Optimize Your Procurement Strategy for Type 1 Plug Sourcing

Introduction: Navigating the Global Market for type 1 plug

In the rapidly evolving landscape of global commerce, type 1 plugs serve as essential components that facilitate reliable electrical connections across various industries. For B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of type 1 plug sourcing is paramount for ensuring operational efficiency and compliance with regional standards. These plugs are not merely functional; they are critical for maintaining the safety, reliability, and performance of electrical systems in diverse applications, from manufacturing to energy management.

This comprehensive guide will equip procurement professionals with the insights needed to make informed sourcing decisions. It covers a wide array of topics, including different types of type 1 plugs, material specifications, manufacturing quality control measures, and supplier evaluation criteria. Additionally, it delves into cost structures, prevailing market trends, and practical answers to frequently asked questions tailored to the unique challenges faced by international buyers.

By leveraging this resource, businesses can navigate the complexities of the global market with confidence, streamline their procurement processes, and foster long-term partnerships with reliable suppliers. Ultimately, understanding the intricacies of type 1 plugs will empower B2B buyers to optimize their supply chains, reduce operational risks, and enhance their competitive edge in an interconnected world.

Understanding type 1 plug Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type 1 Plug | Two flat pins; designed for light-duty applications | Household appliances, small electronics | Pros: Cost-effective; Cons: Limited power capacity. |

| Type 2 Plug | Two flat pins with a grounding pin | Commercial equipment, industrial tools | Pros: Enhanced safety; Cons: Requires compatible sockets. |

| Type 3 Plug | Three round pins; robust design | Heavy machinery, high-power devices | Pros: High durability; Cons: Bulkier, less portable. |

| Type 4 Plug | Two round pins with a grounding hole | Electrical appliances in Europe | Pros: Secure connection; Cons: Limited global compatibility. |

| Type 5 Plug | Two flat pins with an additional pin for grounding | Specialized industrial applications | Pros: High safety standards; Cons: More complex sourcing. |

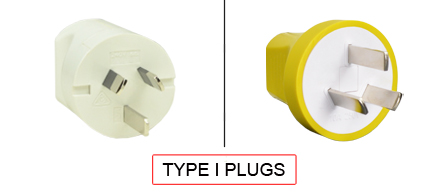

Type 1 Plug

The Type 1 plug is characterized by two flat pins and is typically used in light-duty applications such as household appliances and small electronics. Its widespread availability and cost-effectiveness make it a popular choice for businesses looking to source budget-friendly power solutions. However, B2B buyers should be cautious of its limited power capacity, ensuring that it meets the operational requirements of the intended application.

Type 2 Plug

Featuring two flat pins and an additional grounding pin, the Type 2 plug is designed for enhanced safety in commercial and industrial settings. This plug is commonly used for powering computers and sensitive electronic equipment. Buyers should prioritize sourcing Type 2 plugs that are compatible with existing sockets, as well as verifying the grounding features to protect valuable equipment from electrical faults.

Type 3 Plug

The Type 3 plug, with its three round pins, is known for its robust design and is primarily used in heavy machinery and high-power devices. Its durability makes it suitable for demanding industrial applications where reliability is critical. B2B buyers must consider the specific power requirements of the equipment and the potential limitations regarding portability when selecting this plug type for their operations.

Type 4 Plug

The Type 4 plug is distinguished by two round pins and a grounding hole, ensuring a secure connection for electrical appliances in Europe. This design enhances safety during operation, making it a favored choice among B2B buyers in sectors requiring dependable power supply. However, its limited compatibility outside Europe can pose challenges in international sourcing, necessitating careful consideration of regional electrical standards.

Type 5 Plug

Designed for specialized industrial applications, the Type 5 plug features two flat pins along with an additional grounding pin. This configuration adheres to high safety standards, making it suitable for environments where electrical reliability is paramount. B2B buyers should be aware that sourcing Type 5 plugs can be more complex due to stringent compliance requirements, so it is essential to work with reputable suppliers who can provide the necessary certifications.

