Mastering Electrical Plug Connector Types for Strategic B2B

Introduction: Navigating the Global Market for electrical plug connector types

Electrical plug connectors are critical components in the global supply chain, serving as the backbone for reliable electrical connections across various industries. As international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe (including key markets like Germany and Egypt) navigate the complexities of sourcing these essential products, understanding the different types of electrical connectors becomes paramount. This guide provides a comprehensive overview of connector types, materials, manufacturing quality control, supplier options, and cost factors, ensuring that buyers are well-equipped to make informed sourcing decisions.

In an increasingly interconnected world, the importance of selecting the right electrical plug connector cannot be overstated. Connectors not only facilitate seamless communication and power distribution but also enhance the safety and efficiency of electronic systems. This guide delves into various connector types, including pin and sleeve, twist-lock, USB, and specialized industrial connectors, highlighting their unique applications and advantages.

Moreover, it addresses key considerations such as quality assurance practices and supplier reliability, which are crucial for maintaining operational excellence. With insights into market trends and frequently asked questions, this resource empowers B2B buyers to navigate the global marketplace confidently. By leveraging this guide, you can ensure that your procurement strategy aligns with the latest industry standards and meets your organization’s specific needs, ultimately driving success in your business operations.

Understanding electrical plug connector types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| IEC 60309 (CeeForm) | Cylindrical design, color-coded for voltage, high current capacity | Industrial power distribution, construction sites | Pros: Robust, watertight, easy identification; Cons: Higher cost than standard connectors. |

| Twist-Lock Connectors | Locking mechanism prevents accidental disconnection | Data centers, medical equipment | Pros: Secure connection, vibration resistant; Cons: More complex installation. |

| D-subminiature | D-shaped, polarized design, versatile pin configurations | Computers, telecommunications | Pros: Wide availability, durable; Cons: Limited current capacity compared to heavy-duty options. |

| USB Connectors | Universal standard, various types (Type-A, Type-C) | Consumer electronics, peripherals | Pros: Simultaneous power/data transfer, widely compatible; Cons: Not suitable for high power applications. |

| RCA Connectors | Simple design, color-coded for audio/video signals | Audio-visual equipment | Pros: Easy to use, reliable for analog signals; Cons: Limited to short distances, not for digital use. |

IEC 60309 (CeeForm)

The IEC 60309 connector, commonly known as the CeeForm connector, is designed for high-current applications and is frequently used in industrial settings. Its cylindrical shape and color-coding based on voltage ratings allow for quick identification, enhancing safety during use. B2B buyers should consider the operational environment, as these connectors are robust and watertight, making them suitable for construction sites and outdoor events. Although they come at a higher price point, their durability and reliability justify the investment.

Twist-Lock Connectors

Twist-lock connectors feature a unique locking mechanism that secures the connection by twisting the plug into the socket. This design prevents accidental disconnections caused by vibrations or movement, making them ideal for critical applications such as data centers and medical equipment. When purchasing, B2B buyers should evaluate the specific voltage and pole configurations needed for their applications. While they offer enhanced safety, the installation process can be more complex compared to traditional connectors.

D-subminiature

D-subminiature connectors are characterized by their D-shaped design, which ensures proper alignment and polarization. These connectors are widely used in computers and telecommunications, providing a reliable connection for various devices. When considering D-sub connectors, buyers should assess the pin configuration and current capacity required for their applications. While they are durable and widely available, their current capacity may not meet the demands of heavy-duty applications.

USB Connectors

USB connectors have become a universal standard for connecting a variety of devices, including computers, smartphones, and printers. They come in several types, such as Type-A and Type-C, allowing for both power and data transfer. For B2B buyers, the versatility and compatibility of USB connectors make them ideal for consumer electronics and peripheral devices. However, it is essential to note that they are not suitable for high-power applications, so understanding the specific requirements of the intended use is crucial.

RCA Connectors

RCA connectors are commonly found in audio-visual applications, known for their simplicity and ease of use. They consist of color-coded plugs for video and audio signals, making them user-friendly for both consumer and professional settings. B2B buyers should consider their suitability for short-distance analog connections, as RCA connectors are not designed for digital signals or long-range applications. While they provide a reliable connection, their limitations in terms of distance and signal type may affect purchasing decisions in professional environments.

