Mastering Motor Shaft Coupler Sourcing for Optimal

Introduction: Navigating the Global Market for motor shaft coupler

In today’s interconnected industrial landscape, motor shaft couplers play a pivotal role in ensuring the seamless operation of machinery across various sectors, from manufacturing to agriculture. These components are essential for connecting rotating shafts, accommodating misalignment, and enhancing the reliability of power transmission systems. For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of motor shaft couplers can significantly impact operational efficiency and cost management.

This guide offers a comprehensive exploration of the motor shaft coupler market, designed to empower decision-makers with actionable insights. It covers a wide array of coupler types, including beam, bellows, and chain couplings, each tailored for specific applications and operational requirements. Buyers will find a detailed examination of materials used in coupler manufacturing, highlighting the advantages of different alloys and composites in various environments.

Moreover, the guide delves into critical aspects of manufacturing processes and quality control standards, providing a framework for evaluating potential suppliers. It addresses the cost dynamics of sourcing these components, equipping buyers with benchmark data for effective negotiation strategies. Finally, a curated section of frequently asked questions addresses common sourcing challenges faced by businesses in diverse markets.

By leveraging the insights within this guide, international B2B buyers can make informed decisions that not only enhance procurement outcomes but also contribute to long-term operational success.

Understanding motor shaft coupler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Rigid Coupling | Solid construction; no flexibility; high torque transmission | Heavy machinery, conveyors, pumps | Pros: High torque capacity; Cons: No misalignment accommodation |

| Flexible Coupling | Accommodates misalignment; reduces vibration | Robotics, automotive, HVAC systems | Pros: Versatile; Cons: Limited torque capacity |

| Oldham Coupling | Three-part design; accommodates angular and parallel misalignment | Printing, packaging, and textile machinery | Pros: Low backlash; Cons: Moderate torque limits |

| Chain Coupling | Uses chains for torque transmission; robust design | Heavy-duty applications, agricultural machinery | Pros: High load capacity; Cons: Requires maintenance |

| Bellows Coupling | Flexible bellows; high torsional stiffness | Precision machinery, medical devices | Pros: Excellent for precision; Cons: Limited misalignment tolerance |

Rigid Coupling

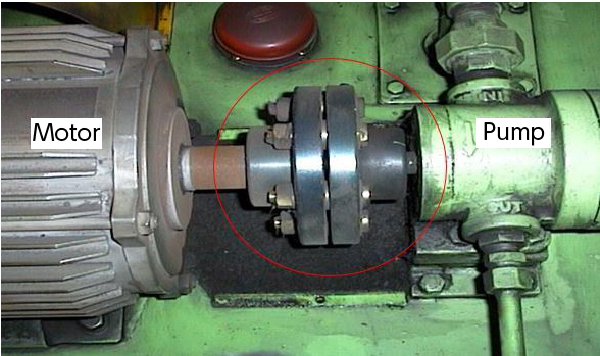

Rigid couplings are designed to connect two shafts in a fixed alignment, providing a solid link that transmits high torque without any flexibility. They are commonly used in applications requiring high torque and precise alignment, such as heavy machinery, conveyors, and pumps. For B2B buyers, the key consideration is ensuring that the coupling meets the torque requirements of the application, as rigid couplings do not accommodate misalignment, which could lead to premature failure if not properly aligned.

Flexible Coupling

Flexible couplings are essential for applications where misalignment may occur, as they can accommodate slight angular and parallel misalignments while reducing vibration and shock loads. They are widely used in robotics, automotive applications, and HVAC systems. When sourcing flexible couplings, buyers should consider factors such as material compatibility, maximum torque capacity, and the specific type of misalignment that the coupling can handle to ensure optimal performance.

Oldham Coupling

Oldham couplings feature a three-part design that allows for both angular and parallel misalignment, making them suitable for applications in printing, packaging, and textile machinery. Their low backlash characteristics make them ideal for precision applications. B2B buyers should evaluate the torque limitations and ensure that the Oldham coupling is compatible with the shafts being connected, as this will impact the overall efficiency of the machinery.

