Mastering Interior Door Latch Types: Key Insights for B2B

Introduction: Navigating the Global Market for interior door latch types

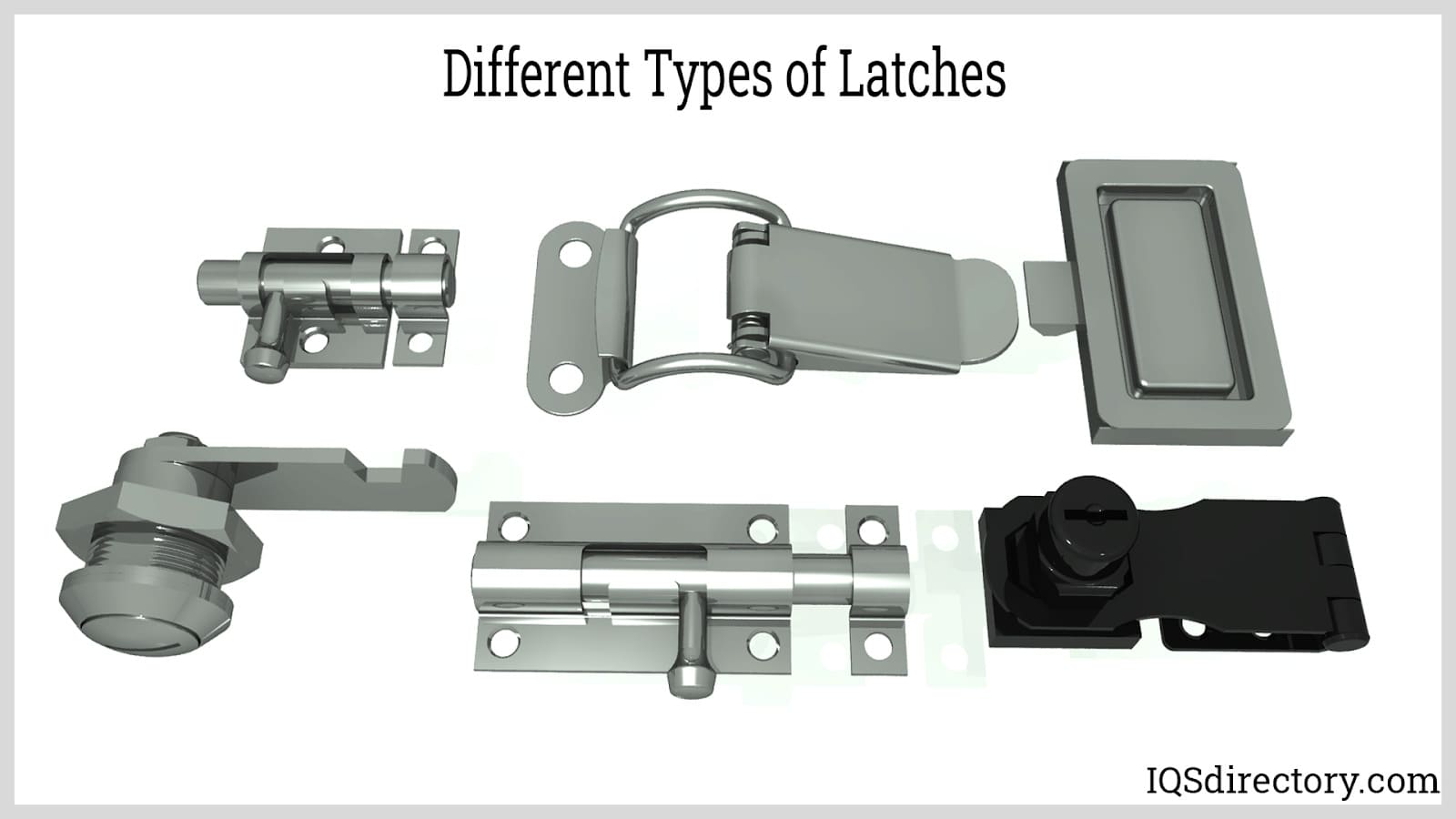

Navigating the global market for interior door latch types requires a keen understanding of their critical role in security and functionality. As essential components in both residential and commercial environments, these latches serve as the backbone of door security, providing peace of mind and ease of access. With a diverse range of latch types available—each tailored for specific applications—international B2B buyers must be well-informed to make optimal sourcing decisions.

