Mastering Platform Scale: Essential Strategies for Global

Introduction: Navigating the Global Market for platform scale

In today’s rapidly evolving global marketplace, platform scale has emerged as a pivotal strategy for B2B enterprises seeking to thrive amidst digital transformation. As businesses transition from traditional models to more interconnected ecosystems, understanding and leveraging platform scale becomes critical. This guide will equip international buyers, particularly those in Africa, South America, the Middle East, and Europe, with the insights needed to navigate this complex landscape effectively.

With a comprehensive scope that encompasses various types of platforms—ranging from aggregation and social platforms to mobilization and learning platforms—this guide will delve into the intricacies of sourcing, manufacturing, quality control, and supplier engagement. Buyers will discover actionable strategies to optimize costs, enhance market competitiveness, and foster robust partnerships.

By offering detailed analyses of market trends, FAQs, and best practices, this resource empowers B2B buyers to make informed sourcing decisions. The emphasis on platform scale not only highlights its potential to unlock significant value but also illustrates how companies can harness network effects to create sustainable growth. As the global B2B landscape continues to shift, understanding platform scale is no longer optional; it is essential for success in a digital-first world.

Understanding platform scale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aggregation Platforms | Connect users to a diverse range of resources and services | Marketplaces, broker services | Pros: Broad access to options; competitive pricing. Cons: May face saturation; quality control challenges. |

| Social Platforms | Facilitate long-term relationships among stakeholders | Networking events, industry forums | Pros: Builds trust and loyalty; fosters collaboration. Cons: Slower transaction pace; can be less focused on immediate sales. |

| Mobilization Platforms | Drive collaborative actions and long-term partnerships | Supply chain networks, distribution systems | Pros: Enhanced operational efficiency; stronger alliances. Cons: Requires commitment; potential for complex coordination. |

| Learning Platforms | Promote knowledge sharing and continuous improvement | Training programs, professional development | Pros: Fosters innovation; builds expertise. Cons: Time investment needed; results may take time to materialize. |

| Subscription Platforms | Offer recurring access to services or products | Software as a Service (SaaS), content platforms | Pros: Predictable costs; ongoing support and updates. Cons: Long-term commitment; potential for service creep. |

Aggregation Platforms

Aggregation platforms serve as a hub for diverse resources, connecting buyers with suppliers, products, or services. They are particularly useful in B2B environments where businesses seek to compare options easily. These platforms often host marketplaces or broker services, allowing users to make informed purchasing decisions. For buyers, the key consideration is the breadth of options available; however, they must also be wary of market saturation and the challenge of ensuring quality across numerous suppliers.

Social Platforms

Social platforms are designed to foster long-term relationships and community engagement among stakeholders. In a B2B context, they facilitate networking events and industry forums where businesses can connect over shared interests. These platforms are valuable for building trust and loyalty, which can lead to more fruitful partnerships. Buyers should consider the slower transaction pace typical of these platforms, as they prioritize relationship-building over immediate sales, potentially delaying decision-making processes.

Mobilization Platforms

Mobilization platforms focus on collaborative actions, enabling businesses to work together towards common goals. They are particularly prevalent in supply chain networks and distribution systems, where long-term partnerships are essential. For B2B buyers, these platforms enhance operational efficiency and foster stronger alliances. However, they require a commitment to collaboration and can involve complex coordination among multiple parties, which may pose challenges for some organizations.

Learning Platforms

Learning platforms facilitate knowledge sharing and continuous improvement among participants. They are often used for training programs and professional development, making them valuable in industries where expertise is crucial. B2B buyers can benefit from the innovation and skill-building that these platforms promote. However, they also require a time investment, and the benefits may take time to materialize, which buyers should factor into their decision-making processes.

Subscription Platforms

Subscription platforms provide recurring access to services or products, commonly seen in Software as a Service (SaaS) models. They offer predictable costs and ongoing support, making them attractive for businesses looking to streamline operations. Buyers must consider the long-term commitment associated with these platforms, as well as the potential for service creep, where additional costs may accrue over time. This model can provide significant value but requires careful management to ensure alignment with business needs.