Chain Coupling

Chain couplings utilize chains to transmit torque, making them robust and ideal for heavy-duty applications such as agricultural machinery and heavy industrial equipment. These couplings are known for their high load capacity but require regular maintenance to ensure longevity and optimal performance. When considering chain couplings, buyers should assess the specific load requirements and maintenance capabilities to avoid operational disruptions.

Bellows Coupling

Bellows couplings consist of flexible bellows that provide high torsional stiffness, making them suitable for precision applications in machinery and medical devices. They excel in applications requiring accurate positioning while accommodating slight misalignments. Buyers should focus on the coupling’s torque transmission capacity and misalignment tolerance, as well as the material used in the bellows, to ensure compatibility with their specific operational environments.

Related Video: Types of Shaft Coupling, Animation, Machine Design | Solidworks

Key Industrial Applications of motor shaft coupler

| Industry/Sector | Specific Application of motor shaft coupler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Connecting motors to conveyor systems | Ensures efficient power transmission and reduced downtime | Compatibility with existing machinery and local support |

| Agriculture | Coupling motors to pumps for irrigation systems | Enhances water distribution efficiency and reliability | Durability in harsh environments and maintenance support |

| Mining | Connecting drive motors to crushers and conveyors | Increases operational efficiency and minimizes wear | Resistance to dust and corrosion, along with load capacity |

| Automotive | Coupling motors in assembly line robotics | Improves precision in manufacturing processes | Adaptability to various motor types and speed control |

| Food Processing | Connecting motors to mixers and packaging machines | Ensures consistent product quality and safety | Compliance with hygiene standards and material suitability |

Manufacturing

In manufacturing, motor shaft couplers are vital for connecting electric motors to conveyor systems. They facilitate the seamless transfer of torque, ensuring that production lines operate smoothly. This connection minimizes downtime, which is crucial for maintaining productivity levels. B2B buyers, particularly from regions like Europe and South America, should focus on sourcing couplers that are compatible with their existing machinery and that come with local technical support to address any installation or operational issues.

Agriculture

In the agricultural sector, motor shaft couplers are commonly used to connect motors to irrigation pumps. This application is essential for ensuring efficient water distribution across fields, which is critical in regions with fluctuating water availability, such as parts of Africa. Buyers should prioritize durable couplers that can withstand harsh environmental conditions and offer reliable performance. Additionally, sourcing suppliers with a strong after-sales support network is essential to ensure prompt maintenance and repairs.

Illustrative Image (Source: Google Search)

Mining

Motor shaft couplers play a crucial role in mining operations by connecting drive motors to crushers and conveyor systems. These couplers help enhance operational efficiency and reduce wear on machinery, which is particularly important in the demanding environments of mining sites. B2B buyers should consider sourcing couplers that are resistant to dust and corrosion, as well as those that can handle high torque loads. Ensuring that suppliers can meet these specific requirements is essential for maintaining continuous operations.

Automotive

In the automotive industry, motor shaft couplers are used in assembly line robotics to connect motors that power various manufacturing processes. This application requires high precision to ensure that components are assembled correctly and efficiently. Buyers should look for couplers that can adapt to different motor types and provide excellent speed control. Establishing relationships with suppliers who understand the unique requirements of automotive manufacturing can lead to significant improvements in production accuracy and efficiency.

Food Processing

Motor shaft couplers are integral to food processing applications, connecting motors to mixers and packaging machines. This ensures consistent product quality and safety, which are paramount in the food industry. B2B buyers should ensure that the couplers they source comply with hygiene standards and are made from suitable materials that can withstand cleaning processes. Partnering with suppliers familiar with food processing regulations can facilitate smoother procurement and compliance efforts.

Related Video: KTR couplings for Pump-Motor applications

Strategic Material Selection Guide for motor shaft coupler

When selecting materials for motor shaft couplers, international B2B buyers must consider various factors that impact performance, durability, and cost. Below is an analysis of four common materials used in the manufacturing of motor shaft couplers, highlighting their properties, advantages, disadvantages, and considerations specific to buyers in Africa, South America, the Middle East, and Europe.

1. Steel

Key Properties:

Steel offers high tensile strength and excellent durability, making it suitable for high-load applications. It typically has a temperature rating of up to 400°C and can withstand significant pressure.

