Mastering the Market for Portable Clean Rooms: Your

Introduction: Navigating the Global Market for portable clean room

In today’s competitive manufacturing landscape, the demand for portable cleanrooms is surging, driven by the need for adaptable, high-quality environments that meet stringent contamination control standards. These modular solutions offer businesses the flexibility to swiftly deploy cleanroom facilities wherever needed, making them invaluable across various sectors, including pharmaceuticals, electronics, and biotechnology. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate this dynamic market, understanding the intricacies of portable cleanrooms becomes critical for informed sourcing decisions.

This comprehensive guide delves into the essential aspects of portable cleanrooms, covering a wide array of topics including types (hardwall vs. softwall), materials used in construction, manufacturing and quality control standards, and the key suppliers shaping the industry. Additionally, it provides insights into cost structures and market trends, empowering buyers to evaluate their options effectively.

By addressing frequently asked questions and highlighting best practices, this guide serves as a vital resource for decision-makers looking to enhance operational efficiency while ensuring compliance with health and safety regulations. With the right knowledge, businesses can confidently invest in portable cleanrooms that not only meet their immediate needs but also position them for future growth in an increasingly globalized marketplace.

Understanding portable clean room Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Modular Hardwall | Rigid structure, superior contamination control | Pharmaceuticals, electronics, aerospace | Pros: Durable, strong contamination barrier. Cons: Higher initial cost and installation time. |

| Modular Softwall | Flexible fabric walls, lightweight, easy to install | Biotechnology, research labs, food processing | Pros: Cost-effective, quick setup. Cons: Less durable than hardwall options. |

| Mobile Cleanroom Trailers | Fully equipped trailers, transportable environments | Construction sites, outdoor events, emergency response | Pros: High mobility, immediate deployment. Cons: Limited space and customization options. |

| Pass-Through Cleanrooms | Specialized entry and exit systems for materials | Pharmaceutical compounding, medical device manufacturing | Pros: Enhanced material handling, reduces contamination risk. Cons: Requires precise installation and maintenance. |

| Temporary Cleanrooms | Short-term use, often rented, modular design | Events, short-term projects, product launches | Pros: Flexible, cost-effective for short-term needs. Cons: May not meet all long-term regulatory standards. |

Modular Hardwall Cleanrooms

Modular hardwall cleanrooms are characterized by their rigid construction, typically made of materials like metal or composite panels. They provide superior contamination control, making them ideal for sensitive industries such as pharmaceuticals and aerospace. When considering a purchase, buyers should evaluate the installation process, as it can be time-intensive and costly. However, the durability and long-term reliability often justify the investment.