Related Video: USB Cable Types: How to Identify and Use Different USB Connectors

Key Industrial Applications of type 1 plug

| Industry/Sector | Specific Application of type 1 plug | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Power supply for machinery and tools | Ensures reliable operation and minimizes downtime | Compatibility with voltage and amperage requirements; compliance with safety standards. |

| Construction | Temporary power connections on sites | Facilitates efficient power distribution for tools | Durability against harsh environmental conditions; ease of installation and removal. |

| Agriculture | Irrigation and water management systems | Enhances efficiency in water distribution | Resistance to moisture and corrosion; adaptability to various voltage levels. |

| Telecommunications | Equipment power supply for networks | Supports continuous operation of communication systems | Reliability under varying load conditions; compliance with international standards. |

| Energy | Connection to renewable energy systems | Integrates solar or wind energy solutions | Compatibility with grid requirements; certification for safety and performance. |

Manufacturing

In the manufacturing sector, type 1 plugs are crucial for powering various machinery and tools. These plugs ensure reliable operation, which is vital to minimize downtime and maintain productivity. For international B2B buyers, it is essential to verify compatibility with local voltage and amperage standards, as well as compliance with safety regulations. Engaging with certified suppliers can mitigate risks related to equipment failure.

Construction

Type 1 plugs are extensively used for temporary power connections at construction sites, enabling the efficient distribution of electricity to tools and machinery. This application is particularly important for maintaining workflow and operational efficiency. Buyers should consider the durability of plugs against harsh environmental conditions and their ease of installation and removal. Ensuring that the plugs meet local electrical codes is also critical to avoid safety hazards.

Agriculture

In agriculture, type 1 plugs are employed in irrigation and water management systems, enhancing the efficiency of water distribution. This is vital for optimizing resource use and improving crop yields. B2B buyers in this sector must prioritize sourcing plugs that are resistant to moisture and corrosion, as well as those that can adapt to varying voltage levels. Understanding local agricultural practices and energy needs can guide procurement decisions.

Telecommunications

Type 1 plugs are integral to powering telecommunications equipment, ensuring continuous operation of communication networks. Their reliability under varying load conditions is essential for maintaining service quality. Buyers should ensure that the plugs comply with international standards to guarantee safety and performance. Establishing relationships with suppliers who understand the specific requirements of telecommunications can facilitate smoother procurement processes.

Energy

In the energy sector, type 1 plugs are utilized for connecting renewable energy systems, such as solar panels and wind turbines, to the grid. This application supports the integration of sustainable energy solutions into existing infrastructures. International B2B buyers should focus on sourcing plugs that are compatible with grid requirements and have the necessary certifications for safety and performance. Collaborating with experienced suppliers can help navigate the complexities of renewable energy integration.

Related Video: Semiconductors, Insulators & Conductors, Basic Introduction, N type vs P type Semiconductor

Strategic Material Selection Guide for type 1 plug

When selecting materials for type 1 plugs, B2B buyers must consider various factors that influence performance, durability, and compliance with regional standards. Below, we analyze four common materials used in the manufacturing of type 1 plugs, focusing on their properties, advantages, disadvantages, and specific considerations for international buyers.

Thermoplastic Elastomers (TPE)

Key Properties: TPEs exhibit excellent flexibility, temperature resistance (up to 120°C), and good electrical insulation properties. They are also resistant to many chemicals and UV radiation, making them suitable for outdoor applications.

Pros & Cons: TPEs are relatively easy to process, leading to lower manufacturing costs. They provide good durability and can withstand repeated flexing. However, they may not perform well in extreme temperatures beyond their rated limits, which can lead to premature failure in high-stress environments.

Impact on Application: TPEs are compatible with a range of media, including water and mild chemicals, making them versatile for various applications. However, they may not be suitable for high-pressure environments or aggressive chemicals.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local safety standards, as TPEs might not meet stringent industrial requirements in certain sectors. Familiarity with ASTM and ISO standards is crucial for ensuring product reliability.

Polyvinyl Chloride (PVC)

Key Properties: PVC is known for its excellent chemical resistance, durability, and good electrical insulating properties. It can withstand temperatures up to 80°C and is resistant to corrosion from many acids and alkalis.

