Master Water Flow Meter Types for Efficient B2B Sourcing

Introduction: Navigating the Global Market for water flow meter types

In an era where resource management is paramount, understanding the various types of water flow meters is essential for international B2B buyers. These instruments not only facilitate accurate flow measurement but also play a pivotal role in enhancing operational efficiency, ensuring regulatory compliance, and optimizing resource allocation across industries such as agriculture, manufacturing, and water treatment. With the growing demand for precision and reliability, selecting the right flow meter type can significantly impact operational costs and sustainability efforts.

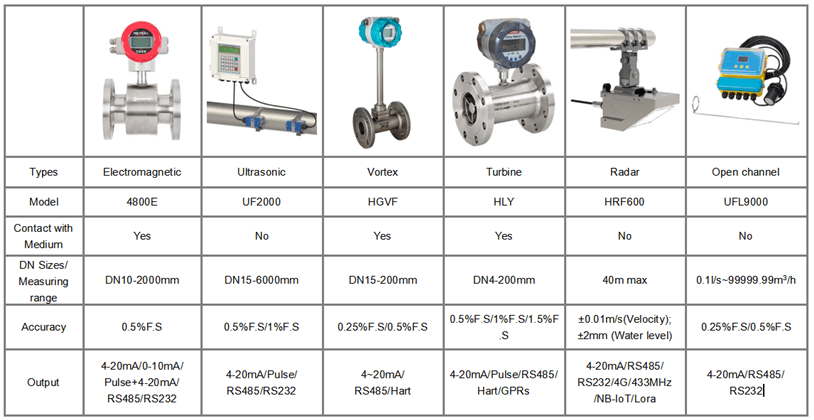

This comprehensive guide delves into the intricacies of water flow meters, offering insights into their diverse types—including differential pressure, positive displacement, turbine, electromagnetic, and ultrasonic flow meters. It covers critical aspects such as materials, manufacturing quality control, supplier selection, cost considerations, and market trends, tailored specifically for buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Poland.

By equipping buyers with actionable information and expert insights, this guide empowers them to make informed sourcing decisions. Whether navigating the complexities of procurement or seeking to enhance operational efficiencies, understanding the nuances of flow meter types will enable B2B buyers to align their choices with industry needs and regulatory standards, ultimately driving success in their projects and investments.

Understanding water flow meter types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Differential Pressure Flow Meters | Utilize pressure differences across constrictions to measure flow. | Oil & Gas, Water Treatment | Pros: Cost-effective, suitable for high-pressure. Cons: Accuracy affected by installation conditions. |

| Positive Displacement Flow Meters | Measure flow by trapping fixed volumes and counting cycles. | Fuel Dispensing, Viscous Liquid Measurement | Pros: High accuracy, ideal for viscous fluids. Cons: Moving parts may wear out, limited to clean fluids. |

| Turbine Flow Meters | Employ a rotor that spins with fluid flow to measure rate. | Chemical Processing, Water Distribution | Pros: High accuracy, wide flow range. Cons: Susceptible to wear, not suitable for high-viscosity fluids. |

| Electromagnetic Flow Meters | Use electromagnetic induction to measure conductive fluid flow. | Wastewater Treatment, Slurries | Pros: No moving parts, minimal maintenance. Cons: Requires conductive fluids, higher initial cost. |

| Ultrasonic Flow Meters | Utilize sound waves to measure flow rate in liquids. | HVAC Systems, Water Management | Pros: Non-intrusive, works with various fluids. Cons: Accuracy depends on fluid properties, installation can be complex. |

Differential Pressure Flow Meters

Differential pressure flow meters are widely recognized for their simplicity and cost-effectiveness. They function by measuring the pressure drop across a constriction in the flow path, such as orifice plates or Venturi tubes. These meters are particularly suitable for industries like oil and gas and water treatment, where accurate flow measurement is critical. When purchasing, consider installation requirements and the potential impact of pressure loss on overall efficiency.

Positive Displacement Flow Meters

Positive displacement flow meters are ideal for applications requiring high accuracy, especially when measuring viscous liquids like oils and syrups. They operate by trapping a set volume of fluid and counting the number of cycles, providing precise flow measurements. Commonly used in fuel dispensing and small-scale operations, buyers should assess the cleanliness of the fluid and the potential for wear on moving parts when selecting these meters.