Related Video: Large Language Models (LLMs) – Everything You NEED To Know

Key Industrial Applications of platform scale

| Industry/Sector | Specific Application of platform scale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Smart Manufacturing Platforms | Increased operational efficiency and reduced downtime | Evaluate the platform’s integration capabilities with existing systems. |

| Logistics and Supply Chain | Cross-Border B2B Shipping Solutions | Enhanced delivery speed and cost transparency | Assess the platform’s regional fulfillment capabilities and compliance with local regulations. |

| Financial Services | Digital Payment and Transaction Platforms | Improved cash flow and reduced transaction costs | Look for platforms that offer robust security and compliance features. |

| Retail and E-commerce | Marketplace Platforms for B2B Transactions | Expanded market reach and streamlined procurement processes | Consider user interface and accessibility for diverse buyer demographics. |

| Energy and Utilities | Energy Management Platforms | Optimized resource allocation and reduced operational costs | Ensure platform scalability and adaptability to local energy regulations. |

Manufacturing: Smart Manufacturing Platforms

Smart manufacturing platforms leverage IoT and data analytics to enhance production processes. These platforms enable real-time monitoring and predictive maintenance, thus reducing downtime and improving efficiency. For international buyers, particularly in Africa and South America, it’s essential to evaluate how these platforms integrate with existing machinery and software. They should also consider the scalability of the solution to accommodate future growth and technology advancements.

Logistics and Supply Chain: Cross-Border B2B Shipping Solutions

Cross-border shipping platforms facilitate seamless international trade by providing real-time tracking, cost transparency, and efficient customs clearance. This is particularly beneficial for businesses in the Middle East and Europe looking to streamline their logistics. Buyers should prioritize platforms that offer regional fulfillment options to minimize transit times and ensure compliance with local regulations, thereby enhancing customer satisfaction.

Financial Services: Digital Payment and Transaction Platforms

Digital payment platforms enable businesses to conduct transactions securely and efficiently across borders. By automating payment processes, these platforms help improve cash flow and reduce transaction fees. International buyers from Europe and Africa should focus on platforms that provide robust security features and comply with local financial regulations to mitigate risks associated with digital transactions.

Retail and E-commerce: Marketplace Platforms for B2B Transactions

Marketplace platforms connect businesses with suppliers and buyers, streamlining procurement and expanding market reach. These platforms allow for bulk purchasing, which can lead to significant cost savings. Buyers should look for platforms that offer user-friendly interfaces and support for multiple languages and currencies, catering to diverse demographics in South America and Europe.

Energy and Utilities: Energy Management Platforms

Energy management platforms help companies optimize their energy usage and reduce operational costs. By providing insights into energy consumption patterns, these platforms enable businesses to make informed decisions about resource allocation. Buyers in regions like Africa and the Middle East should ensure that the platforms they choose are scalable and can adapt to local energy regulations and sustainability goals.

Related Video: Uses and Gratifications Theory

Strategic Material Selection Guide for platform scale

When selecting materials for platform scale applications, international B2B buyers must consider various factors that influence performance, cost, and compliance. Below is an analysis of four common materials used in platform scale construction, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Aluminum

Key Properties:

Aluminum is lightweight, has excellent corrosion resistance, and can withstand moderate temperatures and pressures. It is also highly malleable, allowing for complex shapes.

Pros & Cons:

Aluminum’s durability and resistance to corrosion make it ideal for outdoor applications. However, it can be more expensive than other metals and may not perform well under extreme temperatures. Manufacturing complexity can also increase if intricate designs are required.

Impact on Application:

Aluminum is compatible with various media, including water and mild chemicals, making it suitable for diverse applications. However, it may not be the best choice for highly corrosive environments.

Considerations for International Buyers:

Buyers must ensure compliance with relevant standards such as ASTM and DIN. In regions with high humidity or salt exposure, additional protective coatings may be necessary to enhance longevity.

Stainless Steel

Key Properties:

Stainless steel is known for its high strength, excellent corrosion resistance, and ability to withstand high temperatures and pressures. It is available in various grades, each suited for specific applications.

Pros & Cons:

The primary advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is heavier and more expensive than aluminum, and its manufacturing processes can be complex.

Impact on Application:

Stainless steel is compatible with a wide range of media, including aggressive chemicals, making it a preferred choice for food processing and pharmaceutical applications.

Considerations for International Buyers:

Compliance with international standards is crucial, especially in regulated industries. Buyers should also consider the availability of specific grades in their region, as supply chains may vary.

