Master the Types of AC Power Plugs for Seamless

Introduction: Navigating the Global Market for types of ac power plugs

In an increasingly interconnected world, the importance of understanding AC power plugs cannot be overstated. For international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe, the nuances of various plug types, standards, and specifications are critical to ensuring seamless operations and compliance with local regulations. With diverse electrical systems across countries, selecting the right type of power plug is not merely a technical choice but a strategic imperative that impacts equipment compatibility, safety, and operational efficiency.

This comprehensive guide delves into the myriad types of AC power plugs available on the global market, exploring key aspects such as materials, manufacturing quality control, leading suppliers, and cost considerations. We will also address common questions, equipping buyers with the knowledge needed to navigate the complexities of sourcing power plugs effectively.

By leveraging this guide, international buyers will be empowered to make informed sourcing decisions, ultimately enhancing their supply chain resilience and operational effectiveness. Understanding the dynamics of the AC power plug market enables businesses to mitigate risks, optimize procurement processes, and build robust partnerships with suppliers, ensuring they are well-prepared to meet the demands of a globalized marketplace.

Understanding types of ac power plugs Types and Variations

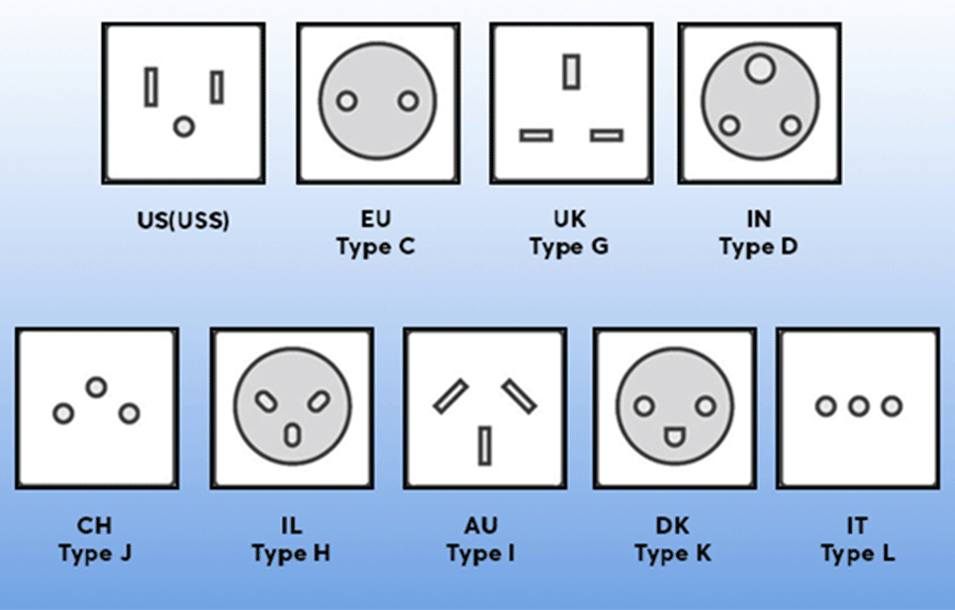

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type A | Two flat parallel pins; 15A, 125V rated | North America, small appliances | Pros: Widely available; Cons: Not suitable for high power. |

| Type C | Two round pins; 2.5A, 250V rated | Europe, Asia, general electronics | Pros: Versatile; Cons: Limited to low power applications. |

| Type D | Three large round pins in a triangular pattern | India, heavy machinery | Pros: High power capacity; Cons: Bulky and less common. |

| Type G | Three rectangular prongs; fused | UK, industrial equipment | Pros: Safe and reliable; Cons: Requires specific sockets. |

| Type I | Two flat pins in a V-shape; grounding pin | Australia, New Zealand, appliances | Pros: Good for high power; Cons: Adapters needed for other types. |

Type A

Type A plugs are characterized by their two flat parallel pins and are commonly used in North America. Rated for 15A at 125V, they are typically found in small appliances and consumer electronics. For B2B buyers, the major consideration is the availability of compatible sockets and devices. While they are widely used, they are not suited for high power applications, limiting their use in industrial settings.

