Master the Types of Dryers: Essential Insights for B2B

Introduction: Navigating the Global Market for types of dryers

In the ever-evolving landscape of global commerce, understanding the diverse types of dryers is essential for international B2B buyers. These industrial machines play a critical role across various sectors, including food processing, pharmaceuticals, textiles, and agriculture. By efficiently removing moisture from products, dryers not only enhance shelf life but also improve product quality, making them indispensable in today’s market.

This comprehensive guide delves deep into the various types of dryers available, such as rotary, fluidized bed, spray, and belt dryers, each suited for specific applications and materials. It examines the manufacturing processes and quality control measures necessary to ensure reliable performance, alongside insights into reputable suppliers and cost considerations. Furthermore, it provides an analysis of market trends that can inform strategic purchasing decisions.

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe—especially countries like Poland and the UK—this guide serves as a vital resource. It empowers decision-makers to navigate the complexities of sourcing industrial dryers effectively. By leveraging the insights presented, buyers can make informed choices that align with their operational needs and market demands, ultimately driving their businesses toward greater success.

Understanding types of dryers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rotary Dryers | Inclined rotating drum, internal flights for even drying | Food processing, minerals, animal feed | Pros: Continuous operation, good for bulk materials. Cons: Higher initial cost, requires maintenance. |

| Fluidized Bed Dryers | Particles suspended in hot air, excellent for uniform drying | Pharmaceuticals, grains, chemicals | Pros: Fast drying, uniformity. Cons: Limited to specific particle sizes, may require additional equipment. |

| Spray Dryers | Atomization of liquid feed into fine droplets, rapid drying | Dairy products, pharmaceuticals, food additives | Pros: Efficient for heat-sensitive products. Cons: Complex setup, may have high operational costs. |

| Belt Dryers | Material spread on moving belt, controlled environment | Fruits, vegetables, chemicals | Pros: Scalability, easy operation. Cons: Limited to flat products, potential for uneven drying. |

| Drum Dryers | Rotating drums for liquid feed dehydration | Baby food, starches, instant products | Pros: Continuous process, good for large volumes. Cons: Less effective for delicate materials, higher energy consumption. |

Rotary Dryers

Rotary dryers feature a slightly inclined rotating drum equipped with internal flights that lift and tumble materials to ensure even drying. This type is particularly suitable for bulk materials like grains, minerals, and animal feed. When considering a rotary dryer, buyers should evaluate the initial investment against the operational efficiency and maintenance requirements, as these dryers can be more complex to maintain.

Fluidized Bed Dryers

Fluidized bed dryers utilize a mechanism where hot air flows upwards through a bed of particles, causing them to become suspended or “fluidized.” This method is ideal for drying powdered and granular materials, making it popular in the pharmaceutical and agricultural sectors. Buyers should consider the specific particle size and moisture content of the materials being processed, as fluidized bed dryers may require additional equipment for optimal performance.

