Master Voto Manufacturers Sales: A Comprehensive B2B

Introduction: Navigating the Global Market for voto manufacturers sales

Navigating the complex landscape of voto manufacturers sales is essential for international B2B buyers seeking reliable industrial solutions. Voto manufacturers, such as the well-established Voto Manufacturers Sales Company, play a pivotal role in supplying high-quality products that enhance operational efficiency across diverse sectors. As an ISO 9001:2015 certified entity, Voto exemplifies the standard of excellence that buyers can expect when sourcing from reputable manufacturers.

This comprehensive guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe by providing insights into various aspects of voto manufacturers sales. It covers essential topics, including the types of products available, the materials used in manufacturing, quality control processes, supplier evaluations, cost considerations, market trends, and frequently asked questions. Each section is designed to equip buyers with the knowledge needed to make informed sourcing decisions, ensuring that they select the right products tailored to their specific needs.

Understanding the voto manufacturing landscape not only helps buyers optimize their supply chains but also enhances their competitive edge in the global market. With this guide, international buyers can confidently navigate the complexities of sourcing, ultimately driving operational success and fostering long-term partnerships with trusted manufacturers.

Understanding voto manufacturers sales Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigging Solutions | Includes wire ropes, chains, hoists, and custom hardware. | Construction, shipping, and heavy machinery industries. | Pros: High safety standards, customizable. Cons: Can be costly depending on specifications. |

| Earth Moving Equipment | Ground-engaging tools like buckets, teeth, and adapters. | Construction, mining, and excavation projects. | Pros: Enhances productivity, durable materials. Cons: Requires proper training for effective use. |

| Custom Hose Solutions | Tailored hydraulic, air, and chemical hoses with fittings. | Manufacturing, automotive, and industrial processes. | Pros: Optimized for specific applications, reliable. Cons: Longer lead times for custom orders. |

| Steel Products | High-strength steel, abrasion-resistant options, cut-to-order. | Construction, manufacturing, and fabrication sectors. | Pros: Excellent durability and performance. Cons: May require additional processing for specific applications. |

| Inspection Services | Quality assurance and compliance checks for products. | Industrial sectors requiring regulatory compliance. | Pros: Ensures safety and quality standards. Cons: Additional costs for inspection services. |

Rigging Solutions

Rigging solutions are essential for industries that rely on lifting heavy objects. This category encompasses wire ropes, chains, hoists, and specialized rigging hardware. Buyers should consider the safety standards and certifications associated with these products, as they are crucial for compliance in construction and shipping operations. Customization options are available, enabling businesses to tailor solutions to their specific lifting requirements, although this may increase costs.

Earth Moving Equipment

Earth moving equipment includes a range of ground-engaging tools such as buckets, teeth, and adapters designed for heavy machinery. These products are critical in construction and mining, where efficiency and durability are paramount. When purchasing, B2B buyers should evaluate the compatibility of these tools with their existing machinery and consider the training requirements for their teams to ensure effective use. The long-term benefits of investing in high-quality tools can significantly enhance productivity.

Custom Hose Solutions

Custom hose solutions provide tailored options for hydraulic, air, and chemical applications. These hoses are manufactured to meet specific operational needs, ensuring optimal performance in various industrial settings. Buyers should assess the lead times for custom orders, as these can vary based on complexity. Additionally, the reliability of these hoses is essential for maintaining seamless operations, making it crucial to partner with reputable manufacturers who offer quality assurance.

Steel Products

Steel products are foundational in many industries, offering high-strength and abrasion-resistant options that can be cut to order. These materials are widely used in construction and manufacturing, where durability is key. Buyers should consider the specific requirements of their projects, including any processing that may be needed to fit their applications. While the initial investment in high-quality steel may be higher, the long-term benefits in terms of performance and longevity often justify the cost.