Composite Materials

Key Properties:

Composites, often made from a combination of polymers and reinforcing materials (like fiberglass), offer lightweight, high strength, and excellent corrosion resistance. They can also be engineered for specific thermal and mechanical properties.

Pros & Cons:

The main advantage of composites is their versatility and lightweight nature, which can lead to cost savings in transportation and installation. However, they may not be as strong as metals and can be more expensive to manufacture.

Impact on Application:

Composites are suitable for environments where weight reduction is critical, such as in aerospace or automotive applications. They also offer good resistance to chemicals and moisture.

Considerations for International Buyers:

Buyers should be aware of the varying standards for composites in different regions. Additionally, the lifecycle and disposal of composite materials can be a concern, particularly in environmentally conscious markets.

High-Density Polyethylene (HDPE)

Key Properties:

HDPE is a strong, durable plastic known for its excellent chemical resistance and low moisture absorption. It performs well in a wide temperature range and is lightweight.

Pros & Cons:

HDPE is cost-effective and easy to manufacture, making it suitable for large-scale applications. However, it may not withstand high temperatures as well as metals or composites.

Impact on Application:

HDPE is compatible with many chemicals and is often used in applications involving liquids, such as storage tanks and piping systems. Its lightweight nature facilitates easy handling and installation.

Considerations for International Buyers:

Buyers should ensure compliance with local regulations regarding plastic materials. In regions with stringent environmental regulations, sourcing HDPE from certified suppliers may be necessary.

Summary Table

| Material | Typical Use Case for platform scale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight structures, outdoor applications | Excellent corrosion resistance | Higher cost, limited high-temp performance | Medium |

| Stainless Steel | Food processing, pharmaceutical equipment | High strength and durability | Heavier, more expensive | High |

| Composite Materials | Aerospace, automotive components | Lightweight and versatile | May lack strength compared to metals | High |

| High-Density Polyethylene (HDPE) | Storage tanks, piping systems | Cost-effective and easy to manufacture | Limited high-temperature performance | Low |

This guide provides a comprehensive overview of materials suitable for platform scale applications, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for platform scale

Understanding Manufacturing Processes for Platform Scale

In the realm of platform scale manufacturing, understanding the intricacies of production processes and quality assurance is essential for international B2B buyers. This section delves into the typical manufacturing stages, key techniques employed, and the critical quality control measures that ensure product integrity.

Main Stages of Manufacturing

The manufacturing process for platform scale typically consists of four main stages: Material Preparation, Forming, Assembly, and Finishing.

-

Material Preparation

– Selection: The choice of raw materials is crucial. Materials such as metals, plastics, and composites are often selected based on their properties, cost, and availability.

– Processing: This may involve cutting, machining, or molding to prepare the materials for the next stage. Advanced techniques such as laser cutting or CNC machining are commonly employed for precision. -

Forming

– Techniques: Common forming methods include stamping, forging, and extrusion. Each method has specific applications depending on the material and desired product characteristics.

– Automation: Incorporating automation in this stage enhances efficiency and consistency, reducing human error and production time. -

Assembly

– Sub-assembly: Components are often pre-assembled into sub-units to streamline the final assembly process. Techniques such as robotic assembly or manual assembly lines are utilized.

– Integration: Ensuring that all components fit and work together seamlessly is critical. This stage often includes alignment checks and functional testing. -

Finishing

– Surface Treatment: This may involve processes such as painting, anodizing, or plating to enhance appearance and protect against corrosion.

– Final Inspection: A thorough inspection is conducted to ensure that the product meets specifications before delivery.

Key Techniques in Manufacturing

To achieve platform scale, manufacturers employ various techniques that enhance efficiency and product quality:

- Lean Manufacturing: Focuses on minimizing waste without sacrificing productivity. This approach is beneficial for B2B buyers seeking cost-effective solutions.

- Just-In-Time (JIT): Reduces inventory costs by receiving goods only as they are needed in the production process, thus improving cash flow.

- Digital Twins: Utilizing digital replicas of physical assets to simulate, predict, and optimize manufacturing processes in real-time.

Quality Assurance in Manufacturing

Quality assurance (QA) is integral to the manufacturing process, ensuring that products meet specific standards and customer expectations. For international B2B buyers, understanding QA processes is vital for mitigating risks associated with procurement.