Related Video: Automotive Electrical Wire Connector Types Explained

Key Industrial Applications of electrical plug connector types

| Industry/Sector | Specific Application of Electrical Plug Connector Types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power distribution in heavy machinery using IEC 60309 connectors | Ensures reliable power supply to machinery, reducing downtime. | Look for connectors with high current ratings and environmental ratings for harsh conditions. |

| Telecommunications | Data transmission using D-sub connectors | Facilitates stable connections for data transfer, enhancing service reliability. | Ensure compatibility with existing systems and check for durability in high-usage environments. |

| Construction | Use of twist-lock connectors for temporary power supply | Prevents accidental disconnections, ensuring safety on job sites. | Select connectors with appropriate voltage ratings and secure locking mechanisms. |

| Automotive | Automotive electrical connectors for vehicle systems | Supports vehicle reliability and performance, crucial for customer satisfaction. | Source connectors that meet automotive standards and can withstand vibrations and temperature variations. |

| Consumer Electronics | USB connectors for device charging and data transfer | Provides universal compatibility, enhancing customer convenience. | Consider the latest USB standards for faster data transfer and charging capabilities. |

In the manufacturing sector, IEC 60309 connectors are crucial for power distribution in heavy machinery. These connectors offer high current capacity and are designed to withstand harsh industrial environments, reducing the risk of downtime caused by power interruptions. International buyers should prioritize sourcing connectors that meet local electrical standards and have proven durability in similar operational conditions.

In telecommunications, D-sub connectors are widely used for data transmission between devices. Their robust design ensures stable connections, which is vital for maintaining service reliability. Buyers should verify compatibility with existing systems and assess the connectors’ performance under high-usage conditions, ensuring they meet the required specifications for data integrity.

The construction industry frequently employs twist-lock connectors for temporary power supply setups. These connectors feature a locking mechanism that prevents accidental disconnections, significantly enhancing safety on job sites. Buyers must consider the voltage ratings and ensure that the connectors are suitable for outdoor use, especially in environments prone to vibration or movement.

In the automotive industry, specialized electrical connectors are essential for ensuring the reliability of vehicle systems. These connectors must endure extreme conditions, including temperature fluctuations and vibrations. B2B buyers should focus on sourcing connectors that comply with automotive standards, ensuring they can maintain performance and safety throughout the vehicle’s lifecycle.

Lastly, in the realm of consumer electronics, USB connectors play a vital role in device connectivity for charging and data transfer. Their universal design allows for compatibility across various devices, enhancing user convenience. Buyers should stay updated on the latest USB standards to ensure they are acquiring connectors that support faster data transfer and charging, thereby improving overall product functionality.

Related Video: Electrical Conduit: Types and Uses

Strategic Material Selection Guide for electrical plug connector types

When selecting materials for electrical plug connectors, it is essential to understand the properties, advantages, disadvantages, and specific applications of each material. This knowledge is particularly valuable for international B2B buyers, as it aids in making informed decisions that align with operational requirements and regulatory standards.

1. Plastic (Polycarbonate/Polyamide)

Key Properties:

Plastic materials such as polycarbonate and polyamide are lightweight and exhibit excellent electrical insulation properties. They can typically withstand temperatures ranging from -40°C to 120°C and possess good chemical resistance.

Pros & Cons:

Pros: They are cost-effective and easy to mold into complex shapes, making them suitable for high-volume production.

Cons: Plastics can be less durable than metals, particularly in high-stress environments, and may degrade under prolonged exposure to UV light or extreme temperatures.

Impact on Application:

Plastic connectors are ideal for consumer electronics and low-voltage applications. However, they may not be suitable for high-temperature or high-load scenarios, necessitating careful consideration of the application environment.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as IEC and ASTM. In regions like Europe, adherence to RoHS directives for hazardous substances is critical.