Turbine Flow Meters

Turbine flow meters are recognized for their high accuracy and ability to handle a wide flow range. The rotor within the meter spins in response to fluid flow, with its speed directly correlating to the flow rate. These meters are prevalent in chemical processing and water distribution. Buyers should be mindful of the potential for wear and the need for clean, low-viscosity fluids to ensure optimal performance.

Electromagnetic Flow Meters

Electromagnetic flow meters leverage Faraday’s law of electromagnetic induction, making them suitable for measuring conductive fluids, including wastewater and slurries. These meters feature no moving parts, leading to minimal maintenance requirements. However, they necessitate a conductive fluid and may involve higher initial costs. B2B buyers should consider the long-term maintenance benefits versus the upfront investment when evaluating these options.

Ultrasonic Flow Meters

Ultrasonic flow meters employ sound waves to measure the flow rate, offering a non-intrusive solution suitable for a variety of fluids. They can operate effectively in large pipes and are commonly used in HVAC systems and water management. However, their accuracy can be influenced by fluid characteristics, and installation may require careful consideration. Buyers should weigh the advantages of non-intrusive measurement against the potential complexities of installation and accuracy dependencies.

Related Video: Water Flow Meter and Its Type?

Key Industrial Applications of water flow meter types

| Industry/Sector | Specific Application of Water Flow Meter Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water Treatment | Monitoring flow rates in filtration and treatment plants | Ensures compliance with regulations, enhances operational efficiency | Need for high accuracy and reliability, suitable for varying water quality |

| Agriculture | Irrigation management and water usage monitoring | Optimizes resource use, reduces costs, and improves crop yield | Meters must handle varying flow conditions and be durable against environmental factors |

| Food and Beverage | Measuring water usage in production processes | Maintains product quality and consistency, ensures regulatory compliance | Hygiene standards, compatibility with food-grade materials, accuracy in measurement |

| Construction | Water usage tracking on construction sites | Helps manage costs and resource allocation, ensures compliance with local regulations | Meters need to be portable, durable, and capable of handling high flow rates |

| Chemical Processing | Monitoring flow rates of water used in chemical reactions | Enhances process control and efficiency, ensures safety in operations | Must withstand corrosive environments, require compatibility with various chemical compositions |

Water Treatment

In water treatment facilities, water flow meters are essential for monitoring flow rates during various stages of filtration and treatment. They ensure that the facility meets environmental regulations and operates efficiently. Accurate measurements help in optimizing chemical dosing and maintaining water quality. International buyers should consider the meter’s compatibility with different water qualities and its reliability in varying conditions, especially in regions with fluctuating water sources.

Agriculture

In agriculture, water flow meters are used for effective irrigation management, allowing farmers to monitor and control water usage efficiently. This application is crucial for optimizing resources, reducing operational costs, and improving crop yields. For buyers in Africa and South America, it is vital to select meters that can withstand harsh environmental conditions and provide accurate readings under varying flow scenarios, ensuring sustainability in water use.

Food and Beverage

Water flow meters are critical in the food and beverage industry, where precise measurement of water used in production processes is necessary. They help maintain product quality and consistency while ensuring compliance with health regulations. Buyers should prioritize meters that meet hygiene standards and are made from food-grade materials. Additionally, accuracy in measurement is paramount to prevent wastage and ensure product safety.

Construction

On construction sites, water flow meters are utilized to track water usage for various activities, including mixing concrete and dust control. This monitoring helps manage costs and ensures compliance with local regulations regarding water usage. Buyers should look for portable and durable flow meters that can handle high flow rates and rough handling typical in construction environments.

Chemical Processing

In chemical processing, water flow meters monitor the flow rates of water used in various reactions and processes. Accurate flow measurement is crucial for enhancing process control and ensuring safety. Buyers must consider meters that can withstand corrosive environments and are compatible with a range of chemical compositions, particularly in the Middle East where such conditions are prevalent. Selecting the right meter can significantly impact operational efficiency and safety in chemical manufacturing.

Related Video: Types of Flow Meter

Strategic Material Selection Guide for water flow meter types

When selecting materials for water flow meters, it is crucial to consider the specific requirements of the application, including the types of fluids being measured, environmental conditions, and regulatory standards. Below is an analysis of four common materials used in water flow meter construction, highlighting their properties, advantages, disadvantages, and considerations for international B2B buyers.

