Mastering Types of Fastening: Essential Insights for B2B

Introduction: Navigating the Global Market for types of fastening

In the ever-evolving landscape of global manufacturing, the choice of fastening solutions plays a pivotal role in ensuring product quality, safety, and operational efficiency. Fasteners are not merely components; they are the unseen heroes that hold together structures and machinery across industries. For international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe, understanding the types of fastening is essential for making informed procurement decisions.

This comprehensive guide delves into the intricate world of fasteners, exploring various types—from bolts and screws to rivets and anchors—alongside their materials and manufacturing processes. It also addresses critical aspects such as quality control measures, supplier evaluations, and cost considerations. By equipping buyers with actionable insights, this guide aims to empower organizations to optimize their sourcing strategies, enhance product integrity, and streamline assembly processes.

Navigating the complexities of fastening solutions is crucial, as the wrong choice can lead to significant operational setbacks and inflated maintenance costs. Whether you are involved in construction, automotive, or manufacturing sectors, this resource serves as an authoritative roadmap, enabling you to strengthen your competitive edge in the global market. With a thorough understanding of fastening types and their applications, you can ensure that your projects meet the highest standards of durability and reliability.

Understanding types of fastening Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bolts | Externally threaded fasteners that require a nut for securing | Structural steel, machinery, automotive | Pros: High load capacity. Cons: Requires additional components (nuts). |

| Screws | Threaded fasteners that cut their own mating thread | Electronics, woodworking, metalworking | Pros: Easy to install and remove. Cons: May weaken material if over-tightened. |

| Rivets | Permanent fasteners that deform to secure materials | Aerospace, automotive, construction | Pros: High strength and durability. Cons: Difficult to remove once installed. |

| Self-Tapping Screws | Create their own threads while being driven into material | HVAC, plastics, light metal applications | Pros: No pre-drilling needed. Cons: Can strip material if over-tightened. |

| Anchors | Fasteners that provide a secure hold in various substrates | Construction, masonry, drywall | Pros: Effective in various materials. Cons: Installation can be complex. |

Bolts

Bolts are robust fasteners characterized by their external threading and compatibility with nuts to secure them in place. They are crucial in applications where high tensile strength and shear resistance are required, such as in structural steel and machinery assembly. For B2B buyers, selecting the right bolt involves considering factors such as load capacity, material compatibility, and environmental conditions that may affect performance. Additionally, the need for nuts and washers increases the complexity of procurement.

Screws

Screws are versatile fasteners designed to create their own threads when driven into materials. They are commonly used in electronics, woodworking, and metalworking due to their ease of installation and removal. B2B buyers should consider the material of the screw and the substrate to ensure optimal performance. While screws offer the advantage of adjustability, care must be taken to avoid over-tightening, which can compromise the integrity of the material being fastened.

Rivets

Rivets are permanent fasteners that provide a strong and durable connection by deforming their tail end during installation. They are widely used in high-strength applications such as aerospace and automotive manufacturing. For international buyers, understanding the installation requirements is critical, as rivets typically require access to both sides of the materials being fastened. While rivets offer superior strength, their permanence can be a disadvantage in applications requiring frequent disassembly.

Self-Tapping Screws

Self-tapping screws are engineered to create their own threads as they are driven into materials, eliminating the need for pre-drilling. They are particularly advantageous in HVAC and plastic applications, where time efficiency is crucial. B2B buyers should evaluate the type of material being fastened, as self-tapping screws can strip or weaken the substrate if over-tightened. Their ease of use makes them a popular choice, but understanding the limitations is vital for optimal application.

Anchors

Anchors are specialized fasteners designed to provide a secure hold in various substrates, including masonry and drywall. They are essential in construction and renovation projects where traditional screws may not suffice. B2B buyers must consider the specific type of anchor suited for their application, as different materials and installation methods can significantly impact performance. While anchors offer excellent holding power, the complexity of installation can pose challenges, making knowledge of the product crucial for successful procurement.

