Master the Selection Process for Kinds of Dryers: A B2B

Introduction: Navigating the Global Market for kinds of dryers

In today’s competitive global landscape, the choice of industrial dryers can significantly impact operational efficiency, product quality, and overall profitability. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the diverse types of dryers available is crucial. This guide serves as an essential resource, offering a comprehensive exploration of various dryer types, including convection, vacuum, and freeze dryers, along with their specific applications across industries.

The importance of selecting the right dryer cannot be overstated. It influences not only the drying efficiency but also energy consumption and maintenance costs. As buyers navigate this complex market, they will find detailed insights into the materials used in dryer construction, manufacturing quality control processes, and a thorough analysis of leading suppliers. Furthermore, cost considerations and market trends will be dissected to empower informed purchasing decisions.

This guide is tailored to help B2B buyers streamline their sourcing strategies. It includes a FAQ section to address common concerns and challenges faced by businesses in diverse sectors, ensuring that stakeholders are well-equipped to make decisions that align with their operational needs. By leveraging this knowledge, buyers can enhance their competitive edge in their respective markets, ultimately driving growth and innovation.

Understanding kinds of dryers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Convection Dryer | Uses hot air to remove moisture; versatile design. | Food processing, textiles, wood. | Pros: Efficient, uniform drying. Cons: High energy consumption. |

| Spray Dryer | Atomizes liquid into fine droplets; rapid drying. | Pharmaceuticals, dairy, chemicals. | Pros: Quick processing, high-quality end product. Cons: High initial cost. |

| Vacuum Dryer | Reduces pressure to lower boiling points; gentle drying. | Heat-sensitive materials, food. | Pros: Preserves quality, reduces oxidation. Cons: Slower process, higher energy use. |

| Drum Dryer | Uses rotating drums; ideal for viscous materials. | Pulp and paper, food, chemicals. | Pros: Continuous operation, good for large volumes. Cons: Requires significant space. |

| Freeze Dryer | Removes moisture by sublimation; preserves structure. | Pharmaceuticals, food preservation. | Pros: Maintains flavor and nutrients. Cons: Expensive setup and maintenance. |

Convection Dryer

Convection dryers operate by circulating hot air to remove moisture from materials. They are commonly used in food processing, textiles, and wood industries. Buyers should consider the energy efficiency of the model, as some convection dryers can consume significant amounts of energy. Additionally, ensure that the dryer offers uniform heat distribution to prevent uneven drying.

Spray Dryer

Spray dryers are designed to convert liquid into a fine mist, facilitating rapid drying through hot air. They are particularly effective in the pharmaceutical, dairy, and chemical industries. When purchasing, buyers should evaluate the initial investment costs and the potential return on investment through increased production efficiency. The quality of the final product is often superior, making it a preferred choice for high-value applications.

Vacuum Dryer

Vacuum dryers operate by reducing the pressure within the drying chamber, allowing moisture to evaporate at lower temperatures. This feature makes them suitable for heat-sensitive materials, especially in the food and pharmaceutical sectors. Buyers should consider the balance between drying speed and energy consumption. While they preserve product quality effectively, the process can be slower and may require more energy compared to other drying methods.

Drum Dryer

Drum dryers utilize rotating drums to dry viscous materials continuously. They are widely used in the pulp and paper industry, as well as in food and chemical applications. Buyers must assess the space requirements for installation, as drum dryers can be sizable. Additionally, their continuous operation can lead to high throughput, making them ideal for large-scale production environments.

Freeze Dryer

Freeze dryers remove moisture through sublimation, preserving the structure and nutritional quality of the product. This method is commonly employed in the pharmaceutical and food preservation sectors. When considering a freeze dryer, buyers should be aware of the higher setup and maintenance costs associated with this technology. However, the benefits of maintaining flavor and nutrients can justify the investment for businesses focused on high-quality products.