1. Stainless Steel

Key Properties: Stainless steel offers excellent corrosion resistance, high strength, and can withstand a wide range of temperatures and pressures. It typically has a temperature rating of up to 400°F (204°C) and can handle pressures exceeding 3000 psi.

Pros & Cons:

– Advantages: Durable and long-lasting, stainless steel is suitable for various applications, including those involving corrosive fluids. It is also easy to clean, making it ideal for sanitary applications.

– Disadvantages: The initial cost can be high, and it may require specialized welding techniques during manufacturing, which can complicate the production process.

Impact on Application: Stainless steel is compatible with a wide range of media, including water, oils, and chemicals. Its corrosion resistance makes it suitable for harsh environments often found in industries such as oil and gas.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM A312 for stainless steel pipes. In markets like Africa and South America, the availability of high-quality stainless steel can vary, impacting supply chain reliability.

2. PVC (Polyvinyl Chloride)

Key Properties: PVC is lightweight, resistant to corrosion, and has a temperature rating of up to 140°F (60°C). It is suitable for low-pressure applications and can handle a pH range of 0-14.

Pros & Cons:

– Advantages: PVC is cost-effective and easy to install, making it a popular choice for residential and agricultural applications. Its chemical resistance allows it to be used with many fluids.

– Disadvantages: It has lower temperature and pressure ratings compared to metals, limiting its use in high-pressure environments. Additionally, it can become brittle over time when exposed to UV light.

Impact on Application: PVC is ideal for water distribution systems and irrigation, particularly in regions where high temperatures are not an issue. Its lightweight nature simplifies transportation and installation.

Considerations for International Buyers: Compliance with local standards such as ASTM D1784 is essential. Buyers in regions like South America should consider the availability of quality PVC products, as lower-quality materials can lead to premature failure.

3. Bronze

Key Properties: Bronze is known for its excellent corrosion resistance, particularly in marine environments. It can withstand temperatures up to 400°F (204°C) and offers good mechanical strength.

Pros & Cons:

– Advantages: Bronze is durable and has a low friction coefficient, making it suitable for applications involving moving parts, such as turbine flow meters. It also has antimicrobial properties, beneficial in potable water applications.

– Disadvantages: The cost can be higher than plastic options, and it may require more maintenance due to potential corrosion in certain environments.

Impact on Application: Bronze is commonly used in applications that involve water and steam, making it suitable for industrial settings. Its corrosion resistance is particularly valuable in coastal areas.

Considerations for International Buyers: Buyers should be aware of regulations regarding lead content in bronze, especially in Europe and the Middle East, where strict compliance with health standards is enforced.

4. Aluminum

Key Properties: Aluminum is lightweight and has good corrosion resistance, with a temperature rating of up to 300°F (149°C). It is also non-magnetic and has a good strength-to-weight ratio.

Pros & Cons:

– Advantages: Its lightweight nature makes it easy to handle and install. Aluminum is also cost-effective compared to stainless steel and can be anodized for enhanced corrosion resistance.

– Disadvantages: While it performs well in many applications, aluminum is not suitable for high-pressure environments and can be susceptible to corrosion in certain chemical exposures.

Impact on Application: Aluminum is often used in portable flow meters and applications where weight is a concern. It is suitable for clean water applications but may not be ideal for corrosive or high-pressure situations.

Considerations for International Buyers: Compliance with standards such as ASTM B221 is important. Buyers in regions like Africa should consider local sourcing options to reduce costs and ensure quality.

Summary Table

| Material | Typical Use Case for water flow meter types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial applications, oil & gas | Excellent corrosion resistance | High initial cost, complex manufacturing | High |

| PVC | Water distribution, irrigation | Cost-effective, easy to install | Lower temperature/pressure ratings | Low |

| Bronze | Marine environments, potable water | Durable, low friction | Higher cost, maintenance required | Medium |

| Aluminum | Portable flow meters, clean water | Lightweight, cost-effective | Not suitable for high-pressure applications | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers to make informed decisions regarding water flow meter types, ensuring compatibility with their specific applications and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for water flow meter types

In the competitive landscape of water flow meter manufacturing, understanding the processes and quality assurance measures is essential for international B2B buyers. This knowledge not only aids in selecting the right suppliers but also ensures that the products meet necessary standards and performance expectations. Below, we delve into the typical manufacturing processes and quality assurance protocols for water flow meters.

