Mastering Brush Types: The Ultimate B2B Guide for Optimal

Introduction: Navigating the Global Market for brush types

In the ever-evolving global marketplace, the selection of the right industrial brush types is pivotal for businesses aiming to enhance productivity and maintain high-quality standards. From manufacturing and automotive industries to food processing and electronics, brushes play an essential role in diverse applications, including cleaning, deburring, polishing, and surface finishing. For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of brush types is not just beneficial—it’s critical.

This comprehensive guide delves into the various brush types available, their materials, manufacturing and quality control processes, and market dynamics. It addresses the specific needs of buyers by providing insights into suppliers, cost considerations, and frequently asked questions. By equipping you with this knowledge, we empower you to make informed sourcing decisions, ensuring that you select the most suitable brushes for your operational requirements.

Whether you are in Argentina, Brazil, or any other global market, this guide serves as a valuable resource for navigating the complexities of industrial brushes. By understanding the specific characteristics and applications of different brush types, you can optimize your procurement strategy, enhance your manufacturing processes, and ultimately drive your business success.

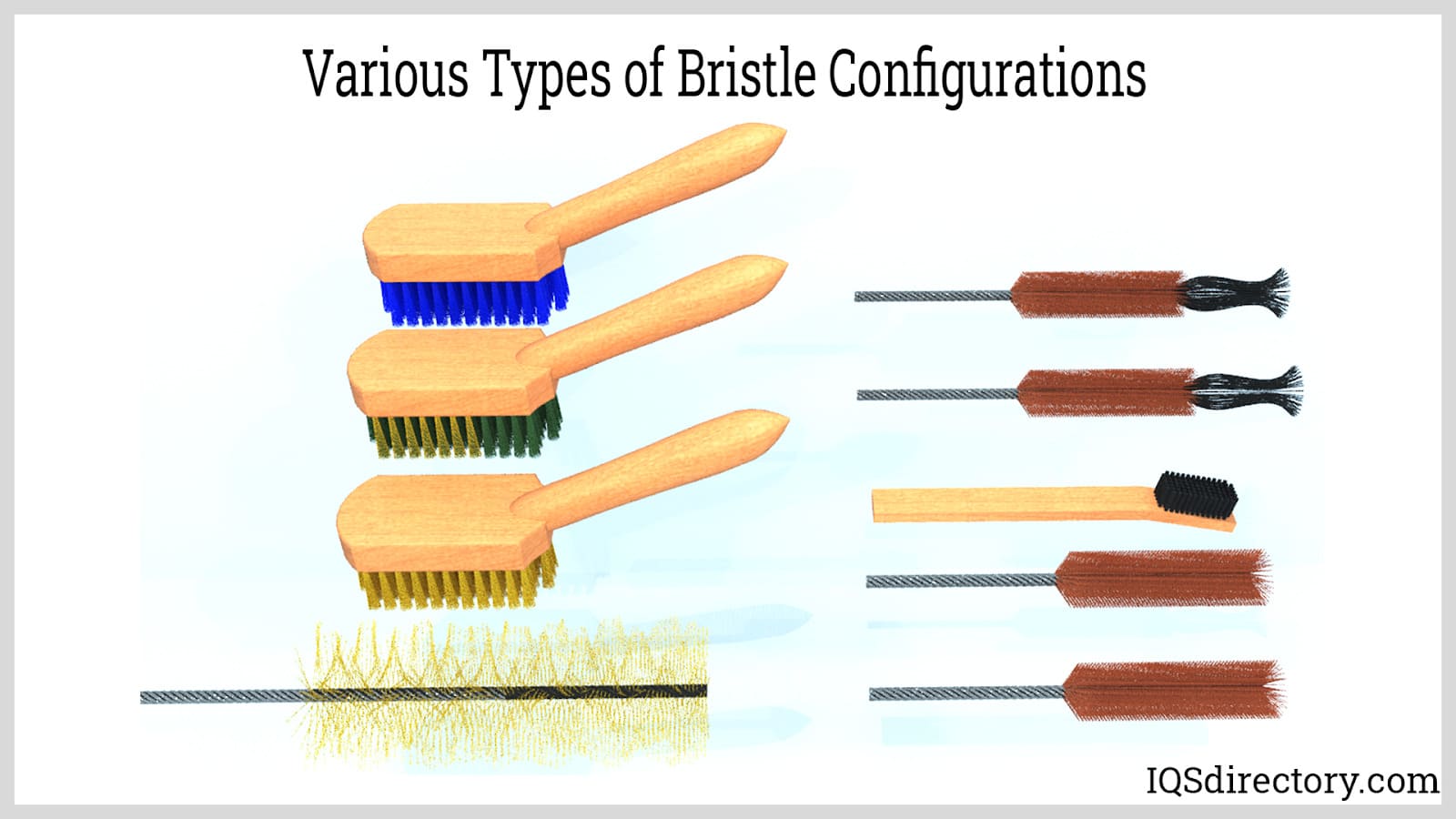

Understanding brush types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cylinder Brushes | Continuous brushing action; customizable sizes | Cleaning conveyor belts, material transport | Pros: Versatile, effective for debris removal. Cons: May require specific sizing for optimal performance. |

| Wheel Brushes | Designed for straight line brushing; various bristle materials | Surface finishing, deburring, rust removal | Pros: Highly effective for surface prep. Cons: Limited use in intricate applications. |

| Disk Brushes | Circular shape; ideal for flat surfaces | Abrasive cleaning, deburring, polishing | Pros: Excellent for even surface contact. Cons: Not suitable for uneven surfaces. |

| Strip Brushes | Flexible bristle arrangement; various lengths | Sealing, dusting, cleaning applications | Pros: Adaptable to different tasks. Cons: Limited effectiveness for heavy-duty applications. |

| Twisted-in-Wire Brushes | Stiff bristles twisted around a wire core | Cleaning hard-to-reach areas, deburring | Pros: Effective in confined spaces. Cons: Can wear out faster in heavy use. |

Cylinder Brushes