Related Video: Types of Dryers

Key Industrial Applications of kinds of dryers

| Industry/Sector | Specific Application of kinds of dryers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Drying fruits and vegetables | Extends shelf life, enhances flavor and texture | Regulatory compliance, energy efficiency, capacity |

| Pharmaceutical | Drying active pharmaceutical ingredients | Ensures product stability and potency | Material compatibility, controlled environments, scale |

| Textile Manufacturing | Drying fabrics and garments | Reduces production time, improves fabric quality | Temperature control, moisture removal efficiency |

| Chemical Industry | Drying chemicals and powders | Prevents clumping, ensures uniformity | Safety standards, handling of hazardous materials |

| Agriculture | Drying grains and seeds | Increases market value, prevents spoilage | Equipment durability, local climate considerations |

Food Processing

In the food processing industry, dryers are essential for removing moisture from fruits and vegetables, which significantly extends their shelf life while enhancing flavor and texture. For international buyers, particularly in Africa and South America, sourcing equipment that meets local food safety regulations and is energy-efficient is crucial. Additionally, understanding the capacity and throughput of the dryer can help optimize production processes.

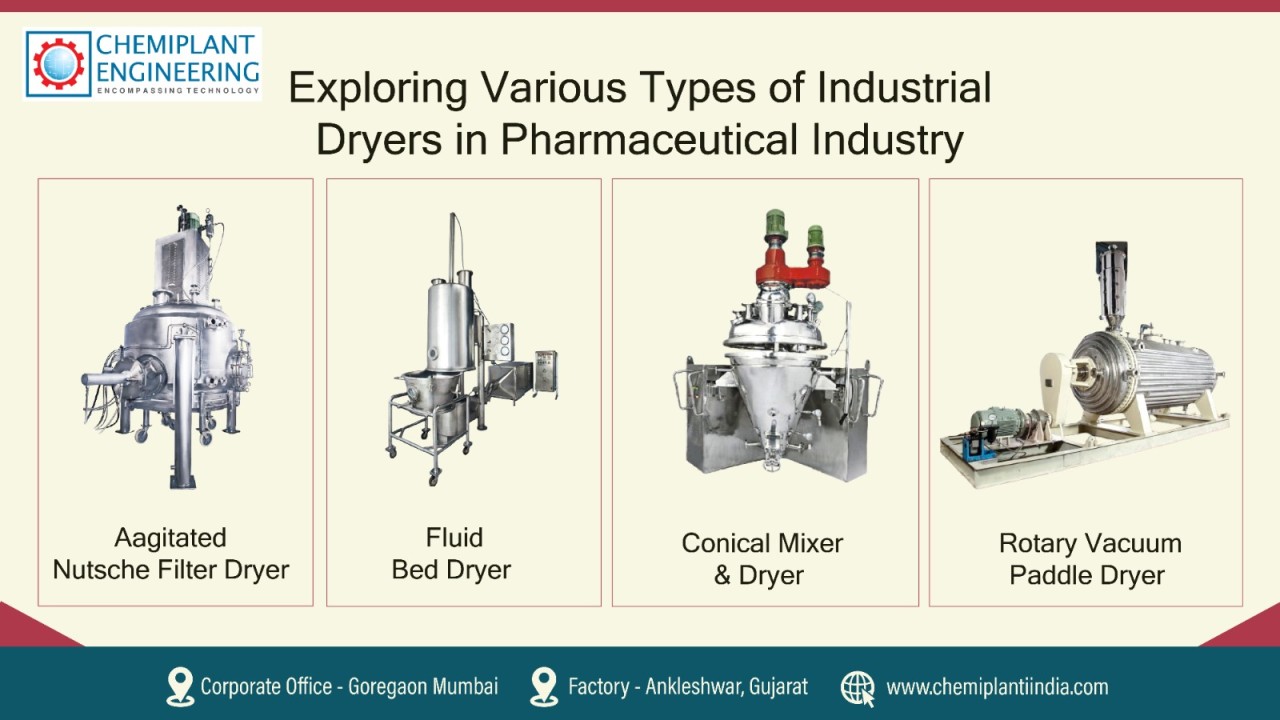

Pharmaceutical

In the pharmaceutical sector, dryers play a critical role in processing active pharmaceutical ingredients (APIs). They ensure that moisture is adequately removed, which is vital for maintaining product stability and potency. Buyers need to consider equipment that can operate in controlled environments to meet stringent quality standards. Material compatibility is also essential to prevent contamination and ensure compliance with health regulations.

Textile Manufacturing

Dryers in textile manufacturing are used to dry fabrics and garments after washing and dyeing processes. Efficient drying reduces production time and enhances the quality of the final product. B2B buyers should focus on dryers that offer precise temperature control and moisture removal efficiency to prevent fabric damage. Sourcing from reputable manufacturers who understand the textile industry’s specific needs can lead to better quality outputs.