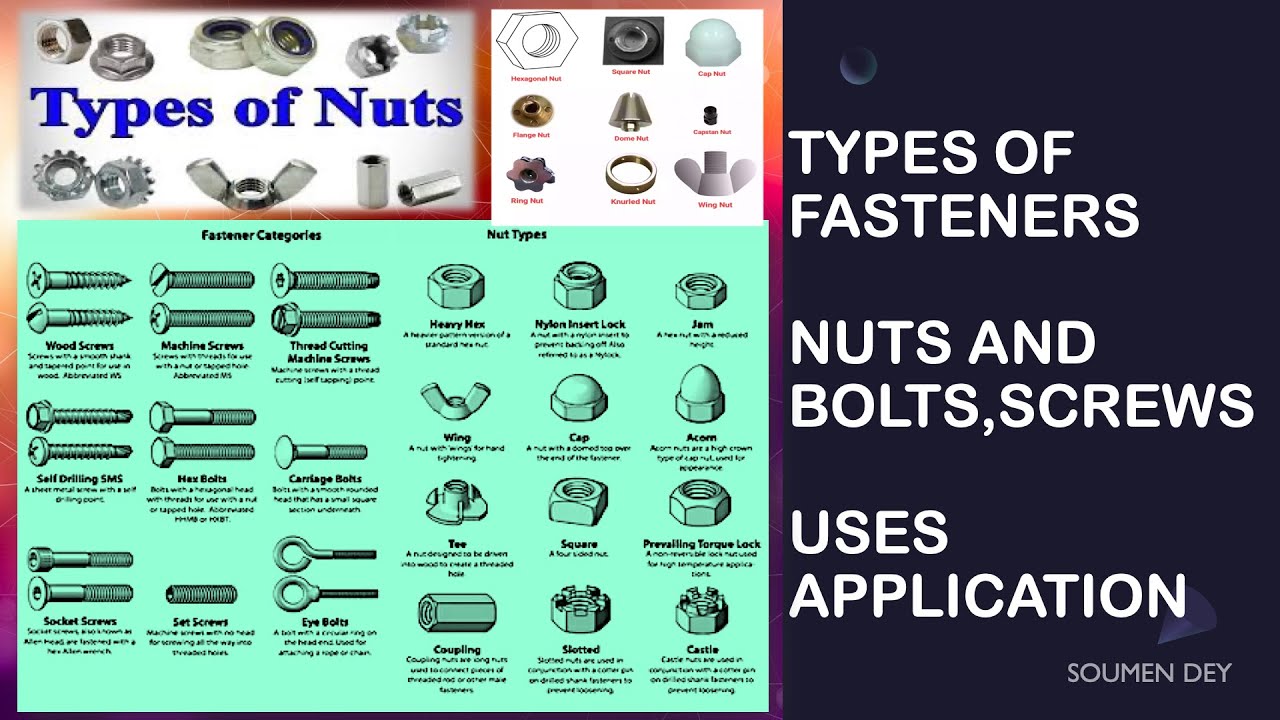

Related Video: Nuts 101 Overview – The Types of Fastener Nuts | Fasteners 101

Key Industrial Applications of types of fastening

| Industry/Sector | Specific Application of types of fastening | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural steel connections | Ensures structural integrity and safety | Compliance with local building codes and standards |

| Automotive | Assembly of vehicle components | Enhances durability and performance | Availability of specialized fasteners for high-stress areas |

| Aerospace | Aircraft assembly | Provides high strength and reliability | Certification and adherence to strict aerospace standards |

| Electronics | Enclosures and component assembly | Facilitates efficient assembly and maintenance | Sourcing from suppliers with quality control certifications |

| Manufacturing | Machinery and equipment assembly | Improves operational efficiency and uptime | Consideration of material compatibility and cost-effectiveness |

Construction

In the construction industry, structural steel connections are critical for ensuring the integrity and safety of buildings and infrastructure. Fasteners such as bolts and rivets are extensively used to join steel beams and girders. For international buyers, particularly those in Africa and South America, understanding local building codes and standards is essential to ensure compliance. Additionally, sourcing high-quality fasteners that can withstand environmental factors like humidity and temperature variations is crucial to avoid costly repairs and ensure long-term durability.