Pros & Cons:

Steel couplers are robust and can handle heavy-duty applications, but they are susceptible to corrosion unless treated. The manufacturing process is relatively straightforward, but the cost can vary depending on the grade of steel used.

Impact on Application:

Steel is compatible with a wide range of media, including oils and water, but it may not be suitable for corrosive environments unless coated or alloyed.

Considerations for International Buyers:

Buyers should ensure compliance with local standards such as ASTM or DIN. In regions like Kenya and Egypt, sourcing from local manufacturers can reduce lead times and shipping costs.

2. Aluminum

Key Properties:

Aluminum is lightweight and has good corrosion resistance, with temperature ratings typically around 200°C. It is also non-magnetic, which can be beneficial in certain applications.

Pros & Cons:

The primary advantage of aluminum couplers is their low weight, which can reduce the overall load on motors. However, they are less durable than steel and may not be suitable for high-torque applications.

Impact on Application:

Aluminum couplers are often used in applications where weight savings are critical, such as in aerospace and automotive sectors. They are compatible with various media but may require protective coatings in harsh environments.

Considerations for International Buyers:

Buyers in Europe may prefer aluminum due to stringent weight regulations in transportation. Understanding local recycling policies can also influence material choice, as aluminum is highly recyclable.

3. Stainless Steel

Key Properties:

Stainless steel combines high strength with excellent corrosion resistance, making it suitable for harsh environments. It can operate effectively at temperatures up to 800°C.

Pros & Cons:

The durability and resistance to rust make stainless steel an ideal choice for food processing and chemical applications. However, it is generally more expensive than regular steel and can be more complex to machine.

Impact on Application:

Stainless steel is compatible with a wide range of chemicals and is often used in industries such as pharmaceuticals and food production. Its non-reactive nature is critical in these applications.

Considerations for International Buyers:

Compliance with international standards such as JIS for food safety is crucial. Buyers in the Middle East should consider the local availability of stainless steel to avoid delays.

4. Plastic (e.g., Nylon, Polycarbonate)

Key Properties:

Plastic couplers are lightweight and can offer good chemical resistance, with operating temperatures typically up to 100°C. They are non-conductive and can dampen vibrations.

Pros & Cons:

The main advantage of plastic couplers is their low cost and ease of manufacturing. However, they are less durable than metal options and may not be suitable for high-load applications.

Impact on Application:

Plastic couplers are often used in low-torque applications, such as in small motors or electronic devices. They are compatible with a variety of media but can degrade under UV exposure.

Considerations for International Buyers:

Buyers should assess the environmental impact of plastic materials and consider local regulations regarding plastic use. In South America, where recycling initiatives are growing, sourcing recyclable plastics may be advantageous.

Summary Table

| Material | Typical Use Case for motor shaft coupler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Aerospace and automotive applications | Lightweight and corrosion-resistant | Less durable under high torque | Medium |

| Stainless Steel | Food processing and chemical industries | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Plastic | Low-torque motors and electronic devices | Low cost and lightweight | Less durable and limited temperature | Low |

This strategic material selection guide aims to equip international B2B buyers with the necessary insights to make informed decisions when sourcing motor shaft couplers, ensuring compatibility with their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for motor shaft coupler

Motor shaft couplers play a pivotal role in ensuring efficient power transmission and alignment between rotating shafts in various industrial applications. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance protocols is crucial for making informed purchasing decisions. This section delves into the typical manufacturing stages, key techniques, and quality control measures relevant to motor shaft couplers.

Manufacturing Processes

The manufacturing of motor shaft couplers involves several key stages, each designed to ensure the final product meets performance and durability standards.

Material Preparation

The first step in the manufacturing process is selecting appropriate materials. Common materials include:

- Steel Alloys: Known for their strength and durability.

- Aluminum Alloys: Lighter and resistant to corrosion, suitable for specific applications.

- Composite Materials: Used for applications where weight reduction is critical.

Once materials are selected, they undergo preparation, which includes cutting, machining, and treating to ensure they meet required specifications. The choice of material affects the coupler’s performance, so buyers should consider the environmental conditions (e.g., humidity, temperature, and exposure to chemicals) where the couplers will be used.

Forming

The forming stage involves shaping the prepared materials into the desired coupler design. Common techniques include:

- Casting: Used for complex geometries, where molten metal is poured into molds.