Pros & Cons: PVC is cost-effective and widely available, making it a popular choice for many applications. However, it can become brittle over time, especially when exposed to UV light or extreme temperatures, which may limit its lifespan in outdoor applications.

Impact on Application: PVC is suitable for use in plumbing, electrical, and construction applications where chemical exposure is a concern. Its compatibility with various media makes it a reliable choice, but it may not be ideal for high-temperature or high-pressure scenarios.

Considerations for International Buyers: Compliance with local regulations is vital, particularly in Europe where REACH regulations apply. Buyers must verify that the PVC used meets the necessary safety and environmental standards.

Polypropylene (PP)

Key Properties: Polypropylene is lightweight, has a high melting point (up to 160°C), and exhibits good chemical resistance. It is also resistant to fatigue, making it suitable for applications that require repeated stress.

Pros & Cons: PP is durable and offers a good balance between cost and performance. However, it can be less flexible than TPE, which may limit its applications in environments requiring high elasticity.

Impact on Application: PP is suitable for a variety of media, including water and some chemicals, but it may not be compatible with strong solvents or acidic substances. Its durability makes it ideal for industrial applications.

Considerations for International Buyers: Buyers should ensure that PP products comply with relevant standards such as ISO and ASTM. In regions like the Middle East, where temperatures can be extreme, it is crucial to verify the material’s performance under local conditions.

Stainless Steel

Key Properties: Stainless steel offers excellent strength, corrosion resistance, and can withstand high temperatures (up to 800°C). It is also non-reactive, making it suitable for food and pharmaceutical applications.

Pros & Cons: The durability and longevity of stainless steel make it ideal for harsh environments. However, it is more expensive than plastic alternatives and may require specialized manufacturing processes, increasing lead times.

Impact on Application: Stainless steel is highly compatible with a wide range of media, including corrosive substances. Its robustness makes it suitable for high-pressure and high-temperature applications.

Considerations for International Buyers: Buyers must consider compliance with international standards such as ASTM and DIN for stainless steel products. In Europe, certifications for food-grade materials are essential for applications in the food and beverage industry.

Summary Table

| Material | Typical Use Case for type 1 plug | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Thermoplastic Elastomers (TPE) | Outdoor electrical applications | Excellent flexibility and insulation | Limited high-temperature performance | Medium |

| Polyvinyl Chloride (PVC) | Plumbing and electrical installations | Cost-effective and widely available | Can become brittle over time | Low |

| Polypropylene (PP) | Industrial applications requiring durability | High melting point and fatigue resistance | Less flexibility than TPE | Medium |

| Stainless Steel | Food and pharmaceutical applications | Excellent strength and corrosion resistance | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for type 1 plugs, equipping international B2B buyers with the insights needed to make informed decisions tailored to their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for type 1 plug

Manufacturing Processes for Type 1 Plug

The manufacturing of Type 1 plugs involves several key stages that ensure the final product meets industry specifications and performance standards. Understanding these processes is crucial for B2B buyers to assess the quality and reliability of their suppliers.

Material Preparation

The first step in the manufacturing process is material preparation. Common materials used for Type 1 plugs include high-grade thermoplastics and metal alloys, which provide durability and conductivity. The selection of materials should consider environmental factors such as temperature and humidity, especially relevant for buyers in diverse climates like those in Africa and South America.

Key Techniques:

– Material Selection: Choosing the right type of plastic or metal based on electrical and thermal properties.

– Pre-processing: This may include drying plastics to remove moisture or treating metals to prevent corrosion.

Forming

The forming stage involves shaping the prepared materials into the desired plug configuration. This can be achieved through various techniques depending on the material used.

Key Techniques:

– Injection Molding: A common method for producing plastic components, where molten material is injected into a mold.

– Die Casting: Used for metal components, where molten metal is poured into a mold to create precise shapes.

Assembly

Once the individual components are formed, they undergo an assembly process to create the complete Type 1 plug. This stage is critical as it impacts the plug’s functionality and safety.

Key Techniques:

– Automated Assembly: Robotics may be employed for consistent and efficient assembly, reducing human error.

– Manual Assembly: Certain delicate components may still require manual assembly to ensure precision.

