Mastering the Forging Procedure: Essential Insights for B2B

Introduction: Navigating the Global Market for forging procedure

In an era where industrial efficiency and material integrity are paramount, understanding the intricacies of forging procedures becomes essential for B2B buyers. Forging, a process that shapes metals into robust components, plays a critical role across various sectors, including automotive, aerospace, energy, and construction. The ability to navigate the complexities of forging not only enhances product quality but also significantly impacts production costs and timelines.

This comprehensive guide is designed to equip international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe (including key markets like Germany and Italy), with actionable insights into the forging landscape. It covers a wide array of topics, including:

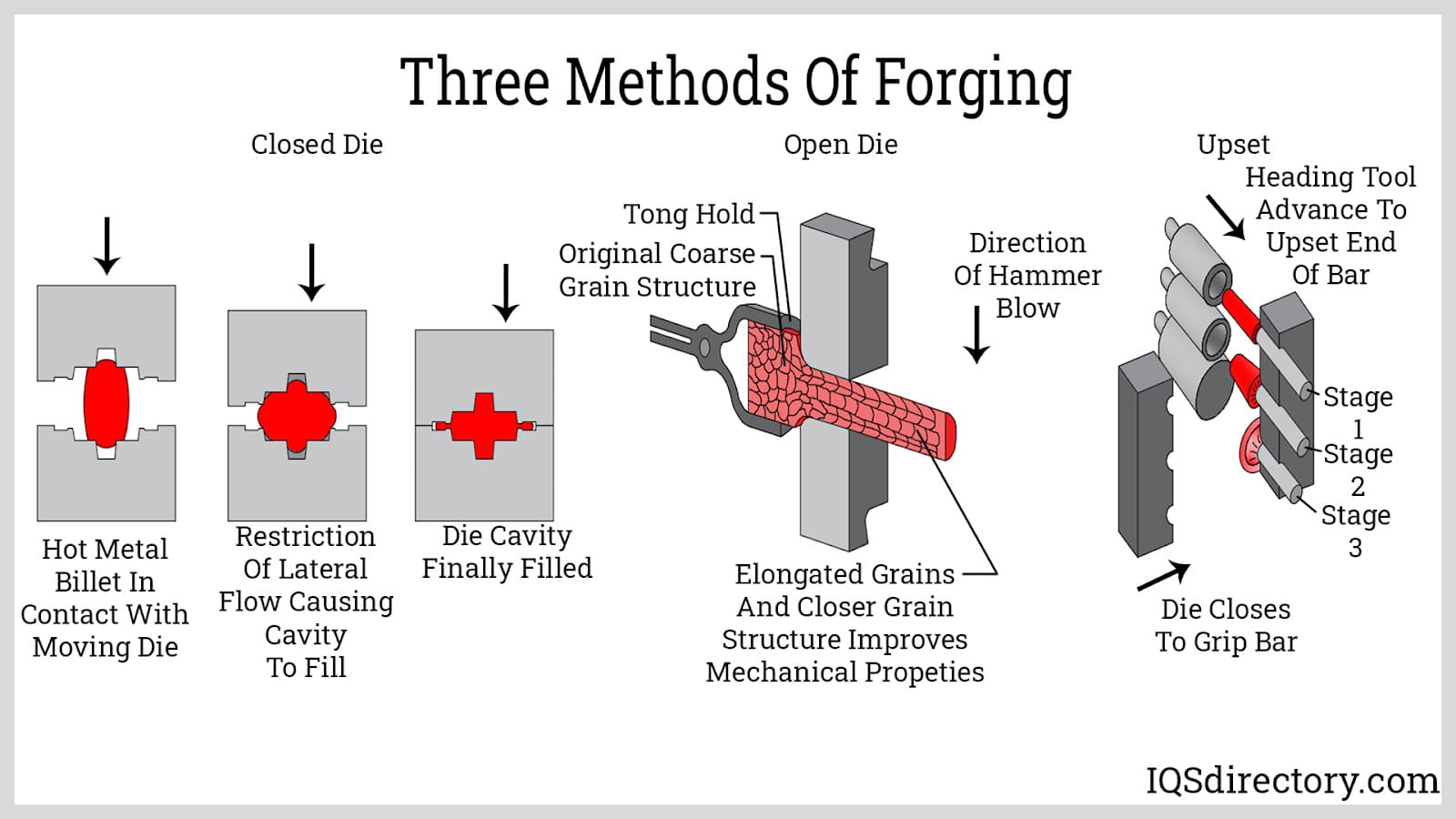

- Types of forging processes and their specific applications

- Material selection and the implications for performance and durability

- Manufacturing workflows alongside quality control best practices

- Supplier profiles and effective sourcing strategies

- Cost considerations, budgeting, and lifecycle management

- Analysis of regional market trends and entry strategies

- Frequently asked questions addressing common buyer concerns

By providing a structured roadmap, this guide empowers decision-makers to make informed, strategic choices in sourcing forging technologies. Understanding these elements is vital for enhancing operational efficiency and achieving competitive advantages in diverse markets.

Understanding forging procedure Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Drop Hammer Forging | High-velocity hammer strikes; open or closed dies | Automotive, agriculture, tools, hardware | Pros: High strength parts; Cons: Limited to simpler shapes; significant vibration/noise |

| Mechanical Press Forging | Controlled force via mechanical drive; steady high-speed press | High-volume fasteners, automotive, hardware | Pros: Fast production, precision; Cons: Limited part size; higher initial investment |

| Hydraulic Press Forging | Hydraulic power for variable, sustained pressure | Structural parts, large components, aerospace | Pros: Handles large/complex parts; Cons: Slower cycle times; higher operating costs |

| Upset Forging | Increases section thickness by compressive force | Bolts, valves, shafts, fasteners | Pros: Ideal for high-strength fasteners; Cons: Limited to specific geometries |