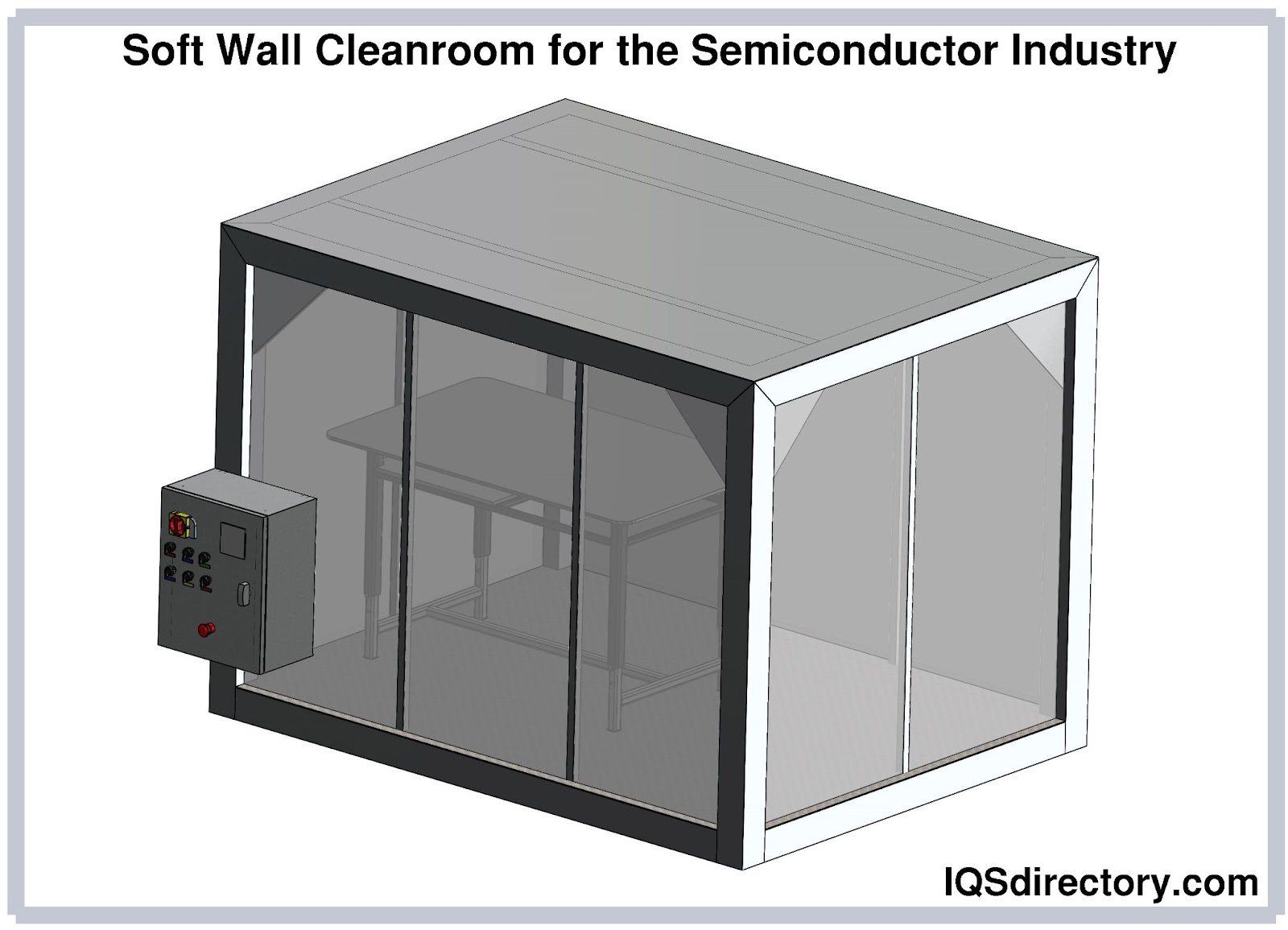

Modular Softwall Cleanrooms

Softwall cleanrooms utilize flexible fabric walls and are easier to install than their hardwall counterparts. They are particularly suited for biotechnology and research labs where quick adaptability is essential. B2B buyers should consider the cost-effectiveness and rapid setup time, although they may sacrifice some durability. This makes softwall cleanrooms a popular choice for projects with fluctuating cleanliness requirements.

Mobile Cleanroom Trailers

These fully equipped trailers offer a portable cleanroom solution that is ideal for construction sites or emergency response situations. Their mobility allows for immediate deployment, making them valuable for industries needing on-the-go contamination control. Buyers should weigh the benefits of high mobility against the limited space and customization options, which might affect specific operational needs.

Pass-Through Cleanrooms

Designed with specialized entry and exit systems, pass-through cleanrooms are excellent for minimizing contamination during material transfers. They find application in pharmaceutical compounding and medical device manufacturing. When purchasing, businesses should focus on the precision of installation and ongoing maintenance requirements to ensure consistent operational efficiency and compliance with health standards.

Temporary Cleanrooms

Temporary cleanrooms are modular, often rented solutions that cater to short-term projects or events. They are highly flexible and cost-effective, making them attractive for businesses needing a clean environment without long-term commitments. However, buyers should be cautious about ensuring these solutions meet all regulatory standards if they plan to use them for extended periods.