Chemical Industry

The chemical industry often requires dryers to remove moisture from various chemicals and powders. This process is crucial to prevent clumping and ensure uniformity in the final product. Buyers must prioritize safety standards, especially when dealing with hazardous materials, and ensure that the drying equipment is designed to handle specific chemical properties. Understanding local regulations regarding chemical processing is also vital for compliance.

Agriculture

In agriculture, dryers are used for drying grains and seeds, which is essential for increasing their market value and preventing spoilage. For international B2B buyers, particularly in regions with high humidity, selecting durable equipment that can withstand local climate conditions is crucial. Additionally, understanding the energy consumption and capacity of the drying equipment can help in making cost-effective decisions that align with agricultural practices.

Strategic Material Selection Guide for kinds of dryers

When selecting materials for different types of dryers, it is essential to consider their properties, advantages, limitations, and suitability for specific applications. Below is an analysis of four common materials used in the construction of dryers, tailored for international B2B buyers.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, high strength, and ability to withstand high temperatures and pressures. It typically has a temperature rating of up to 800°C and can handle pressures up to 10 bar, making it suitable for various drying processes.

Pros & Cons:

The main advantage of stainless steel is its durability and resistance to rust and oxidation. However, it is more expensive than other materials like carbon steel, which can impact overall project costs. Manufacturing complexity is moderate, requiring specialized welding techniques.

Impact on Application:

Stainless steel is compatible with a wide range of media, including food products, chemicals, and pharmaceuticals, making it ideal for industries requiring stringent hygiene standards.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM A240 or DIN 1.4301. In regions like Africa and South America, where corrosion can be a concern, opting for higher grades like 316L can provide additional protection.

Carbon Steel

Key Properties:

Carbon steel is characterized by its high tensile strength and ability to withstand high temperatures, typically up to 400°C. However, it is less resistant to corrosion compared to stainless steel.

Pros & Cons:

The primary advantage of carbon steel is its low cost, making it an attractive option for budget-conscious projects. However, its susceptibility to rust and corrosion limits its use in humid or corrosive environments, potentially increasing maintenance costs.

Impact on Application:

Carbon steel is suitable for applications where exposure to moisture is minimal, such as in certain industrial settings. However, it may not be suitable for food processing or chemical drying without proper coatings.

Considerations for International Buyers:

Buyers should be aware of local environmental conditions that may affect the longevity of carbon steel. Compliance with standards like ASTM A36 is crucial, especially in regions with high humidity levels.

Aluminum

Key Properties:

Aluminum is lightweight, has good thermal conductivity, and can withstand temperatures up to 300°C. It is also resistant to corrosion, especially when anodized.

Pros & Cons:

The lightweight nature of aluminum makes it easy to handle and install, reducing labor costs. However, it is less durable than stainless steel and may not withstand high-pressure applications, limiting its use in certain dryer types.

Impact on Application:

Aluminum is often used in applications requiring rapid heating and cooling, such as in spray dryers. Its compatibility with non-corrosive materials makes it suitable for specific food and pharmaceutical applications.

Considerations for International Buyers:

Buyers should check for compliance with standards like ASTM B221. In markets like the Middle East, where high temperatures are common, ensuring proper alloy selection is essential for maintaining performance.

Composite Materials

Key Properties:

Composite materials, often made from a combination of polymers and fibers, offer excellent thermal insulation and resistance to corrosion. They can handle temperatures up to 150°C and are lightweight.

Pros & Cons:

The key advantage of composites is their versatility and customization potential. However, they may not be suitable for high-pressure applications and can be more expensive than traditional materials.

Impact on Application:

Composites are ideal for applications where thermal insulation is critical, such as in vacuum dryers. Their resistance to chemical attack makes them suitable for specific industrial applications.

Considerations for International Buyers:

Buyers should ensure that composite materials meet relevant standards, such as ASTM D3039. In Europe, compliance with REACH regulations is also necessary, particularly for chemical compatibility.