| Roll Forging | Rotating, grooved rolls for incremental shaping | Long shafts, levers, hand tools, automotive bars | Pros: Uniform grain flow; Cons: Limited to elongated shapes; not for intricate parts |

Drop Hammer Forging

Drop hammer forging is characterized by its use of high-velocity hammer strikes to shape heated metal. This method is prevalent in industries such as automotive and agriculture, where strong, durable parts are essential. B2B buyers should consider the lower initial investment costs and the ability to produce high-strength components. However, the noise and vibration associated with this process may necessitate additional considerations for plant layout and worker safety.

Mechanical Press Forging

Mechanical press forging utilizes mechanical drives to create consistent and rapid pressing cycles, making it ideal for high-volume production of precise components. Industries such as automotive and hardware benefit from this method due to its efficiency and ability to produce detailed parts. Buyers should weigh the advantages of reduced labor costs and increased throughput against the limitations in part size and the higher upfront investment required for these machines.

Hydraulic Press Forging

Hydraulic press forging employs hydraulic power to deliver sustained and controllable pressure, allowing for the creation of large and complex components, particularly in aerospace and heavy machinery. This method is advantageous for its design flexibility, enabling the production of intricate shapes. However, B2B buyers need to consider the potential for slower cycle times and higher operational costs, which can impact overall production efficiency.

Upset Forging

Upset forging is a specialized technique that focuses on increasing the diameter of a workpiece along its axis. This method is particularly useful for manufacturing high-strength fasteners such as bolts and valves. For buyers in sectors like oil and gas, the reliability and integrity of upset-forged components are crucial. However, the specific geometries that can be produced may limit the versatility of this process.

Roll Forging

Roll forging involves passing heated material through rotating, grooved rolls, resulting in gradual shaping. This technique is particularly effective for producing elongated components such as shafts and automotive bars. B2B buyers appreciate the uniform grain flow that enhances material properties. Nonetheless, the limitation to simpler, elongated shapes means that roll forging may not be suitable for applications requiring intricate designs.

Related Video: Forging ! Forging Manufacturing Process !! Fully Explained !!! ASK Mechnology !!!!