Related Video: Under the Hood: Changing the Filter on a Portable Clean Room

Key Industrial Applications of portable clean room

| Industry/Sector | Specific Application of Portable Clean Room | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Sterile manufacturing of drugs and vaccines | Ensures product safety and compliance with regulations | ISO classification, modular design, ease of installation |

| Electronics | Production of semiconductors and microchips | Reduces contamination risks, enhancing product quality | Airflow management, filtration systems, mobility options |

| Aerospace & Defense | Assembly of sensitive components and equipment | Guarantees precision and reliability in high-stakes environments | Compliance with aerospace standards, temperature control |

| Food Processing | Preparation of packaged foods and beverages | Maintains hygiene and extends shelf life of products | Cleanliness standards, modularity, adaptability to different processes |

| Medical Device Manufacturing | Production of sterile surgical instruments and implants | Protects patient safety and meets stringent industry standards | Material certifications, contamination control, scalability |

Pharmaceuticals

In the pharmaceutical sector, portable clean rooms are essential for the sterile manufacturing of drugs and vaccines. They provide a controlled environment that minimizes the risk of contamination, which is critical for products that require strict adherence to safety regulations. International buyers should focus on sourcing clean rooms that meet specific ISO classifications, as well as those that offer modular designs to allow for swift installation and reconfiguration as needed. This adaptability is particularly beneficial in regions where production demands fluctuate.

Electronics

The electronics industry relies heavily on portable clean rooms for the production of semiconductors and microchips. These environments are designed to prevent contamination from dust and other particulates that could compromise sensitive electronic components. For B2B buyers, it is vital to consider clean rooms equipped with advanced airflow management and filtration systems to ensure optimal cleanliness. Additionally, the mobility of these clean rooms allows manufacturers to quickly adapt to changing production needs, a significant advantage in competitive markets.

Aerospace & Defense

In aerospace and defense, portable clean rooms facilitate the assembly of sensitive components and equipment, where precision and reliability are paramount. These clean environments help prevent contamination that could affect performance and safety. Buyers in this sector should prioritize sourcing clean rooms that comply with stringent aerospace standards and provide effective temperature and humidity control. The ability to easily relocate these clean rooms enhances operational efficiency, especially for projects requiring mobility.

Food Processing

Portable clean rooms are increasingly being utilized in food processing for the preparation of packaged foods and beverages. They help maintain hygiene standards and extend the shelf life of products by ensuring a contaminant-free environment. B2B buyers in this industry must consider sourcing clean rooms that adhere to food safety regulations and offer modularity to adapt to various processing needs. This flexibility is especially valuable in regions with diverse food production requirements.

Medical Device Manufacturing

The medical device manufacturing sector benefits from portable clean rooms used in the production of sterile surgical instruments and implants. These environments are crucial for protecting patient safety and ensuring compliance with industry standards. Buyers should seek clean rooms that feature material certifications and effective contamination control measures. Scalability is also essential, as manufacturers may need to expand their cleanroom capabilities in response to evolving market demands.

Related Video: A Day in the Life of a Clean Room Technician

Strategic Material Selection Guide for portable clean room

When selecting materials for portable clean rooms, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials used in the construction of portable clean rooms: Polycarbonate, Stainless Steel, Aluminum, and PVC. Each material has unique characteristics that can significantly affect performance, costs, and compliance with international standards.

Polycarbonate

Key Properties: Polycarbonate is known for its high impact resistance and transparency. It can withstand temperatures ranging from -40°C to 120°C and offers good UV resistance.

Pros & Cons: The durability of polycarbonate makes it a preferred choice for clean room applications where visibility is essential. However, it can be more expensive than other plastic options and may scratch easily, which can compromise its clarity over time. Additionally, while it is lightweight and easy to install, the manufacturing complexity can increase with custom designs.

Impact on Application: Polycarbonate is particularly suitable for clean rooms in industries such as pharmaceuticals and electronics, where visibility into the clean environment is necessary for monitoring processes.

Considerations for International Buyers: Compliance with standards like ASTM D256 for impact resistance is crucial. Buyers from regions like Africa and South America should ensure that local suppliers can provide materials that meet these standards.

Stainless Steel

Key Properties: Stainless steel is renowned for its corrosion resistance and strength, with temperature ratings often exceeding 500°C. It is also non-porous, making it easy to clean and maintain.

Pros & Cons: The longevity and durability of stainless steel make it ideal for high-traffic clean rooms. However, it can be costly and heavier than alternatives, which may complicate installation. Additionally, while it offers superior structural integrity, it may not be the best insulator, leading to potential temperature control issues in some applications.

