documented use attributed to Leonardo da Vinci in the 15th century. However, it was not until the Industrial Revolution in the 19th century that ball bearings became integral to machinery, significantly improving efficiency and performance. Innovations such as the introduction of hardened steel and precision manufacturing techniques further advanced their application across various industries.

In recent decades, the evolution of materials and design has led to the development of specialized bearings, such as angular contact and self-aligning ball bearings, catering to specific industrial needs. This historical context underscores the importance of continuous innovation in the ball bearing sector, enabling international B2B buyers to leverage advanced solutions that enhance operational efficiency and sustainability in their supply chains.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of types of ball bearings

-

What key factors should I consider when vetting suppliers for ball bearings?

When vetting suppliers, prioritize their industry reputation, production capabilities, and quality assurance processes. Check for certifications such as ISO 9001 or specific bearing quality standards. It’s also beneficial to review their client testimonials and case studies, especially from companies in your region. Understanding their experience in international trade, including compliance with export regulations and tariffs, is crucial. Finally, assess their responsiveness and customer service, as these factors can impact your partnership. -

Can I request customization for ball bearings, and what are the implications?

Yes, many manufacturers offer customization options for ball bearings to meet specific operational needs. Customization can involve alterations in size, material, or design features. However, be aware that this may lead to longer lead times and potentially higher costs. It’s essential to clearly communicate your requirements and ensure the supplier has the technical capabilities to deliver. Always request a prototype or sample before placing a bulk order to confirm that the customization meets your specifications. -

What are the typical minimum order quantities (MOQ) and lead times for ball bearings?

Minimum order quantities can vary widely among suppliers but generally range from 100 to 1,000 units, depending on the type and customization of the bearings. Lead times also differ based on factors such as the complexity of the order and the supplier’s production capacity, typically ranging from 2 to 12 weeks. For international buyers, consider the time required for shipping and customs clearance in your planning. Always confirm these details upfront to avoid unexpected delays. -

What payment options are commonly available for international B2B transactions?

International suppliers often accept various payment methods, including wire transfers, letters of credit, and PayPal. Wire transfers are the most common for larger orders, while letters of credit provide additional security for both parties. Ensure you understand the payment terms, including deposits and payment schedules. Be cautious of suppliers demanding full payment upfront, as this could indicate a higher risk. It’s advisable to establish clear terms in a contract to protect your interests. -

How can I ensure the quality of the ball bearings I purchase?

To ensure quality, request detailed documentation from suppliers, including certificates of compliance and test reports. Many reputable manufacturers will conduct quality assurance tests and provide third-party certifications. It’s advisable to incorporate quality checks into your procurement process, such as inspecting samples before full-scale production. Consider establishing a quality agreement that outlines specific performance metrics and consequences for non-compliance. -

What logistical considerations should I keep in mind when sourcing ball bearings internationally?

Logistics play a critical role in international sourcing. Assess the supplier’s shipping options, including freight forwarders and carriers, to optimize costs and delivery times. Understand customs regulations in both the supplier’s and your country to avoid delays and additional fees. It’s also wise to plan for potential disruptions in supply chains, such as political unrest or natural disasters. Establishing a buffer stock can help mitigate risks associated with lead time variability. -

What steps should I take if a dispute arises with a supplier?

In the event of a dispute, first attempt to resolve the issue amicably through direct communication with the supplier. If that fails, refer to the terms outlined in your contract, which should include dispute resolution procedures. Consider mediation or arbitration as alternatives to litigation, as they can be more cost-effective and faster. Document all communications and agreements related to the dispute for reference. If necessary, consult with a legal expert specializing in international trade to understand your rights and obligations. -

How do I assess the reliability of a supplier in terms of delivery and service?

To assess reliability, review the supplier’s track record for on-time delivery and service quality. Request references from past clients, particularly those from similar industries or regions. Additionally, investigate any past issues with order fulfillment or customer service. Utilizing performance metrics, such as delivery lead times and responsiveness to inquiries, can help you gauge reliability. It’s also beneficial to start with a smaller order to evaluate their performance before committing to larger contracts.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of ball bearings

Strategic sourcing in the realm of ball bearings is essential for international B2B buyers aiming to optimize their operations and supply chains. Understanding the different types of ball bearings—such as deep-groove, angular contact, and thrust ball bearings—enables businesses to select products that align with their specific application requirements. By leveraging strategic sourcing, companies can ensure they are acquiring high-quality bearings that enhance performance, reduce maintenance costs, and increase overall equipment reliability.

Key Takeaways:

– Diverse Applications: Different types of ball bearings serve unique functions across industries, from automotive to manufacturing.

– Cost Efficiency: Investing in the right bearing type can lead to significant cost savings in maintenance and downtime.

– Quality Over Price: Focusing on the quality and suitability of bearings can yield better long-term value than merely opting for the lowest price.

As the global market for bearings continues to evolve, international buyers from regions such as Africa, South America, the Middle East, and Europe should remain proactive in their sourcing strategies. By staying informed about industry trends and supplier capabilities, businesses can position themselves to capitalize on innovations and improvements in bearing technology. Now is the time to engage with reliable suppliers and enhance your supply chain resilience—ensure that your operations are equipped with the best solutions available.