Cylinder brushes are engineered for continuous brushing action, making them ideal for applications that require consistent contact with surfaces. They are often used in industries like food processing for cleaning conveyor belts and in manufacturing for material transport. When purchasing, buyers should consider the diameter and length of the brush to ensure it fits their machinery. Additionally, the choice of bristle material can affect durability and cleaning effectiveness, so it is essential to select a brush that aligns with specific operational needs.

Wheel Brushes

Wheel brushes are characterized by their ability to provide straight-line brushing action, making them suitable for surface finishing, polishing, and deburring operations. Commonly utilized in the automotive and manufacturing sectors, these brushes can handle a variety of materials, including metals and plastics. Buyers should assess the brush’s bristle material to match their application requirements, as different materials offer varying levels of durability and cleaning efficiency. It’s also important to consider the brush’s size and compatibility with existing equipment.

Disk Brushes

Disk brushes feature a circular design that allows for effective brushing on flat surfaces, making them particularly useful in abrasive cleaning and polishing tasks. They are widely used in applications such as glass and ceramics, where even surface contact is crucial. When selecting disk brushes, B2B buyers should evaluate the diameter and bristle stiffness to ensure they meet the specific demands of their tasks. Additionally, compatibility with existing machinery is a key consideration to maximize performance.

Strip Brushes

Strip brushes consist of bristles set into a flexible backing, allowing them to adapt to various surfaces. They are commonly used for sealing, dusting, and light cleaning applications across multiple industries. Buyers should consider the length and density of the bristles when selecting strip brushes, as these factors will influence their effectiveness in specific tasks. While versatile, strip brushes may not be suitable for heavy-duty applications, so understanding the intended use is critical for optimal performance.

Twisted-in-Wire Brushes

Twisted-in-wire brushes have bristles that are twisted around a wire core, making them particularly effective for cleaning hard-to-reach areas and deburring applications. These brushes are often used in industries such as electronics and automotive manufacturing. Buyers should take into account the stiffness of the bristles and the overall size of the brush when making a purchase, as these factors will determine the brush’s effectiveness in specific applications. Although they are well-suited for tight spaces, these brushes can wear out more quickly under heavy usage, necessitating regular replacements.