Manufacturing Processes

The manufacturing of water flow meters typically involves several key stages, each crucial for the final product’s performance and reliability.

1. Material Preparation

The first step in the manufacturing process is material preparation. This includes selecting high-quality raw materials such as metals (stainless steel, brass), polymers, and electronic components, which are essential for durability and functionality.

- Material Selection: Buyers should prioritize suppliers who utilize materials compliant with international standards (e.g., ASTM, ISO) to ensure longevity and resistance to corrosion, especially for meters used in harsh environments.

- Pre-processing: Raw materials undergo processes like cutting, machining, and surface treatment to ensure they meet the specifications required for the flow meter components.

2. Forming

The forming stage involves shaping the prepared materials into the necessary components of the flow meter.

- Casting and Machining: For components like housings and bodies, techniques such as casting and CNC machining are employed. This ensures precise dimensions and surface finishes.

- Injection Molding: For non-metal components, injection molding is often used. This method allows for the efficient production of complex shapes, particularly in plastic flow meters.

3. Assembly

Once the components are formed, they are assembled into complete flow meters.

- Sub-assembly: Individual components such as sensors, displays, and flow tubes are first assembled into sub-units.

- Final Assembly: The sub-units are then brought together. This step often requires skilled labor to ensure that all components fit together correctly and function as intended.

4. Finishing

The finishing stage includes various processes that enhance the product’s durability and aesthetic appeal.

- Surface Treatment: Techniques such as anodizing, powder coating, or plating may be used to improve corrosion resistance and surface hardness.

- Final Inspection: Before packaging, a thorough inspection is conducted to check for any defects in assembly and finish.

Quality Assurance

Quality assurance is critical in the manufacturing of water flow meters, ensuring that the products meet specified standards and perform reliably in their intended applications.

Relevant International Standards

B2B buyers should be aware of the following quality standards that apply to water flow meters:

- ISO 9001: This is a widely recognized standard for quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

- CE Marking: For products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: For flow meters used in the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step ensures that raw materials meet specified standards before they are used in production. Buyers should inquire about the supplier’s IQC processes.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps catch defects early. Techniques such as statistical process control (SPC) can be employed.

- Final Quality Control (FQC): Before products leave the factory, they undergo final inspections and testing to ensure they meet performance standards.

Common Testing Methods

Testing methods are critical for verifying the accuracy and reliability of water flow meters:

- Calibration Tests: Flow meters are calibrated against known flow rates to verify accuracy.

- Pressure Tests: These tests check for leaks and ensure that the meter can withstand operational pressures.

- Electrical Testing: For electronic flow meters, electrical testing ensures that sensors and displays function correctly.

Verification of Supplier Quality Control

For international buyers, particularly from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial:

- Supplier Audits: Conducting regular audits of potential suppliers can provide insights into their manufacturing practices and quality control measures. This includes reviewing quality management documentation and observing production processes.

- Quality Reports: Requesting detailed quality reports and certifications can help assess whether the supplier adheres to international standards.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an objective evaluation of the supplier’s quality control systems and product quality.

Quality Control Nuances for International Buyers

B2B buyers should be aware of specific nuances when sourcing from different regions:

- Regulatory Compliance: Ensure that suppliers are compliant with local and international regulations, which may vary by region. For instance, regulations in Europe may differ significantly from those in the Middle East or Africa.

- Cultural Considerations: Understanding cultural differences in business practices can aid in smoother negotiations and collaborations. Clear communication regarding quality expectations is essential.

- After-Sales Support: Evaluate the supplier’s ability to provide after-sales support and warranty services. This is particularly important in regions where access to replacement parts or service may be limited.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for water flow meters is vital for international B2B buyers. By focusing on material quality, manufacturing techniques, and stringent quality control measures, buyers can ensure they select reliable suppliers that meet their specific needs. Being proactive in verifying supplier capabilities and standards can significantly enhance the purchasing decision, leading to long-term partnerships and successful project outcomes.