- Forging: Involves shaping the metal using compressive forces, enhancing strength and durability.

- Machining: Precision machining processes, such as turning and milling, are employed to achieve tight tolerances and surface finishes.

The chosen forming technique should align with the specific requirements of the application, such as load capacity and alignment needs.

Assembly

In the assembly stage, various components of the coupler are joined together. This may involve:

- Welding: For permanent joins, ensuring high strength.

- Bolting or Clamping: Used for designs requiring disassembly.

- Adhesives: In some cases, adhesives may be used for lightweight couplers.

During assembly, ensuring proper alignment and fit is critical to prevent premature failure and operational inefficiencies.

Finishing

The finishing stage enhances the coupler’s resistance to wear and corrosion. Common finishing techniques include:

- Surface Treatment: Processes such as plating, anodizing, or powder coating improve corrosion resistance and aesthetics.

- Heat Treatment: Strengthens the coupler by altering its microstructure, enhancing durability under load.

Finishing not only contributes to the longevity of the product but also affects its performance in specific environments.

Quality Assurance

Quality assurance (QA) is vital in ensuring that motor shaft couplers meet international standards and customer specifications. For B2B buyers, understanding these QA processes can help mitigate risks associated with procurement.

International Standards

Several international standards govern the quality of motor shaft couplers, including:

- ISO 9001: A widely recognized standard that outlines quality management principles, ensuring consistent quality in manufacturing.

- CE Marking: Indicates compliance with European safety, health, and environmental protection standards.

- API Standards: Specific to the oil and gas industry, these standards ensure that couplers meet rigorous performance criteria.

Buyers should verify that suppliers adhere to these standards, as compliance reflects a commitment to quality and reliability.

Quality Control Checkpoints

Quality control (QC) is integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production, including dimensional checks and performance testing.

- Final Quality Control (FQC): Comprehensive inspections of finished products, including functional tests and dimensional verification.

These checkpoints help identify and rectify issues early, preventing defective products from reaching the market.

Common Testing Methods

Various testing methods are employed to ensure the integrity and performance of motor shaft couplers:

- Static Load Testing: Determines the coupler’s ability to withstand forces without failure.

- Dynamic Load Testing: Simulates real-world conditions to assess performance under operational loads.

- Vibration Testing: Evaluates how well the coupler can absorb shocks and vibrations.

B2B buyers should inquire about the specific testing protocols used by suppliers to ensure that the products meet required performance standards.

Supplier Verification

To ensure that suppliers maintain high-quality standards, buyers can employ several verification methods:

- Audits: Conducting regular supplier audits to assess compliance with quality standards and manufacturing processes.

- Quality Reports: Requesting detailed quality reports that document the results of IQC, IPQC, and FQC processes.

- Third-Party Inspections: Engaging independent organizations to conduct inspections and testing can provide additional assurance of quality.

For buyers in Africa, South America, the Middle East, and Europe, understanding the nuances of QC certification is essential. Buyers should ensure that the certifications are recognized in their respective markets, which can vary significantly by region.

Conclusion

For international B2B buyers, particularly those in emerging markets, a comprehensive understanding of the manufacturing processes and quality assurance protocols for motor shaft couplers is essential. By focusing on material selection, manufacturing techniques, and quality control measures, buyers can make informed decisions that enhance operational efficiency and reduce risks associated with procurement. Ultimately, establishing strong relationships with reliable suppliers who adhere to international standards will support long-term business success and product reliability.

Related Video: BMW Car PRODUCTION ⚙️ ENGINE Factory Manufacturing Process

Comprehensive Cost and Pricing Analysis for motor shaft coupler Sourcing

Understanding the cost structure and pricing dynamics of motor shaft couplers is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. By dissecting the various cost components and price influencers, buyers can make informed decisions that optimize their procurement strategies.

Cost Components

-

Materials: The choice of materials significantly impacts the cost of motor shaft couplers. Common materials include aluminum, stainless steel, and specialized alloys, with prices fluctuating based on global commodity markets. Higher quality materials may incur a premium but can offer better durability and performance.