Key Industrial Applications of forging procedure

| Industry/Sector | Specific Application of forging procedure | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Production of crankshafts and gears | Enhanced strength and durability of components | Material quality certifications (ISO, EN), delivery reliability, and cost-effectiveness |

| Aerospace | Manufacturing of landing gear components | High precision and reliability under stress | Compliance with stringent aerospace standards, supplier reputation, and technical support |

| Oil & Gas | Forging of valves and fittings | Ensures integrity and safety in critical applications | Material composition and mechanical properties, sustainability practices, and logistical efficiency |

| Construction | Structural components like beams and reinforcements | Improved load-bearing capacity and longevity | Flexibility in production schedules, quality assurance processes, and pricing strategies |

| Energy | Production of turbine components | Increased efficiency and performance in energy generation | Innovation capabilities, adherence to environmental standards, and total cost of ownership considerations |

Automotive Industry

In the automotive sector, forging procedures are crucial for producing components such as crankshafts and gears. These parts must endure high stress and torque, requiring materials that offer exceptional strength and durability. B2B buyers must prioritize suppliers with robust material quality certifications (e.g., ISO, EN) to ensure compliance with industry standards. Additionally, delivery reliability is vital, as delays can significantly affect production timelines. Cost-effectiveness remains a key consideration, especially for manufacturers operating in competitive markets in Africa and South America.

Aerospace Sector

The aerospace industry demands precision-engineered components, particularly for critical parts like landing gear. The forging process allows for the production of lightweight yet robust structures that meet rigorous safety standards. International buyers must ensure that suppliers adhere to strict aerospace certifications and quality controls. Supplier reputation plays a significant role in decision-making, as does the availability of technical support for complex design requirements. Engaging with suppliers who have a proven track record in aerospace can mitigate risks associated with performance and compliance.

Oil & Gas Industry

In the oil and gas sector, forging is essential for creating valves and fittings that withstand extreme conditions. The integrity of these components is critical for safety and operational efficiency. B2B buyers should focus on the material composition and mechanical properties to ensure they meet specific industry demands. Sustainability practices are increasingly important, as companies seek to reduce their environmental impact. Furthermore, logistical efficiency can enhance the supply chain, making it crucial to partner with suppliers who can offer timely deliveries without compromising quality.

Construction Industry

Forging procedures are employed to manufacture structural components like beams and reinforcements, which enhance the load-bearing capacity of buildings and infrastructure. Buyers in the construction sector should prioritize suppliers that demonstrate flexibility in production schedules to accommodate project timelines. Quality assurance processes are essential to ensure the reliability and safety of forged products. Competitive pricing strategies are also a significant factor, especially in regions where cost constraints are prevalent, such as in parts of Africa and South America.

Energy Sector

In the energy sector, especially with renewable energy sources, forging is used to produce turbine components that maximize efficiency and performance. Buyers must consider suppliers’ innovation capabilities, as advancements in technology can lead to better-performing products. Adherence to environmental standards is increasingly relevant, as companies strive to minimize their carbon footprint. Additionally, total cost of ownership is a critical consideration, encompassing not only the purchase price but also long-term maintenance and operational costs associated with forged components.

Related Video: 10 Nifty Uses for Oscillating Multitool Saws

Strategic Material Selection Guide for forging procedure

When selecting materials for forging procedures, B2B buyers must consider various factors that influence the performance, cost, and suitability of the final products. Below is an analysis of four common materials used in forging, tailored for international buyers from regions such as Africa, South America, the Middle East, and Europe.

Carbon Steel

Key Properties: Carbon steel is known for its excellent strength and toughness, making it suitable for high-stress applications. It typically exhibits good wear resistance and can withstand high temperatures, depending on the carbon content.

Pros & Cons: Carbon steel is relatively inexpensive and widely available, which makes it a popular choice for various forging applications. However, its corrosion resistance is limited, necessitating protective coatings or treatments in corrosive environments. Additionally, higher carbon content can complicate the manufacturing process, requiring precise temperature control during forging.

Impact on Application: Carbon steel is commonly used in automotive parts, tools, and structural components. Its performance in high-stress environments makes it ideal for applications where durability is critical.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM A36 or EN 10025. It’s essential to source from reputable suppliers who can guarantee material quality and consistency.

Alloy Steel

Key Properties: Alloy steels are enhanced with elements like chromium, nickel, and molybdenum, which improve strength, toughness, and wear resistance. They can also offer better hardenability and resistance to deformation under heat.

Pros & Cons: The primary advantage of alloy steel is its versatility and ability to perform well under varying conditions. However, the complexity of its composition can lead to higher costs and require more sophisticated manufacturing techniques. Additionally, alloy steels may require specific heat treatments to achieve desired mechanical properties.

Impact on Application: Alloy steels are frequently used in the aerospace, automotive, and oil & gas industries due to their superior mechanical properties. They are particularly effective in high-pressure applications.