Inspection Services

Inspection services play a vital role in ensuring the quality and compliance of products used in industrial applications. These services help businesses meet regulatory requirements and maintain safety standards, which is particularly important in sectors such as construction and manufacturing. B2B buyers should weigh the added costs of these services against the potential risks of non-compliance. Investing in thorough inspections can prevent costly issues down the line and enhance overall operational reliability.

Key Industrial Applications of voto manufacturers sales

| Industry/Sector | Specific Application of voto manufacturers sales | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Excavation | Custom wire rope and rigging solutions for heavy lifting operations | Enhances safety and efficiency in lifting heavy materials | Ensure compliance with local safety standards and certifications |

| Mining | Durable ground-engaging products for earth-moving machinery | Increases productivity and reduces operational downtime | Assess product durability and compatibility with existing equipment |

| Oil & Gas | High-strength hoses for hydraulic and chemical transfer | Ensures safe and reliable transport of fluids | Verify resistance to harsh chemicals and pressure requirements |

| Manufacturing | Custom fabricated metal products for machinery parts | Improves machinery performance and longevity | Evaluate precision and customization options available |

| Agriculture | Agricultural equipment rigging and lifting solutions | Enhances operational efficiency in farming equipment operations | Consider local agricultural practices and equipment specifications |

Detailed Applications

Construction & Excavation

Voto Manufacturers Sales excels in providing custom wire rope and rigging solutions tailored for heavy lifting operations in the construction and excavation sectors. These products are crucial for safely moving heavy materials, ensuring that projects are completed efficiently and without accidents. For international buyers, particularly from regions like Africa and South America, it is essential to ensure that the rigging solutions comply with local safety regulations and certifications, which can vary significantly across countries.

Mining

In the mining industry, Voto’s durable ground-engaging products, such as bucket teeth and cutting edges, are vital for enhancing the performance of earth-moving machinery. These components are designed to withstand harsh conditions and heavy use, thus minimizing wear and tear. Buyers should assess the durability and compatibility of these products with existing machinery, as this can significantly impact operational efficiency and reduce downtime.

Oil & Gas

Voto’s high-strength hoses are essential for the oil and gas industry, particularly for hydraulic and chemical transfer applications. These hoses are engineered to handle high pressure and resist harsh chemicals, ensuring safe and reliable transport of fluids. International B2B buyers must verify that the hoses meet specific resistance requirements for their local environments, which can include extreme temperatures and corrosive substances.

Manufacturing

For the manufacturing sector, Voto offers custom fabricated metal products that can enhance machinery performance. These products are tailored to meet precise specifications, which can significantly improve the longevity and efficiency of manufacturing processes. Buyers should consider the level of customization available and ensure that the products align with their operational needs and standards.

Agriculture

In agriculture, Voto provides rigging and lifting solutions that enhance the efficiency of farming equipment operations. These solutions are essential for tasks such as lifting heavy machinery or moving large loads of produce. Buyers in this sector should consider local agricultural practices and specific equipment specifications to ensure that the rigging solutions are suitable for their operational needs, especially in diverse environments like those found in Europe and the Middle East.

Related Video: Uses and Gratifications Theory – UGT

Strategic Material Selection Guide for voto manufacturers sales

When selecting materials for products in the Voto Manufacturers Sales portfolio, it is essential to consider the unique properties, advantages, and limitations of each material. This guide analyzes four common materials used in the manufacturing of industrial products, focusing on their performance characteristics, application impacts, and considerations for international B2B buyers.

Steel

Key Properties:

Steel is known for its high tensile strength, durability, and versatility. It can withstand high temperatures and pressures, making it suitable for various industrial applications. Additionally, different grades of steel can provide varying levels of corrosion resistance.

Pros & Cons:

The primary advantage of steel is its strength, which allows for the manufacturing of robust products that can handle heavy loads. However, steel can be susceptible to corrosion if not properly treated or coated, which can limit its lifespan in certain environments. The cost of steel can vary significantly based on the grade and treatment processes.

Impact on Application:

Steel is commonly used in rigging hardware, earth-moving equipment, and structural components. Its compatibility with heavy-duty applications makes it ideal for industries such as construction and mining.