This comprehensive guide delves into the various types of interior door latches, including compression, draw, cam, and slide-to-open latches, along with their respective materials and manufacturing standards. We will explore the quality control processes that ensure reliability, highlight reputable suppliers across different regions, and provide insight into cost considerations that can affect purchasing decisions.

Furthermore, the guide addresses the unique market dynamics in regions such as Africa, South America, the Middle East, and Europe, including specific insights relevant to countries like Egypt and Mexico. By equipping buyers with actionable knowledge on latch types and their applications, this resource empowers them to make informed choices that enhance security and operational efficiency in their projects. Whether for industrial, commercial, or residential use, understanding the nuances of interior door latch types is crucial for any procurement strategy aimed at optimizing safety and functionality.

Understanding interior door latch types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Slide-to-Open Latch | Simple sliding mechanism for quick access | Machinery enclosures, electrical cabinets | Pros: Fast operation, easy access. Cons: Limited security features. |

| Draw Latch | Over-center locking action for tight closure | Cargo containers, HVAC units, toolboxes | Pros: Strong closure, vibration-resistant. Cons: May require more space for installation. |

| Compression Latch | Applies compressive force for sealing | Electrical housings, food processing equipment | Pros: Excellent sealing capabilities. Cons: Potentially higher cost due to complexity. |

| Cam Latch | Rotational locking mechanism | Access panels, storage cabinets | Pros: Cost-effective, easy to install. Cons: Less secure than draw and compression latches. |

| Pull Latch | Utilizes a handle for strong fastening | Industrial doors, gates, and cabinets | Pros: User-friendly, strong hold. Cons: Requires manual operation, which may not be ideal for all applications. |

Slide-to-Open Latch

Slide-to-open latches are characterized by their straightforward sliding action, allowing for quick engagement and disengagement. These latches are particularly well-suited for applications where frequent access is necessary, such as in machinery enclosures and electrical cabinets. B2B buyers should consider the operational efficiency and ease of use, especially in environments where speed is crucial. However, it is essential to note that these latches may not offer robust security features, making them less ideal for sensitive or high-security applications.

Draw Latch

Draw latches, also known as tension latches, provide a secure closure by pulling two surfaces tightly together. This type of latch is commonly used in cargo containers and HVAC units, where vibration resistance is essential. For B2B buyers, the draw latch is an excellent choice for applications requiring a strong hold, but it may require more installation space compared to other latch types. Buyers should evaluate the specific requirements of their application, including the need for frequent access versus security.

Illustrative Image (Source: Google Search)

Compression Latch

Compression latches excel in providing a sealed closure by applying compressive force between surfaces. They are ideal for environments that require protection against dust, moisture, and electromagnetic interference, making them suitable for electrical housings and food processing equipment. B2B buyers should consider the enhanced sealing capabilities of compression latches, which can justify their potentially higher cost. However, it is crucial to assess the specific sealing requirements of the application to ensure optimal performance.

Cam Latch

Cam latches utilize a simple rotational mechanism to secure doors and panels, making them a cost-effective and easy-to-install option for various applications, such as access panels and storage cabinets. While they are suitable for less critical security needs, B2B buyers should be aware that cam latches may not provide the same level of security as draw or compression latches. Their affordability and ease of use make them a popular choice for businesses looking to balance cost with functionality.