Considerations for International Buyers: Compliance with standards such as ASTM AISI 4140 or DIN 42CrMo4 is crucial. Buyers should also consider the availability of alloy steel in their region, as sourcing can be more complex than with carbon steel.

Stainless Steel

Key Properties: Stainless steel is renowned for its corrosion resistance, high-temperature strength, and aesthetic appeal. It contains a minimum of 10.5% chromium, which forms a protective oxide layer.

Pros & Cons: The durability and low maintenance requirements of stainless steel make it an attractive option for many applications. However, it is generally more expensive than carbon and alloy steels, and its forging process can be more challenging due to its work-hardening characteristics.

Impact on Application: Stainless steel is commonly used in food processing, medical devices, and marine applications where corrosion resistance is paramount. Its ability to maintain integrity in harsh environments is a significant advantage.

Considerations for International Buyers: Buyers should ensure that the stainless steel grades meet standards like ASTM A240 or EN 10088. Understanding the specific grade requirements for their applications is vital to ensure compliance and performance.

Titanium Alloys

Key Properties: Titanium alloys are known for their high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. They are lightweight yet incredibly strong, making them suitable for demanding applications.

Pros & Cons: The primary advantage of titanium alloys is their superior performance in extreme environments, such as aerospace and medical applications. However, they are significantly more expensive than other materials and can be challenging to forge due to their unique properties.

Impact on Application: Titanium alloys are often used in aerospace components, medical implants, and high-performance automotive parts. Their ability to perform under extreme conditions makes them ideal for specialized applications.

Considerations for International Buyers: Buyers must ensure compliance with standards such as ASTM B348 or ISO 5832 for medical applications. The higher costs associated with titanium alloys should be factored into the overall project budget.

Summary Table

| Material | Typical Use Case for forging procedure | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Automotive parts, tools | Inexpensive and widely available | Limited corrosion resistance | Low |

| Alloy Steel | Aerospace, automotive | Superior mechanical properties | Higher cost, complex manufacturing | Medium |

| Stainless Steel | Food processing, medical devices | Excellent corrosion resistance | Higher cost, challenging to forge | High |

| Titanium Alloys | Aerospace components, medical implants | High strength-to-weight ratio | Very high cost, difficult to forge | High |

This guide aims to empower B2B buyers by providing a clear understanding of material options for forging procedures, enabling informed decisions that align with specific industry needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for forging procedure

Overview of Manufacturing Processes for Forging

The manufacturing process for forging involves several critical stages that ensure the transformation of raw materials into high-quality forged products. Understanding these stages is essential for B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe.

1. Material Preparation

The first step in the forging process is material preparation, where raw materials are selected based on specific mechanical and chemical properties required for the final product. This often involves:

- Material Selection: Choosing the right type of metal (e.g., carbon steel, alloy steel, or titanium) according to the application requirements.

- Heat Treatment: Preheating the metal to enhance ductility and reduce brittleness, which is crucial for successful forging.

- Cutting and Shaping: The material is cut into manageable sizes, often referred to as billets or bars, which are then pre-formed to fit the forging die.

This stage is critical for ensuring that the properties of the raw material align with the intended application, influencing the performance and longevity of the forged products.

2. Forming

Forming is where the actual forging takes place. Depending on the type of forging process—such as hot, cold, or warm forging—various techniques are employed:

- Hot Forging: Involves heating the metal above its recrystallization temperature, allowing it to be shaped without cracking. This method is often used for complex shapes and larger components.

- Cold Forging: Conducted at room temperature, this process is ideal for producing smaller, high-precision parts. Cold forging enhances the strength of the material through strain hardening.

- Pressing and Hammering: Techniques such as mechanical or hydraulic pressing and drop hammering are used to apply significant force to the workpiece, reshaping it according to the die design.

Effective forming requires skilled operators and sophisticated machinery to ensure precision and consistency across production runs.

3. Assembly

In some cases, multiple forged components may need to be assembled to create a final product. This stage can involve:

- Welding or Joining: Techniques such as welding, bolting, or riveting to combine different forged parts.

- Inspection and Testing: Each assembled unit undergoes inspection to ensure it meets the specified requirements before moving on to the finishing stage.

This phase ensures that the assembled products maintain the integrity and performance standards expected in demanding applications, such as aerospace or automotive.