Key Industrial Applications of brush types

| Industry/Sector | Specific Application of brush types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Polishing and deburring engine components | Enhances product quality and reduces rework costs | Look for durable materials that withstand high temperatures. |

| Food Processing | Cleaning machinery and equipment | Maintains hygiene standards, preventing contamination | Ensure brushes are made from food-safe materials like polypropylene. |

| Manufacturing | Surface finishing for metals and plastics | Improves surface quality and adhesion for coatings | Consider customized brushes tailored to specific surface types. |

| Electronics | Cleaning delicate electronic components | Ensures functionality and longevity of devices | Source brushes with non-abrasive materials to prevent damage. |

| Packaging | Sorting and feeding products in automated systems | Increases efficiency and reduces labor costs | Evaluate the brush’s ability to handle various product sizes and shapes. |

Automotive Industry

In the automotive sector, industrial brushes are crucial for polishing and deburring engine components. These brushes help eliminate sharp edges and imperfections, thereby enhancing the quality of finished parts. For international buyers, particularly from regions like South America and Europe, sourcing brushes made from durable materials that can withstand high temperatures is essential. This ensures longevity and effectiveness during the manufacturing process, reducing the need for frequent replacements and minimizing downtime.

Food Processing

In food processing, maintaining hygiene standards is paramount. Industrial brushes are employed to clean machinery and equipment, preventing contamination during production. Buyers from Africa and the Middle East must prioritize sourcing brushes made from food-safe materials, such as polypropylene or nylon, to comply with health regulations. Additionally, the ability to customize brushes for specific equipment shapes can enhance cleaning efficiency, ensuring that all surfaces are adequately sanitized.

Manufacturing

Manufacturing industries utilize industrial brushes for surface finishing on metals and plastics. These brushes remove debris and prepare surfaces for coating, which is critical for ensuring proper adhesion and a smooth finish. B2B buyers in Europe and South America should consider customized brushes that cater to specific surface types and conditions. This customization can lead to improved surface quality, reducing the likelihood of defects and enhancing the overall product appeal.

Electronics

In the electronics industry, brushes are used to clean delicate components, ensuring they function correctly and have a longer lifespan. The use of non-abrasive materials is crucial, as any damage to these components can lead to significant operational issues. International buyers, particularly from regions with emerging electronics markets, should focus on sourcing high-quality brushes that meet specific cleaning requirements without risking damage to sensitive parts.

Packaging

Industrial brushes play a vital role in sorting and feeding products within automated packaging systems. They help maintain consistent flow and positioning of items, significantly increasing efficiency and reducing labor costs. Buyers from Africa and South America should evaluate the brush’s design to ensure it can handle various product sizes and shapes, facilitating seamless integration into existing machinery. This capability can lead to smoother operations and improved productivity in packaging lines.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for brush types

When selecting the right materials for industrial brushes, understanding the properties, advantages, disadvantages, and specific applications of each material is crucial for B2B buyers. This guide focuses on four common materials used in brush manufacturing: Nylon, Stainless Steel, Brass, and Natural Hair. Each material has unique characteristics that can significantly impact performance and suitability for various applications.

Nylon

Key Properties: Nylon brushes are known for their excellent durability and resistance to wear. They can withstand temperatures up to 120°C (248°F) and are resistant to many chemicals, making them suitable for a variety of applications.

Pros & Cons: The primary advantage of nylon brushes is their versatility and ability to maintain performance under stress. However, they may not be suitable for high-temperature applications beyond their rating, and their cost can be higher compared to other synthetic options.

Impact on Application: Nylon is compatible with various media, including solvents and oils, making it ideal for cleaning and polishing applications in industries such as automotive and manufacturing.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards regarding material safety and environmental impact, as nylon production can involve specific regulations.

Stainless Steel

Key Properties: Stainless steel brushes offer exceptional strength and corrosion resistance, making them ideal for harsh environments. They can handle high temperatures and pressures, making them suitable for heavy-duty applications.