Summary Table

| Material | Typical Use Case for kinds of dryers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost | High |

| Carbon Steel | Industrial applications | Low cost | Susceptible to corrosion | Low |

| Aluminum | Spray dryers, lightweight applications | Lightweight and good thermal conductivity | Limited high-pressure use | Medium |

| Composite Materials | Vacuum dryers, thermal insulation | Versatile and customizable | Not suitable for high pressure | Medium to High |

This strategic material selection guide provides international B2B buyers with actionable insights to make informed decisions regarding the types of dryers suited for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for kinds of dryers

Manufacturing Processes for Different Types of Dryers

The manufacturing of industrial dryers involves a systematic approach that ensures efficiency, reliability, and quality. Understanding these processes is crucial for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Raw Materials: The first step involves sourcing quality materials suited for the specific type of dryer being manufactured. Common materials include stainless steel for durability and corrosion resistance, as well as specialized alloys for high-temperature applications.

– Material Testing: Conducting tests on raw materials to ensure they meet industry standards is essential. This includes tensile strength tests, corrosion resistance evaluations, and thermal conductivity assessments. -

Forming

– Fabrication Techniques: Various techniques such as cutting, bending, and machining are employed to shape the raw materials. Advanced technologies like laser cutting and CNC machining are increasingly used for precision.

– Welding and Joining: After forming, components are welded or joined together. Automated welding techniques enhance consistency and reduce human error. -

Assembly

– Component Integration: After the individual parts are fabricated, they are assembled into the dryer unit. This stage requires skilled labor to ensure that all parts fit together seamlessly.

– Installation of Control Systems: Modern dryers often include sophisticated control systems for monitoring temperature, humidity, and airflow. Integrating these systems is critical for the performance of the dryer. -

Finishing

– Surface Treatment: To enhance durability and aesthetics, surface treatments such as powder coating or anodizing are applied. This protects against environmental factors and improves the equipment’s lifespan.

– Final Assembly Checks: Before the dryers leave the factory, final assembly checks ensure that all components function as intended.

Quality Assurance Practices

Quality assurance (QA) is fundamental in the manufacturing of dryers, ensuring that each unit meets the required standards and specifications.

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system (QMS). Compliance indicates that the manufacturer consistently provides products that meet customer and regulatory requirements.

- CE Marking: For manufacturers targeting the European market, CE marking signifies that the product conforms to health, safety, and environmental protection standards.

- API Standards: For dryers used in specific industries such as oil and gas, adherence to American Petroleum Institute (API) standards is essential for ensuring safety and reliability.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– At this stage, raw materials are inspected for quality before they enter the production process. This includes verifying certificates of compliance and conducting material tests. -

In-Process Quality Control (IPQC)

– Throughout the manufacturing process, periodic checks are performed to ensure that production parameters are met. This includes monitoring the precision of machining processes and the quality of welds. -

Final Quality Control (FQC)

– The final product undergoes comprehensive testing before shipping. This may involve operational tests to ensure the dryer functions correctly under expected conditions.

Common Testing Methods

- Performance Testing: Assessing the dryer’s efficiency in removing moisture and ensuring it meets specified drying times.

- Durability Testing: Subjecting the dryer to extreme conditions to verify its robustness and longevity.

- Safety Testing: Ensuring that the dryer complies with safety standards to prevent hazards during operation.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in regions with varying standards and practices, verifying a supplier’s quality control measures is vital.

-

Supplier Audits

– Conducting on-site audits of manufacturing facilities allows buyers to assess the quality management systems and production capabilities firsthand. This includes reviewing documentation and observing production processes. -

Quality Reports

– Requesting detailed quality reports from suppliers can provide insights into their production processes, quality metrics, and compliance with international standards. -

Third-Party Inspections

– Engaging third-party inspection agencies to evaluate product quality before shipment can provide an additional layer of assurance. These agencies perform independent checks and can issue certification based on their findings.

Quality Control Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe should be aware of the following nuances in quality control:

- Cultural Differences: Understanding how quality is perceived and prioritized in different regions can affect negotiations and expectations. Buyers should communicate clearly about their quality requirements.

- Regulatory Compliance: Each region may have specific regulations governing product safety and quality. Familiarity with these regulations is essential for ensuring compliance and avoiding legal issues.

- Supply Chain Transparency: Buyers should seek suppliers who are open about their production processes and quality control measures. Transparency fosters trust and facilitates smoother transactions.

By understanding the manufacturing processes and quality assurance practices in the dryer industry, international B2B buyers can make informed purchasing decisions, ensuring they procure reliable and efficient drying solutions that meet their operational needs.