Pull Latch

Pull latches offer a user-friendly design, utilizing a handle or lever to secure doors and gates effectively. They are commonly found in industrial settings where a strong fastening solution is needed. B2B buyers should appreciate the ease of operation and the strong hold provided by pull latches. However, since they require manual operation, businesses should consider whether this aligns with their operational needs, especially in high-traffic areas where quick access is necessary.

Related Video: Door Latch

Key Industrial Applications of interior door latch types

| Industry/Sector | Specific Application of interior door latch types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Latches for machinery access panels | Ensures quick access for maintenance, reducing downtime | Durability, resistance to vibration, and ease of use |

| Transportation | Cargo container and trailer door latches | Provides secure closure, preventing cargo loss | Weather resistance, locking mechanism options |

| HVAC Systems | Latches in air handling units | Maintains airtight seals, improving energy efficiency | Compression features, compliance with safety standards |

| Food Processing | Latches for storage cabinets and equipment doors | Ensures hygiene and safety, preventing contamination | Material compliance (e.g., FDA), ease of cleaning |

| Pharmaceuticals | Latches for laboratory equipment and storage | Protects sensitive materials from contamination | Sterilization compatibility, secure locking mechanisms |

Detailed Applications

Manufacturing

In the manufacturing sector, interior door latches are critical for securing machinery access panels. These latches facilitate quick access for maintenance and repairs, which is vital for minimizing downtime and maintaining operational efficiency. International buyers should prioritize latches that are durable and resistant to vibrations, ensuring they can withstand the rigors of industrial environments. Additionally, ease of use is crucial to promote safety and efficiency among workers.

Transportation

For the transportation industry, latches are essential for securing cargo containers and trailer doors. These latches not only provide a secure closure but also help prevent cargo loss during transit, which is a significant concern for logistics companies. Buyers in regions like Africa and South America should consider latches that offer weather resistance to ensure reliability in various climatic conditions, as well as options for enhanced locking mechanisms to deter theft.

HVAC Systems

In HVAC systems, interior door latches are used in air handling units to maintain airtight seals. This is crucial for improving energy efficiency and ensuring optimal system performance. Buyers from the Middle East and Europe, where energy costs can be high, should look for latches with compression features that securely clamp panels together, preventing air leaks. Compliance with safety standards is also an important consideration, as it ensures reliable operation within these systems.

Food Processing

Interior door latches play a significant role in the food processing industry, particularly in securing storage cabinets and equipment doors. These latches help maintain hygiene and safety standards by preventing contamination of food products. B2B buyers should focus on latches made from materials that comply with food safety regulations, such as FDA-approved materials, and those designed for easy cleaning to facilitate sanitation processes.

Pharmaceuticals

In the pharmaceutical sector, latches are crucial for securing laboratory equipment and storage facilities. They protect sensitive materials from contamination, ensuring compliance with strict regulatory standards. Buyers should seek latches that are compatible with sterilization processes and offer secure locking mechanisms to safeguard valuable and sensitive products. This focus on safety and compliance is especially important for international buyers operating in diverse regulatory environments.

Strategic Material Selection Guide for interior door latch types

When selecting materials for interior door latch types, it’s essential to consider the specific properties and applications of each material. This analysis will focus on four common materials: stainless steel, zinc die-cast, plastic, and brass. Each material has unique characteristics that can influence performance, durability, and suitability for various environments.

Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance, strength, and durability. It can withstand high temperatures and pressures, making it suitable for various applications, including industrial settings.

Pros & Cons:

– Advantages: High durability and resistance to rust and corrosion, making it ideal for humid or wet environments. It also offers a sleek appearance, which is aesthetically pleasing for interior applications.

– Disadvantages: The cost of stainless steel is generally higher than other materials, which can impact budget considerations for large projects. Manufacturing complexity can also be a factor, as machining stainless steel requires specialized tools.

Impact on Application:

Stainless steel latches are compatible with various media, including moisture-laden environments, making them suitable for kitchens, bathrooms, and industrial settings.