Automotive

The automotive sector relies heavily on various types of fasteners for the assembly of vehicle components. Bolts, screws, and rivets are used to secure parts such as engine mounts, chassis, and body panels. Buyers must ensure that the fasteners selected can withstand high levels of stress and vibration, which are common in automotive applications. In regions like the Middle East and Europe, sourcing fasteners that meet specific automotive standards and regulations will help maintain product quality and safety, ultimately enhancing vehicle performance and longevity.

Aerospace

In the aerospace industry, aircraft assembly demands the highest standards of quality and reliability. Fasteners must provide exceptional strength and durability to withstand extreme conditions during flight. Solid rivets and high-strength bolts are commonly used in this sector. International buyers, particularly from Europe and Turkey, should prioritize sourcing fasteners that are certified and compliant with aerospace standards. This ensures not only the safety of the aircraft but also adherence to stringent regulatory requirements that govern aviation manufacturing.

Electronics

The assembly of enclosures and components in the electronics industry often utilizes machine screws and self-tapping screws. These fasteners allow for efficient assembly and easy access for maintenance. For B2B buyers in South America and Africa, it’s vital to source fasteners from suppliers with robust quality control measures to prevent issues like loosening or corrosion, which can affect the longevity of electronic devices. Additionally, understanding the specific requirements for material compatibility is essential for ensuring optimal performance in various environmental conditions.

Manufacturing

In the manufacturing sector, fasteners are integral to machinery and equipment assembly. The right fasteners can significantly improve operational efficiency and reduce downtime. Buyers need to consider the compatibility of fasteners with different materials and the potential for wear and tear over time. In regions like Africa and the Middle East, sourcing durable and cost-effective fasteners can also impact the overall production costs. Establishing strong relationships with reliable suppliers who can provide consistent quality is key to maintaining competitive advantage in this dynamic industry.

Related Video: Tensile Bolted Joint – Breaking / Yielding – Fastening Theory Part 4

Strategic Material Selection Guide for types of fastening

When selecting fasteners for various applications, the choice of material is paramount. Different materials offer distinct properties that can significantly affect performance, durability, and suitability for specific environments. Below, we analyze four common materials used in fastening, highlighting their key properties, advantages, disadvantages, and implications for international B2B buyers.

Steel

Key Properties:

Steel fasteners are renowned for their high tensile strength and durability. They can withstand significant loads and are available in various grades, which determine their temperature and pressure ratings. Steel also has good corrosion resistance, especially when treated with coatings like zinc or chrome.

Pros & Cons:

Steel fasteners are generally cost-effective and widely available, making them a popular choice for many applications. However, they can be prone to rust if not properly coated, which may limit their use in humid or corrosive environments. Additionally, the manufacturing complexity increases with higher-grade steels, which can affect lead times.

Impact on Application:

Steel fasteners are suitable for a wide range of applications, including construction, automotive, and machinery. However, their performance in corrosive environments must be carefully considered, as inadequate protection can lead to premature failure.

Considerations for International Buyers:

Buyers should ensure compliance with international standards such as ASTM and DIN. In regions like Africa and South America, where environmental conditions may vary, selecting the right grade and coating is crucial to avoid costly failures.

Stainless Steel

Key Properties:

Stainless steel fasteners are highly resistant to corrosion, making them ideal for applications exposed to moisture and chemicals. They maintain their strength at elevated temperatures and can handle a variety of mechanical stresses.

Pros & Cons:

While stainless steel offers superior durability and aesthetic appeal, it comes at a higher cost compared to standard steel. The manufacturing process can also be more complex, leading to longer lead times. However, the long-term savings from reduced maintenance and replacement costs often justify the initial investment.

Impact on Application:

These fasteners are commonly used in food processing, marine applications, and chemical industries where corrosion resistance is critical. Their compatibility with various media, including saline environments, makes them a preferred choice.