Type C

Type C plugs feature two round pins and are rated for 2.5A at 250V, making them ideal for general electronics and small appliances in Europe and Asia. Their versatility allows them to be used with various devices, but they are limited to lower power applications. B2B buyers should consider the compatibility of their equipment with Type C sockets, especially when importing goods from regions where this plug type is standard.

Type D

Type D plugs, with three large round pins arranged in a triangular pattern, are primarily used in India and are rated for higher power applications. They are suitable for heavy machinery and industrial equipment. Buyers should note the durability and power handling capabilities of Type D plugs, but they may face challenges due to their bulkiness and less common usage outside India.

Type G

Type G plugs have three rectangular prongs and are fused for safety, commonly used in the UK and for industrial equipment. They are known for their reliability and safety features, making them a preferred choice for B2B buyers in industries where equipment safety is paramount. However, the need for specific sockets can pose a challenge for businesses operating internationally.

Type I

Type I plugs are distinguished by two flat pins in a V-shape with an additional grounding pin, primarily used in Australia and New Zealand. Rated for higher power applications, they are suitable for various appliances and industrial uses. B2B buyers should consider the need for adapters when dealing with international suppliers, as compatibility with other plug types may be an issue.

Related Video: GCSE Physics – Plugs and Wires

Key Industrial Applications of types of ac power plugs

| Industry/Sector | Specific Application of types of ac power plugs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Powering Heavy Machinery | Ensures operational efficiency and reduces downtime | Compliance with international standards and voltage requirements |

| Construction | Temporary Power Supply on Job Sites | Facilitates construction work continuity | Durability and weather resistance for outdoor applications |

| Telecommunications | Connecting Communication Equipment | Reliable power for uninterrupted service | Compatibility with local standards and surge protection |

| Healthcare | Medical Equipment Power Supply | Critical for patient safety and operational reliability | Strict adherence to safety standards and certifications |

| Hospitality | Powering Equipment in Hotels and Restaurants | Enhances guest experience through reliable services | Versatility in plug types to accommodate various appliances |

Manufacturing

In the manufacturing sector, types of AC power plugs are crucial for powering heavy machinery, such as CNC machines and assembly line equipment. These plugs need to support high voltage and current ratings to ensure machinery operates efficiently. International B2B buyers must consider sourcing plugs that comply with local electrical standards to minimize downtime due to electrical failures. Additionally, the durability of plugs is essential to withstand the demanding environments of manufacturing facilities.

Construction

Temporary power supply is a common application in construction sites, where AC power plugs are used to connect various tools and equipment. Construction sites often face harsh weather conditions, so plugs must be robust and weather-resistant to prevent failures. For B2B buyers in this sector, sourcing plugs that meet IP (Ingress Protection) ratings is vital to ensure long-lasting performance. Ensuring quick and easy installation can also enhance productivity on-site.

Telecommunications

In telecommunications, AC power plugs are essential for connecting communication equipment like routers and switches. Reliable power is crucial for maintaining uninterrupted service, especially in critical infrastructure. Buyers should focus on sourcing plugs that offer compatibility with local electrical standards and include features like surge protection to safeguard sensitive equipment. This is particularly important for international buyers who may face varying standards across different regions.

Healthcare

Medical facilities rely heavily on AC power plugs to supply power to essential medical equipment, including life support systems and diagnostic machines. The reliability of power supply directly impacts patient safety and operational efficiency. B2B buyers in this sector must prioritize sourcing plugs that adhere to strict safety standards and certifications, ensuring they can withstand the rigorous demands of healthcare environments. This includes considerations for grounding and insulation to prevent electrical hazards.

Hospitality

In the hospitality industry, AC power plugs are used to power various equipment, from kitchen appliances to guest room electronics. Reliable power supply enhances the guest experience, making it essential for hotels and restaurants to have high-quality plugs. Buyers should consider the versatility of plug types to accommodate different appliances and ensure compliance with local electrical codes. Additionally, sourcing aesthetically pleasing designs can contribute to the overall ambiance of hospitality environments.

Related Video: All Power Supply Cable Types EXPLAINED

Strategic Material Selection Guide for types of ac power plugs

When selecting materials for AC power plugs, it is crucial to understand their properties, advantages, and limitations in the context of specific applications. Below, we analyze four common materials used in the manufacturing of AC power plugs, focusing on their performance characteristics and implications for international B2B buyers.