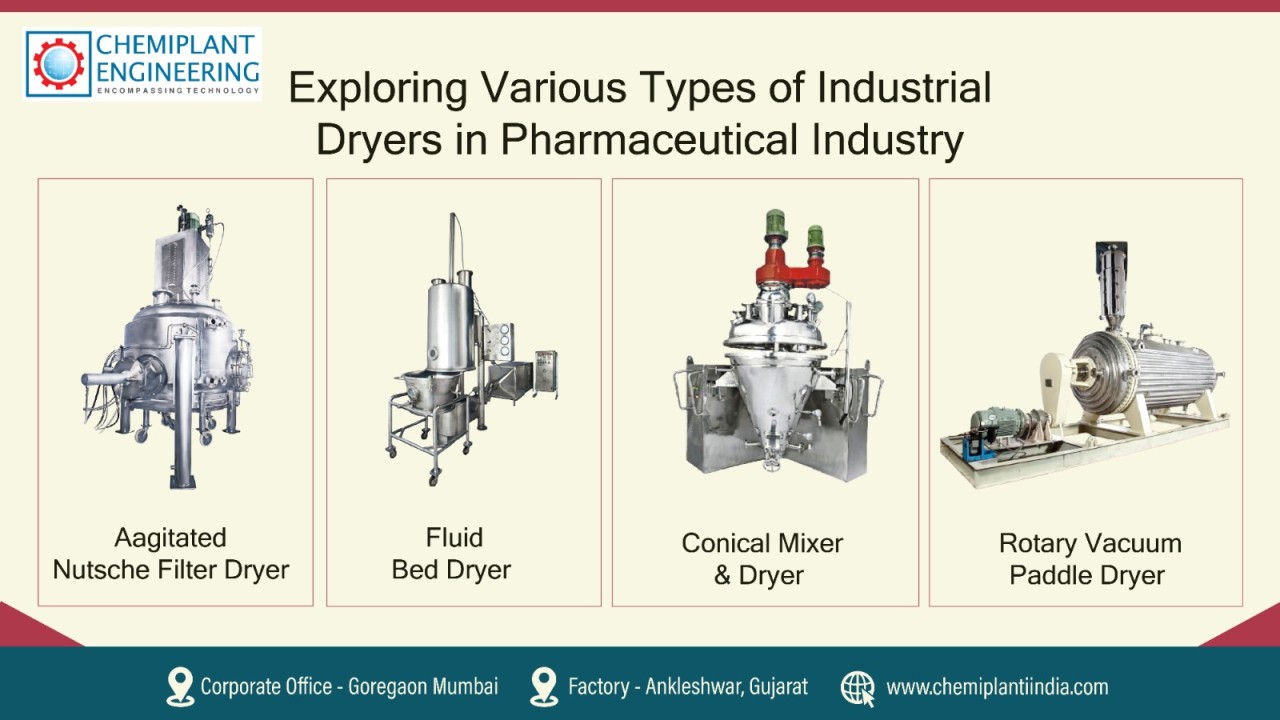

Illustrative Image (Source: Google Search)

Spray Dryers

Spray dryers are designed to convert liquid feed into fine powders through rapid atomization and drying. This technology is commonly employed in the dairy and pharmaceutical industries for products that are sensitive to heat. Buyers must assess the complexity of the setup and the operational costs, as spray drying can be more expensive but offers superior efficiency for heat-sensitive materials.

Belt Dryers

Belt dryers operate by spreading materials on a moving belt within a heated chamber, allowing for controlled drying. This type is versatile and can handle various products, including fruits, vegetables, and chemicals. When purchasing a belt dryer, buyers should consider the scalability and ease of operation, although they may face challenges with uneven drying if the material is not uniformly distributed.

Drum Dryers

Drum dryers consist of one or two rotating drums that dehydrate liquid feeds into powders or flakes. This method is effective for large volumes of products like baby food and starches. Buyers should weigh the benefits of continuous processing against the potential for higher energy consumption and the limitations for drying delicate materials.

Related Video: Types of Dryers

Key Industrial Applications of types of dryers

| Industry/Sector | Specific Application of Types of Dryers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Drying fruits and vegetables using belt dryers | Extends shelf life and preserves nutritional value | Consider energy efficiency, capacity, and compliance with food safety standards. |

| Pharmaceuticals | Spray drying for active pharmaceutical ingredients | Ensures product stability and consistency in dosage forms | Assess compatibility with sensitive compounds and regulatory compliance. |

| Agriculture | Rotary dryers for grains and seeds | Reduces moisture content, preventing spoilage and enhancing storage | Evaluate throughput capacity and adaptability to various crop types. |

| Textiles | Fluidized bed dryers for fabric drying | Improves production speed and quality of the final product | Look for customization options for different fabric types and energy consumption. |

| Chemical Manufacturing | Drum dryers for polymer resins | Facilitates rapid processing and enhances product quality | Focus on material compatibility and maintenance requirements. |

Food Processing

Belt dryers are widely used in the food processing industry to dry fruits and vegetables. This application is crucial for extending the shelf life of perishable goods while preserving their nutritional value. For international buyers, especially from regions with diverse agricultural outputs like Africa and South America, sourcing belt dryers should involve considerations such as energy efficiency, capacity to handle varying batch sizes, and compliance with local food safety standards. Efficient drying processes not only minimize waste but also enhance product marketability.

Pharmaceuticals

In the pharmaceutical sector, spray dryers are employed to convert liquid formulations into fine powders. This method is essential for producing active pharmaceutical ingredients (APIs) that require precise dosage forms and stability. Buyers from Europe and the Middle East must ensure that their sourcing aligns with stringent regulatory standards, particularly regarding the compatibility of spray dryers with sensitive compounds. Additionally, understanding the technology’s capacity to deliver consistent results is vital for maintaining product quality and efficacy.