Considerations for International Buyers:

Buyers should be aware of compliance with international standards such as ASTM and ISO. In regions like Africa and South America, local regulations may dictate specific grades of steel for construction and safety purposes.

Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal and electrical conductivity. It performs well in various temperatures, although it has lower tensile strength compared to steel.

Pros & Cons:

The main advantage of aluminum is its weight, which can reduce shipping costs and improve the efficiency of machinery. However, its lower strength may limit its use in heavy-load applications. Additionally, aluminum can be more expensive than steel, particularly for high-grade alloys.

Impact on Application:

Aluminum is often used in applications where weight savings are critical, such as in lifting devices and custom assemblies. Its corrosion resistance makes it suitable for environments exposed to moisture.

Considerations for International Buyers:

International buyers should consider the availability of aluminum alloys that meet local standards. In regions like the Middle East, where high temperatures can affect material performance, selecting the right aluminum grade is crucial.

Rubber

Key Properties:

Rubber is highly elastic, providing excellent vibration dampening and shock absorption. It is also resistant to many chemicals and has good temperature tolerance, though it can degrade under UV exposure.

Pros & Cons:

Rubber’s flexibility and durability make it ideal for hoses and seals. However, it can be less durable than metal alternatives in high-pressure applications. The cost of rubber products can vary based on the type and quality of rubber used.

Impact on Application:

Rubber is commonly used in hydraulic hoses and seals, where flexibility and chemical resistance are critical. Its compatibility with various media makes it a versatile choice for many industrial applications.

Considerations for International Buyers:

Buyers should ensure that rubber products meet relevant standards such as ASTM D2000 for rubber materials. In regions like Europe, compliance with REACH regulations regarding chemical safety is also essential.

Composite Materials

Key Properties:

Composite materials combine two or more materials to achieve superior properties, such as lightweight strength and corrosion resistance. They can be engineered for specific applications, providing tailored performance characteristics.

Pros & Cons:

The key advantage of composites is their ability to be customized for specific applications, offering benefits like reduced weight and enhanced durability. However, they can be more expensive to manufacture and may require specialized handling and processing.

Impact on Application:

Composites are increasingly used in high-performance applications, such as in aerospace and advanced machinery. Their resistance to corrosion and fatigue makes them suitable for demanding environments.

Considerations for International Buyers:

International buyers should be aware of the specific standards and certifications required for composite materials in their region. In South America and Africa, understanding local manufacturing capabilities for composites is crucial for successful sourcing.

Summary Table

| Material | Typical Use Case for voto manufacturers sales | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Rigging hardware, structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lifting devices, custom assemblies | Lightweight and corrosion-resistant | Lower strength compared to steel | High |

| Rubber | Hydraulic hoses, seals | Excellent flexibility and dampening | Less durable in high-pressure uses | Medium |

| Composite Materials | High-performance machinery components | Customized properties for specific needs | Higher manufacturing costs | High |

This strategic material selection guide should assist international B2B buyers in making informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for voto manufacturers sales

The manufacturing processes and quality assurance systems employed by Voto Manufacturers Sales are critical for ensuring the reliability and performance of their extensive range of industrial products. Understanding these processes can empower international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Manufacturing Processes

1. Material Preparation

The initial phase of the manufacturing process involves sourcing high-quality raw materials, which are essential for product durability and performance. Voto Manufacturers Sales prioritizes the selection of materials that meet industry standards, including carbon and high-strength steel, and abrasion-resistant materials. Suppliers are evaluated based on their ability to provide materials that adhere to relevant specifications, which is crucial for maintaining product integrity.

2. Forming

Once materials are prepared, they undergo various forming techniques to achieve the desired shapes and specifications. Common techniques include:

- Cutting: This includes methods such as laser cutting and water jet cutting, which provide precision and efficiency.

- Bending and Shaping: Techniques like roll forming and stamping are utilized to create specific geometries, especially for steel components.