-

Labor: Labor costs vary by region and can affect the overall pricing of couplers. In regions with higher wage standards, such as parts of Europe, labor costs may be higher compared to countries in Africa or South America where labor might be more affordable. Understanding local labor rates can aid in negotiating better pricing.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, equipment depreciation, and facility costs. Efficient manufacturing processes can lower these overheads, enabling suppliers to offer more competitive pricing.

-

Tooling: Custom tooling for specific coupler designs can represent a significant upfront cost. Buyers should consider whether they require custom solutions or can utilize standard designs to reduce tooling expenses.

-

Quality Control (QC): Rigorous quality control processes ensure that couplers meet industry standards and specifications. The costs associated with QC can vary significantly based on the complexity of the product and the certifications required (e.g., ISO, ASTM).

-

Logistics: Shipping and handling costs can vary greatly depending on the distance between suppliers and buyers, transportation modes, and regional tariffs. Buyers should factor in these logistics costs to understand the total expenditure.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on the supplier’s market position, brand reputation, and the level of competition in the market.

Price Influencers

-

Volume/MOQ: Bulk orders often lead to discounts due to economies of scale. Buyers should assess their demand to negotiate favorable terms based on minimum order quantities (MOQs).

-

Specifications/Customization: Custom specifications can increase costs. Buyers should evaluate the necessity of custom features against the potential cost savings of standard products.

-

Quality/Certifications: Higher quality and certified products may command a premium price. However, investing in quality can lead to lower total cost of ownership (TCO) through reduced failure rates and maintenance.

-

Supplier Factors: The reputation, reliability, and relationship with suppliers can influence pricing. Long-term partnerships may yield better terms and more consistent pricing.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they dictate the responsibilities of buyers and sellers regarding shipping costs, risk, and insurance. Choosing favorable Incoterms can mitigate unforeseen costs.

Buyer Tips

-

Negotiation: Approach negotiations with a clear understanding of your needs and the market. Leverage multiple quotes to establish a competitive baseline.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the initial purchase price. Consider maintenance, potential downtime, and replacement costs over the product lifecycle.

-

Pricing Nuances: Be aware of regional pricing variations. Factors such as currency fluctuations, local demand, and economic conditions can affect pricing.

-

Research: Conduct thorough research on suppliers, including their production capabilities and compliance with international standards. This will not only help in negotiating better prices but also in ensuring the quality of the couplers.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of motor shaft couplers is essential for international B2B buyers. By analyzing cost components, recognizing price influencers, and employing strategic negotiation techniques, buyers can achieve significant cost savings and enhanced operational efficiency.

Disclaimer: Prices can vary significantly based on a multitude of factors, including market conditions, supplier negotiations, and specific buyer requirements. Always consult multiple sources and conduct thorough market analysis before finalizing procurement decisions.

Spotlight on Potential motor shaft coupler Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘motor shaft coupler’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for motor shaft coupler

Understanding the essential technical properties and trade terminology for motor shaft couplers is crucial for international B2B buyers. This knowledge not only aids in effective procurement but also ensures that the selected components meet the specific operational requirements of diverse industries across Africa, South America, the Middle East, and Europe.

Key Technical Properties

-

Material Grade

– Definition: The quality and composition of the material used in the coupler, typically metals such as stainless steel, aluminum, or various alloys.

– B2B Importance: Material grade affects the coupler’s strength, durability, and resistance to corrosion and wear. Buyers must assess material specifications to ensure compatibility with environmental conditions and mechanical demands of their applications. -