Considerations for International Buyers:

Buyers must be aware of the specific grades of stainless steel (e.g., 304, 316) and their respective properties. Compliance with standards like JIS and ASTM is essential, especially in Europe and the Middle East, where quality regulations are stringent.

Aluminum

Key Properties:

Aluminum fasteners are lightweight yet strong, offering excellent corrosion resistance. They are non-magnetic and have good thermal and electrical conductivity, making them suitable for specific applications.

Pros & Cons:

The lightweight nature of aluminum can lead to reduced overall project weight, which is beneficial in aerospace and automotive industries. However, aluminum fasteners may not handle high loads as effectively as steel or stainless steel, making them less suitable for heavy-duty applications.

Impact on Application:

Aluminum is often used in applications requiring weight savings, such as in the aerospace sector and in portable equipment. Its compatibility with non-ferrous materials is a significant advantage in mixed-material assemblies.

Considerations for International Buyers:

International buyers should consider the strength-to-weight ratio and ensure that aluminum fasteners meet regional standards. In markets like Turkey and the UK, understanding the specific alloy used is vital for ensuring performance in demanding environments.

Plastic

Key Properties:

Plastic fasteners offer excellent resistance to corrosion and chemicals, making them suitable for applications in harsh environments. They are lightweight and can be molded into various shapes, providing design flexibility.

Pros & Cons:

While plastic fasteners are cost-effective and resistant to rust, they are generally not suitable for high-load applications due to their lower tensile strength. They may also be affected by temperature fluctuations, which can lead to brittleness over time.

Impact on Application:

Plastic fasteners are ideal for electronic devices, automotive interiors, and applications where weight and corrosion resistance are priorities. However, their performance under mechanical stress should be evaluated carefully.

Considerations for International Buyers:

Buyers should ensure that plastic fasteners meet relevant industry standards, especially in electronics and automotive sectors. Understanding the specific type of plastic used (e.g., nylon, polycarbonate) is crucial for ensuring compatibility with end products.

Summary Table

| Material | Typical Use Case for types of fastening | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Construction, automotive, machinery | High tensile strength | Prone to rust without coating | Medium |

| Stainless Steel | Food processing, marine, chemical | Superior corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Aerospace, portable equipment | Lightweight and corrosion-resistant | Lower load capacity | Medium |

| Plastic | Electronics, automotive interiors | Cost-effective and lightweight | Not suitable for high-load applications | Low |

This strategic material selection guide serves as a resource for international B2B buyers to make informed decisions based on the specific requirements of their applications. Understanding the properties and implications of each material will lead to enhanced product integrity and operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for types of fastening

Manufacturing Processes for Types of Fastening

The manufacturing of fastening components is a complex process that requires precision and adherence to quality standards. Understanding the typical stages involved can empower B2B buyers to make informed decisions when sourcing fasteners. The main stages of manufacturing include material preparation, forming, assembly, and finishing, each incorporating key techniques that contribute to the final product’s integrity.

1. Material Preparation

The manufacturing process begins with the selection of raw materials, which may include steel, aluminum, brass, or specialized alloys. The choice of material is crucial, as it affects the strength, corrosion resistance, and overall performance of the fastener.

- Material Inspection: Incoming materials undergo rigorous inspection to ensure they meet specified mechanical and chemical properties. This includes checking for impurities and verifying material grades against international standards (e.g., ASTM, ISO).

- Cutting and Shaping: Raw materials are cut into appropriate lengths and shapes, often utilizing processes like shearing or sawing. For screws, wire rods are typically used, while bolts may require bars to be cut down to size.

2. Forming

Forming is a critical stage where the fastener takes its final shape. This can involve several techniques depending on the type of fastener being produced.

- Cold Heading: Used primarily for bolts and screws, cold heading involves shaping metal without heating it, which increases strength through work hardening. This process is efficient for mass production and results in minimal waste.

- Thread Rolling: For fasteners requiring threads, thread rolling is a common technique. It forms threads by displacing material rather than cutting it, producing stronger threads with better surface finishes.

- Stamping and Forging: These methods are often used for washers and specialized fasteners. Stamping involves pressing material into a mold, while forging shapes the material under high pressure and temperature, enhancing durability.