- Welding: Advanced welding methods, including MIG and TIG welding, ensure strong and durable joints, particularly in complex assemblies.

These techniques are vital for ensuring that the products can withstand the rigorous demands of industrial applications.

3. Assembly

The assembly stage involves integrating various components into final products. Voto specializes in custom-made assemblies, particularly for industrial hose applications and rigging solutions. Key steps in this phase include:

- Component Inspection: Each component is checked against specifications before assembly to prevent defects.

- Final Assembly: Skilled technicians perform the assembly, often utilizing automated systems for efficiency and consistency.

4. Finishing

The finishing process enhances the product’s performance and aesthetic appeal. This includes:

- Coating: Protective coatings are applied to prevent corrosion and wear, particularly for products exposed to harsh environments.

- Surface Treatment: Techniques such as sandblasting or polishing improve surface quality and prepare products for final inspection.

Quality Assurance

Quality assurance is integral to Voto Manufacturers Sales’ operations, ensuring that products meet both international and industry-specific standards.

International Standards

Voto is ISO 9001:2015 certified, a testament to its commitment to quality management systems. This certification requires:

- Documentation: Maintaining comprehensive records of processes and procedures.

- Continuous Improvement: Regular evaluations and updates to processes based on performance metrics.

Industry-Specific Standards

In addition to ISO certification, Voto products may also comply with other standards such as CE marking for products sold in Europe and API specifications for oil and gas applications. These certifications assure buyers that products meet safety and performance criteria.

Quality Control Checkpoints

Quality control (QC) is embedded throughout the manufacturing process, with several key checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify issues early.

- Final Quality Control (FQC): A thorough inspection of finished products ensures they meet all defined standards before shipment.

Testing Methods

Common testing methods used by Voto include:

- Destructive Testing: Assessing the limits of materials by applying stress until failure to determine strength characteristics.

- Non-Destructive Testing (NDT): Methods like ultrasonic testing or magnetic particle inspection ensure product integrity without damaging the components.

- Functional Testing: Products undergo real-world simulations to verify that they perform as intended under operational conditions.

Verifying Supplier Quality Control

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is essential. Here are several actionable steps buyers can take:

-

Supplier Audits: Conduct regular audits of suppliers to evaluate their quality management systems and manufacturing processes. This can include on-site visits to observe operations directly.

-

Request Documentation: Buyers should request quality assurance documentation, including ISO certificates, QC reports, and test results. This information provides insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies conduct independent evaluations of products and processes, providing unbiased reports.

-

Feedback from Other Buyers: Gathering testimonials and feedback from other clients who have sourced products from the supplier can provide valuable insights into their reliability and quality.

Conclusion

Understanding the manufacturing processes and quality assurance systems in place at Voto Manufacturers Sales is crucial for B2B buyers looking to source high-quality industrial products. By familiarizing themselves with these processes and implementing robust verification strategies, buyers can make informed decisions that will ultimately enhance their operational efficiency and product reliability.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for voto manufacturers sales Sourcing

Understanding Cost Structure and Pricing for Voto Manufacturers Sales

When sourcing from Voto Manufacturers Sales, it’s essential to grasp the underlying cost structure and how it influences pricing. This knowledge can empower international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, to make informed purchasing decisions.

Cost Components

- Materials: The primary cost driver in manufacturing is the raw materials used. For Voto, this includes high-strength steel, wire rope, and various industrial components. Prices fluctuate based on global market conditions, quality, and sourcing location.