Impact on Application: Stainless steel is commonly used in pharmaceutical clean rooms where stringent cleanliness and durability are required. Its resistance to harsh cleaning agents is a significant advantage.

Considerations for International Buyers: Buyers should verify compliance with standards such as ASTM A240 for stainless steel grades. In regions like the Middle East, where humidity can be high, selecting the right grade (e.g., 316) is essential for preventing corrosion.

Aluminum

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It typically withstands temperatures up to 150°C.

Pros & Cons: The low weight of aluminum facilitates easier installation and mobility, making it suitable for portable clean rooms. However, it is softer than stainless steel, which may lead to dents and scratches. The cost is generally moderate, but the need for protective coatings can increase overall expenses.

Impact on Application: Aluminum is widely used in clean rooms for electronics manufacturing, where lightweight and non-corrosive materials are essential.

Considerations for International Buyers: Compliance with standards such as ASTM B221 for aluminum extrusions is vital. Buyers in Europe should also consider the EU regulations regarding aluminum recycling and sustainability.

PVC

Key Properties: PVC is a versatile plastic that offers good chemical resistance and can operate effectively within a temperature range of -15°C to 60°C.

Pros & Cons: The affordability and ease of installation of PVC make it a popular choice for temporary or less stringent clean room applications. However, it is less durable than metal options and can be susceptible to damage from UV exposure and certain chemicals.

Impact on Application: PVC is suitable for clean rooms in food processing and light manufacturing, where stringent cleanliness is required but not to the extent of pharmaceutical applications.

Considerations for International Buyers: Buyers should ensure that the PVC used complies with local regulations regarding food safety and chemical resistance, particularly in regions with strict food safety laws.

Summary Table

| Material | Typical Use Case for portable clean room | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polycarbonate | Pharmaceuticals, Electronics | High impact resistance and visibility | Scratches easily, higher cost | Medium |

| Stainless Steel | Pharmaceutical clean rooms | Excellent durability and cleanliness | High cost, heavy | High |

| Aluminum | Electronics manufacturing | Lightweight and corrosion-resistant | Softer, may dent | Medium |

| PVC | Food processing, light manufacturing | Cost-effective and easy to install | Less durable, UV sensitive | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for portable clean room

Understanding the Manufacturing Processes of Portable Clean Rooms

Manufacturing portable clean rooms involves a systematic approach with several stages. Each stage is critical to ensuring the final product meets stringent cleanliness standards essential for various applications, particularly in pharmaceuticals, electronics, and biotechnology.

Main Stages of Manufacturing

-

Material Preparation

– Selection of Materials: The first step involves choosing suitable materials that meet the cleanroom specifications, such as non-porous surfaces and low particle emissions. Common materials include stainless steel, aluminum, and specialized plastics.

– Pre-treatment: Materials often undergo pre-treatment processes, including cleaning and surface treatment, to remove contaminants and enhance adhesion for coatings. -

Forming

– Cutting and Shaping: Advanced techniques like CNC machining are employed to cut and shape materials precisely. This ensures that components fit together seamlessly, minimizing potential contamination points.

– Modular Design: Portable clean rooms are typically designed in modular sections for easy assembly and disassembly. This modular approach allows for flexibility in configuration based on specific client needs. -

Assembly

– Joinery and Sealing: Components are assembled using specialized techniques to ensure airtight seals, which is vital for maintaining controlled environments. Techniques like welding, adhesive bonding, and mechanical fastening are common.

– Integration of Systems: Essential systems such as HVAC, filtration, and monitoring are integrated during assembly. This stage is crucial for achieving the desired ISO classification levels for cleanrooms. -

Finishing

– Surface Treatment: Final surface treatments, including coatings that enhance cleanliness and durability, are applied. These treatments can also provide additional resistance to chemical exposure.

– Quality Control: Each unit undergoes rigorous inspection to ensure compliance with cleanliness standards and functional specifications before delivery.

Quality Assurance Protocols

Quality assurance in the manufacturing of portable clean rooms is critical to ensure that they meet international standards and industry-specific requirements. This process typically includes various checkpoints and testing methods.