Agriculture

Rotary dryers play a pivotal role in the agricultural industry by effectively drying grains and seeds. This process reduces moisture content, preventing spoilage and enhancing the storage life of agricultural products. For B2B buyers in Africa and South America, it is important to evaluate the dryer’s throughput capacity and its adaptability to different crop types. A reliable rotary dryer can significantly improve post-harvest processing efficiency, thus adding value to agricultural operations.

Textiles

Fluidized bed dryers are utilized in the textile industry for the drying of fabrics. This technology not only enhances the production speed but also improves the quality of the final product by ensuring uniform drying. Buyers from Europe, particularly in countries like Poland and the UK, should consider customization options that cater to various fabric types and the energy consumption of the dryers. Investing in efficient drying technology can lead to lower operational costs and increased competitiveness in the textile market.

Chemical Manufacturing

Drum dryers are commonly used in the chemical manufacturing sector to process polymer resins. This application facilitates rapid drying and enhances the quality of the end product. For international buyers, it is essential to focus on the compatibility of the dryer with various materials and the maintenance requirements to ensure long-term operational efficiency. Understanding these factors can help businesses streamline their production processes and reduce downtime, ultimately improving profitability.

Related Video: Dryers and its types

Strategic Material Selection Guide for types of dryers

When selecting materials for industrial dryers, it is crucial for international B2B buyers to consider the specific properties of each material, their advantages and disadvantages, and how these factors impact the intended application. Below is an analysis of four common materials used in the construction of dryers, focusing on their performance characteristics, suitability for various applications, and considerations for buyers from diverse regions.

Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, high-temperature tolerance (up to 800°C), and good mechanical strength. It is often used in environments where hygiene is paramount, such as food processing and pharmaceuticals.

Pros & Cons: The durability of stainless steel makes it ideal for long-term use, reducing maintenance costs. However, it is more expensive than other materials, which may impact initial investment costs. Manufacturing complexity can also be higher due to the need for specialized welding techniques.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive substances. Its non-reactive nature ensures that no unwanted chemical reactions occur during the drying process, making it suitable for sensitive applications.

Considerations for Buyers: Buyers in regions like Europe and the Middle East should ensure compliance with EU regulations regarding food safety and material standards. Familiarity with ASTM and DIN standards can guide the selection of appropriate grades of stainless steel.

Carbon Steel

Key Properties: Carbon steel is known for its high strength and ability to withstand significant pressure, making it suitable for high-capacity dryers. However, it has lower corrosion resistance compared to stainless steel and may require protective coatings.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness, making it an attractive option for large-scale operations. However, its susceptibility to rust and corrosion can lead to higher maintenance costs over time, especially in humid environments.

Impact on Application: Carbon steel is suitable for drying non-corrosive materials. Its use in applications involving moisture-laden products requires careful consideration of protective measures to prevent degradation.

Considerations for Buyers: Buyers from Africa and South America should assess local environmental conditions when choosing carbon steel. Understanding local standards, such as JIS for Japan or ASTM for the U.S., can aid in selecting the right protective coatings for specific applications.

Aluminum

Key Properties: Aluminum is lightweight and has excellent thermal conductivity, making it efficient for heat transfer applications. It can withstand temperatures up to 400°C and is resistant to corrosion when anodized.

Pros & Cons: The lightweight nature of aluminum allows for easier handling and installation, which can reduce labor costs. However, it is less durable than stainless or carbon steel and can be more expensive than carbon steel for certain applications.

Impact on Application: Aluminum is particularly effective for drying applications involving lightweight materials or where rapid heating is required. Its thermal properties make it ideal for processes that require quick temperature changes.

Considerations for Buyers: Buyers in Europe and the Middle East should be aware of the need for anodizing or other protective treatments to enhance corrosion resistance. Compliance with local standards for aluminum alloys is essential for ensuring product quality.

Composite Materials

Key Properties: Composite materials, often made from a combination of polymers and fibers, offer unique properties such as lightweight construction and resistance to corrosion and chemicals. They can be engineered for specific thermal properties.

Pros & Cons: The versatility of composites allows for tailored solutions for specific drying applications. However, they can be more expensive than traditional materials and may have limitations in high-temperature applications.