4. Finishing

The finishing stage is crucial for preparing the forged products for their intended applications. It typically includes:

- Machining: Precision machining processes are employed to achieve the required tolerances and surface finishes. This may involve turning, milling, or grinding operations.

- Surface Treatment: Techniques like shot blasting, coating, or anodizing are used to enhance corrosion resistance and surface durability.

- Final Inspection: A thorough final quality check is performed to verify that all specifications and tolerances are met before the products are dispatched.

This stage not only improves the aesthetic quality of the forged items but also enhances their functional performance.

Quality Assurance in Forging

Quality assurance (QA) is vital in the forging process to ensure that the final products meet both international standards and industry-specific requirements. Here are the key components of a robust QA system:

International Standards and Certifications

B2B buyers should prioritize suppliers who adhere to recognized international standards. Key certifications include:

- ISO 9001: This standard ensures quality management systems are in place, focusing on customer satisfaction and continuous improvement.

- CE Marking: Indicates that products conform to health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Essential for products used in the oil and gas sector, ensuring they meet specific performance and safety criteria.

These certifications provide a framework for consistent quality and reliability in forging processes.

Quality Control Checkpoints

Quality control (QC) checkpoints throughout the manufacturing process are critical for maintaining product integrity. Key checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the forging process helps identify any deviations from standards in real time.

- Final Quality Control (FQC): The final inspection ensures that all products conform to the required specifications before shipping.

Implementing these checkpoints allows for early detection of potential issues, minimizing waste and rework.

Common Testing Methods

Various testing methods are employed to verify the quality and performance of forged products:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, radiography, and magnetic particle inspection help identify internal flaws without damaging the product.

- Destructive Testing: Tensile tests, impact tests, and hardness tests provide insights into the mechanical properties of the materials used.

- Visual Inspection: A thorough visual assessment is often the first line of defense in identifying surface defects.

These methods give B2B buyers confidence in the quality of their products and the reliability of their suppliers.

Verifying Supplier Quality Control

B2B buyers can take several steps to verify a supplier’s quality control processes:

- Supplier Audits: Conducting regular audits of suppliers’ facilities to assess compliance with quality standards and certifications.

- Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including inspection reports and test results.

- Third-Party Inspections: Engaging independent inspectors to evaluate the quality of products and processes can offer unbiased insights into a supplier’s capabilities.

These practices are particularly important for international buyers, as they help navigate potential disparities in quality assurance practices across different regions.

Conclusion

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the intricacies of the forging manufacturing process and quality assurance is vital. By focusing on material preparation, forming techniques, assembly, and finishing, alongside robust quality control measures, buyers can ensure they source high-quality forged products that meet their specific needs. Prioritizing suppliers with strong QA frameworks and certifications will further enhance the reliability and performance of the products, ultimately contributing to successful business outcomes.

Comprehensive Cost and Pricing Analysis for forging procedure Sourcing

Understanding the cost structure and pricing dynamics of forging procedures is essential for international B2B buyers, especially those navigating diverse markets in Africa, South America, the Middle East, and Europe. By grasping the various cost components and price influencers, buyers can make informed decisions that enhance their procurement strategies.

Cost Components

-

Materials: The cost of raw materials is a significant factor in the overall pricing of forging procedures. Prices can vary based on the type of steel or alloy required, with specific grades demanding premium pricing due to their mechanical properties and certifications. Buyers should ensure that material quality aligns with their production needs to avoid costly failures.

-

Labor: Labor costs encompass wages for skilled operators and technicians involved in the forging process. The complexity of the operation often dictates the level of skill required, influencing labor costs. In regions with high labor costs, like parts of Europe, manufacturers may implement automation to mitigate expenses.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and indirect labor. Efficient manufacturing processes and energy management can help reduce overhead costs, making it crucial for buyers to assess the operational efficiency of potential suppliers.

-

Tooling: Tooling costs vary significantly based on the complexity and longevity of the dies and molds used in forging. Custom tooling may require substantial upfront investment but can lead to cost savings over time through increased production efficiency.

-

Quality Control (QC): Ensuring product quality incurs costs associated with testing and inspection processes. Buyers should prioritize suppliers with robust QC measures, as this can prevent costly reworks and ensure compliance with industry standards.