2. Copper Alloy

Key Properties:

Copper alloys, including brass and bronze, are known for their excellent electrical conductivity and mechanical strength. They can handle high temperatures and exhibit good corrosion resistance, particularly when treated with protective coatings.

Pros & Cons:

Pros: High durability and reliability make copper alloys suitable for heavy-duty applications. They also have a long lifespan, reducing the need for frequent replacements.

Cons: The cost of copper alloys is generally higher than plastics, and they may require more complex manufacturing processes.

Impact on Application:

These materials are commonly used in industrial and automotive connectors, where high current capacity and durability are essential. They are particularly effective in environments where mechanical stress is a concern.

Considerations for International Buyers:

Buyers should be aware of the varying standards for copper alloys in different regions, such as DIN standards in Germany and JIS standards in Japan. Additionally, the sourcing of copper may be subject to ethical and environmental considerations.

3. Stainless Steel

Key Properties:

Stainless steel provides exceptional corrosion resistance and mechanical strength. It can withstand extreme temperatures and harsh environmental conditions, making it suitable for a wide range of applications.

Pros & Cons:

Pros: Its durability and resistance to corrosion make stainless steel connectors ideal for outdoor and industrial applications. They are also less prone to wear and tear compared to other materials.

Cons: The higher cost and weight of stainless steel can be limiting factors, especially in applications where weight savings are critical.

Impact on Application:

Stainless steel connectors are often used in marine, aerospace, and industrial applications where exposure to moisture and corrosive substances is common.

Considerations for International Buyers:

It is crucial for buyers to verify compliance with international standards for stainless steel grades, such as ASTM A276 or DIN 1.4301. Additionally, buyers should consider the availability of specific grades in their region.

4. Aluminum

Key Properties:

Aluminum is lightweight, has good electrical conductivity, and offers excellent corrosion resistance when anodized. It can typically operate effectively in temperatures up to 150°C.

Pros & Cons:

Pros: Aluminum connectors are often more affordable than copper and stainless steel, making them a popular choice for cost-sensitive applications.

Cons: They may not be as strong as copper alloys or stainless steel, and their mechanical properties can be affected by high temperatures.

Impact on Application:

Aluminum connectors are widely used in telecommunications and automotive applications where weight savings and cost-effectiveness are priorities.

Considerations for International Buyers:

Buyers should ensure that aluminum connectors meet regional standards for electrical performance and corrosion resistance. In Europe, compliance with CE marking may be necessary.

| Material | Typical Use Case for electrical plug connector types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Consumer electronics, low-voltage applications | Cost-effective and lightweight | Less durable in high-stress areas | Low |

| Copper Alloy | Industrial and automotive connectors | High durability and reliability | Higher cost and complex mfg process | High |

| Stainless Steel | Marine, aerospace, industrial applications | Exceptional corrosion resistance | Higher cost and weight | High |

| Aluminum | Telecommunications, automotive applications | Lightweight and cost-effective | Lower strength than copper alloys | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for electrical plug connector types

Manufacturing Processes for Electrical Plug Connectors

Understanding the manufacturing processes of electrical plug connectors is vital for international B2B buyers aiming to ensure quality and reliability in their supply chains. The manufacturing process typically involves several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first step in the manufacturing process involves selecting appropriate materials. Electrical connectors usually comprise two main components: the housing, which is typically molded from high-quality plastics or ceramics, and the terminals, often made from conductive metals such as copper or brass. The choice of materials directly affects the connector’s durability, conductivity, and resistance to environmental factors.

- Material Selection: Buyers should prioritize suppliers who utilize materials that meet international standards for electrical safety and performance.

- Pre-Processing: This includes cutting, shaping, and treating materials to ensure they meet the specifications required for their intended application.

Forming

The forming stage involves shaping the prepared materials into the desired connector forms. This can include various techniques depending on the type of connector being produced.

- Injection Molding: Commonly used for housing components, this process allows for high precision and repeatability, essential for large production runs.

- Stamping and Machining: These techniques are often used for metal terminals to create the necessary shapes and dimensions for effective electrical contact.

Assembly

Once the components are formed, they are assembled into finished connectors. The assembly process can vary significantly based on the connector type and application.