Polyvinyl Chloride (PVC)

Key Properties: PVC is a widely used thermoplastic known for its excellent insulation properties and resistance to moisture and chemicals. It operates effectively within a temperature range of -10°C to 60°C, making it suitable for various environments.

Pros & Cons:

– Advantages: PVC is cost-effective and easy to manufacture, allowing for high-volume production. It also provides good electrical insulation and is resistant to corrosion.

– Disadvantages: Its flexibility can be a limitation in high-temperature applications, where it may deform or degrade over time.

Impact on Application: PVC is suitable for residential and light commercial applications, particularly where cost is a significant factor. However, it may not be the best choice for high-performance industrial settings.

Considerations for International Buyers: Buyers should ensure compliance with local electrical standards, such as IEC standards in Europe and SANS in South Africa, which may dictate the use of specific materials for safety.

Thermoplastic Elastomer (TPE)

Key Properties: TPE combines the properties of rubber and plastic, offering flexibility, durability, and resistance to extreme temperatures, typically ranging from -40°C to 120°C.

Pros & Cons:

– Advantages: TPE is highly resilient, making it ideal for applications requiring frequent plugging and unplugging. It also provides excellent electrical insulation and is resistant to UV light and ozone.

– Disadvantages: The manufacturing process can be more complex and costly compared to PVC, which may affect overall product pricing.

Impact on Application: TPE is well-suited for outdoor and industrial applications where flexibility and durability are paramount. Its resistance to environmental factors makes it a preferred choice for harsh conditions.

Considerations for International Buyers: Buyers should verify that TPE products meet relevant certifications, such as UL or CE marking, to ensure safety and compliance in their respective markets.

Metal (Copper and Brass)

Key Properties: Metals like copper and brass are known for their excellent electrical conductivity and mechanical strength. They can withstand high temperatures and pressures, making them suitable for heavy-duty applications.

Pros & Cons:

– Advantages: Metals provide superior performance in terms of conductivity and durability, ensuring reliable connections. They are also resistant to wear and tear.

– Disadvantages: The cost of metals can be significantly higher than plastics, and they may require additional coatings to prevent corrosion.

Impact on Application: Metal plugs are ideal for industrial and commercial applications where high current loads are common. They ensure efficient energy transfer and long-lasting performance.

Considerations for International Buyers: Buyers must consider the specific standards for metal components in their regions, such as ASTM in the U.S. or DIN in Europe, to ensure compliance and safety.

Nylon

Key Properties: Nylon is a strong, lightweight thermoplastic known for its high tensile strength and resistance to abrasion and chemicals. It operates effectively within a temperature range of -40°C to 85°C.

Pros & Cons:

– Advantages: Nylon is highly durable and resistant to impact, making it suitable for rugged environments. It also offers good electrical insulation properties.

– Disadvantages: Nylon can be more expensive than PVC and may require specialized manufacturing processes.

Impact on Application: Nylon is often used in applications where durability and resistance to environmental factors are critical, such as in industrial machinery and outdoor equipment.

Considerations for International Buyers: Buyers should ensure that nylon products comply with relevant international standards, particularly for safety and environmental impact.

Summary Table

| Material | Typical Use Case for types of ac power plugs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyvinyl Chloride | Residential and light commercial applications | Cost-effective and easy to manufacture | Limited high-temperature performance | Low |

| Thermoplastic Elastomer | Outdoor and industrial applications | Highly resilient and flexible | More complex and costly manufacturing | Medium |

| Metal (Copper/Brass) | Industrial and commercial applications | Superior conductivity and durability | Higher cost and potential corrosion issues | High |

| Nylon | Rugged environments and industrial machinery | Durable and impact-resistant | More expensive than PVC | Medium |

This guide provides a comprehensive overview of the strategic material selection for AC power plugs, enabling international B2B buyers to make informed decisions based on performance requirements, cost considerations, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of ac power plugs

The manufacturing processes for AC power plugs involve several critical stages that ensure product quality and compliance with international standards. For B2B buyers, understanding these processes can significantly enhance procurement strategies and supplier evaluations.

Illustrative Image (Source: Google Search)

Manufacturing Processes

Material Preparation

The manufacturing process begins with material selection, which is crucial for safety and performance. Common materials used include:

– Thermoplastics: For insulation and housing, offering good electrical properties and durability.