Relevant International Standards

- ISO 9001: This standard outlines criteria for a quality management system (QMS) and is applicable to any organization, regardless of its size or sector. It emphasizes a process-based approach to enhance customer satisfaction.

- Industry-Specific Standards:

– CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– API Spec Q1: Relevant for companies in the oil and gas industry, focusing on quality management systems in the supply chain.

Quality Control Checkpoints

Quality control (QC) checkpoints are essential throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Inspection of raw materials before production begins to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing process to detect defects early.

- Final Quality Control (FQC): Comprehensive inspection of the finished product to verify compliance with standards and specifications.

Common Testing Methods

B2B buyers should be aware of the following testing methods commonly used in quality assurance:

- Destructive Testing: Tests such as tensile and impact tests that assess the material’s properties until failure.

- Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing that evaluate material integrity without causing damage.

- Functional Testing: Ensures that the product performs as intended under specified conditions.

Verifying Supplier Quality Control

For B2B buyers, particularly those in diverse regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensuring product reliability. Here are actionable strategies:

- Conduct Audits: Regular supplier audits can provide insights into their quality management practices and compliance with international standards.

- Request Quality Reports: Suppliers should provide documentation of quality assurance processes, including records of inspections and tests conducted.

- Engage Third-Party Inspectors: Hiring independent inspectors can offer an unbiased assessment of supplier capabilities and product quality.

Quality Control Nuances for International Buyers

Understanding the nuances of quality control is essential for international B2B buyers:

- Cultural Differences: Quality perceptions can vary by region. Buyers should engage with suppliers to align on quality expectations and standards.

- Regulatory Compliance: Different countries have varying regulatory requirements. Buyers should ensure that suppliers are compliant with both local and international standards.

- Supply Chain Transparency: Establishing clear communication channels with suppliers can help in understanding their QC processes and addressing any potential issues proactively.

Conclusion

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, a thorough understanding of manufacturing processes and quality assurance practices is essential. By focusing on material preparation, forming, assembly, and finishing, along with adhering to relevant standards and implementing robust QC measures, buyers can ensure they partner with reliable suppliers capable of delivering high-quality products at scale.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for platform scale Sourcing

In today’s competitive B2B landscape, understanding the cost structure and pricing dynamics of platform-scale sourcing is crucial for international buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. This section breaks down the essential cost components, identifies key price influencers, and offers practical tips for negotiation and cost management.

Cost Components

When engaging in platform-scale sourcing, it is vital to consider the following cost components:

- Materials: The choice of materials significantly impacts overall costs. Sourcing high-quality, certified materials may increase initial expenses but can lead to lower maintenance costs and higher durability.

- Labor: Labor costs can vary widely depending on the region and the skill level required. Understanding local labor markets can help in negotiating better terms.

- Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Efficient management of overhead can significantly affect pricing.

- Tooling: Initial tooling costs can be substantial, especially for custom orders. Buyers should inquire about tooling fees and whether they are one-time costs or recurring expenses.

- Quality Control (QC): Implementing stringent QC measures can add to costs but is necessary to ensure that products meet required specifications. Consider the balance between quality and cost.

- Logistics: Shipping and handling can account for a significant portion of the total cost. Factors such as distance, mode of transport, and delivery timelines should be carefully evaluated.

- Margin: Suppliers will build a profit margin into their pricing. Understanding typical margins within your industry can aid in negotiations.

Price Influencers

Several factors can influence pricing in platform-scale sourcing:

- Volume/MOQ (Minimum Order Quantity): Higher volumes typically lead to lower per-unit costs. Buyers should assess their demand to negotiate better terms based on larger orders.

- Specifications/Customization: Custom products may incur additional costs. Clearly defining specifications upfront can prevent unexpected expenses later.

- Materials: The type and quality of materials used directly affect costs. Buyers should compare material options for cost-effectiveness without compromising quality.

- Quality/Certifications: Products with recognized certifications may have higher costs but can lead to increased buyer trust and marketability.

- Supplier Factors: The supplier’s location, reputation, and operational efficiency can impact pricing. Conducting thorough due diligence on suppliers is essential.