- Manual vs. Automated Assembly: While some high-volume connectors may be assembled using automated machinery, others may require manual assembly due to their complexity or low production volume.

- Connection Techniques: Methods such as soldering, crimping, or using screw terminals are employed to ensure a secure electrical connection between terminals and wires.

Finishing

The finishing stage enhances the connector’s performance and aesthetic appeal. This may include surface treatments, coatings, and testing.

- Coatings: Applying anti-corrosion coatings to metal parts can significantly extend the lifespan of connectors in harsh environments.

- Quality Testing: Before final packaging, connectors undergo rigorous testing to ensure they meet specified performance criteria.

Quality Assurance in Manufacturing

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that electrical connectors meet both customer expectations and regulatory standards. Buyers should familiarize themselves with relevant international standards and industry-specific certifications.

International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for manufacturers looking to demonstrate their commitment to quality.

- CE Marking: Particularly relevant for European markets, CE marking indicates that products comply with EU safety, health, and environmental protection standards.

Industry-Specific Certifications

- API (American Petroleum Institute): For connectors used in the oil and gas industry, compliance with API standards is critical.

- UL Certification: Underwriters Laboratories (UL) certification is essential for connectors used in North America, ensuring safety and performance.

Quality Control Checkpoints

Quality control (QC) measures are implemented at various checkpoints throughout the manufacturing process to ensure that products meet established standards.

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials for compliance with specifications before they enter the production process.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to identify and rectify any defects early in the process.

- Final Quality Control (FQC): After assembly, connectors undergo final testing, including electrical performance tests, mechanical integrity checks, and environmental simulations.

Common Testing Methods

To validate the quality of electrical connectors, manufacturers employ various testing methods:

- Electrical Testing: This includes continuity tests, insulation resistance tests, and dielectric strength tests to ensure safe and reliable electrical performance.

- Mechanical Testing: Tests such as pull-out strength and vibration tests assess the physical robustness of connectors under operational conditions.

- Environmental Testing: Connectors may be subjected to temperature, humidity, and corrosion tests to evaluate their performance in extreme conditions.

Verifying Supplier Quality Control

For B2B buyers, ensuring supplier quality control is paramount. Here are several strategies to verify the QC processes of potential suppliers:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s processes, facilities, and adherence to quality standards.

- Quality Reports: Requesting detailed QC reports, including testing results and compliance certifications, provides insights into the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s QC processes and the quality of the final products.

QC and Certification Nuances for International Buyers

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to QC and certification:

- Regulatory Variations: Different regions may have varying regulatory requirements and standards. Buyers should ensure that their suppliers are compliant with both local and international regulations.

- Cultural Considerations: Understanding the cultural context in which manufacturers operate can aid in establishing effective communication and expectations regarding quality standards.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance mechanisms for electrical plug connectors is crucial for international B2B buyers. By focusing on material selection, manufacturing techniques, and robust quality control measures, buyers can ensure they procure reliable and high-quality connectors tailored to their specific applications.

Related Video: How Electric Wires are Made in Factory with Amazing Process | Electric Cables Manufacturing

Comprehensive Cost and Pricing Analysis for electrical plug connector types Sourcing

When sourcing electrical plug connectors, understanding the comprehensive cost structure and pricing dynamics is essential for international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe. Below is an analysis that outlines the key cost components, price influencers, and practical tips for effective purchasing.

Cost Components

-

Materials: The primary cost driver is the raw materials used in manufacturing connectors. Common materials include plastics for housings and metals like copper or aluminum for terminals. The quality and type of materials significantly influence pricing.

-

Labor: Labor costs vary based on the region of production. Countries with lower labor costs can offer more competitive pricing. However, highly skilled labor is often required for quality assurance and specialized manufacturing processes.

-

Manufacturing Overhead: This includes costs associated with factory operations such as utilities, maintenance, and management. Higher overhead can arise from compliance with safety and environmental regulations, especially in regions with stringent standards.

-

Tooling: Initial investment in tooling and molds is crucial for custom connector designs. This cost is amortized over the production volume, affecting the unit price for lower volume orders.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, especially for connectors used in critical applications. Enhanced QC measures can increase costs but are necessary for compliance with international standards.