Finishing

The finishing stage enhances the plug’s performance characteristics and aesthetic appeal. This may include surface treatments, coatings, and final inspections.

Key Techniques:

– Surface Treatment: Processes like plating or coating to improve durability and resistance to environmental factors.

– Quality Checks: Ensuring that the plug meets dimensional and functional specifications before packaging.

Quality Assurance in Manufacturing

Quality assurance (QA) is integral to the manufacturing of Type 1 plugs. It ensures that the products not only meet customer expectations but also comply with international standards.

Relevant International Standards

B2B buyers should be aware of various international standards that govern the quality of electrical components:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent product quality.

- CE Marking: Required for products sold in the European Economic Area, indicating compliance with health, safety, and environmental protection standards.

- API Standards: For plugs used in industries like oil and gas, adherence to American Petroleum Institute (API) standards is vital for safety and reliability.

Quality Control Checkpoints

To ensure that the manufacturing processes are effective, several checkpoints are established throughout production:

- Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early, allowing for corrective actions before the final assembly.

- Final Quality Control (FQC): A thorough inspection of the finished product, ensuring it meets all specifications and is ready for distribution.

Common Testing Methods

B2B buyers should familiarize themselves with common testing methods employed during the quality assurance process:

- Electrical Testing: Ensures that the plug can handle specified voltage and current levels without failure.

- Mechanical Testing: Evaluates the physical integrity of the plug, including tensile strength and durability under stress.

- Environmental Testing: Assesses how well the plug withstands various environmental conditions, such as temperature extremes and humidity.

Verifying Supplier Quality Control

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with procurement.

Audit and Inspection

- Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. This helps ensure compliance with international standards.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased evaluation of the supplier’s quality assurance processes and product quality.

Documentation and Reporting

- Quality Reports: Request detailed reports from suppliers outlining their quality control measures, testing results, and compliance with relevant standards. This documentation is vital for understanding the supplier’s reliability.

- Certificates of Compliance: Ensure that suppliers provide certifications that demonstrate adherence to international standards, which can be crucial for regulatory compliance in your region.

Nuances for International Buyers

When sourcing Type 1 plugs from international suppliers, consider the following nuances:

- Regional Compliance: Different regions may have specific regulations that impact product design and safety. Understanding these can prevent costly compliance issues.

- Cultural Differences: Communication styles and business practices can vary significantly across regions, affecting negotiations and partnerships. Being culturally aware can facilitate smoother transactions.

Conclusion

Understanding the manufacturing processes and quality assurance measures for Type 1 plugs is crucial for B2B buyers looking to procure reliable and compliant products. By focusing on material selection, manufacturing techniques, and robust quality control, buyers can ensure they are sourcing high-quality plugs that meet their operational needs and adhere to international standards. This knowledge empowers buyers to make informed decisions, reducing risks and enhancing the overall efficiency of their supply chains.

Related Video: Lean Manufacturing – Pull Systems

Comprehensive Cost and Pricing Analysis for type 1 plug Sourcing

Understanding the cost structure and pricing dynamics of sourcing Type 1 plugs is essential for international B2B buyers looking to optimize their procurement strategies. The complexity of these components necessitates a thorough analysis of various cost components, price influencers, and actionable tips for negotiations.

Cost Components

The overall cost of Type 1 plugs can be broken down into several key components:

-

Materials: The choice of materials significantly impacts the cost. High-quality, durable materials like thermoplastics or specific alloys enhance performance but can increase initial expenses. Buyers should assess the material requirements based on application needs to avoid overspending.

-

Labor: Labor costs vary by region and manufacturing practices. Countries with lower labor costs may offer competitive pricing, but this can sometimes compromise quality. Therefore, evaluating supplier labor practices is crucial for ensuring value.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and operational expenses. Suppliers with efficient production processes may offer lower prices due to reduced overhead costs.

-

Tooling: The cost of molds and equipment used in production is a critical factor. Custom tooling for specialized designs can add significant expenses. Buyers should consider whether standard designs can meet their needs to minimize tooling costs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but can increase costs. Buyers should inquire about the QC protocols of potential suppliers and assess whether these costs are justified by the quality benefits.