- Incoterms: The chosen Incoterms determine who is responsible for shipping, duties, and insurance. Understanding these terms is critical to avoid hidden costs.

Buyer Tips

To navigate the complexities of international B2B sourcing, consider the following strategies:

- Negotiation: Always enter negotiations with a clear understanding of your needs and the current market rates. Leverage competitive bids to strengthen your position.

- Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes purchase price, shipping, handling, and lifecycle costs. This holistic view can lead to better sourcing decisions.

- Pricing Nuances: Be aware of regional pricing differences and currency fluctuations. Incorporating flexible pricing strategies can mitigate risks associated with currency volatility.

- Local Regulations: Understand the import/export regulations in your target markets. Compliance can prevent costly delays and fines.

- Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing, priority service, and access to exclusive products.

Disclaimer

Prices are indicative and can vary significantly based on market conditions, supplier negotiations, and specific project requirements. Always conduct thorough market research and consult with local experts to obtain accurate pricing information tailored to your sourcing needs.

Spotlight on Potential platform scale Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘platform scale’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for platform scale

Key Technical Properties for Platform Scale

When engaging in B2B transactions involving platform scales, understanding their technical properties is essential for making informed purchasing decisions. Here are some critical specifications:

-

Load Capacity

– Definition: This refers to the maximum weight that a platform scale can accurately measure.

– Importance: Choosing a scale with an appropriate load capacity is vital for ensuring safety and accuracy. An inadequate capacity can lead to inaccurate readings and potential damage to the scale. -

Accuracy Class

– Definition: Accuracy class indicates the degree of precision a scale can provide, typically expressed as a percentage of the load.

– Importance: High accuracy is crucial in industries where precise measurements are essential, such as pharmaceuticals or food production. It minimizes errors that could lead to compliance issues or financial losses. -

Material Composition

– Definition: The materials used in the scale’s construction, such as stainless steel, aluminum, or plastic.

– Importance: The choice of material affects durability, weight, and resistance to environmental factors like moisture and chemicals. For example, stainless steel is preferable in wet environments due to its corrosion resistance. -

Platform Dimensions

– Definition: The physical size of the platform, including length, width, and height.

– Importance: Proper dimensions ensure that the scale can accommodate the specific items being weighed. A scale that is too small may not be suitable for larger products, affecting operational efficiency. -

Tolerance

– Definition: Tolerance is the allowable deviation from a specified measurement, often expressed in grams or kilograms.

– Importance: Understanding tolerance helps buyers determine the reliability of the scale for their specific applications. Tighter tolerances are required in industries with stringent regulatory standards. -

Power Source

– Definition: The method by which the scale is powered, such as AC mains, batteries, or rechargeable systems.

– Importance: Knowing the power source is crucial for ensuring that the scale can be used in the intended location without interruptions, especially in remote or field applications.

Common Trade Terminology

Familiarizing yourself with industry jargon can facilitate smoother transactions and better communication with suppliers. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Relevance: Understanding OEM relationships can help buyers identify quality standards and warranty conditions, as well as potential sourcing options. -

MOQ (Minimum Order Quantity)

– Definition: The smallest number of units a supplier is willing to sell.

– Relevance: Knowing the MOQ is essential for budgeting and inventory management. Buyers should assess if the MOQ aligns with their demand to avoid overstocking. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to solicit price offers from suppliers for specific products or services.

– Relevance: An RFQ is a critical step in procurement, allowing buyers to compare prices and terms from different suppliers, ultimately aiding in cost-effective purchasing decisions. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms that clarify the responsibilities of buyers and sellers in shipping goods.

– Relevance: Familiarity with Incoterms helps buyers understand their obligations regarding transportation, insurance, and customs clearance, reducing the risk of disputes. -

Landed Cost

– Definition: The total cost of a product once it has arrived at the buyer’s location, including purchase price, shipping, duties, and taxes.

– Relevance: Understanding landed cost is crucial for pricing strategies and profitability analysis, especially for cross-border transactions. -

Lead Time

– Definition: The time taken from placing an order to receiving the goods.

– Relevance: Knowing lead times aids in planning and inventory management, especially in industries where timely delivery is critical to maintaining operations.