Relevant International Standards

- ISO 9001: A widely recognized standard that establishes criteria for a quality management system. Compliance ensures that organizations consistently provide products that meet customer and regulatory requirements.

- ISO 14644: Specific to cleanrooms, this standard outlines the classification of air cleanliness and establishes criteria for cleanroom environments.

- CE Marking: Required for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- API Standards: Relevant in the pharmaceutical industry, these standards ensure that cleanrooms used in drug manufacturing meet stringent quality criteria.

Quality Control Checkpoints

-

Incoming Quality Control (IQC)

– Verification of raw materials and components against specifications before they enter the manufacturing process. This may include documentation reviews and material testing. -

In-Process Quality Control (IPQC)

– Continuous monitoring during the manufacturing process. This includes checks for dimensional accuracy, material integrity, and adherence to assembly procedures. -

Final Quality Control (FQC)

– A thorough inspection of the completed clean room. This includes functional testing of systems (HVAC, filtration), visual inspections for defects, and cleanliness testing using particle counters.

Common Testing Methods

- Particle Counting: Used to measure airborne particulates in the cleanroom environment to ensure compliance with ISO classifications.

- Airflow Visualization: Techniques like smoke testing are employed to assess airflow patterns and identify any potential contamination sources.

- Pressure Differential Testing: Ensures that the clean room maintains the appropriate pressure differentials necessary to prevent contamination ingress.

Verifying Supplier Quality Control

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are key strategies:

-

Supplier Audits

– Conducting on-site audits to review the supplier’s quality management system, manufacturing processes, and adherence to international standards. This provides firsthand insight into their operational capabilities. -

Documentation Review

– Requesting detailed quality assurance documentation, including certificates of compliance, inspection reports, and testing results. This helps buyers assess the supplier’s commitment to quality. -

Third-Party Inspections

– Engaging independent third-party organizations to perform inspections and audits can provide an unbiased evaluation of the supplier’s quality control processes and product compliance.

Quality Control Nuances for International Buyers

Understanding the nuances of quality control is essential for B2B buyers navigating international markets. Buyers should consider the following:

- Cultural Differences: Different regions may have varying interpretations of quality standards. Understanding local practices and expectations can help bridge gaps in compliance.

- Regulatory Compliance: Buyers must be aware of both local and international regulations that apply to portable clean rooms, as non-compliance can lead to significant operational disruptions.

- Post-Purchase Support: Ensuring that suppliers provide adequate after-sales support, including maintenance and training, is vital for sustaining the clean room’s operational efficacy over time.

Conclusion

The manufacturing processes and quality assurance protocols for portable clean rooms are intricate and designed to meet stringent cleanliness requirements. For international B2B buyers, particularly those operating in diverse markets, understanding these processes and verifying supplier quality control is crucial for ensuring compliance and maintaining operational efficiency. By engaging with suppliers who adhere to recognized standards and implementing robust verification strategies, buyers can secure high-quality portable clean rooms that meet their specific needs.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for portable clean room Sourcing

Portable cleanrooms are essential for various industries, including pharmaceuticals, electronics, and biotechnology, and understanding their cost structure and pricing is crucial for international B2B buyers. This analysis covers the key components of costs, price influencers, and practical tips for buyers seeking to optimize their sourcing strategies.

Cost Components

-

Materials: The primary cost driver for portable cleanrooms is the materials used in their construction. Options include softwall and hardwall systems, with materials ranging from vinyl to aluminum frames and HEPA filters. Higher-quality materials typically increase durability and compliance with cleanliness standards, impacting overall costs.

-

Labor: Labor costs encompass both assembly and installation. Skilled labor is required to ensure that cleanrooms are constructed to meet industry standards. Buyers should consider the availability of skilled labor in their region, as this can affect lead times and costs.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses associated with the production of cleanrooms. Companies with efficient operations may offer more competitive pricing.

-

Tooling: Customization of cleanrooms often requires specialized tools and molds. The costs associated with these tools can be significant, especially for custom solutions tailored to specific industry needs.

-

Quality Control (QC): Maintaining stringent quality control processes adds to the cost. Cleanrooms must meet specific ISO classifications, which necessitates regular testing and compliance checks, increasing overall expenses.