3. Assembly

In some cases, fasteners consist of multiple components that need to be assembled. This is particularly true for items like rivets and specialized screws.

- Sub-Assembly Processes: Automated machines may be employed to assemble parts like screws with washers or nuts with bolts. This stage often includes feeding mechanisms that ensure consistent and efficient assembly.

- Quality Checks: During assembly, quality control checkpoints are established to ensure that components fit correctly and meet design specifications.

4. Finishing

Finishing processes are vital for enhancing the appearance, performance, and durability of fasteners.

- Surface Treatments: Fasteners are often coated to improve resistance to corrosion and wear. Common techniques include electroplating, galvanizing, and applying coatings like zinc or chrome.

- Heat Treatment: Certain fasteners undergo heat treatment to increase hardness and tensile strength. This process is essential for fasteners used in high-stress applications, such as in aerospace and automotive industries.

- Final Inspection: After finishing, fasteners are inspected for defects, ensuring they meet the required specifications before packaging and shipping.

Quality Assurance in Fastening Manufacturing

Quality assurance (QA) is paramount in the manufacturing of fastening components. Buyers must be aware of the international standards and industry-specific regulations that govern quality practices.

Relevant International Standards

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is applicable to any organization seeking to enhance customer satisfaction and ensure consistent quality.

- CE Marking: Required for products sold in the European Economic Area (EEA), CE marking indicates that a product meets EU safety, health, and environmental protection standards.

- API Standards: The American Petroleum Institute (API) provides standards for fasteners used in the oil and gas industry, ensuring they can withstand harsh conditions.

Quality Control Checkpoints

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This step involves inspecting raw materials before production begins. Buyers should ensure that suppliers have robust IQC processes to avoid defects in the final product.

- In-Process Quality Control (IPQC): During manufacturing, real-time inspections are conducted to monitor the production process. This includes checking dimensions, tolerances, and material properties.

- Final Quality Control (FQC): After manufacturing, a thorough inspection is performed on the finished products. This includes functional testing and dimensional checks to ensure compliance with specifications.

Common Testing Methods

To verify the quality of fasteners, various testing methods are employed:

- Tensile Testing: Measures the strength and ductility of the fastener material.

- Hardness Testing: Assesses the hardness of the fastener, which is crucial for its durability.

- Corrosion Resistance Testing: Evaluates the fastener’s ability to withstand corrosive environments, particularly important for applications in humid or saline conditions.

Verifying Supplier Quality Control

B2B buyers should take proactive steps to verify the quality control measures of potential suppliers:

- Supplier Audits: Conducting audits allows buyers to assess the manufacturing processes and quality systems in place. This can include reviewing documentation, inspecting facilities, and interviewing staff.

- Quality Reports: Requesting quality reports and certifications from suppliers can provide insights into their adherence to international standards and testing protocols.

- Third-Party Inspections: Engaging independent third-party inspectors can further validate the quality claims of suppliers. This is especially important when sourcing from international markets, where standards may vary.

Quality Control Nuances for International Buyers

When dealing with suppliers from diverse regions such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances:

- Regional Standards Variability: Different regions may have varying standards and regulations. Buyers must ensure that suppliers comply with both local and international standards relevant to their market.

- Cultural Considerations: Understanding cultural differences in business practices can impact quality assurance. Building strong relationships with suppliers can facilitate better communication regarding quality expectations.

- Logistical Challenges: International shipping can introduce risks to product quality. Buyers should ensure that suppliers have measures in place to protect products during transit, including appropriate packaging and handling procedures.

In summary, a comprehensive understanding of manufacturing processes and quality assurance practices for fastening components is essential for B2B buyers. By focusing on these areas, companies can ensure they source high-quality fasteners that meet their operational needs and compliance requirements.

Related Video: Types of Production Processes

Comprehensive Cost and Pricing Analysis for types of fastening Sourcing

Understanding the cost structure and pricing dynamics of fastening solutions is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will break down the key components influencing costs, price determinants, and practical tips for negotiating favorable terms.