– Copper Alloys: For conducting components, chosen for their excellent conductivity and resistance to corrosion.

– Nickel Plating: Applied to connectors to enhance durability and corrosion resistance.

During this stage, materials undergo quality checks to ensure they meet specified standards. This includes testing for electrical conductivity, thermal resistance, and mechanical strength.

Forming

In this stage, raw materials are shaped into the necessary components:

– Injection Molding: Often used for creating plastic housings and insulators. This method allows for precision in dimensions and reduces waste.

– Stamping: Employed for metal parts, where sheets of metal are cut and shaped into connectors and pins. This process ensures high precision and repeatability.

Advanced techniques like CNC machining may also be used for creating intricate designs and ensuring tight tolerances.

Assembly

Once the components are formed, they are assembled:

– Automated Assembly Lines: These are commonly used for mass production, improving efficiency and consistency. Robots may be utilized to place and secure components, reducing human error.

– Manual Assembly: In some cases, especially for specialized or low-volume products, skilled labor is employed to assemble the plugs.

During assembly, each plug is subjected to intermediate quality checks to identify defects early in the process.

Finishing

The final stage involves preparing the plugs for market:

– Surface Treatment: This includes processes like polishing and coating to improve aesthetics and functionality. For example, adding a textured finish can enhance grip.

– Final Testing: Each plug undergoes rigorous testing to ensure it meets electrical and safety standards. This may involve electrical testing, insulation resistance testing, and stress tests.

Quality Assurance

Quality assurance is paramount in the production of AC power plugs, particularly for international markets. B2B buyers must ensure that suppliers adhere to relevant quality standards.

International Standards

Several key standards govern the quality of AC power plugs:

– ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing.

– IEC 60884-1: This international standard specifies safety requirements for plugs and sockets used in household and similar applications.

– CE Marking: Indicates compliance with European health, safety, and environmental protection standards.

In addition to these, industry-specific certifications (e.g., API for industrial applications) may be relevant depending on the plug’s application.

Quality Control Checkpoints

To ensure quality throughout the manufacturing process, several checkpoints are established:

– Incoming Quality Control (IQC): Inspection of raw materials upon arrival to verify compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to catch defects early. This may include dimensional checks and functional tests.

– Final Quality Control (FQC): Comprehensive testing of finished products, including electrical testing and safety inspections.

Common Testing Methods

Testing methods used in the quality assurance of AC power plugs include:

– Electrical Testing: Measures the plug’s ability to conduct electricity safely.

– Thermal Testing: Assesses the plug’s performance under high temperatures.

– Mechanical Testing: Evaluates the durability of the plug under stress and strain.

Verifying Supplier Quality Control

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing capabilities and adherence to quality standards. This should include a review of their quality management system and manufacturing processes.

-

Requesting Quality Reports: Suppliers should provide documented evidence of their quality control processes, including IQC, IPQC, and FQC reports. This documentation can help buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging independent inspection services can offer an unbiased evaluation of the supplier’s quality practices. This is particularly crucial for international transactions, where buyers may not have direct oversight.

Quality Control and Certification Nuances for International Buyers

B2B buyers from regions such as Africa, South America, the Middle East, and Europe must be aware of the nuances in quality control and certification. Here are some considerations:

-

Regional Standards: Different regions may have specific requirements for AC power plugs. For example, European buyers must ensure compliance with EU directives, while Middle Eastern buyers may need to adhere to local standards.

-

Documentation and Traceability: Buyers should ensure that suppliers can provide complete documentation for all quality control processes. This includes certificates of compliance, test results, and traceability records for materials used.

-

Cultural Considerations: Understanding cultural differences in business practices can enhance communication and cooperation with suppliers, ensuring that quality expectations are clearly defined and met.

By grasping the intricacies of manufacturing processes and quality assurance for AC power plugs, international B2B buyers can make informed decisions, reduce risks, and foster long-term partnerships with reliable suppliers.

Related Video: 18650 Cell Manufacturing Process, Automatic Production Line

Comprehensive Cost and Pricing Analysis for types of ac power plugs Sourcing

When sourcing AC power plugs, a thorough understanding of the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the various components that contribute to the pricing of AC power plugs, alongside actionable insights for effective procurement.