-

Logistics: Shipping costs can vary widely based on the destination, size of the cleanroom, and chosen logistics partners. International shipping may incur additional tariffs and fees, which should be factored into the total cost.

Illustrative Image (Source: Google Search)

- Margin: Suppliers typically include a profit margin that can range from 10% to 30%, depending on the level of customization and market demand. Understanding the supplier’s market position can help buyers negotiate better pricing.

Price Influencers

Several factors influence the pricing of portable cleanrooms:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts. Buyers should assess their production needs to negotiate favorable terms.

-

Specifications/Customization: Custom designs tailored to specific applications can significantly increase costs. Standard models typically offer cost savings.

-

Materials: The choice of materials directly affects pricing. For instance, opting for high-grade materials may enhance longevity and compliance but will increase initial costs.

-

Quality/Certifications: Cleanrooms that come with certifications (ISO, GMP) may carry a premium price tag but provide assurance of quality and compliance, which can reduce long-term risks.

-

Supplier Factors: Supplier reputation, experience, and service offerings can influence costs. Established suppliers may offer better warranties and support but at higher prices.

-

Incoterms: The terms of shipping and delivery can impact overall costs. Understanding Incoterms is crucial for international buyers to avoid unexpected costs.

Buyer Tips

-

Negotiation: Leverage volume and long-term purchasing agreements to negotiate better prices. Establishing a relationship with suppliers can lead to more favorable terms over time.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential downtime. A higher upfront investment in quality materials may lead to savings in the long run.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of local economic conditions, currency fluctuations, and regional tariffs that can affect pricing. Engaging local suppliers may mitigate some of these costs.

-

Due Diligence: Always conduct thorough research on potential suppliers, including their compliance history and customer feedback, to ensure you are making an informed purchasing decision.

Disclaimer

Prices for portable cleanrooms can vary widely based on numerous factors, and the information provided is indicative only. Buyers should seek detailed quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Spotlight on Potential portable clean room Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘portable clean room’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for portable clean room

Key Technical Properties of Portable Clean Rooms

When considering the acquisition of portable clean rooms, understanding their critical technical properties is essential for ensuring compliance, efficiency, and effectiveness in manufacturing processes. Here are some of the key specifications to consider:

-

Material Grade

The materials used in the construction of portable clean rooms are crucial for durability and contamination control. Common materials include stainless steel, aluminum, and specialized plastics. Importance: High-grade materials enhance longevity and are easier to clean, thus minimizing contamination risks. -

Classifications (ISO Levels)

Portable clean rooms are classified according to ISO standards, ranging from ISO Class 5 to ISO Class 9. These classifications indicate the maximum allowable particulate contamination levels within the environment. Importance: Understanding these classifications helps buyers select clean rooms that meet specific industry requirements, especially in pharmaceuticals and electronics. -

Airflow and Filtration Systems

Effective airflow management is vital for maintaining cleanliness. Portable clean rooms often utilize HEPA or ULPA filters that can capture particles down to 0.3 microns. Importance: A robust filtration system ensures that the clean room environment remains uncontaminated, which is especially critical in sensitive manufacturing processes. -

Temperature and Humidity Control

Many portable clean rooms come equipped with systems to regulate temperature and humidity. Specifications may include ranges such as 20°C to 25°C for temperature and 30% to 50% for humidity. Importance: Precise environmental controls are essential for processes sensitive to temperature and humidity fluctuations, thus safeguarding product integrity. -

Mobility Features

The design of portable clean rooms often includes features such as wheels or modular components for easy relocation. Importance: This mobility allows businesses to adapt quickly to changing production needs, making it easier to scale operations without extensive downtime or infrastructure changes. -

Tolerance Levels

Tolerance levels refer to the permissible deviations in clean room dimensions and performance parameters. These might include variations in pressure differentials and airflow rates. Importance: Ensuring that these tolerances are within acceptable limits is crucial for maintaining the clean room’s effectiveness and compliance with industry standards.