Cost Components of Fastening Solutions

-

Materials: The choice of materials significantly impacts the cost of fasteners. Common materials include carbon steel, stainless steel, and specialized alloys. Higher-quality materials often come at a premium but can enhance durability and performance, reducing long-term replacement costs.

-

Labor: Labor costs vary by region and can influence the overall pricing of fasteners. In regions with lower labor costs, such as parts of South America and Africa, manufacturers may offer competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes costs associated with the production process, such as factory maintenance, utilities, and administrative expenses. Efficient manufacturing processes can lower overhead costs, allowing suppliers to offer better prices.

-

Tooling: The initial investment in tooling for specific fastener designs can be substantial. Custom tooling increases upfront costs but may lead to lower per-unit costs for high-volume orders. Understanding tooling costs is critical for buyers considering customized solutions.

-

Quality Control (QC): Rigorous quality control processes ensure that fasteners meet industry standards. However, these processes add to the manufacturing cost. Buyers should assess the level of QC necessary for their applications to balance cost and quality.

-

Logistics: Shipping and handling costs can vary widely based on distance, weight, and the chosen Incoterms. Efficient logistics management can mitigate costs, particularly for international shipments.

-

Margin: Suppliers will typically include a margin to cover their costs and provide profit. This margin can vary based on competition, market demand, and the supplier’s positioning in the market.

Price Influencers

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally reduce the per-unit cost due to economies of scale. Buyers should negotiate volume discounts when possible.

-

Specifications/Customization: Custom fasteners may require additional costs for design and tooling. It’s essential to weigh the benefits of customization against the potential cost increases.

-

Materials: As mentioned, the choice of materials directly affects pricing. Opting for standard materials can lower costs, while specialized or high-performance materials will increase them.

-

Quality/Certifications: Fasteners that meet international standards or have certifications (e.g., ISO, ASTM) may come at a higher price but provide assurance of quality and reliability.

-

Supplier Factors: The reputation, reliability, and service level of the supplier can influence pricing. Established suppliers may charge more but often provide better support and quality assurance.

-

Incoterms: The chosen Incoterms (e.g., FOB, CIF) affect logistics costs and risk allocation. Buyers should understand these terms to accurately assess total costs.

Buyer Tips

-

Negotiate: Leverage volume purchases and long-term contracts to negotiate better pricing and terms. Building relationships with suppliers can lead to favorable adjustments in pricing.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also maintenance, replacement, and operational costs associated with the fasteners over their lifespan.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import tariffs, and regional pricing disparities that can affect overall costs.

-

Conduct Market Research: Stay informed about market trends and competitor pricing to ensure you are making competitive offers.

-

Quality Assurance: Prioritize suppliers who demonstrate robust quality control measures, even if their prices are slightly higher. This can prevent costly failures and replacements in the long run.

Disclaimer

Prices can vary widely based on market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing tailored to your specific needs.

Spotlight on Potential types of fastening Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘types of fastening’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for types of fastening

Critical Technical Properties of Fasteners

Understanding the essential technical properties of fasteners is vital for B2B buyers to ensure they select the right components for their specific applications. Here are several key specifications that should be considered:

-

Material Grade

Fasteners are available in various materials such as stainless steel, carbon steel, and alloys, each offering different strength, corrosion resistance, and thermal properties. The material grade often adheres to international standards (e.g., ASTM, ISO) and impacts the fastener’s performance in specific environments. Selecting the appropriate material ensures longevity and reliability in applications, especially in demanding sectors like construction and aerospace. -

Tolerance

Tolerance refers to the allowable deviation in dimensions of fasteners, impacting how they fit and function within assemblies. High-precision applications require tight tolerances to ensure proper alignment and load distribution. Understanding tolerance specifications helps buyers avoid issues such as misalignment or excess wear that could lead to operational failures. -

Strength Class

Fasteners are rated based on their tensile strength, which indicates the maximum load they can withstand before failure. Common strength classes include grade 8.8, 10.9, and 12.9 for bolts, where a higher number signifies a stronger fastener. This classification is crucial for ensuring that the fasteners can handle the operational loads without risk of breaking or deforming, particularly in heavy machinery or structural applications. -