Related Video: Water Quality Testing Methods

Comprehensive Cost and Pricing Analysis for water flow meter types Sourcing

Understanding the Cost Structure of Water Flow Meters

When sourcing water flow meters, it is essential to comprehend the various components that contribute to their overall cost. The cost structure typically includes:

- Materials: The choice of materials (e.g., stainless steel, plastic, or specialized alloys) significantly impacts the price. Higher quality materials increase durability and resistance to corrosion but also raise the initial cost.

- Labor: Skilled labor is required for manufacturing sophisticated flow meters, particularly for custom solutions. Labor costs can vary widely based on geographic location and labor market conditions.

- Manufacturing Overhead: This includes expenses related to factory operations such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce these overheads.

- Tooling: Initial investments in molds and machinery for production can be substantial, especially for custom or specialized flow meters. These costs are often spread over the production volume.

- Quality Control (QC): Rigorous testing and quality assurance processes are vital for ensuring accuracy and reliability, particularly in critical applications. This adds to the overall cost but is essential for compliance with industry standards.

- Logistics: Transportation and shipping costs can vary based on the destination and chosen Incoterms. Import duties and tariffs may also affect the final pricing for international buyers.

- Margin: Suppliers will typically add a profit margin based on their operational costs, market conditions, and competition.

Influencers on Pricing

Several factors influence the pricing of water flow meters, which international buyers should consider:

- Volume/MOQ: Bulk orders generally result in lower per-unit costs. Understanding the minimum order quantities (MOQs) can help buyers negotiate better deals.

- Specifications/Customization: Custom features or specifications can significantly increase costs. Standard models are usually more cost-effective than custom-engineered solutions.

- Materials: The choice of materials can alter the price. For instance, electromagnetic flow meters, which require conductive materials, may have a higher cost than simpler mechanical meters.

- Quality/Certifications: Certifications for compliance with international standards (e.g., ISO, API) can increase costs but are often necessary for regulatory compliance in certain industries.

- Supplier Factors: The supplier’s reputation, reliability, and service capabilities can influence pricing. Established suppliers may charge a premium for their products but often provide better support and warranty services.

- Incoterms: Understanding the chosen Incoterms can significantly affect total landed costs. For example, FOB (Free on Board) may mean different responsibilities and costs compared to CIF (Cost, Insurance, and Freight).

Buyer Tips for Cost-Efficiency

To maximize value when sourcing water flow meters, consider the following strategies:

- Negotiate: Always engage in negotiations with suppliers. Highlight your potential for repeat business and willingness to explore long-term contracts to secure better pricing.

- Total Cost of Ownership (TCO): Evaluate the TCO, which includes not only the purchase price but also maintenance, operational costs, and the expected lifespan of the flow meter. Opt for products that offer long-term savings even if the upfront cost is higher.

- Pricing Nuances: Be aware of the pricing fluctuations that can occur due to currency exchange rates, geopolitical factors, and supply chain disruptions, especially when sourcing from different regions.

- Research Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may offer better support for installation and maintenance.

- Certifications and Standards: Ensure that the products meet the necessary local and international standards. This may prevent costly compliance issues in the future.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, specific supplier negotiations, and the unique requirements of each order. Always conduct thorough market research and consult multiple suppliers to obtain accurate pricing tailored to your needs.

Spotlight on Potential water flow meter types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘water flow meter types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for water flow meter types

Key Technical Properties of Water Flow Meters

When selecting water flow meters, several technical specifications are critical for ensuring the right choice for your application. Understanding these properties can greatly enhance decision-making and procurement processes.

-

Material Grade

– Definition: Refers to the type of materials used in the construction of the flow meter, such as stainless steel, PVC, or brass.

– Importance: The material affects durability, resistance to corrosion, and suitability for specific fluids. For example, stainless steel is ideal for corrosive liquids, while PVC may be sufficient for less aggressive applications. -

Flow Range

– Definition: The minimum and maximum flow rates that a meter can accurately measure, typically expressed in liters per minute (L/min) or cubic meters per hour (m³/h).

– Importance: Choosing a flow meter with an appropriate flow range ensures accurate measurements and prevents potential damage or malfunction due to over or under flow conditions. -

Accuracy

– Definition: The degree to which the measured flow rate corresponds to the actual flow rate, often expressed as a percentage (e.g., ±1% of reading).

– Importance: High accuracy is crucial in applications like pharmaceuticals and food processing, where precise measurements are vital for quality control and regulatory compliance. -

Pressure Rating

– Definition: The maximum pressure that the flow meter can handle, usually measured in bar or psi.