Related Video: Amazing factories | Manufacturing method and top 4 processes | Mass production process

Comprehensive Cost and Pricing Analysis for kinds of dryers Sourcing

When sourcing industrial dryers, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis covers the key components that contribute to the overall cost of dryers, the factors that influence pricing, and actionable tips for buyers to optimize their procurement strategies.

Cost Components

-

Materials: The choice of materials significantly affects the cost of dryers. Common materials include stainless steel, aluminum, and specialized alloys. High-quality materials may increase the initial purchase price but can enhance durability and efficiency.

-

Labor: Labor costs vary by region and depend on the complexity of the manufacturing process. Countries with lower labor costs may offer more competitive pricing, but this can also impact the quality of craftsmanship.

-

Manufacturing Overhead: This includes costs related to factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The cost of tooling is particularly relevant for customized or specialized dryers. High tooling costs can be amortized over larger production runs, making it essential to consider the order volume when negotiating prices.

-

Quality Control (QC): Implementing rigorous QC processes adds to the cost but is vital for ensuring product reliability. Certifications such as ISO or CE can also influence pricing, as they indicate adherence to international quality standards.

-

Logistics: Shipping costs can vary widely based on the origin of the product, destination, and chosen Incoterms. Buyers should factor in freight, insurance, and potential tariffs, especially when sourcing from overseas.

-

Margin: Supplier margins can vary based on their market position and the competitive landscape. Understanding a supplier’s pricing strategy can provide leverage in negotiations.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders typically yield better unit prices due to economies of scale. Buyers should assess their needs to balance inventory costs with purchasing efficiency.

-

Specifications/Customization: Custom features and specifications will increase costs. Buyers should define their requirements clearly to avoid unnecessary expenses.

-

Quality/Certifications: Higher quality and certified products generally command higher prices. Buyers should weigh the benefits of these investments against their operational requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may offer better quality assurance but at a higher cost. Conducting thorough supplier evaluations is crucial.

-

Incoterms: Understanding Incoterms is essential for cost calculations. Different terms can shift responsibilities for shipping and customs, impacting the overall cost structure.

Buyer Tips

-

Negotiation: Engage in open discussions with suppliers regarding pricing. Leverage competitive quotes to negotiate better terms without compromising quality.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes initial purchase price, operating costs, maintenance, and disposal costs. A lower purchase price may lead to higher long-term expenses.

-

Pricing Nuances: Be aware of the pricing dynamics in different regions. For instance, suppliers in Africa or South America may have different cost structures compared to those in Europe or the Middle East.

-

Local Partnerships: Consider forming partnerships with local suppliers for better logistics and lower shipping costs. Local suppliers may also provide faster response times for service and support.

-

Market Research: Stay informed about market trends and fluctuations in material costs. This knowledge can provide leverage during negotiations and help buyers anticipate price changes.

Disclaimer

Prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Spotlight on Potential kinds of dryers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘kinds of dryers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for kinds of dryers

In the industrial dryer market, understanding essential technical properties and trade terminology is crucial for B2B buyers looking to make informed purchasing decisions. Below are key specifications and common industry terms that can enhance your procurement strategy.

Key Technical Properties

-

Material Grade

– Definition: Refers to the type and quality of materials used in the construction of the dryer, such as stainless steel or carbon steel.

– B2B Importance: Higher material grades often mean better durability and resistance to corrosion, which is vital for maintaining operational efficiency and longevity, particularly in industries like food processing and pharmaceuticals. -

Drying Capacity

– Definition: The amount of product that can be processed within a specific time frame, usually measured in kilograms per hour (kg/h).

– B2B Importance: Understanding drying capacity helps businesses evaluate whether the dryer meets their production needs, avoiding bottlenecks in manufacturing processes. -

Temperature Range

– Definition: The operational temperature limits within which the dryer functions effectively, typically expressed in degrees Celsius.

– B2B Importance: Different materials require specific temperature settings for optimal drying. Knowing the temperature range ensures compatibility with the materials being processed, reducing the risk of damage or inefficiency. -

Energy Efficiency Rating

– Definition: A measure of the energy consumption of the dryer relative to its output, often rated on a scale.