Coating and Finish

The coating of fasteners can enhance their corrosion resistance and overall performance. Common coatings include zinc plating, hot-dip galvanizing, and anodizing. Buyers should assess the environmental conditions (e.g., exposure to moisture or chemicals) to select the appropriate finish that will prolong the life of the fasteners and maintain structural integrity. -

Thread Type

The type of thread (e.g., coarse, fine, or self-tapping) affects how the fastener interacts with the materials it joins. Different thread types are suited to various applications, such as self-tapping screws that eliminate the need for pre-drilling. Understanding thread specifications is essential for achieving optimal engagement and load-bearing capacity.

Common Trade Terms in Fastening

Familiarity with industry-specific terminology is crucial for effective communication and negotiation in the fastener market. Here are several common terms:

- OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fasteners, understanding whether a supplier operates as an OEM can impact sourcing strategies, especially when looking for quality assurance and compliance with industry standards.

Illustrative Image (Source: Google Search)

-

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is essential for buyers to understand their purchasing limits and cost implications. It can also influence inventory management and cash flow, particularly for smaller businesses or those entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers asking for pricing and availability of specific products. Buyers should utilize RFQs to compare offers, ensuring they receive competitive pricing while also assessing quality and delivery terms. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce, which clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for managing shipping costs, risks, and responsibilities, particularly for international B2B transactions. -

Lead Time

Lead time is the period from the placement of an order until the goods are delivered. For fasteners, lead time can vary based on manufacturing processes and supply chain logistics. Buyers need to factor in lead times to align procurement with project schedules and avoid costly delays.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance their procurement processes and ensure the integrity of their projects across various industries.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the types of fastening Sector

Global fastener markets are being shaped by several key drivers, including technological advancements, increasing construction activities, and the rising demand for lightweight materials across various industries. The proliferation of automation and Industry 4.0 is influencing the types of fastening solutions being sought by international B2B buyers. Smart fasteners equipped with sensors for monitoring tension and structural integrity are becoming more prevalent, particularly in sectors such as aerospace and automotive manufacturing.

Emerging markets in Africa and South America are witnessing a construction boom, prompting an increased demand for reliable fastening solutions. In contrast, buyers in Europe, including Turkey and the UK, are emphasizing efficiency and sustainability, often opting for fasteners that not only meet performance standards but also align with environmental regulations. Additionally, the global shift towards e-commerce platforms has streamlined sourcing processes, enabling buyers to access a wider array of suppliers and products, thus increasing competition and driving down costs.

Sustainability & Ethical Sourcing in B2B

The environmental impact of fasteners cannot be understated. The production and disposal of traditional fasteners contribute to significant waste and resource depletion. As a result, there is a growing emphasis on sustainability in sourcing practices. B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and sustainability. This includes opting for fasteners made from recycled materials or those manufactured using energy-efficient processes.

Moreover, certifications such as ISO 14001 for environmental management and the use of green materials are becoming critical factors in the procurement process. Buyers should seek fasteners that have been certified for sustainability to ensure compliance with local regulations and to enhance their own corporate social responsibility (CSR) profiles. By investing in sustainable fasteners, companies can not only reduce their environmental footprint but also appeal to a growing base of environmentally-conscious consumers and partners.

Brief Evolution/History

The history of fastening technology dates back thousands of years, with the earliest fasteners being simple wooden pegs and metal rivets used in construction and shipbuilding. The industrial revolution marked a significant turning point, introducing standardized bolts and screws that revolutionized manufacturing processes. Over time, advancements in metallurgy and manufacturing techniques have led to the development of high-strength fasteners designed to meet the demands of modern engineering.

Today, the evolution continues with innovations such as self-locking mechanisms and smart fasteners integrated with IoT technology. This ongoing development reflects the industry’s response to the need for enhanced performance, safety, and sustainability in an increasingly competitive global market. As B2B buyers navigate this landscape, understanding the historical context of fastening technologies can inform better sourcing decisions and align procurement strategies with future trends.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of types of fastening

-

How can I effectively vet suppliers for fasteners?