Pros & Cons: The durability of stainless steel brushes translates to a longer lifespan, reducing the need for frequent replacements. However, they can be more expensive and may cause surface scratching on softer materials.

Impact on Application: These brushes are commonly used in metalworking, automotive, and food processing industries where cleanliness and durability are paramount.

Considerations for International Buyers: Compliance with food safety standards (like FDA or EU regulations) is critical for buyers in food processing sectors, especially in Europe and the Middle East.

Brass

Key Properties: Brass brushes are softer than steel, which makes them suitable for cleaning delicate surfaces without causing damage. They have good corrosion resistance and can withstand moderate temperatures.

Pros & Cons: The main advantage of brass brushes is their gentle touch on sensitive materials, making them ideal for applications requiring finesse. However, they are less durable than steel options and may wear out more quickly.

Impact on Application: Brass brushes are often used in applications involving electronics and delicate machinery, where surface integrity is crucial.

Considerations for International Buyers: Buyers should be aware of the specific standards for electrical conductivity and corrosion resistance, particularly in the electronics sector across Europe and the Middle East.

Natural Hair

Key Properties: Natural hair brushes, such as those made from boar or goat hair, offer a unique softness and flexibility. They are generally not suitable for high-temperature applications but excel in delicate cleaning tasks.

Pros & Cons: The primary advantage is their ability to hold and distribute liquids effectively, making them ideal for applications in the food and cosmetics industries. However, they are less durable and can be affected by moisture and chemicals.

Impact on Application: Natural hair brushes are often used in applications that require gentle cleaning or polishing, such as in the cosmetics and food processing industries.

Considerations for International Buyers: Compliance with animal welfare regulations and environmental standards is essential, particularly in Europe, where such regulations are stringent.

Summary Table

| Material | Typical Use Case for brush types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Cleaning and polishing | Excellent durability | Limited high-temperature use | Medium |

| Stainless Steel | Heavy-duty cleaning | Exceptional strength and corrosion resistance | Potential for surface scratching | High |

| Brass | Delicate surface cleaning | Gentle on sensitive materials | Less durable than steel | Medium |

| Natural Hair | Gentle cleaning and polishing | Effective liquid distribution | Less durable, moisture sensitive | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers to make informed decisions when sourcing industrial brushes tailored to their specific needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for brush types

Manufacturing Processes for Brush Types

Understanding the manufacturing processes of industrial brushes is crucial for B2B buyers seeking quality products. The production of brushes typically involves several main stages: material preparation, forming, assembly, and finishing. Each stage is vital in ensuring that the final product meets the specific needs of various applications across industries.

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. This includes selecting appropriate filaments based on the intended use of the brush. Common materials include:

- Synthetic Fibers: Nylon and polypropylene are popular for their durability and resistance to chemicals.

- Metal Filaments: Stainless steel, brass, and bronze are chosen for their strength and ability to withstand high temperatures.

- Natural Fibers: Options like horse hair and boar bristle are selected for delicate applications requiring gentler brushing action.

Once the materials are chosen, they undergo various treatments to enhance their properties. For example, metal filaments may be treated to prevent corrosion, while synthetic fibers might be dyed or coated for added durability.

Forming

After preparing the materials, the next stage is forming the brush components. This process varies based on the type of brush being produced:

- Cylinder Brushes: Filaments are inserted into a cylindrical core, which may be split or solid. The bristles are either glued or stapled into place.

- Wheel Brushes: Similar to cylinder brushes, but designed to provide a flat brushing action, typically used for surface finishing.

- Strip Brushes: Filaments are mounted on a flexible backing, allowing for various configurations depending on the application.

Advanced machinery is often employed during this stage, including CNC machines for precise cutting and shaping, ensuring consistency and quality across batches.

Assembly

The assembly stage involves combining the formed brush components into final products. This may include attaching handles, mounting bases, or other fixtures depending on the brush type. Careful attention is required here to ensure that all parts fit together correctly, as any misalignment can affect performance.

In some cases, brushes are customized to meet specific customer requirements, which may involve additional assembly steps. This customization capability is crucial for B2B buyers looking for tailored solutions that fit unique operational needs.