-

Logistics: Transportation and shipping costs can vary greatly depending on the supplier’s location and the chosen Incoterms. Buyers should factor in potential customs duties, tariffs, and freight charges when calculating the total cost.

-

Margin: Supplier margins will vary based on market conditions and competition. Understanding the typical margins in the industry can help buyers gauge the fairness of pricing.

Price Influencers

Several factors influence the pricing of Type 1 plugs:

-

Volume/MOQ: Larger order quantities typically lead to reduced per-unit pricing. Buyers should negotiate minimum order quantities (MOQs) to leverage volume discounts.

-

Specifications/Customization: Custom specifications can drive up costs. Buyers should evaluate whether standard products could suffice to optimize pricing.

-

Materials: The choice of material affects both performance and cost. Buyers should balance between high-performance materials and budget constraints.

-

Quality/Certifications: Products that meet stringent quality certifications may carry a premium price. Buyers should weigh the importance of certifications against their operational needs.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can affect pricing. Established suppliers might charge more due to their proven track record.

-

Incoterms: The choice of Incoterms impacts shipping responsibilities and costs. Buyers should negotiate terms that minimize their logistical risks and costs.

Buyer Tips

To navigate the complexities of Type 1 plug sourcing effectively, consider the following strategies:

-

Negotiate: Always negotiate pricing and terms. Establishing a long-term partnership with suppliers can often lead to better pricing and service.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. Cheaper upfront costs may lead to higher long-term expenses.

-

Pricing Nuances: For international buyers, be aware of currency fluctuations, local economic conditions, and regional pricing trends that may affect overall costs. Understanding these factors can provide leverage in negotiations.

-

Research Suppliers: Conduct thorough due diligence on potential suppliers to ensure they meet both quality and cost expectations. This includes checking references and reviewing past performance.

In conclusion, while sourcing Type 1 plugs entails navigating a complex cost structure and various price influencers, employing strategic purchasing tactics can lead to substantial savings and enhanced operational efficiency. Buyers should remain informed and proactive in their procurement strategies to secure the best value in the competitive international market.

Illustrative Image (Source: Google Search)

Spotlight on Potential type 1 plug Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘type 1 plug’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for type 1 plug

Critical Specifications for Type 1 Plug

Understanding the essential technical properties of Type 1 plugs is crucial for B2B buyers, as these specifications directly impact product performance, safety, and compliance. Here are the key specifications to consider:

-

Material Grade

The material used in the construction of Type 1 plugs, typically thermoplastics or thermosetting plastics, plays a significant role in durability and electrical insulation. Buyers should ensure that the chosen materials meet regional standards for fire resistance and chemical exposure, as these factors can influence the longevity and safety of the plug in various environments. -

Current Rating

This specification indicates the maximum current that the plug can safely carry without overheating. For B2B buyers, understanding the current rating is essential for matching plugs with the appropriate equipment and preventing electrical failures. It is crucial to select plugs that can handle the specific electrical load required by machinery or appliances. -

Voltage Rating

Voltage rating specifies the maximum voltage the plug can handle. This is vital for ensuring compatibility with local power supply systems. Buyers must consider the voltage requirements of their applications to avoid the risk of short circuits or equipment damage.

-

Temperature Rating

The temperature rating determines the operational limits of the plug in various environmental conditions. For industries operating in extreme temperatures, selecting a plug with a suitable temperature rating ensures reliable performance and reduces the risk of failure due to thermal stress. -

Tolerance

Tolerance refers to the permissible variation in dimensions of the plug components. Precise tolerances are crucial for ensuring proper fit and functionality, especially in applications where multiple components interact. Buyers should be aware of the manufacturing tolerances to ensure compatibility with their existing systems. -

IP Rating (Ingress Protection)

The IP rating indicates the level of protection against dust and moisture. For applications in harsh environments, an appropriate IP rating is essential to prevent failures caused by environmental factors. B2B buyers should evaluate the IP rating based on their specific operational conditions.