Cost Components

-

Materials: The primary cost driver in the manufacturing of AC power plugs. Common materials include high-grade plastics, metals (like copper and aluminum), and rubber. The choice of materials affects both durability and compliance with safety standards.

-

Labor: Labor costs encompass wages for factory workers involved in the assembly and quality control processes. Regions with lower labor costs can provide competitive pricing, but may vary significantly based on local labor laws and market conditions.

-

Manufacturing Overhead: This includes costs related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient production processes can help minimize these costs, ultimately impacting the overall price.

-

Tooling: The initial investment in tooling for production can be substantial, particularly for customized plugs. Buyers should consider this when evaluating quotes, as tooling costs are often amortized over large production runs.

-

Quality Control (QC): Ensuring products meet international standards can incur additional costs. Robust QC processes are essential for minimizing defects and ensuring compliance with safety regulations, especially for buyers in regions with stringent standards.

-

Logistics: Shipping and handling expenses, including freight, customs duties, and insurance, contribute significantly to the final cost. The choice of Incoterms can influence who bears these costs and when they are paid.

-

Margin: Suppliers add their profit margin on top of the cumulative costs. This margin can vary widely based on the supplier’s market positioning and the competitive landscape.

Price Influencers

-

Volume/MOQ: Larger orders typically yield better pricing due to economies of scale. Establishing a Minimum Order Quantity (MOQ) can help negotiate lower per-unit costs.

-

Specifications/Customization: Tailoring plugs to specific requirements can increase costs. Standardized products often have lower prices, so buyers should assess whether customization is essential.

-

Material Quality/Certifications: Higher quality materials and certifications (like CE, UL, or ISO) can elevate costs but are often necessary for compliance and safety, especially in regulated markets.

-

Supplier Factors: Established suppliers with a proven track record may charge more due to their reliability and service level. Conversely, newer suppliers may offer lower prices to gain market share.

-

Incoterms: The terms of shipping can significantly affect pricing. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is vital to manage costs effectively.

Buyer Tips

-

Negotiation: Engage suppliers in discussions regarding pricing, payment terms, and delivery schedules. Building a relationship can lead to better pricing over time.

-

Cost-Efficiency: Look beyond the unit price. Evaluate the Total Cost of Ownership (TCO), which includes the costs associated with logistics, maintenance, and potential downtime.

-

Pricing Nuances: Be aware of fluctuating material costs and currency exchange rates, particularly for international transactions. These can impact overall pricing and should be factored into budget planning.

-

Supplier Diversity: Diversifying your supplier base can mitigate risks and lead to better pricing options. Consider suppliers from different regions to leverage competitive advantages.

Disclaimer

Prices can vary significantly based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to obtain multiple quotes and conduct thorough due diligence before making procurement decisions.

Spotlight on Potential types of ac power plugs Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of ac power plugs’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of ac power plugs

In the realm of AC power plugs, understanding essential technical properties and trade terminology is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Here’s a detailed overview of these specifications and terms that can aid in informed purchasing decisions.

Critical Technical Properties

-

Material Grade

The material used in AC power plugs significantly impacts their durability and safety. Common materials include thermoplastic for the housing and copper for the pins. High-grade materials ensure better resistance to heat and wear, which is vital for long-term use in industrial applications. Buyers should prioritize plugs made from materials that meet international safety standards to minimize risk. -

Electrical Rating

This specification indicates the maximum voltage and current the plug can handle, usually expressed in volts (V) and amperes (A). Selecting plugs with appropriate electrical ratings is essential to prevent overheating and potential electrical failures. Buyers must ensure that the plugs they choose align with the requirements of their equipment to maintain operational safety. -

Insulation Resistance

Insulation resistance is a measure of the plug’s ability to resist electrical leakage. This property is critical in preventing electric shocks and ensuring safety in wet or high-humidity environments. A higher insulation resistance value indicates better safety and reliability, making it a key consideration for B2B buyers in sectors like manufacturing and construction. -

Tolerance

Tolerance refers to the permissible limits of variation in the plug’s dimensions and electrical characteristics. Understanding tolerance levels is vital, as excessive deviation can lead to poor connections, resulting in equipment malfunction or failure. Buyers should look for plugs with tight tolerances to ensure compatibility with their sockets and devices. -