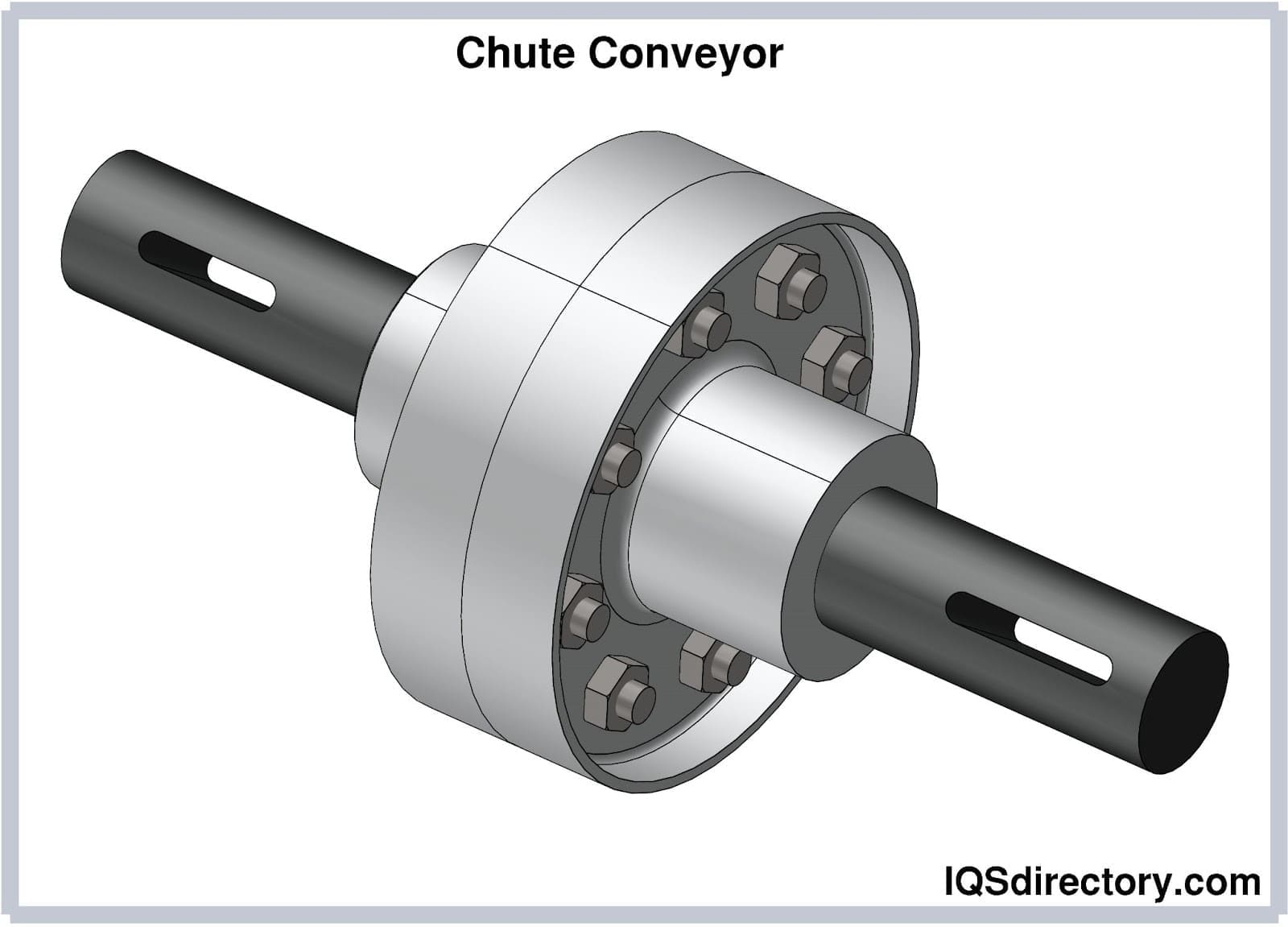

Torque Capacity

– Definition: The maximum torque that a coupler can transmit without failure, often measured in Newton-meters (Nm).

– B2B Importance: Understanding torque capacity is essential for ensuring that the coupler can handle the operational loads of machinery. Selecting a coupler with insufficient torque capacity can lead to premature failure and increased downtime.

Illustrative Image (Source: Google Search)

-

Tolerances

– Definition: The allowable variations in dimensions and shapes of the coupler, which can affect fit and performance.

– B2B Importance: Precise tolerances are vital for ensuring proper alignment between shafts. Misalignment can lead to vibration, increased wear, and ultimately mechanical failure. Buyers should specify tolerances based on their specific application needs. -

Misalignment Accommodation

– Definition: The ability of a coupler to function effectively despite misalignment between connected shafts, which can be angular, parallel, or axial.

– B2B Importance: Many industrial applications experience some degree of misalignment. A coupler that can accommodate misalignment reduces stress on both the coupler and the connected shafts, enhancing overall system reliability. -

Operating Temperature Range

– Definition: The range of temperatures within which the coupler can operate without degradation of performance or materials.