Impact on Application: Composites are particularly useful in industries where chemical resistance is critical, such as pharmaceuticals and certain food applications. Their lightweight nature can also improve energy efficiency in dryer operations.

Considerations for Buyers: Buyers from South America and Africa should evaluate the availability of composite materials in their regions, as well as compliance with international standards for safety and performance.

Summary Table

| Material | Typical Use Case for types of dryers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher initial investment | High |

| Carbon Steel | Bulk drying of non-corrosive materials | Cost-effective for large operations | Susceptible to rust | Low |

| Aluminum | Lightweight materials, rapid heating | Lightweight and good thermal conductivity | Less durable than steel | Medium |

| Composite Materials | Chemical processing, pharmaceuticals | Customizable properties | Higher cost and temperature limitations | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for types of dryers

Manufacturing Processes for Types of Dryers

The manufacturing of industrial dryers is a complex process that involves several key stages, ensuring that the final product meets both functional and quality standards. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding these processes can help in making informed purchasing decisions.

1. Material Preparation

The first stage in the manufacturing process involves selecting and preparing the appropriate materials. Common materials used in the construction of dryers include stainless steel, carbon steel, and specialized alloys that can withstand high temperatures and corrosive environments.

- Material Selection: The choice of material is crucial for durability and efficiency. For instance, stainless steel is favored for food-grade applications due to its resistance to corrosion and ease of cleaning.

- Pre-Treatment: Materials often undergo treatments such as annealing or surface hardening to enhance their properties before fabrication.

2. Forming

In this stage, the prepared materials are shaped into the required components for the dryer. Different techniques are utilized depending on the type of dryer being manufactured.

- Cutting and Machining: Laser cutting, water jet cutting, or CNC machining are employed to create precise components such as drum sections, frames, and nozzles.

- Welding and Assembly: Various welding techniques, including TIG and MIG welding, are used to join metal parts. The assembly process may involve both automated and manual labor to ensure accuracy and quality.

3. Assembly

Once individual components are formed, the next step is to assemble them into a complete dryer unit. This is where the design and engineering expertise come into play.

- Integration of Systems: Components such as heating elements, control systems, and insulation are integrated. For example, in rotary dryers, the drum must be aligned precisely to ensure smooth operation.

- Quality Checks: During assembly, preliminary quality checks (known as In-Process Quality Control or IPQC) are conducted to catch any defects early in the process.

4. Finishing

The final stage includes surface finishing and testing to ensure the dryer meets quality standards.

- Surface Treatment: Depending on the application, surface treatments such as powder coating or anodizing may be applied to enhance corrosion resistance and improve aesthetics.

- Final Assembly and Testing: The dryer undergoes final assembly, followed by rigorous testing to ensure functionality. This includes operational tests under simulated conditions to verify performance metrics.

Quality Assurance in Dryer Manufacturing

Quality assurance is critical in the manufacturing of dryers, particularly for B2B buyers who require reliability and compliance with international standards.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS). Manufacturers with ISO 9001 certification demonstrate a commitment to quality management practices.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For dryers used in the oil and gas industry, adhering to API (American Petroleum Institute) standards is essential for ensuring safety and reliability.

Quality Control Checkpoints

Quality control (QC) checkpoints are integrated at various stages of the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify defects before assembly.

- Final Quality Control (FQC): The completed dryer undergoes final inspections, including performance testing and safety checks, to ensure it meets all specifications.

Common Testing Methods

Testing methods for industrial dryers may include:

- Thermal Efficiency Testing: Measures how effectively the dryer removes moisture from materials.

- Pressure Testing: Ensures that the dryer can withstand operational pressures without failure.

- Vibration Testing: Checks for mechanical stability and potential failure points during operation.

Verifying Supplier Quality Control

For international B2B buyers, verifying the quality control processes of suppliers is vital to ensure they meet your requirements. Here are several strategies:

- Supplier Audits: Conduct regular audits of potential suppliers to assess their manufacturing processes, quality control measures, and compliance with international standards.

- Request for Reports: Ask suppliers for their quality control reports and certifications. This includes ISO certifications and test reports from third-party laboratories.

- Third-Party Inspections: Engage third-party inspection services to evaluate the supplier’s production facilities and processes before making a purchase.