Considerations for International Buyers:

Buyers in Africa, South America, the Middle East, and Europe should ensure compliance with standards such as ASTM and DIN for quality assurance. The availability of stainless steel may vary by region, affecting lead times and costs.

Zinc Die-Cast

Key Properties:

Zinc die-cast offers good strength and corrosion resistance, along with the ability to be molded into complex shapes. It has a lower melting point than other metals, allowing for efficient production.

Pros & Cons:

– Advantages: Cost-effective and allows for intricate designs, making it suitable for decorative latches. It also provides decent resistance to corrosion, especially when coated.

– Disadvantages: While durable, zinc die-cast may not withstand extreme temperatures or heavy loads as well as stainless steel. It can also be prone to wear over time.

Impact on Application:

This material is often used in residential applications where aesthetic appeal is important but extreme durability is not critical. It is suitable for interior doors in low-traffic areas.

Considerations for International Buyers:

Zinc die-cast products should meet local standards, such as JIS in Japan or EN in Europe. Buyers should also consider the availability of coatings that enhance corrosion resistance, especially in humid climates.

Plastic

Key Properties:

Plastic latches are lightweight and can be engineered for specific performance characteristics, including flexibility and impact resistance. They are often molded into complex shapes.

Pros & Cons:

– Advantages: Cost-effective, lightweight, and easy to install. They can be produced in various colors and styles, making them versatile for different design needs.

– Disadvantages: Plastic may not offer the same level of durability or security as metal latches. It can degrade under UV exposure and may not be suitable for high-temperature applications.

Impact on Application:

Plastic latches are ideal for residential applications, particularly in environments where aesthetics and lightweight features are prioritized. They are often used in children’s rooms or in furniture.

Considerations for International Buyers:

Buyers should ensure that plastic latches comply with safety standards relevant to their region, especially in applications involving children. The environmental impact of plastic should also be considered, as some regions are moving towards more sustainable materials.

Brass

Key Properties:

Brass is known for its excellent machinability and corrosion resistance. It has a distinctive golden color, making it a popular choice for decorative applications.

Pros & Cons:

– Advantages: Offers a classic look and good resistance to corrosion, particularly in dry environments. It is also relatively easy to work with during manufacturing.

– Disadvantages: Brass can tarnish over time, requiring maintenance to retain its appearance. It is also more expensive than some alternatives, which can be a consideration for budget-conscious buyers.

Impact on Application:

Brass latches are often used in high-end residential applications where aesthetics are a priority. They are suitable for interior doors that require a touch of elegance.

Considerations for International Buyers:

Buyers should be aware of the varying standards for brass quality across different regions, such as ASTM in the U.S. and EN in Europe. The availability of high-quality brass can also vary, impacting supply chains.

Summary Table

| Material | Typical Use Case for interior door latch types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Industrial and high-traffic areas | Excellent corrosion resistance | Higher cost | High |

| Zinc Die-Cast | Residential low-traffic areas | Cost-effective and decorative | Limited temperature resistance | Medium |

| Plastic | Residential and lightweight applications | Lightweight and versatile | Lower durability | Low |

| Brass | High-end residential applications | Classic appearance and machinability | Tarnishing and maintenance needs | Medium |

This strategic material selection guide provides a comprehensive overview of the various materials used in interior door latches, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for interior door latch types

Manufacturing Processes for Interior Door Latch Types

Manufacturing interior door latches involves several critical stages, each contributing to the product’s overall quality and functionality. Understanding these processes can help B2B buyers make informed decisions when sourcing latches for their operations.

1. Material Preparation

The manufacturing process begins with the selection and preparation of raw materials. Most latches are made from metals such as stainless steel, brass, or zinc alloys, chosen for their strength and corrosion resistance.

- Material Selection: Ensure that the materials comply with international standards for durability and safety.

- Cutting and Shaping: Raw materials are cut into specific dimensions using CNC (Computer Numerical Control) machines to ensure precision. This step is crucial for maintaining uniformity across products.