-

Logistics: Shipping costs can vary based on the origin of production and destination. Factors such as freight charges, insurance, and tariffs must be considered, particularly for international transactions.

-

Margin: Supplier margins can vary based on their market positioning and the level of customization required. Understanding the market dynamics and supplier reputation can help buyers gauge appropriate margins.

Price Influencers

-

Volume/MOQ: Minimum order quantities (MOQs) significantly affect pricing. Higher volumes typically yield lower per-unit costs due to economies of scale. Buyers should assess their demand to optimize order sizes.

-

Specifications/Customization: Custom connectors may incur additional costs related to design and production. Clearly defined specifications can minimize back-and-forth, reducing lead times and costs.

-

Materials: The choice of materials impacts both cost and performance. Buyers should balance cost with the required durability and safety standards for their specific applications.

-

Quality/Certifications: Higher-quality connectors that meet international certifications (e.g., ISO, UL) often come at a premium. Buyers should evaluate whether the added expense aligns with their operational needs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better quality assurance and support.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for determining responsibilities for shipping costs, insurance, and risk. This knowledge helps buyers negotiate more effectively.

Buyer Tips

-

Negotiation: Engage in discussions with suppliers about pricing based on volume and long-term relationships. Leveraging existing contracts can lead to better pricing structures.

-

Cost-Efficiency: Assess the total cost of ownership (TCO) rather than just the initial purchase price. Consider factors like maintenance, reliability, and lifespan of connectors.

-

Pricing Nuances: Be aware of regional pricing differences. For instance, connectors sourced from Europe may have higher quality certifications but also come with higher costs compared to those from Asia or South America.

-

Local Regulations: Familiarize yourself with local import regulations, tariffs, and compliance standards that may affect overall costs when sourcing connectors internationally.

Disclaimer

Pricing for electrical plug connectors can vary widely based on the aforementioned factors, and it is advisable for buyers to request quotes from multiple suppliers to ensure competitive pricing. Always consider the total cost implications in the context of your operational requirements.