-

Logistics: Transportation and delivery costs are pivotal, especially for international transactions. Factors such as shipping methods, distances, and customs duties can significantly impact the total cost. Buyers should evaluate suppliers’ logistics capabilities to optimize delivery timelines and costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on market demand, competition, and operational efficiencies. Understanding the typical margins within specific regions can help buyers gauge fair pricing.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower unit prices, so negotiating for volume discounts can significantly impact overall costs.

-

Specifications/Customization: Unique specifications or custom products may attract higher costs due to the need for specialized tooling and production processes. Buyers should balance the need for customization against potential cost implications.

-

Materials: The choice of materials directly influences pricing. Buyers should consider the long-term benefits of investing in higher-quality materials against their upfront costs.

-

Quality/Certifications: Products that meet higher industry standards or possess relevant certifications (e.g., ISO, ASTM) may command premium prices. However, these investments often translate into enhanced reliability and performance.

-

Supplier Factors: The reputation and reliability of a supplier can affect pricing. Established suppliers with a track record of timely deliveries and quality assurance may charge higher prices but provide better overall value.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they define shipping responsibilities and costs. Choosing favorable terms can lead to significant savings.

Buyer Tips

-

Negotiation: Engage in proactive negotiations to secure the best pricing. Building long-term relationships with suppliers can enhance leverage during price discussions.

-

Cost-Efficiency: Focus on total cost of ownership rather than just initial pricing. Consider factors like maintenance, longevity, and reliability when evaluating suppliers.

-

Pricing Nuances: Be aware of regional pricing variations. For instance, suppliers in Europe may have different cost structures compared to those in Africa or South America due to labor laws and manufacturing practices.

-

Disclaimer for Indicative Prices: Always approach price quotes with caution, as they can fluctuate based on market conditions, availability of materials, and geopolitical factors. It’s advisable to seek multiple quotes and conduct thorough market research before finalizing any sourcing decisions.

In conclusion, understanding the intricacies of cost components and pricing influencers in the forging procedure sourcing process equips B2B buyers with the knowledge needed to optimize procurement strategies and achieve cost efficiencies.

Spotlight on Potential forging procedure Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘forging procedure’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for forging procedure

Key Technical Properties in Forging

Understanding the technical properties associated with forging is crucial for B2B buyers, as these specifications directly influence product quality, performance, and cost-effectiveness. Here are some of the essential properties to consider:

-

Material Grade

– Definition: Material grade refers to the classification of metal based on its mechanical and chemical properties. Common grades include carbon steel, alloy steel, and stainless steel.

– Importance: Selecting the appropriate material grade is vital for ensuring that the forged components meet performance requirements and regulatory standards, especially in industries like automotive and aerospace. -

Tensile Strength

– Definition: Tensile strength measures the maximum amount of tensile (pulling) stress that a material can withstand before failure.

– Importance: High tensile strength is essential for components that will experience significant loads, such as those used in construction or heavy machinery. This property helps buyers assess the durability and safety of the final products. -

Dimensional Tolerance

– Definition: Dimensional tolerance specifies the allowable variation in a component’s size and shape. It includes parameters such as length, width, height, and angle.

– Importance: Tight tolerances are critical for ensuring proper fit and functionality in assembly processes. B2B buyers must communicate their tolerance requirements clearly to prevent costly rework or failures in end-use applications. -

Surface Finish

– Definition: Surface finish refers to the texture and quality of a material’s surface, including aspects like roughness and smoothness.

– Importance: A proper surface finish enhances the performance of forged parts, impacting friction, wear, and corrosion resistance. Buyers should specify surface requirements to align with their application needs. -

Heat Treatment

– Definition: Heat treatment involves processes like annealing, quenching, and tempering to alter the physical and sometimes chemical properties of a material.

– Importance: Proper heat treatment can enhance hardness, strength, and ductility, making it a critical consideration for buyers aiming for optimized performance in high-stress applications. -

Chemical Composition

– Definition: The chemical composition of a material details the specific elements and their proportions within the alloy.

– Importance: Understanding chemical composition is crucial for ensuring that the forged components meet industry standards and performance expectations, particularly in specialized sectors like oil and gas.