2. Forming

The forming stage involves shaping the prepared materials into the desired latch components. Common techniques include:

- Stamping: This method uses dies to cut and form metal sheets into specific shapes. It is efficient for high-volume production.

- Casting: Some latch components are cast from molten metal, allowing for complex shapes that would be difficult to achieve with stamping.

- Machining: Additional shaping may be required to achieve precise tolerances. This includes drilling holes for screws or other fastening mechanisms.

3. Assembly

Once all components are formed, they are assembled into complete latches. This stage includes:

- Joining Techniques: Components may be joined through welding, riveting, or using adhesives, depending on the design and materials.

- Manual vs. Automated Assembly: While some manufacturers use automated assembly lines for efficiency, others may rely on skilled labor for intricate assemblies.

4. Finishing

Finishing processes enhance both the appearance and functionality of the latches:

- Surface Treatment: Techniques such as plating (e.g., nickel or chrome) or powder coating improve corrosion resistance and aesthetic appeal.

- Quality Checks: Finishing is followed by quality checks to ensure that surface treatments meet specified standards.

Quality Assurance in Manufacturing

Quality assurance is integral to the production of interior door latches, ensuring that products meet safety and performance standards. B2B buyers should pay attention to various quality control measures in place at the manufacturing facilities.

Relevant International Standards

Manufacturers should comply with several international quality standards:

- ISO 9001: This standard outlines criteria for a quality management system, ensuring consistent product quality and customer satisfaction.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For latches used in specific industrial applications, adherence to American Petroleum Institute standards may be required.

Key Quality Control Checkpoints

Quality control involves systematic checks at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early. This can include monitoring dimensions, surface finishes, and assembly integrity.

- Final Quality Control (FQC): Before products are shipped, a final inspection ensures that all latches meet the required specifications and standards.

Common Testing Methods

Manufacturers may employ several testing methods to verify the quality of their latches:

- Functional Testing: Ensures that latches operate smoothly and securely under various conditions.

- Durability Testing: Simulates long-term use to assess wear and tear. This may include cycle testing to determine how many times a latch can be opened and closed before failure.

- Environmental Testing: Assesses how well latches withstand environmental factors such as humidity, temperature variations, and exposure to chemicals.

Verifying Supplier Quality Control

B2B buyers must be proactive in verifying the quality assurance processes of their suppliers. Here are several strategies:

- Supplier Audits: Conduct regular audits of manufacturing facilities to assess compliance with quality standards and practices.

- Request Quality Reports: Ask suppliers for detailed quality reports, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of product quality before shipment.

Quality Control and Certification Nuances for International Buyers

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential:

- Cultural and Regulatory Differences: Be aware that quality standards may vary by region. For instance, European buyers may prioritize CE certification, while Middle Eastern buyers may focus on adherence to local regulations.

- Language Barriers: Ensure that documentation, including quality reports and certifications, is available in a language that can be understood by all stakeholders involved in the procurement process.

- Logistical Considerations: Shipping and customs regulations may impact the delivery of quality-certified products. Familiarize yourself with these processes to avoid delays.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is vital for B2B buyers sourcing interior door latches. By focusing on these aspects, buyers can ensure they partner with reliable suppliers that meet their specific quality and performance needs.

Related Video: What is Production? Types of Production, Factors of Production

Comprehensive Cost and Pricing Analysis for interior door latch types Sourcing

Understanding the cost structure and pricing for sourcing interior door latch types is essential for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. This section delves into the various cost components and price influencers that affect purchasing decisions.

Cost Components

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include stainless steel, zinc alloy, and plastic. High-quality materials may lead to increased durability and performance, thus justifying higher prices.

-

Labor: Labor costs vary by region and affect the manufacturing process. Skilled labor is often more expensive, particularly in regions with higher living costs. Consider the labor market in your sourcing region to estimate labor expenses accurately.