– B2B Importance: High energy efficiency translates to lower operational costs, making it a critical factor for budget-conscious buyers. This is particularly relevant for companies in regions with high energy costs. -

Control System

– Definition: The type of automation and control interfaces available (e.g., manual, semi-automated, or fully automated systems).

– B2B Importance: Advanced control systems can enhance precision in drying processes, reduce labor costs, and improve product quality. Buyers should assess their technological capabilities and training needs when considering these systems.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Explanation: A company that produces parts and equipment that may be marketed by another manufacturer.

– Relevance: Knowing whether a dryer is sourced from an OEM can impact quality assurance and warranty considerations, as OEM products often come with more reliable support. -

MOQ (Minimum Order Quantity)

– Explanation: The smallest number of units a supplier is willing to sell.

– Relevance: Understanding MOQ helps buyers negotiate better terms and manage inventory levels, especially in markets with fluctuating demand. -

RFQ (Request for Quotation)

– Explanation: A document issued to suppliers requesting a price quote for specific products or services.

– Relevance: A well-prepared RFQ can lead to competitive pricing and better supplier relationships, ensuring that buyers get the best value for their investment. -

Incoterms (International Commercial Terms)

– Explanation: A set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risks, which is critical for international trade operations. -

Lead Time

– Explanation: The time taken from placing an order to receiving the product.

– Relevance: Knowing the lead time is essential for planning and ensuring that production schedules remain uninterrupted, especially in industries with tight deadlines. -

Warranty Period

– Explanation: The duration during which the manufacturer is responsible for repairing or replacing faulty products.

– Relevance: A longer warranty period often indicates higher quality and reliability, providing peace of mind for buyers investing in capital equipment.

Illustrative Image (Source: Google Search)

Understanding these technical properties and terminology can greatly enhance the decision-making process for international B2B buyers. By equipping themselves with this knowledge, businesses can negotiate better terms, ensure compliance with operational needs, and ultimately drive efficiency in their production processes.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the kinds of dryers Sector

Market Overview & Key Trends

The global market for industrial dryers is experiencing significant transformation, driven by technological advancements, sustainability demands, and evolving consumer preferences. Increased automation is a key trend, with manufacturers adopting smart dryers equipped with IoT capabilities to optimize energy usage and enhance operational efficiency. This trend is particularly relevant for international B2B buyers in regions such as Africa and South America, where energy costs are a critical consideration.

Sourcing trends are also shifting towards localized supply chains. Buyers are increasingly seeking suppliers closer to their operational bases to reduce lead times and shipping costs. This is especially pertinent for European buyers looking to comply with stringent regulations while ensuring timely delivery of equipment. Moreover, the rise of alternative energy sources, such as solar and biomass, is influencing dryer technology, leading to the development of eco-friendly models that appeal to sustainability-conscious businesses.

Additionally, emerging markets in Africa and the Middle East are creating new opportunities for suppliers of industrial dryers. As industries such as agriculture, food processing, and pharmaceuticals expand in these regions, the demand for effective drying solutions is set to rise. Buyers should keep an eye on suppliers that offer customized solutions tailored to local conditions, such as humidity and temperature variations, to maximize efficiency.

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer just a buzzword; it has become a critical factor in the decision-making processes of international B2B buyers. The environmental impact of industrial dryers is significant, with traditional models often consuming excessive energy and emitting greenhouse gases. To mitigate these impacts, buyers should prioritize sourcing from manufacturers who demonstrate a commitment to sustainability through energy-efficient technologies and eco-friendly materials.

Ethical sourcing practices are also gaining traction. Buyers are increasingly holding suppliers accountable for their environmental and social footprints. This includes ensuring that materials used in the production of dryers come from sustainable sources and that manufacturing processes adhere to ethical labor practices. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the integration of green technologies—such as heat recovery systems and low-emission processes—can not only reduce the carbon footprint of drying operations but also lower operating costs. By investing in sustainable solutions, buyers not only enhance their corporate social responsibility but also position themselves competitively in a market increasingly driven by eco-conscious consumers.

Brief Evolution/History

The evolution of industrial dryers has been marked by significant technological advancements. Initially, drying processes were rudimentary, relying heavily on natural evaporation. However, as industries expanded, the demand for more efficient and controlled drying methods emerged. The introduction of convection dryers in the mid-20th century revolutionized the sector, allowing for faster drying times and improved product quality.