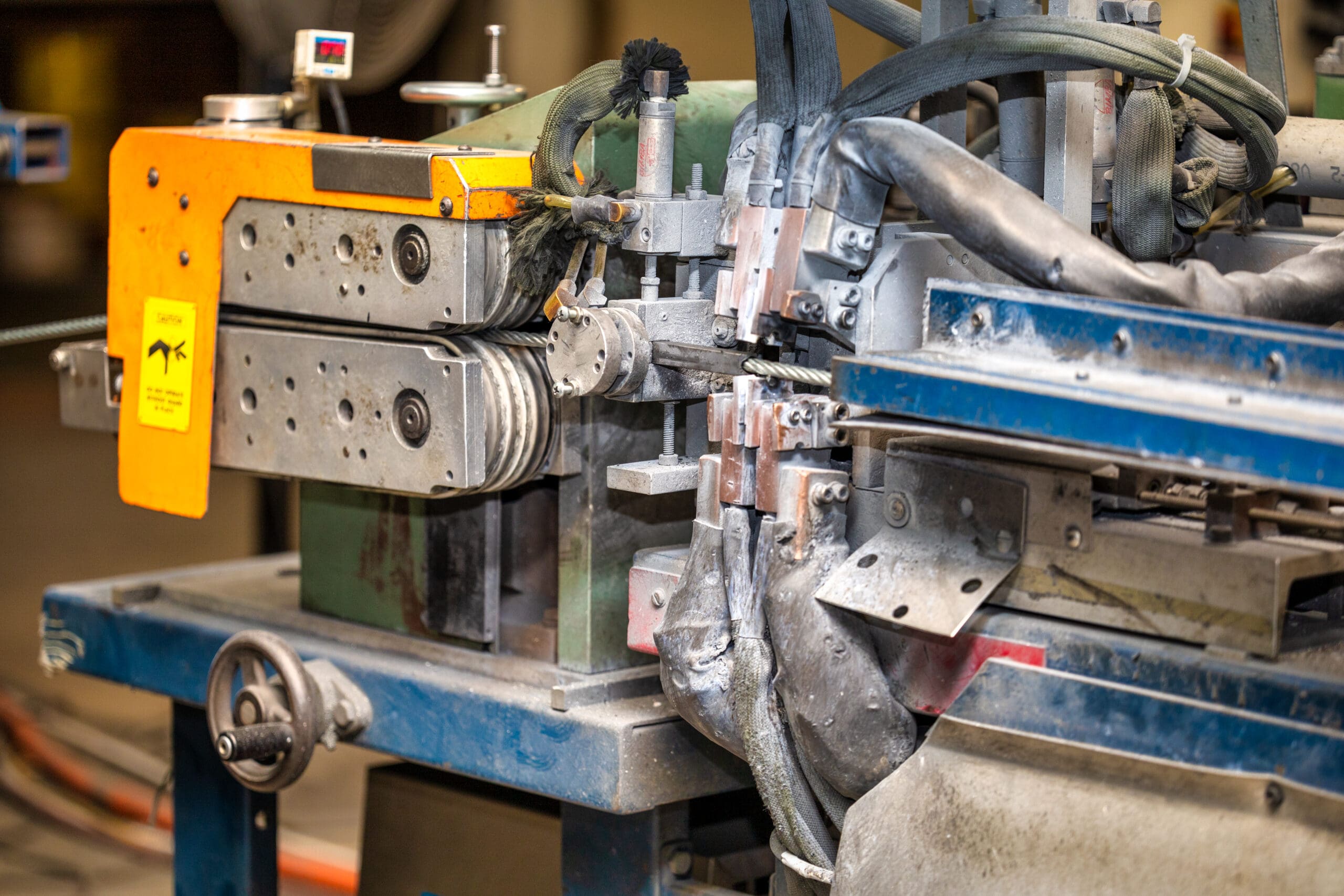

Illustrative Image (Source: Google Search)

-

Labor: Labor costs encompass wages for skilled workers involved in manufacturing and assembly. Voto’s commitment to quality and precision may necessitate a higher labor investment, influencing the final product cost.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient operations can help mitigate overhead costs, impacting overall pricing.

-

Tooling: Custom tooling for specific products can add to upfront costs. Buyers should consider whether the tooling cost is amortized over large production runs, which can lower the per-unit price.

-

Quality Control (QC): Rigorous QC processes ensure that products meet safety and performance standards. While this adds to the cost, it enhances product reliability, which is crucial for B2B buyers.