By mastering these technical properties and trade terms, international B2B buyers can navigate the complexities of platform scale procurement more effectively, ensuring they make informed decisions that align with their operational needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the platform scale Sector

Market Overview & Key Trends

The platform scale sector is witnessing significant transformation driven by several global factors. First, the digital transformation across industries is reshaping how businesses operate, leading to increased reliance on digital platforms for resource allocation and operational efficiency. Key technologies such as IoT, AI, and blockchain are enhancing data flows and enabling real-time decision-making, which is crucial for international B2B buyers looking to optimize their supply chains.

Moreover, the rise of cross-border e-commerce is facilitating greater market access for businesses in Africa, South America, the Middle East, and Europe. The growth of regional fulfillment centers is a notable trend, as companies seek to reduce delivery times and costs while improving customer service. This shift towards Delivered Duty Paid (DDP) models allows sellers to take on customs complexities, providing buyers with a transparent pricing structure and minimizing unexpected costs.

As businesses adapt, the demand for sustainable practices is becoming increasingly prominent. Buyers are prioritizing partnerships with companies that demonstrate a commitment to ethical sourcing and environmental responsibility. The integration of sustainability into platform strategies is not only a competitive advantage but also a key factor in attracting conscientious consumers and partners.

Sustainability & Ethical Sourcing in B2B

In the context of platform scale, sustainability is not merely a trend but a fundamental aspect of business strategy. The environmental impact of supply chains is under scrutiny, prompting international buyers to seek suppliers who prioritize green practices. This includes using renewable materials, reducing carbon footprints, and implementing waste reduction strategies throughout their operations.

Ethical supply chains are critical for fostering trust and loyalty among consumers. Buyers from diverse regions are increasingly looking for transparency in sourcing practices, which can be bolstered by obtaining green certifications such as ISO 14001 or Fair Trade. These certifications signal a company’s commitment to responsible sourcing and environmental stewardship, which can differentiate them in a competitive marketplace.

To effectively navigate these demands, B2B buyers should engage with suppliers who not only comply with regulatory standards but also proactively invest in sustainable technologies and practices. This alignment not only mitigates risks associated with environmental regulations but also enhances brand reputation and customer loyalty.

Brief Evolution/History

The evolution of the platform scale sector can be traced back to the early days of e-commerce and digital marketplaces. Initially characterized by simple transactional websites, the sector has matured into complex ecosystems that leverage advanced technology to facilitate interactions among multiple stakeholders.

As businesses have increasingly recognized the value of data-driven decision-making, platforms have evolved to offer more than just transactional capabilities. They now integrate collaborative features, enabling companies to share insights and resources effectively. This shift represents a significant departure from traditional supply chain models, positioning platforms as essential tools for modern B2B operations.

In summary, international B2B buyers must stay attuned to these evolving dynamics, focusing on sustainable practices, leveraging technology, and embracing innovative sourcing strategies to thrive in the platform scale sector.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of platform scale

-

What criteria should I use to vet potential suppliers for platform scale products?

When vetting suppliers, focus on their industry reputation, experience, and financial stability. Request references from previous clients, especially those in your region. Evaluate their certifications and compliance with international standards, particularly those relevant to your industry. Additionally, consider their capacity for customization and responsiveness to inquiries. Conduct site visits or virtual audits if possible to assess their facilities and operations, ensuring they can meet your quality and delivery expectations. -

Can platform scale products be customized to meet my specific needs?

Many suppliers offer customization options for platform scale products to suit specific business requirements. It’s essential to communicate your needs clearly during the initial discussions. Discuss aspects such as design, features, and functionalities that are critical to your operations. Ensure that the supplier has a proven track record in delivering customized solutions. Keep in mind that customization may affect lead times and minimum order quantities (MOQs), so plan accordingly. -

What are typical minimum order quantities (MOQs) and lead times for platform scale products?

MOQs and lead times can vary significantly based on the supplier and product specifications. Generally, MOQs can range from a few units for standard products to larger quantities for custom solutions. Lead times often depend on the complexity of the order and the supplier’s production capacity; expect anywhere from a few weeks to several months. Discuss these details upfront to align expectations and avoid delays in your supply chain.