Common Trade Terminology

Familiarity with industry jargon can streamline communication and enhance procurement processes. Here are some essential trade terms relevant to Type 1 plugs:

-

OEM (Original Equipment Manufacturer)

Refers to companies that produce components that are used in the manufacturing of another company’s products. Understanding the OEM designation can help buyers identify reputable manufacturers and ensure quality. -

MOQ (Minimum Order Quantity)

The minimum number of units that a supplier is willing to sell in a single order. Knowing the MOQ is essential for budgeting and inventory management, as it can impact purchasing decisions and supply chain efficiency. -

RFQ (Request for Quotation)

A document sent to suppliers requesting pricing and terms for a specific quantity of goods. Utilizing RFQs effectively allows buyers to compare offers and negotiate better deals, ensuring they get the best value for their investments. -

Incoterms (International Commercial Terms)

A set of predefined commercial terms used in international trade, defining the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers to manage logistics and mitigate risks in cross-border transactions. -

Lead Time

The time it takes from placing an order to receiving the goods. Buyers must consider lead times in their procurement planning to avoid disruptions in operations and ensure timely project execution.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Type 1 plugs, ultimately enhancing their operational efficiency and reducing risks associated with procurement.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the type 1 plug Sector

Market Overview & Key Trends

The global market for type 1 plugs is experiencing significant growth, driven by several factors including the expansion of renewable energy projects, increasing electrification in emerging markets, and the ongoing push for more efficient power distribution systems. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, it is crucial to stay attuned to these market dynamics. The demand for type 1 plugs is particularly buoyed by the surge in electric vehicle (EV) infrastructure development and the transition towards smart grid technologies.

Emerging technologies such as IoT-enabled plugs and advanced materials are reshaping sourcing strategies, offering enhanced performance and connectivity. Buyers must consider the implications of these innovations on their procurement processes, focusing on suppliers that invest in R&D to stay ahead of technological advancements. Moreover, the rise of e-commerce platforms is facilitating easier access to global suppliers, which can streamline sourcing operations. However, buyers must navigate complexities such as varying compliance standards and regional certifications, which can impact lead times and costs.

The market is also witnessing a trend towards modular and adaptable plug designs, allowing for flexibility in industrial applications. B2B buyers should prioritize suppliers that offer customizable solutions to meet specific operational needs, ensuring compatibility across different equipment and systems. Understanding these trends will enable buyers to make informed decisions, optimizing their supply chains while mitigating risks associated with sourcing from diverse markets.

Illustrative Image (Source: Google Search)

Sustainability & Ethical Sourcing in B2B

Sustainability is no longer a mere trend but a critical consideration in the sourcing of type 1 plugs. The environmental impact of electrical components, from production to disposal, necessitates a focus on ethical supply chains. B2B buyers should seek suppliers that adhere to sustainable practices, such as reducing carbon emissions during manufacturing and utilizing recyclable materials.

Certifications like ISO 14001 for environmental management and other green certifications can serve as benchmarks for assessing supplier sustainability efforts. Additionally, the use of eco-friendly materials, such as bioplastics or recycled metals, is becoming increasingly important. By choosing suppliers committed to sustainable practices, buyers not only enhance their brand reputation but also contribute to broader environmental goals.

Moreover, ethical sourcing extends to labor practices within the supply chain. Buyers should ensure their suppliers maintain fair labor standards and transparency in their operations. Engaging with suppliers who prioritize corporate social responsibility can create a positive impact on communities, thereby aligning with the values of socially conscious consumers and stakeholders.

Brief Evolution/History

The type 1 plug has evolved significantly since its inception, adapting to the changing demands of technology and energy consumption. Initially designed for basic electrical connections, these plugs have undergone enhancements to improve safety, efficiency, and compatibility with modern devices. The introduction of standardized designs has facilitated international trade, making it easier for B2B buyers to source reliable products across different markets.

In recent years, the shift towards renewable energy and electric vehicles has spurred innovation in plug design and functionality. This evolution reflects a growing awareness of the need for sustainable energy solutions and the integral role of type 1 plugs in facilitating these advancements. As the market continues to develop, buyers must remain informed about these historical trends to effectively navigate the current landscape and anticipate future needs.

Related Video: International Trade Explained

Frequently Asked Questions (FAQs) for B2B Buyers of type 1 plug

-

What should I consider when vetting suppliers for Type 1 plugs?