-

Logistics: Shipping and handling costs vary based on the destination, mode of transport, and volume of goods. Understanding these factors is vital, especially for international buyers dealing with customs and import regulations.

-

Margin: Voto, as a 100% employee-owned company, may have different margin expectations than traditional corporations. This aspect can influence pricing strategies and the flexibility available in negotiations.

Price Influencers

Several factors can affect pricing strategies at Voto Manufacturers Sales:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to discounts due to economies of scale. Buyers should assess their needs to optimize order sizes.

-

Specifications and Customization: Custom products or specific specifications can significantly affect pricing. Ensure that all requirements are clearly communicated to avoid unexpected costs.

-

Material Quality and Certifications: Products that require specific certifications (e.g., ISO, safety standards) may carry higher costs due to compliance requirements.

-

Supplier Factors: Relationships with suppliers and their reliability can influence pricing. Establishing strong ties with Voto can lead to better pricing and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and risk.

Buyer Tips for Cost Efficiency

-

Negotiate Strategically: Engage in open discussions about pricing. Leverage your buying power and explore options for bulk discounts or flexible payment terms.

-

Consider Total Cost of Ownership (TCO): Assess not just the purchase price but also the long-term costs associated with maintenance, operation, and disposal of the products.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures due to local market conditions, tariffs, and taxes. Understanding these nuances can help in budgeting effectively.

-

Conduct Market Research: Before finalizing orders, research competitors’ pricing and product offerings. This information can provide leverage during negotiations.

-

Stay Informed on Market Trends: Keeping abreast of industry trends, material costs, and economic factors can help anticipate price changes and make informed purchasing decisions.

In summary, understanding the cost structure and pricing factors associated with Voto Manufacturers Sales can significantly enhance the buying experience for international B2B buyers. By strategically navigating these elements, buyers can achieve cost-efficiency and secure high-quality products that meet their operational needs.

Spotlight on Potential voto manufacturers sales Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘voto manufacturers sales’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for voto manufacturers sales

Essential Technical Properties

When engaging with voto manufacturers sales, understanding the technical properties of the products is crucial. Here are several key specifications that international B2B buyers should be aware of:

-

Material Grade

This refers to the classification of materials based on their composition and mechanical properties. For instance, steel products may be graded as carbon steel, alloy steel, or stainless steel. Knowing the material grade is essential for ensuring that the components will meet the required strength and durability standards for specific applications. -

Tolerance

Tolerance defines the allowable deviation from a specified dimension. It is critical in manufacturing processes to ensure parts fit together correctly. In B2B transactions, having precise tolerances can significantly affect the performance and safety of the final product, particularly in applications involving machinery and heavy equipment. -

Load Capacity

This specification indicates the maximum weight a component, such as a rigging sling or lifting device, can safely support. Understanding load capacity is vital for buyers to prevent accidents and equipment failure, ensuring compliance with safety regulations. -

Abrasion Resistance

This property measures a material’s ability to withstand wear from mechanical action. For industries involved in heavy-duty applications like mining or construction, selecting products with high abrasion resistance can lead to lower maintenance costs and extended product life. -

Hydraulic Pressure Rating

Particularly relevant for hose and fitting products, this rating indicates the maximum pressure the hose can handle. Buyers must ensure that the hydraulic components chosen can withstand the pressures of their specific applications to avoid system failures. -

Certification Standards

Products may be certified under various international standards (e.g., ISO 9001:2015). These certifications provide assurance of quality and compliance with industry regulations, which can be pivotal for B2B buyers when evaluating suppliers.