– Importance: A flow meter must be rated for the pressures it will encounter in the application to avoid failure, leaks, or inaccurate readings. -

Temperature Range

– Definition: The range of temperatures within which the flow meter can operate effectively, typically specified in degrees Celsius (°C).

– Importance: Different applications may involve varying temperatures; selecting a flow meter that can withstand these conditions is essential for operational reliability.

Illustrative Image (Source: Google Search)

- Installation Type

– Definition: Refers to how the flow meter is installed, such as inline, clamp-on, or insertion.

– Importance: The installation type impacts maintenance requirements, ease of installation, and the suitability for certain applications. For example, clamp-on meters can be installed without interrupting the flow, making them ideal for temporary or non-invasive measurements.

Common Trade Terms in Flow Meter Procurement

Understanding industry jargon is essential for effective communication and decision-making in B2B transactions involving water flow meters.

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Knowing if a flow meter is an OEM product can influence purchasing decisions, as OEMs often provide guaranteed compatibility and quality. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Significance: Understanding the MOQ is crucial for budgeting and inventory management, especially for small businesses or projects with limited requirements.

Illustrative Image (Source: Google Search)

-

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Significance: Submitting an RFQ helps buyers obtain competitive pricing and negotiate better terms, essential for cost-effective procurement. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding the delivery of goods.

– Significance: Familiarity with Incoterms helps in understanding shipping responsibilities, costs, and risks involved in international transactions. -

Calibration

– Definition: The process of adjusting the accuracy of a flow meter to ensure it provides correct measurements.

– Significance: Regular calibration is necessary to maintain measurement accuracy and compliance with industry standards. -

Lead Time

– Definition: The amount of time taken from placing an order to delivery.

– Significance: Knowing the lead time is vital for project planning and ensuring that flow meters are available when needed.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions, ultimately enhancing their operational efficiency and compliance with industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the water flow meter types Sector

Global demand for water flow meters is rapidly evolving, driven by several key factors. One primary driver is the increasing need for precise flow measurement across various industries, including water treatment, agriculture, and manufacturing. As countries in Africa, South America, the Middle East, and Europe seek to optimize resource management and comply with environmental regulations, the demand for advanced flow measurement technologies is surging. Additionally, the rise of smart technologies is influencing sourcing trends, with a growing preference for digital flow meters that offer real-time data analytics and remote monitoring capabilities.

Emerging technologies such as ultrasonic and electromagnetic flow meters are gaining traction due to their accuracy and low maintenance requirements. These innovations are particularly appealing to B2B buyers looking for reliable solutions that minimize operational disruptions. Furthermore, the integration of IoT (Internet of Things) in flow measurement systems is becoming increasingly important, enabling predictive maintenance and enhancing operational efficiencies.

The market dynamics are also shaped by regional differences. For instance, in the Middle East, water scarcity concerns are prompting governments to invest heavily in water management technologies, while European buyers are focusing on sustainability and compliance with strict environmental regulations. Buyers from Africa and South America are increasingly seeking partnerships with suppliers who can provide localized support and expertise in navigating complex regulatory environments.

Sustainability & Ethical Sourcing in B2B

Sustainability is a critical consideration for B2B buyers in the water flow meter sector. The environmental impact of manufacturing processes and the lifecycle of products are under scrutiny, prompting a shift towards greener alternatives. For instance, many companies are prioritizing flow meters made from sustainable materials or those that offer energy-efficient operation. This not only reduces the ecological footprint but also aligns with the growing consumer demand for environmentally friendly practices.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their purchasing decisions. Companies that adhere to responsible supply chain practices—such as fair labor conditions and transparency—are gaining favor in the marketplace. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) can serve as indicators of a supplier’s commitment to sustainability and ethical practices, making them attractive to international buyers.

Moreover, the trend towards circular economy principles is influencing sourcing decisions. B2B buyers are looking for suppliers that offer take-back programs, enabling the recycling of old equipment and minimizing waste. Such initiatives not only help in compliance with regulations but also enhance brand reputation among environmentally conscious consumers.

Brief Evolution/History

The evolution of water flow meters can be traced back to the early 20th century when mechanical devices dominated the market. Over the decades, advancements in technology have led to the development of more sophisticated measurement techniques, including electromagnetic and ultrasonic methods. The introduction of digital technologies in the 21st century marked a significant shift, enabling real-time data collection and analysis.