When vetting suppliers, focus on their industry experience, quality certifications (e.g., ISO 9001), and client testimonials. Evaluate their production capabilities, especially in relation to your specific needs. Additionally, inquire about their track record with international shipping and compliance with regional standards. A supplier that demonstrates transparency in operations and has a responsive customer service team can significantly reduce potential sourcing risks. -

Can Type 1 plugs be customized for specific applications?

Yes, many manufacturers offer customization options for Type 1 plugs. This can include variations in pin size, material choices, and specific electrical ratings to suit particular applications. When discussing customization, clearly outline your requirements, including environmental conditions and operational needs. Ensure that the supplier can provide prototypes or samples for testing before placing a larger order to validate performance. -

What are the typical minimum order quantities (MOQs) and lead times for Type 1 plugs?

MOQs can vary significantly among suppliers but typically range from 100 to 1,000 units. Lead times are often influenced by the complexity of the order and the supplier’s production schedule, averaging between 4 to 12 weeks. Always confirm these details during initial discussions and factor in potential delays, especially when sourcing internationally, to avoid disruptions in your supply chain. -

What quality assurance measures should I expect from my supplier?

A reliable supplier should have rigorous quality assurance (QA) processes in place. This includes material inspections, in-process quality checks, and final product testing to ensure compliance with relevant standards (e.g., IEC, UL). Request documentation of their QA procedures and any certifications they possess. Additionally, consider whether they offer warranties or guarantees, which can provide added assurance of product reliability. -

What certifications should I look for when sourcing Type 1 plugs?

Certifications to consider include IEC (International Electrotechnical Commission) standards for safety and performance, UL (Underwriters Laboratories) for electrical safety, and CE marking for compliance with European health, safety, and environmental protection standards. Depending on your market, local certifications may also be essential. Confirm that the supplier can provide documentation for these certifications to ensure compliance with your regulatory requirements. -

How can I ensure smooth logistics when sourcing Type 1 plugs internationally?

To ensure smooth logistics, work with suppliers who have experience in international shipping and can navigate customs regulations in your country. Discuss shipping options, delivery timelines, and packaging requirements to minimize damage during transit. It’s advisable to partner with a freight forwarder who understands the intricacies of your target market, ensuring that all necessary documentation is in place for a hassle-free import process. -

What should I do if I encounter a dispute with my supplier?

If a dispute arises, start by addressing the issue directly with the supplier through clear and professional communication. Document all interactions and agreements. If the dispute cannot be resolved amicably, refer to the contract terms regarding dispute resolution, which may include mediation or arbitration. Having a clear understanding of your legal rights and obligations can provide leverage in negotiations and help achieve a satisfactory resolution. -

What are the key factors influencing the price of Type 1 plugs?

The price of Type 1 plugs is influenced by several factors, including material costs, manufacturing processes, customization requirements, and order volume. Additionally, fluctuations in currency exchange rates and shipping costs can impact overall pricing, especially for international orders. To secure the best deal, consider negotiating long-term contracts or bulk purchasing agreements with suppliers, which can lead to discounts and more favorable terms.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for type 1 plug

In conclusion, strategic sourcing of type 1 plugs is essential for B2B buyers aiming to enhance operational efficiency and ensure compliance across diverse industries. Understanding the various plug types, their applications, and the associated benefits allows international buyers, particularly from Africa, South America, the Middle East, and Europe, to make informed decisions that align with their specific needs.

Key takeaways include the importance of selecting the right plug type for your application, considering factors such as compatibility, safety standards, and supplier reliability. Additionally, a thorough assessment of material quality and sourcing practices can significantly impact long-term performance and total cost of ownership.

As global markets continue to evolve, staying ahead of emerging trends and technological advancements in plug manufacturing will be crucial. Buyers are encouraged to foster strong relationships with reliable suppliers and continuously evaluate sourcing strategies to mitigate risks and capitalize on opportunities.

Now is the time to embrace a proactive approach in your sourcing efforts, ensuring that your organization is well-positioned to thrive in an increasingly competitive landscape. Invest in strategic sourcing today to secure a sustainable and efficient future for your operations.