Key Trade Terminology

Familiarity with industry terminology enhances communication and decision-making in B2B transactions. Here are several common terms used in the voto manufacturing sector:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding the OEM relationship helps buyers identify reliable suppliers and establish trust in the quality of the products being sourced. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. It is crucial for buyers to be aware of MOQs to align their purchasing strategies with supplier capabilities and avoid overstocking or under-ordering. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. B2B buyers should utilize RFQs to gather competitive pricing and ensure they are making informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for clarifying shipping costs, risk, and delivery obligations, which can significantly impact the total cost of procurement. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is received. For international buyers, knowing lead times is critical for planning and inventory management, especially in markets with fluctuating demand. -

BOM (Bill of Materials)

A BOM is a comprehensive list of materials, components, and assemblies needed to manufacture a product. It provides insight into the complexity of the manufacturing process and helps buyers understand the parts they need to procure for their projects.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, ensuring they select the right products and suppliers for their specific needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the voto manufacturers sales Sector

Market Overview & Key Trends

The voto manufacturing sales sector is experiencing significant growth driven by global demand for industrial products across various industries, including construction, mining, and manufacturing. Key factors influencing this market include the rapid urbanization in Africa and South America, coupled with infrastructural developments in the Middle East and Europe. International B2B buyers are increasingly seeking reliable suppliers who can provide high-quality products and customized solutions to meet specific operational needs.

Emerging B2B technology trends are reshaping the sourcing landscape. Digital platforms for procurement are gaining traction, enabling buyers to streamline their purchasing processes and enhance supplier transparency. Innovations such as real-time inventory tracking and AI-driven analytics are empowering buyers to make informed decisions based on market dynamics. Additionally, the rise of e-commerce in industrial sectors facilitates quicker response times and improved accessibility to diverse product offerings.

Sourcing trends are also evolving, with a noticeable shift towards localized supply chains. This approach not only reduces lead times but also mitigates risks associated with international shipping disruptions. Furthermore, buyers are increasingly prioritizing vendors with robust logistical capabilities and a diverse product range, allowing for comprehensive solutions that cater to varied operational requirements.

Sustainability & Ethical Sourcing in B2B

Sustainability has emerged as a critical consideration in the voto manufacturing sales sector. The environmental impact of industrial operations is under scrutiny, prompting buyers to seek suppliers who adhere to sustainable practices. Ethical sourcing is paramount, as it ensures that materials are obtained responsibly and that labor practices align with international standards.

B2B buyers should look for certifications such as ISO 14001, which denotes effective environmental management systems, and other green certifications that indicate a commitment to sustainability. Additionally, the use of eco-friendly materials and recyclable products is becoming increasingly important. Suppliers who can demonstrate a commitment to reducing their carbon footprint not only appeal to environmentally conscious buyers but also enhance their market competitiveness.

Illustrative Image (Source: Google Search)

Investing in sustainable supply chains is not merely a compliance measure but a strategic advantage. It can lead to cost savings, improved brand reputation, and a stronger alignment with global sustainability goals. Buyers in Africa, South America, the Middle East, and Europe should prioritize partnerships with manufacturers who exhibit transparency in their sourcing processes and a clear commitment to sustainability.

Brief Evolution/History

Founded in 1938, Voto Manufacturers Sales began as a supplier for local steel, power, and coal industries. Over the decades, the company has evolved into a significant player in the industrial supply sector, serving over 3,000 customers, including OEMs and government agencies. The transition to an ISO 9001:2015 certified company reflects its commitment to quality and customer satisfaction. Today, Voto offers a diverse range of products, including custom assemblies for industrial hose applications and advanced rigging solutions. This evolution underscores the importance of adaptability in meeting the changing needs of the global market, making it a vital partner for international B2B buyers seeking reliable and innovative industrial solutions.

Related Video: Global trade will never be the same again, says Christine Lagarde | Power & Politics

Frequently Asked Questions (FAQs) for B2B Buyers of voto manufacturers sales

-

What should I consider when vetting suppliers of Voto products?

When vetting suppliers for Voto products, consider their ISO certifications, such as ISO 9001:2015, which indicate a commitment to quality management. Assess their experience in your industry and their capacity to meet your specific needs. Request references from other international buyers and examine their track record for reliability and service. Additionally, inquire about their product range to ensure they can fulfill your specific requirements, including customization options and support services. -

Can I customize my orders with Voto manufacturers?