-

Manufacturing Overhead: This encompasses costs related to utilities, equipment maintenance, and factory management. In regions where energy costs are high, these overheads can substantially increase the final price of door latches.

-

Tooling: Initial tooling costs can be significant, especially for custom latch designs. Buyers should inquire about tooling costs upfront, as they can be spread over larger orders to reduce per-unit costs.

-

Quality Control (QC): Implementing robust QC processes ensures that latches meet industry standards and specifications, but it also adds to the overall cost. Buyers should evaluate the QC measures in place to ensure quality without unnecessary cost increases.

-

Logistics: Shipping costs can vary widely based on distance, shipping method, and volume. International buyers should consider the total logistics costs, including tariffs and duties, which can significantly impact the final price.

-

Margin: Suppliers typically add a profit margin to their costs. Understanding average market margins can help buyers negotiate better prices.

Price Influencers

-

Volume/MOQ: Bulk purchases often lead to discounts. Minimum Order Quantities (MOQs) can affect pricing, so buyers should assess their needs against supplier requirements.

-

Specifications/Customization: Custom designs or specific specifications can raise costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials: Premium materials can increase costs but may offer long-term savings through enhanced durability and lower maintenance needs.

-

Quality/Certifications: Latches with industry certifications (like ISO or CE) might come at a premium. However, these certifications can be crucial for compliance in certain markets.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers may charge higher prices due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms (International Commercial Terms) affects logistics costs and responsibilities. It is vital for buyers to understand these terms to avoid unexpected shipping costs.

Buyer Tips

-

Negotiation: Always negotiate terms and pricing. Building a long-term relationship with suppliers can lead to better deals and more favorable terms over time.

-

Cost-Efficiency: Assess the total cost of ownership, including maintenance and replacement costs, rather than just the initial purchase price. This approach ensures long-term savings.

-

Pricing Nuances: Be aware of local market conditions that can influence pricing, such as currency fluctuations and regional economic factors. Understanding these nuances can help in making informed purchasing decisions.

-

Research and Comparison: Conduct thorough research and compare prices from multiple suppliers. This practice not only provides a better understanding of market rates but also strengthens your negotiating position.

Disclaimer: The prices and costs mentioned herein are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult directly with suppliers for accurate pricing.

Spotlight on Potential interior door latch types Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘interior door latch types’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for interior door latch types

Key Technical Properties of Interior Door Latch Types

When selecting interior door latches, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade

– Definition: Refers to the type of material used in the latch construction, such as stainless steel, zinc alloy, or plastic.

– Importance: Material grade affects durability, corrosion resistance, and overall performance. For instance, stainless steel latches are ideal for humid environments in regions like coastal Africa, while zinc alloys may suffice in dry areas. -

Load Capacity

– Definition: The maximum weight or force that a latch can withstand without failing.

– Importance: Buyers must consider the load capacity to ensure the latch can securely hold the door or gate in place. This is particularly important for heavy doors in commercial settings or industrial applications in South America. -

Tolerance

– Definition: The permissible limit or limits of variation in the latch dimensions.

– Importance: Proper tolerance ensures that latches fit correctly with door frames, affecting ease of installation and long-term functionality. Inaccurate tolerances can lead to operational issues and increased maintenance costs. -

Finish

– Definition: The surface treatment applied to the latch, such as powder coating, plating, or anodizing.

– Importance: The finish can enhance aesthetics and provide additional protection against wear and corrosion. Buyers should choose finishes that match their design requirements and environmental conditions, especially in regions with high humidity. -

Actuation Type

– Definition: Refers to how the latch is engaged or disengaged, such as manual, electronic, or mechanical.

– Importance: Different actuation types cater to various security needs and ease of use. For example, electronic latches may be preferable in high-security environments in the Middle East, while mechanical latches suffice in residential settings. -

Compliance Standards

– Definition: Refers to the standards and regulations that the latch must meet, such as ANSI/BHMA or ISO certifications.