In recent years, the focus has shifted towards integrating smart technologies and sustainable practices. As businesses face increasing pressure to reduce their environmental impact, the development of energy-efficient dryers that leverage advanced sensors and automated controls has become paramount. This trajectory highlights the ongoing importance of innovation in meeting the evolving needs of international B2B buyers across diverse industries.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of kinds of dryers

-

What key factors should I consider when vetting suppliers for industrial dryers?

When vetting suppliers, prioritize their manufacturing capabilities, quality certifications (like ISO), and experience in your specific industry. Conduct due diligence by checking references and customer reviews. Also, assess their financial stability and reputation in the market. For international buyers, ensure the supplier can navigate customs and trade regulations in your region. Consider visiting the facility if possible or using third-party inspection services to verify their operations. -

Can I customize the dryers to meet specific operational needs?

Yes, many manufacturers offer customization options for industrial dryers. Specify your requirements regarding size, drying capacity, energy efficiency, and material compatibility. Discussing these needs during the initial consultation can help ensure the final product aligns with your operational processes. Be aware that customization may impact lead times and costs, so clarify these aspects early in the negotiation. -

What are the typical minimum order quantities (MOQs) and lead times for industrial dryers?

MOQs vary by supplier and can range from one unit for custom orders to several units for standard products. Lead times are influenced by factors such as complexity, customization, and the supplier’s production schedule. Generally, expect lead times of 4-12 weeks for standard models and longer for customized solutions. Always confirm these details upfront to align your production schedules and avoid operational disruptions. -

What payment terms should I expect when sourcing dryers internationally?

Payment terms can vary significantly between suppliers. Common practices include a deposit (20-50%) upfront with the balance due upon delivery or before shipment. Some suppliers may offer letters of credit or trade finance options for international transactions. Ensure you understand the payment methods accepted, and consider using escrow services for added security. Discussing and agreeing on payment terms in advance can help prevent disputes later. -

What quality assurance measures should be in place for industrial dryers?

Quality assurance is critical for ensuring the reliability and efficiency of industrial dryers. Suppliers should provide documentation of compliance with international standards (e.g., CE, UL certifications). Request detailed quality control processes, including in-process inspections and final testing. Consider establishing a pre-shipment inspection process to verify compliance with your specifications before shipment, especially for high-value orders.

Illustrative Image (Source: Google Search)

-

How can I manage logistics and shipping when importing dryers?

Managing logistics effectively involves selecting a reliable freight forwarder experienced in handling industrial equipment. Discuss shipping methods (e.g., air freight for speed, sea freight for cost-efficiency) based on your timeline and budget. Ensure that the supplier provides all necessary export documentation to avoid delays at customs. Calculate potential import duties and taxes in advance to budget accurately for the total cost of acquisition. -

What steps should I take if a dispute arises with my supplier?

In the event of a dispute, first attempt to resolve the issue through direct communication with the supplier. Document all correspondence and agreements as evidence. If direct negotiations fail, consult your contract for dispute resolution clauses, which may include mediation or arbitration. Engage legal counsel if necessary, especially for international contracts, to ensure compliance with relevant laws and protect your interests. -

What certifications should I look for in suppliers of industrial dryers?

When sourcing industrial dryers, prioritize suppliers with recognized quality certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management. Additionally, certifications like CE or UL indicate compliance with safety standards, which is crucial for equipment used in industrial settings. These certifications not only assure quality but also demonstrate the supplier’s commitment to adhering to international standards, which is essential for building trust in international trade.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for kinds of dryers

As international B2B buyers navigate the diverse landscape of industrial dryers, understanding the unique characteristics and applications of various dryer types is paramount. Strategic sourcing plays a crucial role in optimizing procurement processes, ensuring that businesses not only acquire the right equipment but also maximize operational efficiency and cost-effectiveness.

Key takeaways include the importance of aligning dryer selection with specific industry needs, considering factors such as energy efficiency, drying capacity, and material compatibility. Buyers should prioritize suppliers who demonstrate reliability, technological innovation, and a strong track record in after-sales support, especially in emerging markets in Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for advanced drying technologies is expected to rise, driven by sustainability initiatives and increasing production demands. Investing in the right drying solutions today will pave the way for enhanced productivity tomorrow. Engage with reputable suppliers, leverage competitive pricing, and stay informed about technological advancements to ensure your operations remain at the forefront of efficiency and innovation.