– B2B Importance: Buyers need to consider the operating environment when selecting a coupler. Extreme temperatures can affect material properties, potentially leading to failure. Proper assessment ensures longevity and reliability in diverse climates.

Common Trade Terms

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Significance: Understanding OEM relationships can help buyers identify quality suppliers and ensure compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest amount of a product that a supplier is willing to sell.

– Significance: Buyers must be aware of MOQ requirements to optimize inventory management and avoid excess stock. This is particularly important in regions with varying demand patterns. -

RFQ (Request for Quotation)

– Definition: A formal request to suppliers for pricing and terms on specific products or services.

– Significance: Crafting an effective RFQ can help buyers secure competitive pricing and favorable terms, facilitating better procurement strategies. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Significance: Knowledge of Incoterms is essential for understanding shipping responsibilities, risk transfer, and cost allocation, which can significantly impact total landed costs. -

Lead Time

– Definition: The time taken from placing an order to the delivery of the product.

– Significance: Understanding lead times helps buyers plan their production schedules and manage inventory effectively, ensuring that operational demands are met without delays.

By familiarizing themselves with these properties and terms, B2B buyers can navigate the complexities of sourcing motor shaft couplers more effectively, ensuring that their procurement decisions contribute to operational efficiency and cost-effectiveness.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the motor shaft coupler Sector

Market Overview & Key Trends

The global motor shaft coupler market is experiencing significant growth, driven by the increasing demand for automation across various industries, including manufacturing, automotive, and energy. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly influenced by several key trends. One of the most notable trends is the shift towards smart technologies and IoT integration, which enhance the functionality of motor shaft couplers by providing real-time data on performance and maintenance needs. This trend is paving the way for predictive maintenance solutions that can significantly reduce downtime.

Additionally, the customization of couplers is on the rise. Buyers are increasingly seeking bespoke solutions tailored to specific operational requirements, which necessitates close collaboration with suppliers. This demand for customization extends to material selection, where buyers prioritize lightweight yet durable materials to improve efficiency and reduce energy consumption.

Supply chain resilience has also emerged as a critical focus area. Buyers are navigating the complexities of global supply chains, influenced by recent disruptions and geopolitical factors. As a result, many are diversifying their supplier base and considering local sourcing options to mitigate risks associated with long lead times and fluctuating raw material costs.

Furthermore, sustainability is becoming a central theme in sourcing strategies. Companies are increasingly evaluating suppliers based on their environmental impact and commitment to sustainable practices, which reflects a broader shift towards corporate social responsibility.

Sustainability & Ethical Sourcing in B2B

The environmental impact of manufacturing motor shaft couplers is a crucial consideration for international buyers. As industries face mounting pressure to reduce their carbon footprints, the sourcing of materials and components must align with sustainability goals. Buyers should prioritize suppliers who implement environmentally friendly practices, such as utilizing recycled materials and adopting energy-efficient manufacturing processes.

Ethical supply chains are equally important. B2B buyers must ensure that their suppliers adhere to fair labor practices and have transparent sourcing strategies. This not only mitigates reputational risks but also fosters stronger relationships with customers who prioritize ethical consumption.

Buyers should look for suppliers that possess recognized green certifications (e.g., ISO 14001) and use sustainable materials, such as biodegradable plastics or eco-friendly alloys, in their motor shaft couplers. By collaborating with suppliers committed to sustainability, buyers can enhance their own environmental credentials and appeal to a market that increasingly values ethical production.

Brief Evolution/History

The evolution of motor shaft couplers can be traced back to the early 20th century when mechanical power transmission systems became essential in industrial applications. Initially, couplers were rudimentary, designed primarily for basic alignment and torque transfer. However, as machinery became more complex and the demand for efficiency grew, the design and functionality of couplers evolved significantly.

By the late 20th century, advancements in materials science led to the introduction of specialized alloys and composites that improved performance characteristics, such as weight reduction and corrosion resistance. Today, the integration of technology into couplers, including sensors and IoT capabilities, represents the latest phase in this evolution, offering buyers enhanced performance monitoring and operational insights. This historical context is essential for B2B buyers as it underscores the importance of selecting cutting-edge solutions that align with modern technological and sustainability standards.