Finishing

The finishing process enhances the brush’s functionality and appearance. This may include:

- Trimming: Ensuring the bristles are of uniform length for consistent performance.

- Coating: Applying protective coatings to metal brushes to improve corrosion resistance.

- Quality Inspections: Conducting visual and mechanical inspections to ensure brushes meet specified standards before packaging.

Quality Assurance

Quality assurance is a critical component of brush manufacturing, ensuring that products meet both international standards and customer expectations. For international B2B buyers, understanding the quality control processes can significantly influence purchasing decisions.

International Standards

Manufacturers often adhere to recognized international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with ISO standards demonstrates a commitment to quality and consistency in production. Other industry-specific certifications may include:

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Certification: Relevant for brushes used in the oil and gas industry, ensuring they meet specific performance and safety requirements.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Inspecting raw materials before production begins to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Monitoring the manufacturing process through regular inspections to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before they are packaged and shipped.

Common testing methods include tensile testing for filament strength, visual inspections for defects, and performance testing to verify that brushes function as intended under operational conditions.

Verifying Supplier Quality Control

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is vital. Here are several strategies to ensure suppliers adhere to high standards:

- Conduct Audits: Regularly auditing suppliers’ manufacturing facilities can provide insight into their quality control processes and adherence to standards.

- Request Quality Reports: Suppliers should be willing to provide documentation detailing their quality control measures, inspection results, and compliance with international standards.

- Utilize Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality practices and product quality.

Quality Control Nuances for International Buyers

B2B buyers from diverse regions may encounter specific challenges related to quality control. Understanding these nuances can help in establishing effective partnerships:

- Cultural Differences: Different regions may have varying interpretations of quality standards. Buyers should communicate clearly about expectations to avoid misunderstandings.

- Regulatory Compliance: Ensure that suppliers are familiar with and compliant with local regulations and standards in the buyer’s region.

- Logistical Considerations: International shipping can introduce additional quality risks. Buyers should consider how products will be handled during transportation and ensure suppliers take necessary precautions.

By focusing on these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing industrial brushes, ensuring they obtain products that meet their operational needs and quality expectations.

Related Video: Mercedes C-Class CAR FACTORY – HOW IT’S MADE Assembly Production Line Manufacturing Making of

Comprehensive Cost and Pricing Analysis for brush types Sourcing

Understanding Cost Components in Brush Types Sourcing

When sourcing industrial brushes, it is crucial to understand the underlying cost structure. The primary cost components include:

-

Materials: The choice of bristle materials—such as nylon, steel, brass, or natural fibers—significantly impacts costs. For instance, synthetic materials often offer durability and cleaning efficiency, while natural options may be more expensive due to their unique properties.

-

Labor: Labor costs can vary based on the complexity of the brush design and the manufacturing processes involved. More intricate brush types, like custom cylinder or disk brushes, typically require skilled labor, which can increase overall costs.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and equipment maintenance. Efficient production facilities can help minimize overhead costs, which is crucial for competitive pricing.

-

Tooling: The initial investment in tooling for specialized brushes can be significant. Custom designs often necessitate unique tooling, which can affect pricing, especially for smaller production runs.

-

Quality Control (QC): Ensuring that brushes meet industry standards requires investment in quality control processes. This includes testing materials and finished products, which contributes to the overall cost.

-

Logistics: Transportation costs can vary widely based on geographical location and the chosen Incoterms. Importing brushes from manufacturers in other regions may incur additional shipping and customs fees.

-

Margin: Supplier profit margins will vary depending on market positioning and competition. It’s essential to consider how margins affect final pricing.

Key Influencers on Pricing

Several factors can influence the pricing of industrial brushes:

-

Volume/MOQ: Bulk purchasing usually leads to lower unit prices. Suppliers often offer discounts for larger order quantities, making it beneficial for buyers to consolidate their orders.

-

Specifications/Customization: Custom brushes tailored to specific applications often come at a premium. Buyers should weigh the cost against the potential productivity gains from using specialized brushes.