Quality Control Nuances for International Buyers

B2B buyers from Africa, South America, the Middle East, and Europe may encounter specific challenges and nuances in quality control:

- Cultural Differences: Understanding cultural attitudes toward quality and compliance can influence supplier relationships. Building strong communication channels is essential.

- Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should be aware of local regulations that might affect the quality and safety of dryers.

- Supply Chain Considerations: Disruptions in the supply chain can impact the availability of quality materials. Establishing strong relationships with multiple suppliers can mitigate this risk.

In conclusion, comprehending the manufacturing processes and quality assurance standards of industrial dryers is crucial for B2B buyers. By focusing on these elements, businesses can ensure they source reliable, efficient, and compliant products that meet their operational needs.

Comprehensive Cost and Pricing Analysis for types of dryers Sourcing

Understanding the Cost Structure of Industrial Dryers

When sourcing industrial dryers, it is essential to comprehend the various cost components that contribute to the overall pricing. Key elements include:

-

Materials: The type and quality of materials used in manufacturing the dryer significantly affect costs. High-grade metals, insulation, and specialized components can increase the base price.

-

Labor: Skilled labor is required for assembly and quality control. Regions with higher labor costs, such as parts of Europe, may see a direct impact on pricing.

-

Manufacturing Overhead: This encompasses utilities, rent, and other operational costs associated with the manufacturing facility. Efficient manufacturing processes can help reduce this overhead.

-

Tooling: The cost of molds and tools necessary for production must also be factored in. Custom tooling for specialized dryers can lead to higher initial costs but may be justified by efficiency gains.

-

Quality Control (QC): Rigorous QC processes ensure that the dryers meet industry standards and certifications, which can add to the cost but are essential for reliability and safety.

-

Logistics: Shipping and handling costs are crucial, particularly for international shipments. Import duties and tariffs can also significantly impact the total cost.

-

Margin: Suppliers will typically add a profit margin to the base cost, which varies based on market conditions and competition.

Price Influencers in Dryer Sourcing

Several factors can influence the pricing of industrial dryers:

-

Volume/MOQ: Suppliers often provide discounts for larger orders. Understanding the minimum order quantity (MOQ) can lead to significant savings.

-

Specifications and Customization: Custom-designed dryers tailored to specific requirements can increase costs. Buyers should assess whether standard models can meet their needs.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but may enhance performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier play a vital role in pricing. Established suppliers may charge a premium for their products due to their track record.

-

Incoterms: The agreed terms of shipping (e.g., FOB, CIF) can affect the final cost, especially concerning who bears the risk and costs of shipping.

Buyer Tips for Cost Efficiency

To maximize value when sourcing industrial dryers, consider the following strategies:

-

Negotiate: Engage suppliers in discussions regarding pricing, especially if you can commit to larger volumes or longer-term contracts. Leverage competitive quotes to your advantage.

-

Total Cost of Ownership (TCO): Evaluate not just the upfront price but also maintenance costs, energy consumption, and lifespan of the dryer. A higher initial investment may lead to lower operational costs over time.

-

Understand Pricing Nuances: International buyers should be aware of fluctuations in currency exchange rates, local tariffs, and shipping costs. These factors can significantly alter the effective price.

-

Research Local Regulations: Ensure that the dryers meet the regulatory requirements of your region, as non-compliance can lead to additional costs in modifications or penalties.

-

Utilize Technology: Consider using procurement platforms that can streamline the sourcing process and provide insights into competitive pricing trends.

Conclusion

Sourcing industrial dryers requires a thorough understanding of the cost structure and pricing influences. By focusing on the elements outlined above, international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, can make informed decisions that optimize their purchasing strategies. Keep in mind that the prices discussed are indicative and may vary based on specific circumstances and market conditions.

Spotlight on Potential types of dryers Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of dryers’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of dryers

When sourcing industrial dryers, understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions. This knowledge helps buyers from diverse regions, including Africa, South America, the Middle East, and Europe, navigate the complexities of the drying equipment market effectively.

Key Technical Properties of Industrial Dryers

-

Material Grade

– Definition: This refers to the quality and type of materials used in the construction of the dryer, such as stainless steel, carbon steel, or specialized alloys.

– Importance: Higher-grade materials offer better resistance to corrosion and wear, which is vital in harsh industrial environments. Buyers should assess the material grade to ensure longevity and reliability, particularly in food processing or chemical applications. -

Heat Transfer Efficiency

– Definition: This measures how effectively a dryer can transfer heat to the material being dried, usually expressed in BTUs (British Thermal Units) or kW (kilowatts).