Related Video: International Trade 101 | Economics Explained

Frequently Asked Questions (FAQs) for B2B Buyers of motor shaft coupler

-

What criteria should I use to vet suppliers of motor shaft couplers?

When vetting suppliers, prioritize their experience in the industry, specifically in producing motor shaft couplers. Check for certifications like ISO 9001, which indicates adherence to quality management standards. Request references from previous clients, especially those in your region, to gauge reliability and service quality. Additionally, assess their manufacturing capabilities, including technology used and material sourcing, to ensure they can meet your specific needs. -

Can I customize motor shaft couplers to fit my specific applications?

Yes, many suppliers offer customization options for motor shaft couplers. This may include adjustments to dimensions, materials, and design features to accommodate specific torque requirements or environmental conditions. When requesting customization, provide detailed specifications and application contexts to enable suppliers to deliver a product that meets your operational needs. Ensure that you discuss any additional costs and lead times associated with custom orders. -

What are typical minimum order quantities (MOQs) and lead times for motor shaft couplers?

MOQs and lead times can vary significantly by supplier and region. Generally, MOQs may range from 50 to 500 units depending on the supplier’s production capabilities and your customization requirements. Lead times can also vary, often ranging from 4 to 12 weeks. It’s essential to discuss these details upfront and negotiate terms that align with your project timelines and inventory management strategies. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers should implement rigorous quality assurance (QA) processes, including inspections at various stages of production. Expect to see documentation of these processes, such as material certifications, in-process inspection reports, and final product testing results. Ask for details on how they ensure compliance with international standards, as well as any specific certifications relevant to your industry (e.g., CE marking for Europe). -

What logistics considerations should I be aware of when sourcing motor shaft couplers internationally?

Logistics can significantly impact the sourcing process. Consider factors such as shipping methods, customs regulations, and potential tariffs when importing motor shaft couplers. Establish clear communication with your supplier regarding shipping terms (Incoterms), and inquire about their experience in handling international logistics. It’s also wise to factor in lead times for shipping to avoid delays in your operations. -

How can I resolve disputes with suppliers effectively?

To resolve disputes with suppliers, maintain open communication and document all interactions related to the issue. Start by addressing concerns directly with the supplier’s account manager or customer service team. If resolution is not achieved, refer to the terms outlined in your contract regarding dispute resolution procedures, which may include mediation or arbitration. Building a strong relationship with your supplier can also facilitate smoother resolution processes. -

What payment terms are commonly used in international transactions for motor shaft couplers?

Payment terms can vary, but common practices include advance payment, letters of credit, or payment on delivery. International buyers often prefer letters of credit to mitigate risk, while suppliers may request partial upfront payments. Discuss and negotiate payment terms that provide security for both parties and align with your cash flow requirements. Ensure that all terms are documented clearly in the purchase agreement. -

Are there specific certifications or standards I should look for in motor shaft couplers?

Yes, look for certifications that indicate compliance with industry standards relevant to your application. Common certifications include ISO 9001 for quality management and ISO 14001 for environmental management. Depending on your industry, other certifications like CE, UL, or RoHS may also be essential. These certifications provide assurance regarding the quality, safety, and environmental impact of the products you are sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for motor shaft coupler

In the dynamic landscape of motor shaft couplers, international B2B buyers must prioritize strategic sourcing to navigate complexities and capitalize on opportunities. The selection of appropriate couplers significantly impacts operational efficiency, cost control, and long-term reliability. Buyers should focus on understanding various coupling types—such as beam, bellows, and chain couplings—and their suitability for specific applications in diverse industries, from manufacturing to agriculture.

By leveraging comprehensive supplier evaluations, including material compatibility and performance attributes, businesses can mitigate risks associated with supply chain disruptions and fluctuating costs. Additionally, fostering strong relationships with suppliers can enhance access to technical support and innovation, crucial for maintaining competitiveness in regions like Africa, South America, the Middle East, and Europe.

As the global market evolves, staying informed about emerging trends and technological advancements will be vital. Invest in ongoing education and market research to ensure your sourcing strategies remain agile and effective. Embrace this moment to refine your procurement approach, ensuring that your operations are not only resilient but also positioned for future growth and success.