Durability Rating

This property assesses how well a plug can withstand mechanical stress, heat, and environmental conditions over time. A high durability rating is particularly important for industrial applications where plugs may be subjected to rigorous use. Selecting plugs with robust durability can lead to lower replacement costs and reduced downtime.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components or equipment that are then marketed by another company. For B2B buyers, understanding OEM relationships can be crucial when sourcing plugs that need to integrate seamlessly with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is significant for buyers as it can impact inventory management and cash flow. Knowing the MOQ helps in planning purchases effectively, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specified products. This is an essential step in the procurement process, allowing buyers to compare costs and terms across different suppliers to ensure they receive the best value. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) relating to international commercial law. Understanding these terms is crucial for B2B buyers as they dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. -

Certification Standards

These are guidelines established by regulatory bodies to ensure product safety and performance. Certifications such as CE (Conformité Européenne) in Europe or UL (Underwriters Laboratories) in the USA are critical for compliance. Buyers should verify that the plugs they procure meet the necessary certification standards to avoid legal issues and ensure safety.

Illustrative Image (Source: Google Search)

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing AC power plugs, ultimately leading to enhanced operational efficiency and safety in their respective industries.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of ac power plugs Sector

Global demand for AC power plugs is driven by an increasing reliance on electrical devices, global trade, and the expansion of infrastructure projects across various regions, particularly in Africa, South America, the Middle East, and Europe. Key trends affecting the market include the rise of standardization in plug types, influenced by international regulations and the need for compatibility in a globalized economy. Notably, the IEC (International Electrotechnical Commission) standards are being adopted more widely, making it crucial for international B2B buyers to understand the specifications that align with their regional needs.

Emerging technologies such as smart plugs are also making waves in the market. These devices offer features like energy monitoring and remote control, appealing to both consumers and businesses looking to improve energy efficiency. Additionally, the shift towards renewable energy sources is prompting changes in plug design and functionality, with a focus on compatibility with solar and other green technologies. B2B buyers should keep an eye on these technological advancements as they can lead to more innovative sourcing opportunities.

In terms of market dynamics, the geopolitical landscape plays a significant role. Trade agreements and tariffs can affect pricing and availability, making it essential for buyers to establish strong relationships with reliable suppliers. Additionally, regional economic conditions influence demand; for instance, rapid urbanization in Africa and South America is creating a surge in infrastructure projects, driving the need for reliable electrical components.

Sustainability & Ethical Sourcing in B2B

The importance of sustainability in sourcing AC power plugs cannot be overstated. As global awareness of environmental issues rises, businesses are increasingly pressured to adopt sustainable practices. This includes selecting suppliers that prioritize eco-friendly materials and manufacturing processes. The environmental impact of plastic waste, particularly in the production of plugs and sockets, is a significant concern. Thus, B2B buyers should prioritize manufacturers that utilize recycled or biodegradable materials in their products.

Moreover, ethical sourcing is becoming a critical aspect of supply chain management. Buyers should seek suppliers who are transparent about their sourcing practices, ensuring that materials are obtained responsibly and that labor conditions meet international standards. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By choosing partners with these credentials, businesses can mitigate risks associated with reputational damage and regulatory compliance.

Brief Evolution/History

The evolution of AC power plugs can be traced back to the early 20th century when the need for standardized electrical connections emerged alongside the widespread adoption of electricity. Initially, various designs and configurations existed, leading to compatibility issues. The establishment of international standards, particularly by the IEC, helped unify plug designs, fostering easier global trade and enhancing safety. Today, the focus has shifted towards innovation, with the integration of technology and sustainability driving the next phase in the evolution of AC power plugs. Understanding this history equips B2B buyers with insights into the current market landscape and future trends.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of ac power plugs

-

What should I consider when vetting suppliers for AC power plugs?

When vetting suppliers, assess their reputation by checking reviews and testimonials from previous clients. Verify their certifications and compliance with international standards (e.g., IEC, ISO) to ensure product quality. Request samples to evaluate the material and design. Additionally, consider their manufacturing capacity, production lead times, and responsiveness to inquiries. Establish a clear communication channel and gauge their willingness to address any concerns, which is crucial for long-term business relationships. -

Can I customize AC power plugs to meet specific requirements?