-

Materials: The choice of materials can greatly affect the cost. For example, stainless steel brushes may be more expensive but offer longer life and better performance in demanding applications.

-

Quality/Certifications: Brushes that meet specific industry standards or certifications may command higher prices. However, investing in certified products can lead to better performance and compliance, reducing long-term costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their track record and the quality assurance they provide.

-

Incoterms: Understanding the implications of Incoterms is essential for international buyers. Different terms can affect shipping costs and responsibilities, impacting the total cost of ownership.

Buyer Tips for Cost-Efficiency

To navigate the complexities of brush sourcing and ensure cost-efficiency, consider the following tips:

-

Negotiate Terms: Leverage your purchasing power when negotiating prices, especially for large orders. Discuss volume discounts and payment terms to optimize costs.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, consider the long-term costs associated with maintenance, efficiency, and lifespan of the brushes. Higher-quality brushes may have a higher upfront cost but can lead to lower TCO.

-

Research Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, exploring local suppliers may reduce logistics costs and lead times. Additionally, local suppliers may offer better support for customization.

-

Stay Informed on Pricing Trends: Market conditions can affect material costs and supplier pricing strategies. Staying informed will help buyers make timely purchasing decisions.

-

Understand Pricing Nuances: Be aware that prices can vary significantly between regions due to factors like tariffs, trade agreements, and currency fluctuations. This is particularly relevant for buyers importing from or exporting to different continents.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. It is advisable to conduct thorough market research and consult with multiple suppliers to obtain accurate pricing.

Spotlight on Potential brush types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘brush types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for brush types

When purchasing industrial brushes, understanding their essential technical properties and trade terminology can significantly enhance decision-making processes for B2B buyers. This knowledge is crucial for ensuring that the selected brushes meet specific operational needs and align with procurement practices.

Key Technical Properties

-

Material Grade

The material used in brush construction—such as steel, nylon, or natural fibers—determines durability, flexibility, and suitability for specific applications. For instance, stainless steel brushes are favored in the automotive industry for their resistance to high temperatures and corrosion, while nylon brushes are often used in food processing due to their non-abrasive properties. Selecting the right material can enhance productivity and extend the life of the brush. -

Filament Type

Filament type refers to the nature of the bristles, which can be synthetic (e.g., nylon, polypropylene), metal (e.g., brass, stainless steel), or natural (e.g., horse hair, boar bristle). Each type offers distinct benefits; for example, metal filaments are ideal for heavy-duty cleaning, while natural hairs are suitable for delicate applications. Understanding filament types is essential for aligning brush performance with specific tasks. -

Brush Diameter and Length

The dimensions of a brush, including its diameter and length, impact its effectiveness in various applications. For instance, a larger diameter brush may cover more surface area but may be less maneuverable in tight spaces. Buyers should consider the physical space available and the specific cleaning or polishing tasks when selecting brush sizes. -

Bristle Density

Bristle density refers to the number of bristles per unit area on the brush. A denser brush can provide a more thorough cleaning or polishing effect, while a less dense brush may be better suited for gentler applications. This property influences both the efficiency and the quality of the work performed. -

Tolerance Levels

Tolerance levels indicate the permissible variations in brush dimensions and filament placement. High tolerance levels ensure precision in applications where exact dimensions are critical, such as in automotive or aerospace industries. Buyers should verify tolerance specifications to ensure that the brushes will fit seamlessly into their production processes. -

Operating Temperature

The maximum operating temperature indicates the heat resistance of the brush material. This specification is particularly important in industries like automotive or metalworking, where brushes are often subjected to high temperatures during use. Selecting brushes that can withstand specific operational conditions is vital for maintaining efficiency and avoiding premature wear.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of industrial brushes, understanding OEM specifications can help buyers ensure compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ can assist buyers in budgeting and planning their procurement strategies effectively, particularly when sourcing from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a formal request for pricing information from suppliers. This document typically outlines the specifications and quantities needed, enabling suppliers to provide accurate quotes. Utilizing RFQs can streamline the purchasing process and foster competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial for understanding shipping costs and responsibilities in cross-border trade. -