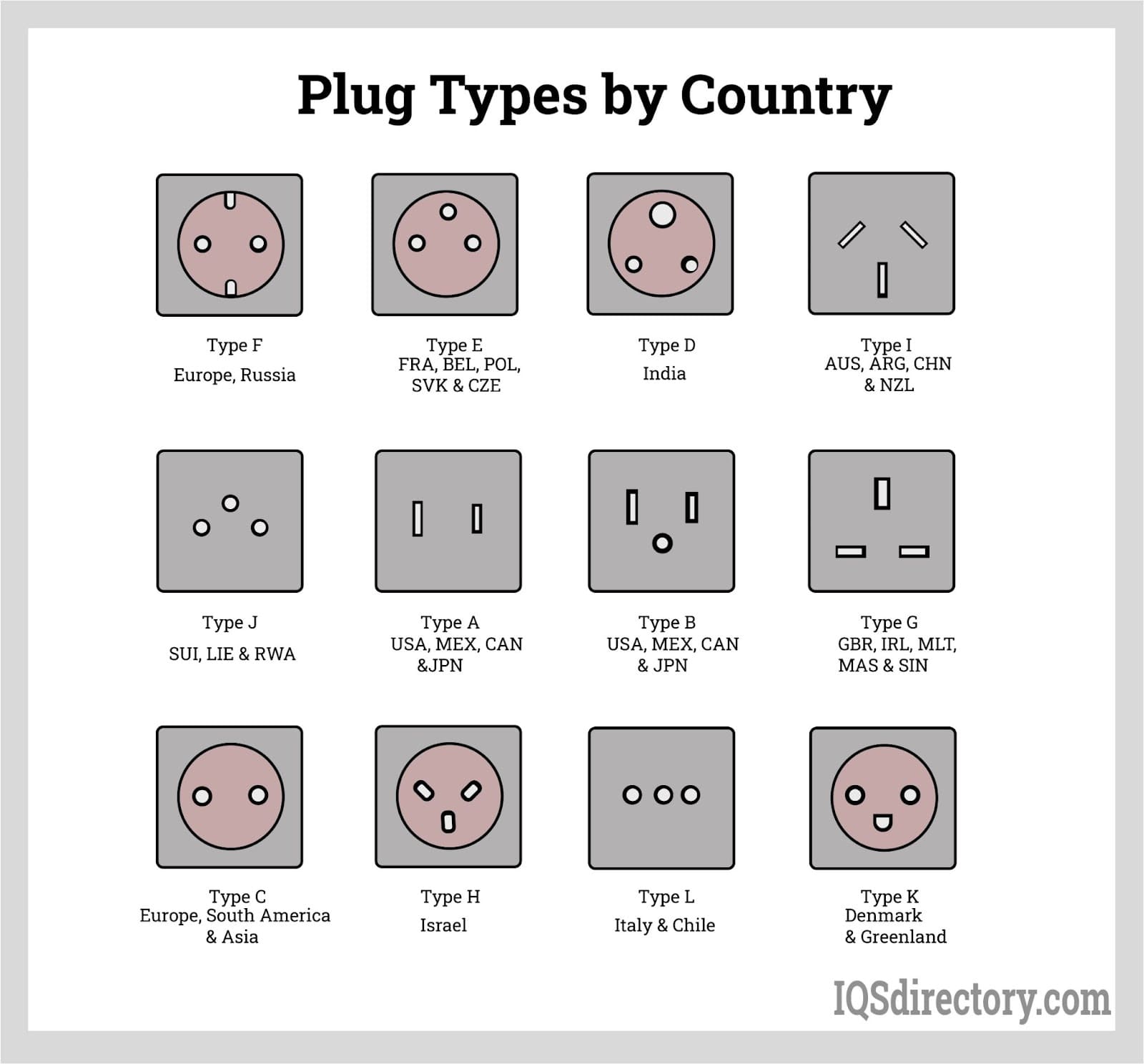

Illustrative Image (Source: Google Search)

Spotlight on Potential electrical plug connector types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘electrical plug connector types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for electrical plug connector types

Key Technical Properties of Electrical Plug Connectors

Understanding the technical properties of electrical plug connectors is crucial for international B2B buyers to make informed purchasing decisions. Here are several critical specifications to consider:

-

Material Grade

– Definition: The composition of materials used in connectors, including metals for terminals (e.g., copper, gold plating) and plastics for housing.

– Importance: Material grade affects conductivity, durability, and resistance to environmental factors. High-quality materials can enhance performance and longevity, reducing the total cost of ownership. -

Current Rating

– Definition: The maximum amount of electrical current a connector can safely carry, typically measured in amperes (A).

– Importance: Selecting a connector with an appropriate current rating is essential to prevent overheating and potential failure in applications, particularly in industrial settings where machinery demands high power. -

Voltage Rating

– Definition: The maximum voltage that a connector can handle, measured in volts (V).

– Importance: Understanding voltage ratings ensures that connectors are suitable for the specific electrical systems in which they will be used, enhancing safety and reliability.

Illustrative Image (Source: Google Search)

-

Temperature Range

– Definition: The range of temperatures within which a connector can operate safely, often specified in degrees Celsius (°C).

– Importance: Connectors must be able to withstand the environmental conditions of their application. In regions with extreme temperatures, such as parts of Africa and the Middle East, this property is critical. -

Ingress Protection (IP) Rating

– Definition: A classification that indicates the degree of protection provided against dust and moisture, typically expressed as “IP” followed by two digits (e.g., IP67).

– Importance: An adequate IP rating is vital for connectors used in outdoor or industrial environments, ensuring they remain functional despite exposure to harsh conditions. -

Tolerance

– Definition: The acceptable range of variation in dimensions and performance characteristics of a connector.

– Importance: Tolerance levels determine the compatibility of connectors with other components. Tight tolerances are essential for precision applications, while looser tolerances may suffice in less critical situations.