– Importance: Compliance ensures that the latch meets safety and performance criteria. International buyers should verify that products comply with local regulations to avoid legal issues.

Common Trade Terminology

Understanding industry jargon is essential for effective communication and negotiation in the B2B space. Here are key terms related to interior door latches:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Knowing whether a latch is OEM can help buyers determine quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Relevance: Understanding MOQ is vital for budgeting and inventory planning. Buyers from Africa and South America should negotiate MOQs that align with their purchasing capabilities. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers requesting pricing and terms for specific products.

– Relevance: An RFQ is a crucial step in the procurement process, allowing buyers to compare offers and make informed decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of sellers and buyers in international transactions.

– Relevance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and insurance requirements, which is essential for international trade. -

Lead Time

– Definition: The time it takes from placing an order until it is received.

– Relevance: Understanding lead time is critical for project planning, particularly in industries with tight schedules, such as construction and manufacturing. -

Warranty

– Definition: A guarantee provided by the manufacturer regarding the condition of the latch and its expected lifespan.

– Relevance: A robust warranty can provide assurance of quality and reduce long-term maintenance costs, making it a key consideration for buyers.

By grasping these technical properties and trade terms, international B2B buyers can navigate the procurement process more effectively, ensuring they select the most suitable interior door latch types for their needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the interior door latch types Sector

Market Overview & Key Trends

The interior door latch market is experiencing significant growth, driven by increasing demand for security and convenience in both residential and commercial applications. Global drivers include urbanization, rising construction activities, and heightened awareness of safety standards. Emerging markets in Africa, South America, and the Middle East are particularly notable, where rapid infrastructure development and a growing middle class are creating substantial opportunities for B2B buyers. In Europe, sustainability concerns and regulatory compliance are shaping purchasing decisions, leading to a preference for innovative latch solutions that enhance security while minimizing environmental impact.

Key trends influencing sourcing in this sector include the integration of smart technologies in latch systems. Smart latches equipped with IoT capabilities allow for remote access and monitoring, making them appealing to tech-savvy consumers and businesses alike. Additionally, manufacturers are increasingly adopting modular designs, enabling easier installation and customization to meet diverse client needs. B2B buyers should prioritize suppliers who can provide detailed product specifications and demonstrate expertise in local regulations, especially when entering new markets.

Sustainability & Ethical Sourcing in B2B

Sustainability is a crucial factor in the sourcing of interior door latch types, reflecting a growing commitment among businesses to reduce their environmental footprint. The manufacturing processes of latches can have significant environmental impacts, including resource consumption and waste generation. B2B buyers should seek suppliers who prioritize eco-friendly production methods, such as using recycled materials and minimizing energy use during manufacturing.

Ethical sourcing is equally important, with buyers encouraged to select suppliers that adhere to fair labor practices and transparent supply chains. Certifications like ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) can serve as indicators of a manufacturer’s commitment to sustainable practices. Additionally, using materials with a lower carbon footprint, such as biodegradable composites or sustainably sourced metals, can enhance the sustainability profile of latch products. By prioritizing these factors, international buyers can align their procurement strategies with global sustainability goals while also meeting consumer demand for ethically produced goods.

Brief Evolution/History

The evolution of door latch mechanisms dates back centuries, with early forms primarily serving simple fastening functions. Over time, advancements in materials and engineering have transformed these devices into sophisticated security solutions. Initially made from wood or simple metal components, modern latches now incorporate advanced materials like stainless steel and high-strength composites, offering enhanced durability and performance. The integration of technology into latch systems represents the latest phase in this evolution, providing features such as electronic access and connectivity that cater to contemporary security needs. For B2B buyers, understanding this evolution is vital in recognizing the value of investing in high-quality, innovative latch solutions that are both functional and secure.

Related Video: Global Trends Tutorial: Chapter 3: IPE

Frequently Asked Questions (FAQs) for B2B Buyers of interior door latch types

-

What should I consider when vetting suppliers for interior door latches?