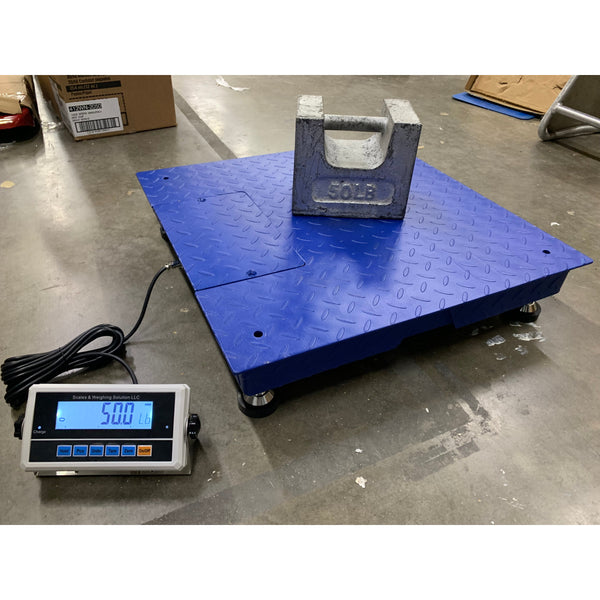

Illustrative Image (Source: Google Search)

- How can I ensure the quality of platform scale products before making a purchase?

To ensure product quality, request detailed product specifications and quality assurance (QA) certifications from suppliers. Inquire about their quality control processes, including testing methods and compliance with international standards. Consider requesting samples or conducting pilot tests before committing to a larger order. Additionally, establish clear quality benchmarks and inspection protocols to be followed upon delivery, which can help mitigate risks associated with defective products.

Illustrative Image (Source: Google Search)

-

What payment terms are typically available when sourcing platform scale products?

Payment terms can vary widely among suppliers but generally include options such as advance payment, partial payment upon order confirmation, and payment upon delivery. It’s crucial to negotiate terms that align with your cash flow requirements and risk tolerance. Consider using secure payment methods, such as letters of credit, to protect your interests in international transactions. Always review the supplier’s payment policies and any potential hidden fees before finalizing agreements. -

What logistics considerations should I keep in mind when importing platform scale products?

Logistics play a critical role in international sourcing. Ensure you understand the shipping terms, including Incoterms like Delivered Duty Paid (DDP), which can simplify customs clearance and cost transparency. Assess the supplier’s ability to handle logistics efficiently, including their partnerships with freight forwarders. Additionally, plan for potential customs delays and ensure compliance with local regulations to avoid unexpected costs. Regional fulfillment strategies can also enhance delivery speed and reliability. -

How should I handle disputes with suppliers?

To effectively manage disputes, establish clear communication channels and protocols from the outset. Document all agreements, including specifications, delivery timelines, and payment terms, to serve as a reference in case of disagreements. If a dispute arises, attempt to resolve it amicably through direct negotiation. If necessary, consider mediation or arbitration as alternatives to legal proceedings, which can be costly and time-consuming. Always consult legal counsel familiar with international trade laws to guide you through complex issues. -

What certifications should I look for when sourcing platform scale products?

Certifications can vary depending on the industry and product type, but essential certifications to look for include ISO 9001 for quality management, CE marking for compliance with European safety standards, and any industry-specific certifications relevant to your sector. These certifications demonstrate a supplier’s commitment to quality and compliance with international standards. Additionally, inquire about environmental certifications like ISO 14001 if sustainability is a priority for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for platform scale

In conclusion, the adoption of platform-scale strategies is essential for B2B buyers looking to thrive in today’s rapidly evolving global marketplace. By leveraging digital platforms, organizations can transition from traditional models to dynamic ecosystems that foster collaboration and innovation. The shift to network orchestrators enables businesses to harness valuable data flows, optimize supply chains, and enhance customer experiences, which are critical in a competitive landscape.

Strategic sourcing remains a cornerstone of this transformation, allowing companies to streamline procurement processes and create robust supplier relationships that are vital for agility and resilience. As businesses from Africa, South America, the Middle East, and Europe navigate these changes, embracing modern fulfillment strategies—such as regional inventory positioning and Delivered Duty Paid (DDP) models—will empower them to mitigate risks and improve service levels.

Looking ahead, international B2B buyers are encouraged to invest in platform strategies that align with their growth objectives. By fostering a mindset of innovation and adaptability, companies can not only secure a competitive edge but also contribute to the creation of sustainable and interconnected global supply chains. The future of B2B commerce is here; seize the opportunity to lead the charge.