Common Trade Terminology

Familiarity with industry jargon can significantly enhance communication and efficiency in B2B transactions. Here are several essential terms:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships is critical for buyers seeking reliable suppliers who can provide components that meet specific quality standards. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their purchases and inventory, ensuring they meet the supplier’s requirements without overcommitting resources. -

RFQ (Request for Quotation)

– Definition: A formal process where a buyer requests pricing and terms from suppliers for specific products.

– Importance: An RFQ is essential for comparing offers from multiple vendors, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

– Definition: A series of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international trade.

– Importance: Familiarity with Incoterms is crucial for understanding the responsibilities of buyers and sellers in international transactions, such as shipping costs and risk management. -

Lead Time

– Definition: The time taken from placing an order to receiving the product.

– Importance: Understanding lead times is vital for planning production schedules and ensuring timely project completion. -

Certification Standards

– Definition: Industry-specific standards that products must meet to ensure safety and performance (e.g., CE, UL).

– Importance: Compliance with certification standards is essential for market acceptance, particularly in regulated industries or regions with strict safety requirements.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of electrical plug connectors more effectively, ensuring they select the right products for their needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the electrical plug connector types Sector

Market Overview & Key Trends

The electrical plug connector types market is experiencing significant growth driven by the increasing demand for connectivity in diverse industries. Key factors fueling this growth include the rapid expansion of the telecommunications sector, the rise of electric vehicles, and the proliferation of IoT devices. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of the ongoing transition towards more integrated and efficient electrical systems, which has led to the development of advanced connector technologies.

One prominent trend is the shift towards modular and customizable connectors that allow for greater flexibility in design and application. This is particularly relevant for industries such as automotive and industrial machinery, where the ability to adapt to varying specifications can enhance operational efficiency. Additionally, the adoption of smart connectors equipped with sensors for monitoring performance and safety is on the rise, offering enhanced data collection capabilities.

Sourcing trends are also evolving, with a noticeable move towards regional suppliers to mitigate risks associated with global supply chain disruptions. Buyers are encouraged to assess local manufacturers that meet international quality standards, as this can significantly reduce lead times and shipping costs. Furthermore, there is a growing emphasis on connectors that comply with global safety and environmental regulations, which is crucial for ensuring market access in regions like Europe and North America.

Sustainability & Ethical Sourcing in B2B

Sustainability is increasingly becoming a priority for B2B buyers in the electrical plug connector sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, calls for a reevaluation of sourcing practices. Buyers should actively seek suppliers that prioritize sustainable materials and production methods. For instance, connectors made from recyclable or bio-based materials contribute to reducing the overall carbon footprint.

Moreover, the importance of ethical supply chains cannot be overstated. Suppliers that adhere to ethical labor practices and environmental regulations not only enhance their corporate reputation but also appeal to socially conscious buyers. Certifications such as ISO 14001 for environmental management and RoHS (Restriction of Hazardous Substances) compliance can serve as indicators of a supplier’s commitment to sustainability.

As the market evolves, buyers are encouraged to incorporate sustainability criteria into their procurement processes, leading to long-term benefits not only for their organizations but also for the planet. By prioritizing ‘green’ certifications and materials, businesses can align themselves with global sustainability goals while meeting the increasing demand from consumers for responsible sourcing.

Brief Evolution/History

The history of electrical connectors dates back to the late 19th century, coinciding with the advent of electrical systems. Initially, connectors were rudimentary, designed primarily for basic electrical connections. As technology progressed, the need for more sophisticated and reliable connectors emerged, leading to the development of various types tailored for specific applications.

The introduction of standards, such as the DIN (Deutsches Institut für Normung) and IEC (International Electrotechnical Commission), helped streamline the manufacturing process and ensure compatibility across devices. Today, connectors are engineered for high-performance applications, with innovations focusing on miniaturization, increased durability, and enhanced functionality, reflecting the growing demands of modern technology.

For B2B buyers, understanding this evolution is crucial for making informed purchasing decisions and identifying opportunities for incorporating advanced connector solutions that meet contemporary operational needs.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of electrical plug connector types

-

What should I consider when vetting suppliers for electrical plug connectors?