Common Trade Terminology

Understanding industry jargon is vital for effective communication and negotiation in the procurement of portable clean rooms. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. Importance: Knowing the OEM can help buyers identify the quality and reliability of the clean room components. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Importance: Understanding MOQ is essential for budgeting and inventory management, particularly for smaller businesses or startups. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for a quote on specific products or services. Importance: This process allows buyers to compare prices and terms from multiple suppliers, aiding in informed decision-making. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Importance: Familiarity with Incoterms is crucial for understanding shipping responsibilities, costs, and risks associated with the delivery of portable clean rooms. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Importance: Knowing the lead time is critical for planning and ensuring that production schedules are met without delays. -

Contamination Control Plan

This is a documented strategy outlining the procedures and measures to prevent contamination in clean room environments. Importance: A robust contamination control plan ensures compliance with industry standards and protects product quality.

By understanding these essential technical properties and trade terms, international B2B buyers can make informed decisions regarding portable clean rooms, ensuring they meet their operational needs while maintaining compliance with industry standards.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the portable clean room Sector

Market Overview & Key Trends

The portable clean room market is experiencing significant growth driven by the increasing demand for flexible manufacturing solutions across various sectors, including pharmaceuticals, biotechnology, and electronics. Key global drivers include a heightened focus on contamination control, the expansion of the biotechnology sector, and the need for rapid deployment of clean environments in response to fluctuating production needs. For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for strategic sourcing.

Emerging technology trends such as modular cleanroom construction and advancements in air filtration systems are reshaping the sourcing landscape. Buyers are increasingly seeking modular systems that allow for quick installation and scalability, thus reducing downtime and overall costs. Additionally, the integration of smart technologies, including IoT-enabled monitoring systems, is enhancing operational efficiency and compliance with stringent cleanliness standards. Buyers must consider suppliers that offer customizable solutions tailored to specific industry requirements, ensuring they remain competitive in a rapidly evolving market.

Market dynamics are also influenced by regional factors. For instance, in regions like the Middle East and Africa, rapid industrialization and the establishment of manufacturing hubs are driving demand for portable cleanrooms. In contrast, European buyers are focusing on sustainability and regulatory compliance, making it essential for suppliers to demonstrate adherence to local standards and environmental practices.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a critical consideration for B2B buyers in the portable clean room sector. The environmental impact of cleanroom manufacturing processes, including energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who employ sustainable practices, such as utilizing energy-efficient systems and recyclable materials in their cleanroom designs.

Ethical sourcing is equally important, as buyers seek suppliers with transparent supply chains and responsible manufacturing practices. This includes the use of ‘green’ certifications and materials that meet eco-friendly standards. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) are becoming benchmarks for assessing supplier sustainability. By opting for certified suppliers, businesses can enhance their brand reputation and meet the growing demand from consumers for responsible sourcing practices.

Investing in portable cleanrooms that incorporate sustainable materials and practices not only helps companies comply with regulatory requirements but also contributes to long-term cost savings through energy efficiency and reduced waste. Buyers should actively engage with suppliers to understand their sustainability initiatives and ensure alignment with their corporate social responsibility goals.

Brief Evolution/History

The concept of cleanrooms emerged in the mid-20th century, primarily driven by advancements in aerospace and semiconductor manufacturing, where contamination control was critical for product integrity. Over the decades, the cleanroom industry evolved, introducing modular and portable solutions to meet the growing needs of various sectors. The rise of biotechnology and pharmaceuticals in the late 20th century further propelled the demand for specialized clean environments.

Today, portable cleanrooms are recognized not just for their adaptability but also for their role in enhancing productivity and compliance across multiple industries. As technology continues to advance, the focus on sustainability and ethical sourcing will further shape the future of portable cleanrooms, making them integral to modern manufacturing practices.

Related Video: Incoterms for beginners | Global Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of portable clean room

-

What should I consider when vetting suppliers for portable clean rooms?

When vetting suppliers, prioritize their experience and reputation in the cleanroom industry. Check for certifications such as ISO 14644, which verifies compliance with cleanliness standards. Evaluate their product range and customization options to ensure they can meet specific industry requirements. Request references from previous clients and assess their responsiveness and support capabilities. Finally, consider their logistics capabilities, especially if you are sourcing from different regions, to ensure timely delivery and installation. -

Can portable clean rooms be customized to meet specific industry needs?