– Importance: Efficient heat transfer reduces energy consumption and operational costs. Understanding this property enables buyers to choose dryers that align with their energy efficiency goals. -

Drying Capacity

– Definition: This indicates the amount of material a dryer can process within a specific time frame, typically expressed in kilograms per hour or tons per day.

– Importance: Knowing the drying capacity helps businesses plan production schedules and avoid bottlenecks. Buyers should match this specification with their operational needs to ensure efficiency. -

Operating Temperature Range

– Definition: The temperature range within which the dryer can effectively operate, often specified in degrees Celsius or Fahrenheit.

– Importance: Different materials require different drying temperatures. Understanding the operating temperature range is essential for processing sensitive materials without degradation.

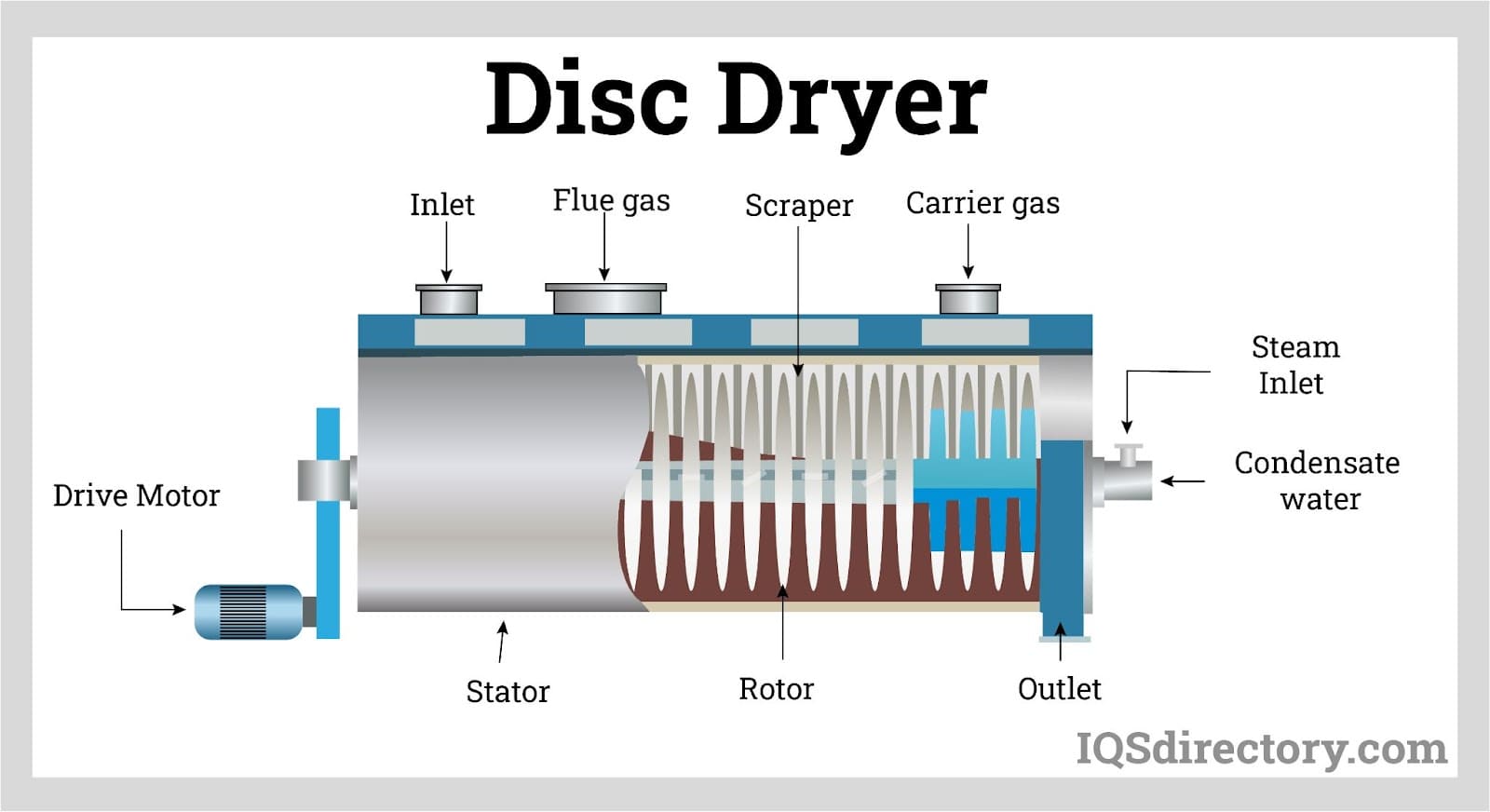

Illustrative Image (Source: Google Search)

- Moisture Removal Rate

– Definition: This is the rate at which moisture is extracted from the material, often measured in percentage or grams of moisture removed per hour.