When vetting suppliers, focus on their industry experience, product quality, and compliance with international standards. Request certifications such as ISO 9001 or UL approval to ensure they meet safety and quality benchmarks. Evaluate their production capacity and lead times by asking for references from previous clients. Additionally, consider their ability to provide customization options and technical support. A thorough site visit or audit can also help gauge their operational capabilities and reliability. -

Can I customize electrical plug connectors to meet specific requirements?

Yes, many suppliers offer customization options for electrical plug connectors. This can include variations in size, material, and pin configuration to suit specific applications. When discussing customization, provide detailed specifications and use cases to ensure the supplier understands your needs. Be aware that customized products may have longer lead times and higher minimum order quantities (MOQs), so factor this into your planning and budgeting. -

What are typical minimum order quantities (MOQs) and lead times for electrical connectors?

MOQs and lead times can vary widely based on the type of connector and supplier. Generally, MOQs may range from 100 to 1000 units for standard connectors, while custom designs can require higher quantities. Lead times typically range from 2 to 12 weeks, depending on production schedules and material availability. Always confirm these details upfront to avoid unexpected delays, and consider negotiating terms if you plan to place ongoing orders. -

What payment terms are common when sourcing electrical plug connectors internationally?

Payment terms can vary by supplier and region, but common practices include advance payments, letters of credit, or payment upon delivery. For larger orders, suppliers may offer installment payments based on production milestones. It is essential to clarify payment methods and terms in your purchase agreement to protect against currency fluctuations and ensure smooth transactions. Consider using escrow services for high-value orders to enhance security. -

How can I ensure quality assurance (QA) and certifications for the connectors I purchase?

Request documentation of quality assurance processes and certifications from your supplier. Look for compliance with international standards such as IEC, UL, or RoHS, which indicate adherence to safety and environmental regulations. Additionally, consider conducting independent third-party inspections before shipment, especially for large orders. Establish a clear return and warranty policy to address any quality concerns post-purchase. -

What logistics considerations should I keep in mind when importing electrical connectors?

Logistics is crucial when importing electrical connectors, as it affects delivery times and costs. Consider the mode of transport (air vs. sea), as air freight is faster but more expensive. Research customs regulations in your country to avoid delays at the border. Work with reliable freight forwarders who have experience handling electrical components and can manage documentation, duties, and taxes efficiently. Also, factor in potential supply chain disruptions when planning your orders. -

How can I resolve disputes with suppliers regarding electrical connectors?

To resolve disputes, first, communicate directly with the supplier to address the issue amicably. Document all correspondence and agreements in writing. If necessary, escalate the matter to a higher management level within the supplier’s company. If resolution is still not achieved, consider mediation or arbitration as a formal dispute resolution process. Ensure that your purchase agreement includes a clear dispute resolution clause to guide this process. -

What should I know about the environmental impact of electrical connectors?

Understanding the environmental impact of electrical connectors is vital, especially as regulations tighten globally. Look for suppliers who adhere to eco-friendly practices, such as using recyclable materials and reducing waste in production. Certifications like RoHS (Restriction of Hazardous Substances) indicate compliance with environmental standards. Additionally, inquire about the end-of-life disposal options for the connectors you purchase, ensuring they align with your sustainability goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for electrical plug connector types

In conclusion, the landscape of electrical plug connector types presents a wealth of opportunities for international B2B buyers. Understanding the diverse range of connectors—from robust industrial options like pin and sleeve connectors to versatile USB types—enables businesses to select the most suitable solutions for their specific applications. Strategic sourcing not only enhances operational efficiency but also ensures reliability and safety in electrical connections, which is vital across industries.

By investing time in evaluating connector specifications, compatibility, and supplier capabilities, buyers can mitigate risks associated with poor connectivity and enhance their product offerings. The need for high-quality connectors will only grow as technological advancements continue to reshape industries worldwide.

As you navigate your sourcing strategy, consider engaging with suppliers who demonstrate a commitment to innovation and quality. By doing so, you will position your business to thrive in an increasingly interconnected global market. Embrace the future of electrical connectivity, and make informed decisions that will drive your success in Africa, South America, the Middle East, and Europe.