Lead Time

Lead time is the duration between placing an order and receiving it. Understanding lead times is essential for inventory management and ensuring that production schedules remain on track, especially when dealing with international suppliers. -

Customization Options

Customization options refer to the ability to tailor brush specifications to meet specific needs, such as size, material, or design. This flexibility can enhance operational efficiency and product performance, making it a key consideration for B2B buyers.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions that optimize their procurement processes and ensure the effective use of industrial brushes in their operations.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the brush types Sector

Market Overview & Key Trends

The global industrial brush market is experiencing significant growth, driven by increasing demand across various sectors such as manufacturing, automotive, and food processing. B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are witnessing a surge in the adoption of advanced industrial brushes due to their versatility in applications like cleaning, polishing, and deburring. Key trends include the customization of brush types to meet specific operational needs, leveraging innovations in materials science to enhance durability and efficiency.

Additionally, the rise of Industry 4.0 is influencing sourcing strategies, with digital platforms facilitating the procurement process. B2B buyers are increasingly utilizing online marketplaces and e-commerce solutions to source industrial brushes, allowing for greater transparency and efficiency in supply chain management. In regions like Argentina and Brazil, where manufacturing is expanding, the demand for high-quality brushes tailored to local requirements is rising.

Moreover, the shift towards automation in manufacturing processes is creating opportunities for specialized brush applications, such as those used in robotic systems. International buyers must stay attuned to these market dynamics to leverage emerging technologies and optimize their sourcing strategies effectively.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a crucial consideration for B2B buyers in the industrial brush sector. The environmental impact of production processes, particularly in terms of waste and energy consumption, necessitates a focus on ethical sourcing practices. Companies are increasingly expected to provide transparency in their supply chains, ensuring that materials used in brush manufacturing are sourced responsibly.

Illustrative Image (Source: Google Search)

Buyers should prioritize suppliers that offer ‘green’ certifications, such as ISO 14001 for environmental management or those that utilize recycled materials in their products. The adoption of eco-friendly materials, such as biodegradable filaments or sustainably sourced natural fibers, is also gaining traction. Not only do these practices help reduce environmental footprints, but they also enhance brand reputation among environmentally conscious consumers.

Furthermore, implementing a circular economy approach, where brushes are designed for longevity and recyclability, can lead to significant cost savings and reduced waste. For B2B buyers, aligning sourcing strategies with sustainability goals is not just a compliance measure but also a competitive advantage in an increasingly eco-conscious market.

Brief Evolution/History

The industrial brush sector has evolved significantly over the past century, transitioning from rudimentary hand-crafted tools to highly specialized, technologically advanced products. Initially, brushes were primarily made from natural materials, such as animal hairs and plant fibers, catering to basic cleaning needs.

With advancements in materials science and manufacturing processes, synthetic materials like nylon and polypropylene became prevalent, offering enhanced durability and versatility. The introduction of automated manufacturing methods allowed for the production of custom brushes tailored to specific industrial applications, thus expanding their utility across various sectors.

Today, the focus on sustainability and ethical sourcing reflects the industry’s adaptation to modern environmental challenges, positioning industrial brushes not just as tools, but as integral components of efficient and responsible manufacturing practices. This evolution underscores the importance of choosing suppliers who are committed to innovation and sustainability in their product offerings.

Related Video: Lesson 1 – A Brief Overview of International Trade

Frequently Asked Questions (FAQs) for B2B Buyers of brush types

-

How do I vet suppliers for industrial brushes?

When sourcing industrial brushes, it’s crucial to conduct thorough due diligence on potential suppliers. Start by checking their credentials, including industry certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, request references from existing clients and evaluate their experience in your specific industry. Consider visiting their manufacturing facility, if feasible, to assess their production capabilities and quality control processes. Online reviews and trade associations can also provide insights into a supplier’s reputation. -

Can industrial brushes be customized for specific applications?