Common Trade Terminology in Forging

Familiarity with industry jargon is essential for effective communication and negotiation in the forging sector. Below are some commonly used terms:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships helps buyers ensure they are sourcing from reputable manufacturers that meet the necessary quality and compliance standards. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Buyers must be aware of MOQs as they affect inventory management and cash flow. Negotiating favorable MOQs can lead to cost savings and better supply chain efficiency. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document issued by a buyer requesting price quotes from suppliers for specific products or services.

– Importance: Submitting an RFQ allows buyers to compare pricing and terms from multiple suppliers, facilitating informed decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions.

– Importance: Understanding Incoterms is critical for buyers to clarify shipping responsibilities, costs, and risks associated with international shipments, ensuring smoother transactions. -

Lead Time

– Definition: Lead time is the time required to manufacture and deliver a product after an order is placed.

– Importance: Buyers need to consider lead times when planning production schedules. Shorter lead times can significantly enhance operational efficiency and responsiveness to market demands. -

Quality Assurance (QA)

– Definition: QA refers to the processes and procedures in place to ensure that products meet specified quality standards.

– Importance: A strong QA program is vital for maintaining product integrity and customer satisfaction. Buyers should prioritize suppliers with robust QA processes to mitigate risks associated with defective products.

By understanding these technical properties and trade terminologies, B2B buyers can make more informed decisions, ultimately leading to improved procurement strategies and enhanced product quality.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the forging procedure Sector

Market Overview & Key Trends

The global forging market is experiencing significant growth, driven by the increasing demand for lightweight and durable components across various industries, including automotive, aerospace, and energy. As of late 2023, the market is projected to reach approximately $150 billion by 2025, with a compound annual growth rate (CAGR) of around 5%. For international B2B buyers from Africa, South America, the Middle East, and Europe, understanding key market dynamics is essential.

Emerging technologies such as automation, artificial intelligence, and advanced materials are reshaping sourcing trends. Automation is enhancing production efficiency and reducing labor costs, while AI is being utilized for predictive maintenance and quality control, thus minimizing downtime. Additionally, there is a growing trend towards just-in-time (JIT) manufacturing, which requires suppliers to maintain flexible inventories and rapid delivery capabilities.

B2B buyers should also be aware of regional variations in market dynamics. For example, European markets emphasize precision and quality, particularly in Germany and Italy, where stringent regulations necessitate high standards in manufacturing processes. In contrast, buyers in Africa and South America may prioritize cost-effectiveness and scalability, as local industries develop. Understanding these nuances will help buyers make informed decisions when sourcing forging machinery and materials.

Sustainability & Ethical Sourcing in B2B

As sustainability becomes a focal point for many industries, the forging sector is not exempt. The environmental impact of forging processes, including energy consumption and waste generation, has prompted a shift towards more sustainable practices. B2B buyers are increasingly seeking suppliers that demonstrate a commitment to sustainability through the adoption of environmentally friendly processes and materials.

Ethical sourcing is also gaining prominence. Buyers are encouraged to partner with suppliers that prioritize ethical labor practices and maintain transparent supply chains. This not only mitigates risks associated with labor violations but also enhances brand reputation, particularly in markets that value corporate social responsibility.

Moreover, “green” certifications and materials are becoming essential criteria in supplier selection. Certifications such as ISO 14001 for environmental management systems and the use of recycled materials can significantly enhance a supplier’s credibility. For example, the adoption of “Green Steel” technologies, which minimize the carbon footprint of steel production, is increasingly attractive to B2B buyers focused on sustainability.

Illustrative Image (Source: Google Search)

Brief Evolution/History

The forging process has a rich history, dating back thousands of years to ancient civilizations that used rudimentary techniques to shape metal. Over the centuries, advancements in metallurgy and technology have transformed forging from a manual craft into a highly mechanized industrial process.

The 20th century marked a significant evolution with the introduction of hydraulic and mechanical presses, greatly enhancing production capabilities. Today, forging is integral to modern manufacturing, providing crucial components that meet the demands of various high-performance applications. This evolution reflects not only technological advancements but also the increasing emphasis on quality, efficiency, and sustainability, shaping the current landscape of B2B sourcing in the forging sector.

By understanding these historical contexts and current trends, B2B buyers can make strategic sourcing decisions that align with both market demands and ethical considerations.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of forging procedure

-

What criteria should I use to vet suppliers for forging procedures?