When vetting suppliers, focus on their industry experience, product quality, and customer reviews. Request samples to assess the latch’s durability and functionality. It’s essential to check for certifications that indicate compliance with international standards, such as ISO or CE marks. Additionally, consider the supplier’s manufacturing capabilities and whether they can meet your specific needs, including customization options. -

Can I customize the interior door latches to fit my project specifications?

Yes, many suppliers offer customization options for interior door latches. You can specify dimensions, materials, colors, and finishes to align with your project’s aesthetic and functional requirements. Communicate your needs clearly and request prototypes if possible to ensure the final product meets your expectations. Customization can enhance your brand’s identity and improve product integration within your projects. -

What are the typical minimum order quantities (MOQs) for interior door latches?

Minimum order quantities vary by supplier and depend on the latch type and customization requirements. Generally, MOQs can range from 100 to 1,000 units. Larger orders may yield better pricing and terms. Always negotiate with suppliers to find a balance that suits your budget while ensuring you can maintain inventory levels for your projects. -

What are the lead times for manufacturing and delivery of door latches?

Lead times can significantly vary based on factors such as the complexity of the order, supplier location, and shipping method. Typically, lead times range from 4 to 12 weeks. For customized orders, it may take longer due to design and production adjustments. Always clarify lead times upfront and factor in potential delays to your project schedule to ensure timely completion. -

How can I ensure quality assurance and certifications for the latches I purchase?

To ensure quality assurance, request documentation from suppliers that outlines their quality control processes. Look for latches that come with certifications relevant to your market, such as ISO 9001 for quality management or specific safety standards applicable in your region. Regular audits and inspections can further validate that the products meet your specifications and regulatory requirements. -

What logistics considerations should I keep in mind when sourcing door latches internationally?

When sourcing internationally, consider shipping costs, customs duties, and potential delays in transportation. It’s crucial to understand the Incoterms (International Commercial Terms) that dictate the responsibilities of buyers and sellers regarding shipping and delivery. Partnering with a reliable logistics provider can help streamline the process and mitigate risks associated with international shipping.

-

How should I handle disputes with suppliers regarding latch quality or delivery issues?

To handle disputes effectively, maintain clear communication with your supplier and document all agreements and transactions. If issues arise, address them promptly by discussing them directly with the supplier. If a resolution cannot be reached, refer to the terms outlined in your contract regarding dispute resolution. Consider utilizing mediation or arbitration services if necessary, especially when dealing with international suppliers. -

What payment methods are typically accepted for purchasing interior door latches?

Most suppliers accept various payment methods, including bank transfers, letters of credit, and online payment platforms. Depending on your relationship with the supplier and the order size, you may negotiate payment terms, such as partial upfront payment or net payment terms. Always ensure that payment methods provide sufficient security and traceability to protect your financial interests.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for interior door latch types

In conclusion, the strategic sourcing of interior door latch types is critical for international B2B buyers seeking to enhance security and operational efficiency across various applications. Understanding the different latch types—such as compression, draw, and slide-to-open latches—allows businesses to select the most suitable solutions that align with their specific needs. Prioritizing quality and durability in latch systems not only bolsters security but also minimizes maintenance costs and downtime, ultimately contributing to a more streamlined operational workflow.

For buyers from regions like Africa, South America, the Middle East, and Europe, it is essential to engage with reputable suppliers who can provide reliable latch mechanisms tailored to local market demands. As global supply chains evolve, leveraging strategic sourcing will ensure access to innovative latch technologies that meet international standards.

Looking ahead, the demand for advanced latch solutions is expected to grow, driven by trends in automation and security. Buyers are encouraged to stay informed about emerging technologies and market developments, positioning themselves to capitalize on new opportunities. Take action now—evaluate your current latch systems and explore strategic partnerships that can drive your business forward.

Illustrative Image (Source: Google Search)