– Importance: A higher moisture removal rate can lead to quicker processing times, which is beneficial for production efficiency. This property is especially crucial for industries like food and pharmaceuticals.

Common Trade Terminology

-

OEM (Original Equipment Manufacturer)

– Explanation: Refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of dryers, it pertains to manufacturers who provide the original equipment for industrial applications.

– Relevance: Buyers should consider OEM relationships to ensure they are sourcing reliable and compatible equipment that meets industry standards. -

MOQ (Minimum Order Quantity)

– Explanation: The smallest quantity of a product that a supplier is willing to sell. This term is critical in negotiations.

– Relevance: Understanding MOQ helps buyers evaluate their purchasing power and negotiate better terms, particularly when sourcing from international suppliers. -

RFQ (Request for Quotation)

– Explanation: A document sent by buyers to suppliers requesting pricing and other details for specific products or services.

– Relevance: A well-structured RFQ can streamline the procurement process, ensuring that buyers receive accurate and competitive quotes tailored to their needs. -

Incoterms (International Commercial Terms)

– Explanation: A set of international rules that define the responsibilities of sellers and buyers in the shipping process.

– Relevance: Familiarity with Incoterms helps buyers understand the logistics, costs, and risks associated with transporting equipment, essential for international trade. -

Lead Time

– Explanation: The time it takes from placing an order to receiving the goods.

– Relevance: Knowing the lead time is crucial for production planning and inventory management. Buyers should account for this in their procurement timelines to avoid disruptions.

By grasping these technical properties and trade terms, international B2B buyers can enhance their understanding of industrial dryers, facilitating better decision-making and more effective negotiations in a competitive marketplace.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of dryers Sector

Market Overview & Key Trends

The industrial dryer market is experiencing significant growth, driven by the increasing demand for processed food, pharmaceuticals, and other materials that require moisture removal. Key trends influencing this sector include the rise of automation and smart technology, which enhance efficiency and reduce operational costs. Innovations such as IoT-enabled dryers allow for real-time monitoring and predictive maintenance, providing international B2B buyers with improved operational insights.

In regions like Africa and South America, where agricultural processing is vital, the demand for efficient drying solutions is surging. In Europe, particularly in countries like Poland and the UK, stringent regulations on product quality and safety are pushing manufacturers to adopt advanced drying technologies. Additionally, the Middle East is witnessing a growing trend towards energy-efficient dryers due to rising energy costs and environmental concerns.

Buyers should be aware of the increasing variety of dryer types, such as rotary, fluidized bed, and spray dryers, each suited to specific materials and processes. Understanding these options will enable international buyers to select the right technology that aligns with their operational needs and market demands.

Sustainability & Ethical Sourcing in B2B

The environmental impact of industrial dryers cannot be overlooked. Energy consumption and emissions from traditional drying methods pose significant challenges. Therefore, sustainability is becoming a critical factor in the purchasing decisions of B2B buyers. Buyers are encouraged to seek out suppliers who adhere to sustainable practices, such as using energy-efficient technologies and renewable energy sources in their operations.

Ethical sourcing is equally important. Buyers should prioritize suppliers that offer transparency in their supply chains and demonstrate a commitment to reducing their environmental footprint. Certifications such as ISO 14001 for environmental management and Energy Star ratings can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the use of eco-friendly materials in the construction of dryers is gaining traction. This includes non-toxic coatings and recyclable components, which not only reduce the environmental impact but also appeal to consumers increasingly concerned about sustainability.

Brief Evolution/History

The evolution of industrial dryers dates back to the early 20th century when simple mechanical systems were employed for moisture removal. As industries expanded, particularly in food processing and pharmaceuticals, the need for more sophisticated drying technologies became evident. The introduction of rotary and spray dryers revolutionized the sector, allowing for higher efficiency and better product quality.