Yes, many manufacturers offer customizable options for portable clean rooms. Buyers can specify dimensions, materials, and features such as air filtration systems and temperature controls. It’s essential to communicate your specific requirements clearly during the initial discussions. Additionally, inquire about the flexibility for future modifications, as production needs may evolve. Customization can significantly impact both cost and lead time, so ensure these factors are addressed in your negotiations. -

What are the typical minimum order quantities (MOQ) and lead times for portable clean rooms?

MOQs for portable clean rooms can vary widely depending on the supplier and the complexity of the product. Generally, suppliers may have a MOQ of one unit for standard configurations. Lead times can range from a few weeks to several months, depending on customization requirements and the supplier’s production capacity. When negotiating, clarify these details to avoid delays in your project timelines. It’s advisable to plan well in advance, especially for critical projects requiring cleanroom environments. -

How do I ensure quality assurance and certifications for portable clean rooms?

Verify that the supplier provides relevant certifications, such as ISO 14644 for cleanroom classification. Request documentation for quality assurance processes, including testing protocols for materials and systems. Suppliers should also have a defined maintenance program to ensure ongoing compliance with cleanliness standards. It’s beneficial to visit the manufacturing facility if possible or request third-party audits to confirm adherence to quality practices. Regular quality checks are essential for maintaining the integrity of your cleanroom environment.

Illustrative Image (Source: Google Search)

-

What payment options are typically available when purchasing portable clean rooms?

Payment options can vary by supplier and may include upfront payments, installment plans, or financing options. It’s common for suppliers to require a deposit upon order confirmation, with the balance due before shipping or upon delivery. Discuss payment terms during negotiations to find a mutually agreeable arrangement. Additionally, consider using letters of credit for international transactions to mitigate risks associated with cross-border payments. Ensure that all terms are documented in the purchase agreement. -

What logistics considerations should I be aware of when sourcing portable clean rooms internationally?

Logistics can be complex when sourcing internationally, particularly concerning shipping regulations and customs clearance. Ensure your supplier is experienced in handling international shipments, including the required documentation for customs. Discuss shipping options such as air or sea freight, as well as estimated costs and timelines. Additionally, consider local transportation needs upon arrival, as portable clean rooms may require specialized handling. Establish clear communication channels for tracking shipments and addressing any potential delays. -

How should disputes regarding portable clean room purchases be handled?

To minimize disputes, clearly outline terms and conditions in your purchase agreement, including delivery timelines, quality expectations, and payment terms. In the event of a dispute, initiate communication with the supplier to resolve the issue amicably. Many suppliers will have a dispute resolution process in place; inquire about this during negotiations. If necessary, consider mediation or arbitration as alternatives to litigation, which can be costly and time-consuming. Always keep thorough documentation of all communications for reference. -

What ongoing support can I expect from suppliers after purchasing a portable clean room?

After purchase, suppliers should offer ongoing support that includes installation assistance, training for staff on cleanroom protocols, and maintenance services. Inquire about warranty options and what they cover, as well as any available technical support for troubleshooting. Regular maintenance is crucial to ensure compliance with cleanliness standards, so ask about service contracts for periodic checks and upgrades. A reliable supplier will provide comprehensive support to help you maintain optimal cleanroom conditions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for portable clean room

In summary, the significance of portable cleanrooms in modern manufacturing cannot be overstated. These modular, adaptable environments not only enhance operational efficiency but also ensure compliance with stringent cleanliness standards across various industries, including pharmaceuticals and electronics. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the advantages of portable cleanrooms—such as flexibility, cost-effectiveness, and rapid deployment—can lead to substantial operational improvements.

Strategic sourcing of portable cleanrooms will empower businesses to respond swiftly to changing production demands while maintaining high-quality standards. This adaptability is particularly crucial in regions with diverse manufacturing needs and fluctuating market conditions.

As the industry continues to evolve with technological advancements, embracing innovative cleanroom solutions will be essential. We encourage buyers to prioritize partnerships with reputable suppliers that offer comprehensive support and the latest technology. By investing in portable cleanrooms, businesses can not only enhance their manufacturing capabilities but also secure a competitive edge in an increasingly global market.