Many suppliers offer customization options for AC power plugs, allowing you to tailor designs, voltages, and current ratings to suit your needs. Discuss your requirements upfront, including the intended application and any specific safety standards. Be prepared to provide technical specifications, as well as any aesthetic preferences. Keep in mind that customization may affect lead times and minimum order quantities (MOQs), so clarify these details early in the negotiation process. -

What are typical minimum order quantities (MOQs) and lead times for AC power plugs?

MOQs for AC power plugs can vary significantly based on the supplier and the complexity of the order. Generally, MOQs range from 100 to 1,000 units for standard models, while custom designs may require higher quantities. Lead times can also differ, typically ranging from 4 to 12 weeks depending on the production schedule and complexity of the customization. Always discuss these factors with suppliers during the initial negotiation to ensure they align with your project timelines. -

What payment terms should I expect when sourcing AC power plugs internationally?

Payment terms for international transactions often include options such as advance payment, letters of credit, or payment upon delivery. Many suppliers prefer partial payment upfront (e.g., 30-50%) with the balance due before shipment. It’s essential to negotiate terms that protect both parties, such as escrow services or third-party verification for large orders. Familiarize yourself with the supplier’s preferred payment methods and assess any potential currency exchange risks involved in the transaction. -

How can I ensure quality assurance and certifications for AC power plugs?

To ensure quality, request copies of relevant certifications from your supplier, such as CE, UL, or RoHS compliance. It’s also advisable to conduct factory audits or third-party inspections before placing large orders. Develop a quality assurance plan that outlines testing protocols for incoming shipments, including random sampling of products for electrical safety and performance tests. Establish clear return policies for defective items to mitigate any potential losses. -

What logistics considerations should I keep in mind when importing AC power plugs?

Logistics play a crucial role in international trade, so work with reliable freight forwarders who understand the nuances of importing electrical components. Consider factors such as shipping methods (air vs. sea), customs clearance processes, and associated costs (duties, taxes, and insurance). Ensure that your supplier provides the necessary documentation for customs, including invoices, packing lists, and any required certifications. Planning for potential delays in shipping or customs clearance is also essential to avoid disruptions in your supply chain. -

How can I handle disputes with suppliers over AC power plugs?

Clear communication and documentation are vital in managing disputes. Ensure that all agreements, specifications, and terms are documented in writing. In case of a dispute, first attempt to resolve the issue amicably through direct communication. If that fails, refer to any conflict resolution clauses in your contract, which may involve mediation or arbitration. Consider involving a legal professional experienced in international trade if the dispute escalates, but aim to maintain a professional relationship with the supplier for future transactions. -

What are the common industry standards for AC power plugs, and why do they matter?

Industry standards for AC power plugs, such as IEC 60309, NEMA, and BS 1363, dictate the design, safety, and performance requirements. Compliance with these standards is essential to ensure compatibility with electrical systems and to minimize risks of electrical hazards. Buyers should prioritize suppliers who adhere to these standards, as this not only guarantees product safety but also facilitates smoother international transactions. Understanding these standards helps in selecting the right products for specific markets, especially when exporting to regions with strict regulatory frameworks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of ac power plugs

In conclusion, the strategic sourcing of AC power plugs is essential for businesses looking to optimize their operations across diverse markets. Understanding the various types and standards of AC power plugs—such as Type A, B, C, and industrial variants—enables B2B buyers to make informed decisions that align with their specific regional requirements and compliance standards.

Key takeaways for international buyers include:

- Compliance and Compatibility: Ensure that the plugs and sockets selected meet the regional electrical standards to prevent operational disruptions.

- Supplier Relationships: Establishing strong relationships with reliable manufacturers can lead to better pricing, quality assurance, and timely deliveries.

- Future-Proofing Purchases: As technology evolves, consider investing in adaptable and versatile plug types that can accommodate changing power needs.

As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for efficient and compliant electrical solutions will escalate. Now is the time to engage with suppliers who can provide innovative and compliant AC power solutions that will support your business’s sustainability and expansion goals. Take proactive steps in your sourcing strategy to stay ahead in this competitive landscape.