Today, the focus is on integrating these technologies with IoT capabilities to enhance operational efficiency. As global industries increasingly prioritize sustainability and efficiency, the water flow meter market continues to adapt, providing innovative solutions that meet the evolving needs of B2B buyers. This historical context highlights the continuous innovation within the sector, underscoring the importance of staying informed about technological advancements for successful sourcing decisions.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of water flow meter types

-

What should I look for when vetting suppliers of water flow meters?

When vetting suppliers, prioritize their industry experience, certifications, and customer references. Check for ISO certifications relevant to quality management systems, such as ISO 9001. Additionally, assess their product range and ability to offer customization to meet specific needs. It’s also beneficial to evaluate their financial stability and after-sales support, as these factors contribute to long-term partnership reliability. -

Can I customize the water flow meters to fit specific requirements?

Yes, many suppliers offer customization options for water flow meters to meet specific operational needs. This can include modifications in size, material, measurement range, and additional features like integrated data logging. It’s essential to communicate your requirements clearly during the negotiation phase to ensure the product aligns with your operational goals and complies with local regulations. -

What are the typical minimum order quantities (MOQ) and lead times for water flow meters?

Minimum order quantities (MOQs) can vary significantly depending on the supplier and the type of flow meter. Typically, MOQs may range from 10 to 100 units. Lead times can also differ based on customization needs, ranging from 4 to 12 weeks. Always clarify these details upfront to avoid unexpected delays, especially when planning for projects in sectors like construction or agriculture. -

What payment terms are commonly offered by international suppliers?

International suppliers often provide flexible payment terms, including upfront payments, net 30/60/90 days, or letters of credit. Consider negotiating terms that minimize cash flow disruption while ensuring supplier security. It’s advisable to use secure payment methods, such as escrow services or bank transfers, and to verify the supplier’s reputation to mitigate risks associated with international transactions. -

How can I ensure quality assurance and certifications for the flow meters I purchase?

To ensure quality assurance, request documentation of compliance with international standards such as ISO 4064 for water meters. You can also ask for test reports and certificates from recognized bodies that validate the performance and accuracy of the flow meters. Conducting pre-shipment inspections can further safeguard against receiving substandard products. -

What logistics considerations should I be aware of when importing water flow meters?

Logistics considerations include shipping methods (air vs. sea), customs regulations, and potential tariffs. Research the import regulations specific to your country to ensure compliance. Collaborating with a logistics provider experienced in international trade can streamline the process, as they can assist with documentation and customs clearance, thus reducing delivery delays. -

How can I handle disputes with suppliers effectively?

To handle disputes, establish clear terms in the contract regarding quality, delivery, and payment conditions. If a dispute arises, maintain open communication with the supplier to resolve issues amicably. If necessary, consider mediation or arbitration as stipulated in the contract. Document all correspondence and agreements, which can serve as evidence if legal intervention becomes necessary. -

What are the common applications for different types of water flow meters?

Water flow meters are utilized across various sectors, including agriculture (for irrigation), industrial processes (for monitoring water usage), and municipal water management (for billing and resource allocation). Understanding the specific application requirements can guide your choice of flow meter type, whether it be electromagnetic for dirty fluids or ultrasonic for clean liquids, ensuring optimal performance in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for water flow meter types

In conclusion, the strategic sourcing of water flow meters is pivotal for businesses aiming to enhance operational efficiency and ensure regulatory compliance. Understanding the various types of flow meters—such as differential pressure, positive displacement, turbine, electromagnetic, and ultrasonic—allows B2B buyers to make informed choices tailored to their specific applications. Each type offers distinct advantages and limitations, emphasizing the need for thorough evaluation based on factors like fluid characteristics, accuracy requirements, and installation conditions.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, investing in the right flow measurement technology can lead to significant cost savings and improved process control. Strategic sourcing not only aids in selecting the appropriate meter but also fosters supplier relationships that can enhance service and support.

As we move forward, the focus on sustainability and efficiency will only intensify. Therefore, it is essential for buyers to stay informed about technological advancements and regulatory changes in their respective markets. Engage with reputable suppliers, leverage industry insights, and prioritize quality to navigate the evolving landscape of water flow measurement effectively.