Yes, many suppliers offer customization options for industrial brushes to meet specific application requirements. Customization may include variations in brush size, bristle material, and filament density. When discussing your needs with a supplier, provide detailed specifications of your application, including the type of material to be brushed and the desired finish. Request samples to evaluate performance before placing a larger order, ensuring the customized brushes will meet your operational demands. -

What are the typical minimum order quantities (MOQs) for industrial brushes?

Minimum order quantities can vary significantly among suppliers and depend on the type of brush and level of customization required. Standard brushes may have lower MOQs, often around 100 to 500 units, while custom brushes can range from 50 to 1,000 units or more. Always clarify MOQs upfront and consider negotiating terms, especially if you plan to establish a long-term partnership. This flexibility can help manage inventory costs effectively, particularly for businesses in Africa and South America where supply chains may be less predictable. -

What are common lead times for brush orders?

Lead times for industrial brush orders can vary based on factors such as the complexity of customization, supplier location, and current production schedules. Typically, standard orders may take 2-4 weeks, while custom orders might require 4-8 weeks or longer. To avoid delays, provide accurate forecasts of your needs and confirm lead times during the negotiation phase. For critical applications, consider establishing safety stock levels or working with suppliers who offer expedited services to ensure continuity in your operations. -

How do I ensure quality assurance and certifications for industrial brushes?

Quality assurance is vital when sourcing industrial brushes, as subpar products can lead to operational inefficiencies. Request documentation of the supplier’s quality management system, including certifications such as ISO 9001 or industry-specific standards. Inquire about their testing procedures, including material inspections and performance evaluations. It’s also advisable to conduct your quality checks upon receipt of goods, particularly for critical applications in industries like food processing or automotive, where compliance with safety standards is paramount. -

What should I consider regarding logistics and shipping when ordering brushes?

Logistics plays a crucial role in the timely delivery of industrial brushes. When discussing shipping options, consider factors such as the supplier’s location, shipping methods, and costs. Ensure that your supplier has experience with international shipping and can provide clear information on customs documentation and duties. Additionally, explore options for bulk shipping to reduce costs, especially for larger orders. For buyers in regions like Africa or South America, understanding local import regulations will also help avoid unexpected delays. -

How can disputes with suppliers be effectively managed?

Disputes can arise over product quality, delivery timelines, or payment terms. To mitigate these issues, establish clear terms in your contract, including specifications, delivery schedules, and penalties for non-compliance. Regular communication with your supplier can help address concerns before they escalate. If a dispute arises, approach it professionally, seeking to resolve issues amicably through negotiation. Consider using mediation services if direct discussions fail, ensuring that both parties are committed to a resolution. -

What payment terms are common for international B2B brush transactions?

Payment terms can vary widely among suppliers but typically include options like advance payment, letters of credit, or net terms (e.g., net 30, net 60). For international transactions, letters of credit provide security for both parties, ensuring payment only occurs upon meeting specified conditions. Discuss payment options during initial negotiations to find a mutually agreeable solution that balances cash flow needs with supplier security. Always review the terms in the context of your local financial regulations, especially in countries with fluctuating currencies.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for brush types

In conclusion, the strategic sourcing of industrial brushes is paramount for enhancing operational efficiency and product quality across various industries. Buyers from Africa, South America, the Middle East, and Europe should prioritize understanding the diverse types of brushes—such as cylinder, wheel, and strip brushes—along with their specific applications and materials. Selecting the right brush not only boosts productivity but also ensures optimal performance in tasks like cleaning, deburring, and polishing.

Illustrative Image (Source: Google Search)

Key B2B Takeaways:

– Customization is Key: Many manufacturers offer tailored solutions, allowing buyers to meet unique operational needs effectively.

– Material Matters: The choice of materials—be it synthetic, natural, or metal—directly impacts the brush’s durability and suitability for specific applications.

– Maintenance is Essential: Regular upkeep prolongs the lifespan of brushes, ensuring consistent performance and reducing replacement costs.

As industries continue to evolve, the demand for high-quality, versatile brushes will grow. International B2B buyers should remain proactive, leveraging strategic sourcing to identify reliable suppliers and innovative brush technologies. Embrace this opportunity to enhance your operational capabilities and drive success in your market.