In recent decades, advancements in materials science and engineering have led to the development of energy-efficient and automated drying solutions. Today, the focus is not only on performance but also on sustainability and ethical sourcing, reflecting the growing awareness of environmental issues among businesses and consumers alike. This historical context is crucial for international B2B buyers as they navigate an increasingly complex market landscape.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of types of dryers

-

What criteria should I consider when vetting suppliers for industrial dryers?

When vetting suppliers, focus on their industry experience, production capacity, and customer reviews. Verify certifications such as ISO 9001 for quality management and CE marking for compliance with EU standards. Request case studies or references from clients in your region. Additionally, assess their after-sales support, including warranty terms and maintenance services, as this can significantly impact your operational efficiency. -

Can I customize the drying equipment to meet my specific needs?

Many suppliers offer customization options for industrial dryers. Discuss your requirements in detail, including material types, moisture content, and production volume. Ensure that the supplier has the capability to adapt their designs or technologies. It’s beneficial to request prototypes or pilot runs to evaluate the effectiveness of any modifications before committing to a full order. -

What are the typical minimum order quantities (MOQ) and lead times for industrial dryers?

MOQs can vary widely based on the supplier and the complexity of the dryer. Generally, for standard models, the MOQ might be one unit, while customized units could require higher quantities. Lead times typically range from 4 to 12 weeks, depending on the supplier’s production schedule and the complexity of customization. Always confirm these details during negotiations to align your procurement strategy with your operational timelines. -

What payment terms should I expect when purchasing industrial dryers?

Payment terms can vary among suppliers but typically include options such as a deposit upfront (often 30-50%) with the balance due before shipment. Some suppliers may offer financing options or extended payment terms based on your creditworthiness. It’s crucial to clarify these terms in the contract and consider using letters of credit for larger transactions to mitigate financial risks. -

How do I ensure quality assurance and certification compliance for the dryers I purchase?

Request documentation of quality assurance processes and relevant certifications from the supplier. Ensure that the dryers comply with international standards such as CE, UL, or ISO certifications that pertain to safety and performance. Consider conducting factory audits or third-party inspections to validate the supplier’s claims and ensure the equipment meets your quality requirements before shipping. -

What logistical considerations should I keep in mind when importing dryers?

Logistics play a crucial role in the procurement process. Consider shipping options, customs clearance procedures, and potential tariffs that may apply to your region. Work with a freight forwarder experienced in handling industrial equipment to ensure smooth transport. Additionally, factor in the time required for installation and commissioning upon arrival to avoid production delays. -

How can I effectively handle disputes with suppliers regarding dryer performance or delivery?

Clearly outline performance expectations, delivery timelines, and penalties for non-compliance in your contract. Maintain open communication with the supplier throughout the procurement process to address any issues as they arise. In case of a dispute, refer to the contract terms and consider mediation or arbitration as a resolution method. Document all communications and agreements to support your position if escalation is necessary. -

What role does after-sales service play in my decision to purchase a dryer?

After-sales service is critical in ensuring the longevity and efficiency of your dryer. Evaluate the supplier’s support offerings, including installation, training, and maintenance services. A robust after-sales program can minimize downtime and enhance productivity. Ensure that the supplier provides accessible technical support and spare parts availability to address any operational challenges you may face post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of dryers

In conclusion, understanding the diverse types of industrial dryers and their applications is crucial for B2B buyers seeking to optimize their operations. Key takeaways include recognizing the importance of selecting the right dryer type—be it rotary, fluidized bed, spray, belt, or drum dryers—tailored to specific material characteristics and industry demands. Strategic sourcing not only enhances product quality but also drives cost efficiency and operational effectiveness.

As international markets continue to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must prioritize reliable suppliers who can offer innovative solutions and robust support. Building partnerships with manufacturers that understand local conditions and requirements will be essential for sustained success.

Looking ahead, the dryer technology landscape is poised for advancements, particularly in energy efficiency and automation. B2B buyers are encouraged to stay informed about emerging trends and technologies that can further enhance their drying processes. By leveraging strategic sourcing and fostering strong supplier relationships, companies can ensure they remain competitive and agile in an increasingly global marketplace. Engage proactively with suppliers to explore tailored solutions that meet your unique drying needs and drive your business forward.