When vetting suppliers, prioritize their reputation and experience in the forging industry. Check for certifications such as ISO 9001 to ensure quality standards. Request references and case studies from similar projects to assess their capability. Evaluate their technical support services, including problem resolution and customization capabilities. Additionally, consider their financial stability and delivery reliability, especially for long-term contracts, to mitigate risks in supply chain disruptions. -

Can I customize the forging process to meet specific project requirements?

Yes, most reputable forging suppliers offer customization options. This can include alterations in material specifications, dimensions, and design features. When discussing your project, clearly outline your requirements and any unique challenges you face. Suppliers often provide engineering support to optimize the forging process for your needs. Be sure to document all specifications in your contract to avoid misunderstandings later in the project. -

What are typical minimum order quantities (MOQs) and lead times for forging products?

Minimum order quantities (MOQs) for forging products can vary widely depending on the supplier and the complexity of the forging process. Generally, MOQs may range from a few hundred to several thousand units. Lead times typically depend on the supplier’s production capacity and your order’s complexity, often ranging from 4 to 12 weeks. Discussing your specific needs with suppliers early in the negotiation process can lead to better understanding and potentially more flexible terms. -

What payment terms are usually offered in international forging contracts?

Payment terms for international forging contracts often include advance payments, such as a deposit (20-50% of the total order), with the balance due upon delivery or acceptance of goods. Some suppliers may offer letter of credit options, which provide security for both parties. It’s crucial to negotiate terms that align with your cash flow needs while considering the supplier’s requirements. Be sure to include payment terms in your contract to avoid disputes later. -

How do I ensure quality assurance and certification compliance in forging products?

To ensure quality assurance, request certificates of compliance for materials used in the forging process, including mechanical and chemical properties. Many suppliers will provide test reports upon request. Establish a quality control plan that includes on-site inspections or third-party audits to verify compliance with international standards. Additionally, communicate your quality expectations clearly at the beginning of the partnership to align with the supplier’s quality management systems. -

What logistics considerations should I keep in mind when sourcing forging products internationally?

Logistics is critical in international sourcing. Consider the shipping methods, transit times, and costs involved, including customs duties and taxes. Work with suppliers who have experience in international shipping to minimize delays. Ensure your contract includes incoterms that define responsibilities for shipping, risk, and costs. Additionally, assess the supplier’s ability to provide tracking and real-time updates on your shipment to manage expectations. -

What steps should I take if a dispute arises with a forging supplier?

In the event of a dispute, first, attempt to resolve the issue directly through open communication with your supplier. Document all correspondence and agreements to maintain a clear record. If resolution is not possible, refer to the dispute resolution clause in your contract, which may include mediation or arbitration procedures. Engage legal counsel familiar with international trade laws to navigate the process effectively. Prioritize maintaining a professional relationship, as long-term partnerships can often withstand challenges. -

How can I assess the sustainability practices of forging suppliers?

To assess sustainability practices, inquire about suppliers’ environmental policies and certifications related to sustainability, such as ISO 14001. Evaluate their use of recycled materials and energy-efficient processes. Request information on waste management strategies and resource conservation efforts. Many suppliers will provide a sustainability report detailing their initiatives and performance. Choosing a supplier committed to sustainability can enhance your brand’s reputation and compliance with increasingly stringent regulations in various markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for forging procedure

In the competitive landscape of forging procedures, strategic sourcing emerges as a critical component for international B2B buyers. The ability to identify and procure the right forging machines and materials not only enhances operational efficiency but also ensures the production of high-quality components that meet rigorous industry standards. Key considerations for buyers include evaluating machine types based on application needs, ensuring material quality, and understanding the intricacies of supplier reliability and delivery timelines.

Illustrative Image (Source: Google Search)

Actionable insights from this guide underscore the importance of aligning sourcing strategies with specific operational goals, including cost-effectiveness and sustainability. As global markets continue to evolve, the ability to adapt and innovate will distinguish successful organizations. Buyers should prioritize partnerships with suppliers who demonstrate a commitment to quality, technical support, and environmental responsibility.

Looking ahead, the forging industry is poised for growth, driven by technological advancements and increasing demand across sectors. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to leverage these insights to forge resilient supply chains. By embracing strategic sourcing practices today, companies can secure a competitive edge for tomorrow’s challenges and opportunities.