To vet suppliers, begin by assessing their reputation in the industry through reviews and testimonials. Request references from other B2B buyers, particularly those in your region. Verify their certifications, such as ISO 9001, which indicates quality management systems. Additionally, inquire about their production capabilities and experience with your specific fastener needs. A site visit or virtual tour can also provide insight into their operations and quality control processes. -

Are custom fasteners available, and how do I request them?

Yes, many suppliers offer customization options for fasteners to meet specific project requirements. To request custom fasteners, provide detailed specifications, including dimensions, materials, and any unique features. It’s beneficial to include application context to help suppliers understand your needs better. Be prepared for discussions on design feasibility and cost implications, as custom orders may involve higher minimum order quantities and longer lead times. -

What are the typical minimum order quantities (MOQs) and lead times for fasteners?

Minimum order quantities can vary widely depending on the type of fastener and supplier. Commonly, MOQs range from 1,000 to 10,000 units for standard fasteners, while custom items may require larger quantities. Lead times typically range from two to eight weeks, influenced by factors such as production schedules and shipping logistics. Always clarify these details during negotiations to ensure they align with your project timelines. -

What payment options are typically available for international fastener purchases?

Payment options for international purchases often include bank transfers, letters of credit, and online payment platforms. Bank transfers are common but may incur fees. Letters of credit provide security for both parties, ensuring payment upon fulfillment of conditions. Discuss payment terms upfront, including deposits or payment schedules, to establish a clear financial agreement that mitigates risks associated with international transactions. -

How do I ensure quality assurance and certifications for fasteners?

To ensure quality assurance, request copies of relevant certifications from your suppliers, such as ISO 9001 or specific industry standards (e.g., ASTM, DIN). Inquire about their quality control processes, including testing protocols for materials and finished products. Consider conducting third-party inspections or audits to verify compliance before finalizing orders. Establishing clear quality expectations in your contract can also help safeguard against potential issues. -

What logistics considerations should I keep in mind when sourcing fasteners internationally?

When sourcing fasteners internationally, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable logistics partner experienced in handling international freight, and factor in delivery times and costs. Ensure that your supplier provides the necessary documentation for customs clearance. It’s also wise to understand the logistics infrastructure in your region to avoid unexpected delays.

Illustrative Image (Source: Google Search)

-

What should I do in case of disputes with a fastener supplier?

In the event of a dispute, start by communicating directly with the supplier to address the issue amicably. Document all correspondence and agreements to have a clear record. If resolution is not achieved, refer to the terms of your contract regarding dispute resolution processes, which may include mediation or arbitration. Engaging legal counsel familiar with international trade laws can also help navigate complex situations. -

How can I stay informed about market trends affecting fastener pricing?

Staying informed about market trends can be achieved through several channels. Subscribe to industry newsletters, follow trade publications, and join relevant professional associations. Networking with other B2B buyers and suppliers can provide insights into pricing fluctuations and availability. Additionally, monitoring global commodity prices, particularly for raw materials like steel and aluminum, can help anticipate changes in fastener costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for types of fastening

In conclusion, the strategic sourcing of fastening solutions is a critical component for international B2B buyers aiming to enhance product quality and operational efficiency. Understanding the diverse range of fasteners—from bolts and screws to rivets—enables businesses to make informed decisions that align with specific application needs. Emphasizing the right materials, coatings, and compliance with international standards can mitigate risks associated with structural failure and costly downtime.

Key takeaways include the importance of selecting fasteners that not only meet performance requirements but also provide ease of installation and maintenance. Buyers should leverage local supplier networks while considering global sourcing opportunities to optimize costs and ensure quality.

As industries continue to evolve, staying abreast of market trends and technological advancements in fastening solutions will be vital. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should proactively engage with suppliers, participate in industry forums, and invest in training to refine their sourcing strategies. Embrace this opportunity to strengthen your competitive edge and drive innovation in your operations.