Yes, Voto manufacturers offer customization for many of their products. This includes made-to-order assemblies, wire rope products, and specific rigging solutions tailored to your operational requirements. When discussing customization, clearly communicate your specifications and expectations. It’s advisable to request samples or prototypes where possible, to ensure the final product meets your operational needs before placing a larger order. -

What are the minimum order quantities (MOQs) and lead times for international shipments?

Minimum order quantities (MOQs) vary based on the type of product and customization level. Generally, Voto manufacturers are flexible and can accommodate smaller orders, especially for international buyers. Lead times depend on product availability and customization requirements, typically ranging from a few weeks to several months. It’s essential to discuss these details upfront with your supplier to align expectations and avoid project delays. -

What payment terms are typically available for international buyers?

Payment terms for international buyers may include options such as letters of credit, advance payments, or open account terms, depending on your relationship with the supplier. Discuss payment methods that suit your financial processes and ensure they are secure. Be aware of currency fluctuations and potential additional costs like tariffs or taxes that might affect the final price. Establishing clear payment terms upfront can help prevent misunderstandings later in the transaction. -

How does Voto ensure quality assurance and certification of their products?

Voto manufacturers uphold quality assurance through rigorous testing and inspection processes aligned with their ISO 9001:2015 certification. They implement quality checks at various stages of production to ensure compliance with industry standards. As an international buyer, request documentation of certifications and quality control processes. This will provide assurance that the products meet the required safety and performance standards for your specific applications. -

What logistics options are available for shipping products internationally?

International shipping options vary based on your location and the supplier’s capabilities. Voto manufacturers typically work with reliable logistics partners to offer various shipping methods, including air freight for faster delivery and ocean freight for cost-effective bulk shipments. Discuss shipping preferences, including Incoterms (like FOB, CIF, etc.), to clarify responsibilities and costs associated with transportation. Ensure that your supplier can provide tracking information for transparency. -

How are disputes resolved when dealing with Voto manufacturers?

Dispute resolution processes should be clearly outlined in your contract with the supplier. Generally, these may involve negotiation, mediation, or arbitration, depending on the nature of the dispute. It’s beneficial to establish a clear communication channel with your supplier to address issues promptly. Keep records of all communications and agreements to facilitate resolution. Understanding the legal framework governing international trade in your contracts can also protect your interests. -

What support services can I expect post-purchase from Voto manufacturers?

Post-purchase support from Voto manufacturers can include installation assistance, maintenance services, and access to technical support. Many suppliers offer training for your staff on product usage and safety protocols. It’s crucial to discuss the extent of post-sale support during the negotiation phase. Ensure you have access to customer service representatives who can address any concerns or questions that may arise after the purchase, enhancing your operational efficiency.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for voto manufacturers sales

In summary, the strategic sourcing of Voto Manufacturers Sales is a vital component for international B2B buyers looking to enhance their operational efficiency and product offerings. With an extensive product range that includes custom solutions for rigging, earth-moving equipment, and high-strength steel, Voto positions itself as a reliable partner for businesses across various sectors. The ISO 9001:2015 certification underscores the company’s commitment to quality, making it an attractive choice for buyers seeking dependable suppliers.

Key Takeaways:

– Diverse Product Portfolio: Voto offers over 1,000 national brands, ensuring buyers can find tailored solutions for their specific needs.

– Employee Ownership: As a 100% employee-owned company, Voto prioritizes customer satisfaction, translating to superior service and support.

– Global Reach: With an established presence in the industrial sector, Voto is well-equipped to serve international markets, including Africa, South America, the Middle East, and Europe.

Looking ahead, B2B buyers are encouraged to leverage the strategic advantages offered by Voto Manufacturers Sales. By establishing partnerships with reliable suppliers, businesses can enhance their supply chains, reduce costs, and ultimately drive growth. Take the next step towards operational excellence by exploring Voto’s offerings and integrating them into your procurement strategy today.